Energy-saving and high-efficiency device for pickling food

A high-efficiency technology for pickling food, applied in food forming, mixer with rotating stirring device, application, etc., can solve the problems of low raw material utilization rate, unsuitable for enterprise utilization, and increased production cost, so as to reduce manpower and The use of pickling raw materials, compact structure, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

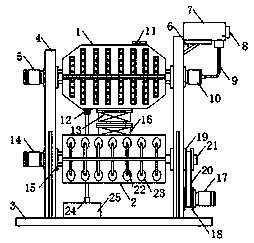

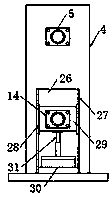

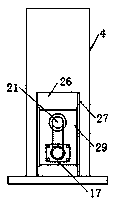

[0021] Such as Figure 1-4 As shown, an energy-saving and high-efficiency device for pickling food includes a pickling tank 1, a flavoring tank 2 and a base 3. Two corresponding end plates 4 are fixed on the base 3, and on the end plate 4 A pickling tank 1 is fixedly installed between the sides, and a feeding port 11 is provided on the pickling tank 1. A main shaft 32 is arranged inside the pickling tank 1, and one end of the main shaft 32 extends to the pickling tank 1. The outside is fixedly connected to the output end of the first driving motor 5 fixed on the side end of the end plate 4, and a number of mixing paddles 33 are installed on the main shaft 32. The inside of the main shaft 32 is a cavity, and the mixing paddles 33 A number of high-pressure through holes 34 are provided on the top, and a water tank 7 is fixedly installed on the end plate 4 at the other end of the pickling tank 1 through a water tank installation frame 6, and a liquid inlet pipe 9 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com