Automatic steelmaking and slag-leaving operation method for converter

An operation method and technology of slag retention, applied in the manufacture of converters, etc., can solve the problems of converter material balance and heat balance without theoretical or empirical reference, automatic steelmaking model is difficult to calculate accurately, and the amount of slag remaining cannot be determined, etc. Achieve the effect of improving economic and technical indicators, improving converter production efficiency, and improving dephosphorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The secondary computer system collected 12.5% of FeO in the slag and 0.65% of Si in the molten iron in the lower furnace;

[0032] (2) The smelting steel grade is X60, and the secondary computer system sets an end point carbon target of 0.06%;

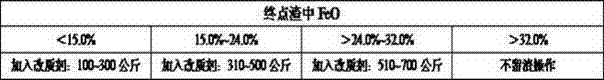

[0033] (3) According to 12.5% FeO content in the slag, add 200kg of modifier for slag conditioning, or add 100kg or 300kg according to the situation, splash the slag for 5 minutes;

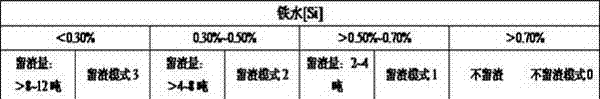

[0034] (4) According to the molten iron [Si] 0.65%, the system automatically matches the corresponding slag retention mode 1. The system prompts to select the slag retention amount between 2 to 4 tons, and the conventional slag retention amount is 3 tons, or 2 tons or 4 tons according to the situation. ;

[0035] (5) The end point carbon target is 0.06%, the system automatically matches the corresponding group number 15, and extracts the corresponding execution parameters;

[0036] (6) The static model performs related calculations, automatically gen...

Embodiment 2

[0038] (1) The secondary computer system collects 20.0% FeO content in the slag and 0.45% Si content in the molten iron in the lower furnace;

[0039] (2) The smelting steel grade is Q345B, and the secondary computer system sets the end point carbon target of 0.12%;

[0040] (3) According to the FeO content in the slag 20.0%, add 400kg of modifier for slag conditioning, or add 310kg or 500kg according to the situation, splash the slag for 7 minutes;

[0041] (4) According to the molten iron [Si] 0.45%, the system automatically matches the corresponding slag retention mode 2. The system prompts to select the slag retention> 4~8 tons, and the conventional input slag retention is 6 tons, or choose 4.1 tons or 8 according to the situation. Ton;

[0042] (5) The end point carbon target is 0.12%, the system automatically matches the corresponding group number 30, and extracts the corresponding execution parameters;

[0043] (6) The static model performs related calculations, automatically ge...

Embodiment 3

[0045] (1) The secondary computer system collects 30.0% FeO content in the slag and 0.28% Si content in the molten iron;

[0046] (2) The smelting steel grade is 08Al, and the secondary computer system sets the end point carbon target of 0.04%;

[0047] (3) According to the FeO content in the slag 30.0%, add 600kg of modifier for slag conditioning, or add 510kg or 700kg according to the situation, and splash the slag for 10 minutes;

[0048] (4) According to 0.28% of the molten iron [Si], the system automatically matches the corresponding slag retention mode 3. The system prompts to select the slag retention> 8-12 tons, and the conventional input slag retention is 10 tons, or select 8.1 tons or 12 according to the situation Ton;

[0049] (5) The end point carbon target is 0.04%, the system automatically matches the corresponding group number 33, and extracts the corresponding execution parameters;

[0050] (6) The static model performs related calculations, automatically generates smel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com