Flannel sticking device for automobile sealing strip

A technology for pasting fleece and sealing strips, which is applied in the field of fleece pasting devices for automobile weather strips. It can solve the problems of difficult to accurately control the gluing area, flying down affects the working environment, and many links, so as to achieve easy control, ensure the quality of pasting, and The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

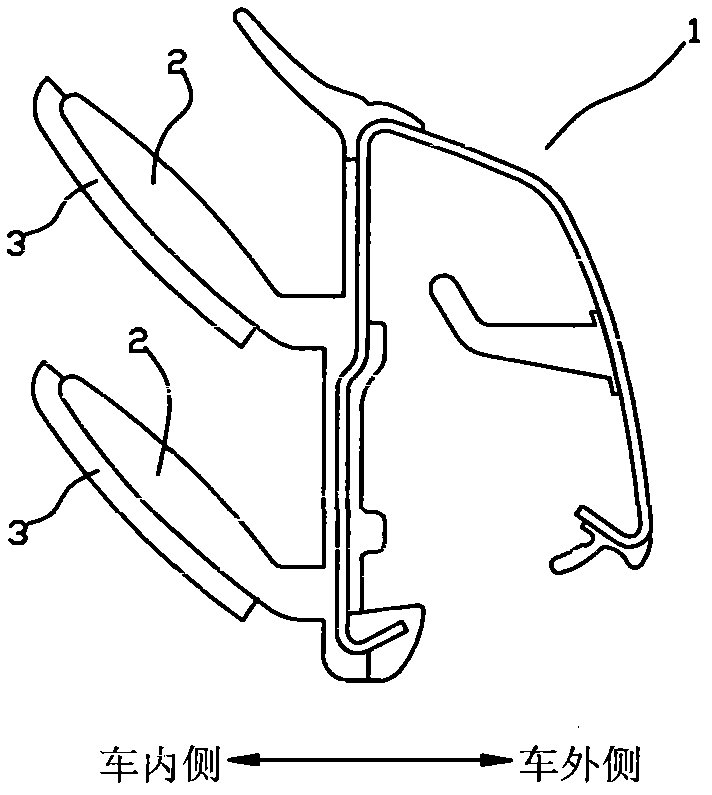

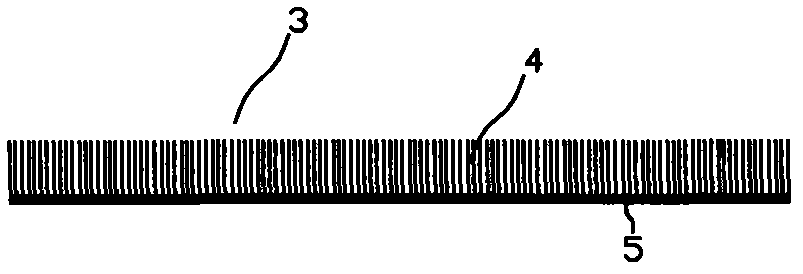

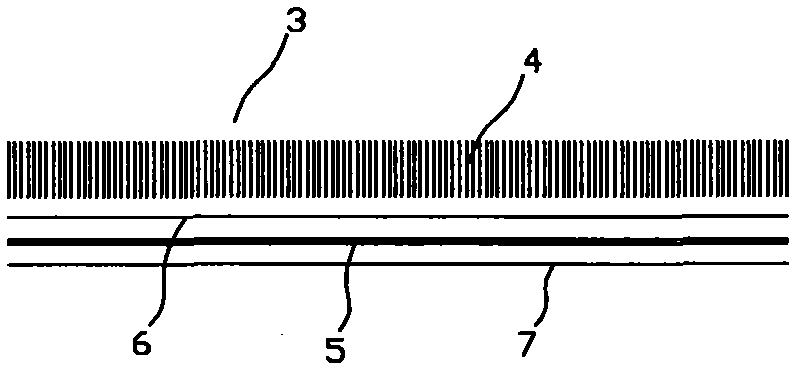

[0018] An outer sealing strip 1 of an automobile window sill, used for sealing the outer side of the window sill, includes a metal skeleton and an organic elastomer attached to the surface, stretched along the same cross section, and its cross section is as follows figure 1 As shown, the metal skeleton is made of stainless steel belt through rolling process, and the organic elastomer is made of modified polyvinyl chloride (PVC) through extrusion processing; the organic elastomer includes two protruding lips 2 extending obliquely upward. The car interior surface of the lip sheet 2 needs to be flocked to form a flocking layer 3 .

[0019] The specific embodiment of the present invention will be described below by taking the above-mentioned napping device of the sealing strip 1 as an example.

[0020] The velvet pasting of the automobile sealing strip 1 is carried out continuously on a sealing strip production line including an extrusion process, such as Figure 4 As shown, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com