A kind of production technology of high-grade sulfur concentrate

A high-grade sulfur concentrate and production process technology, applied in the direction of solid separation, flotation, etc., can solve the problems of unsatisfactory separation of new minerals, comprehensive utilization of unfavorable tailings, and improvement of recovery rate, which is conducive to popularization and application , Improve mineral buoyancy, reduce taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

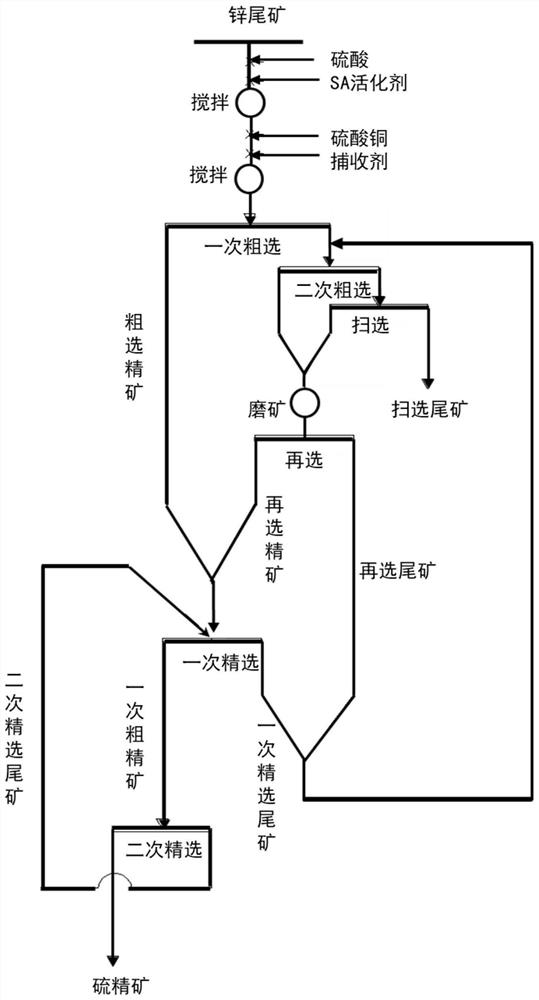

[0035] A production process of high-grade sulfide concentrate includes the following preparation steps:

[0036] (1) A rough selection: take the slurry of zinc tailings with a particle size of 50 μm, add 0.420 kg / t sulfuric acid and 0.420 kg / t SA activator (the SA activator manufacturers used in the specific embodiments of the present invention are all It is activated by Zhaoyuan Jindao Chemical Co., Ltd. of Shandong Province, the same below), 0.07kg / t of copper sulfate (the mass ratio of sulfuric acid, SA activator and copper sulfate is 6:6:1), and add 0.1kg / t The mixture of butyl xanthate and ethyl mercaptan (the mass ratio of butyl xanthate to ethyl mercaptan is 3:1) is adjusted by the collector, and then sent to the flotation tank for rough separation to obtain the rough concentrate And roughing tailings;

[0037] (2) Secondary roughing and sweeping recovery: the roughing tailings are subjected to the second roughing to obtain the second roughing concentrate and the second rou...

Embodiment 2

[0041] A production process of high-grade sulfide concentrate includes the following preparation steps:

[0042] (1) A rough selection: take the slurry of zinc tailings with a particle size of 50μm, add 0.420kg / t sulfuric acid, 0.420kg / t SA activator, 0.07kg / t copper sulfate (sulfuric acid, SA activator and sulfuric acid The mass ratio of copper is 6:6:1) activate, and add 0.1kg / t of a mixture of butyl xanthate and ethyl mercaptan (the mass ratio of butyl xanthate to ethyl mercaptan is 3:1) collector To reconcile, add 0.020kg / t of pine oil and eucalyptus oil (the mass ratio of the two is 1:1) as a foaming agent, and 0.2kg / t of water glass and ethylenediaminetetraacetic acid disodium mixture Used as inhibitor (mass ratio is 3:1), and then sent to the flotation tank for roughing to obtain roughing concentrate and roughing tailings;

[0043] (2) Secondary roughing and sweeping recovery: the roughing tailings are subjected to the second roughing to obtain the second roughing concentra...

Embodiment 3

[0047] A production process of high-grade sulfide concentrate includes the following preparation steps:

[0048] (1) A rough selection: take the slurry of zinc tailings with a particle size of 10μm, add 0.125kg / t sulfuric acid, 0.330kg / t SA activator, 0.042kg / t copper sulfate (sulfuric acid, SA activator and sulfuric acid The mass ratio of copper is 3:8:1) activate, and add 0.2kg / t of a mixture of butyl xanthate and ethanethiol (the mass ratio of butyl xanthate to ethanethiol is 1:1) collector To reconcile, add 0.01kg / t of pine oil and eucalyptus oil mixture (the mass ratio of the two is 1:1) as foaming agent, and 0.1kg / t of water glass and disodium ethylenediaminetetraacetic acid mixture After being used as inhibitor (the mass ratio is 2:1), it is sent to the flotation tank for roughing to obtain roughing concentrate and roughing tailings;

[0049] (2) Secondary roughing and sweeping recovery: the roughing tailings are subjected to the second roughing to obtain the second roughin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com