Sludge crushing and drying device

A drying and sludge technology, applied in the direction of dehydration/drying/thickened sludge treatment, grain treatment, etc., can solve problems such as easy caking, achieve the effects of shortening equipment life, beautiful environment protection, and reducing drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

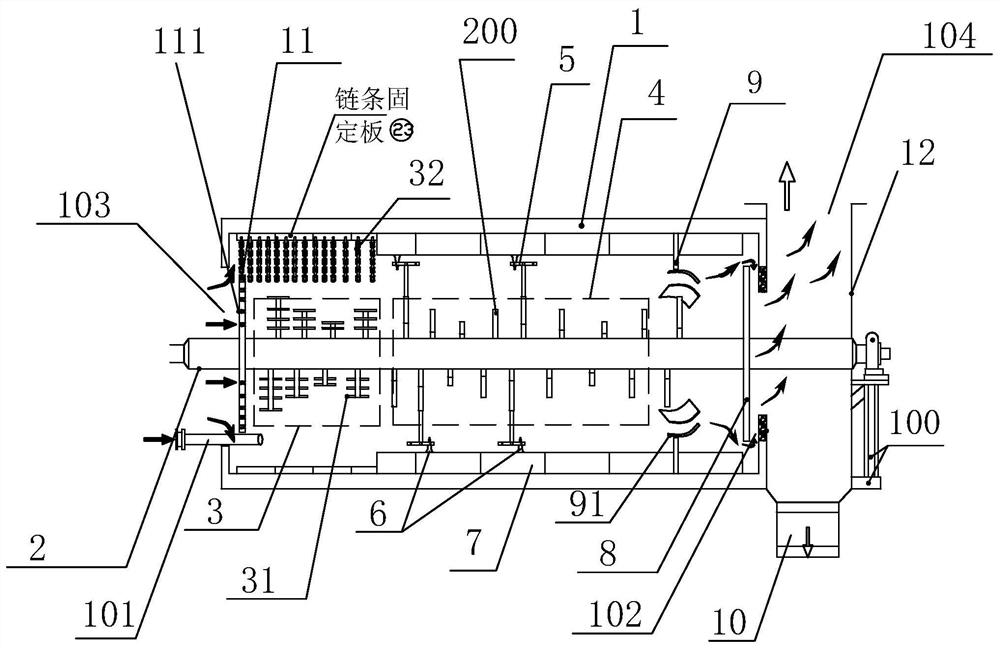

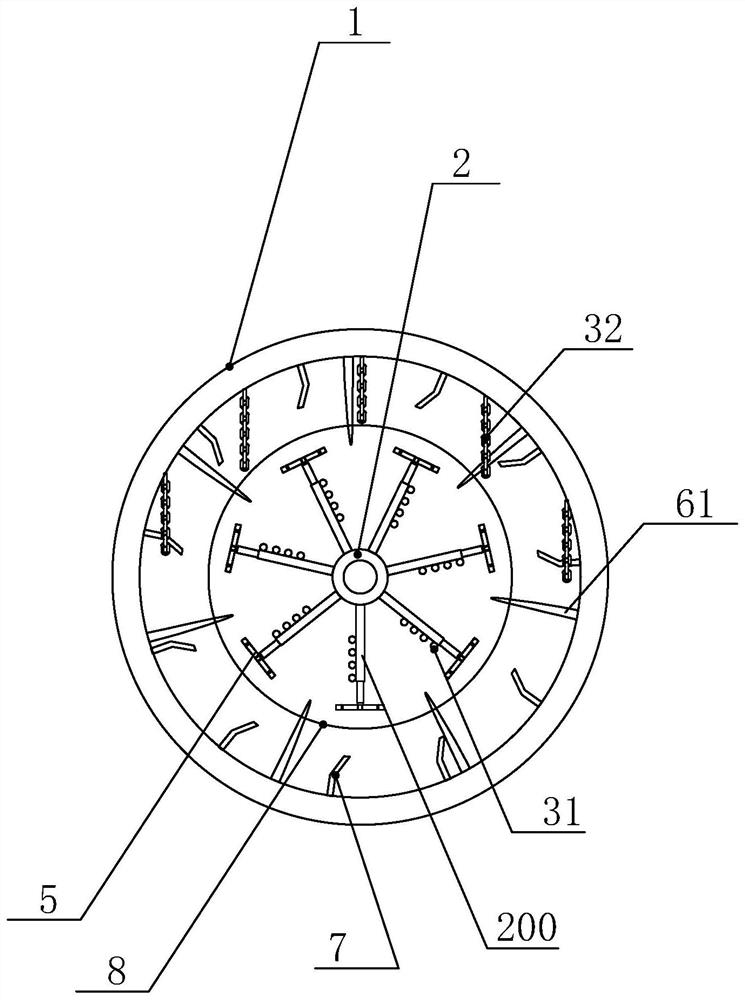

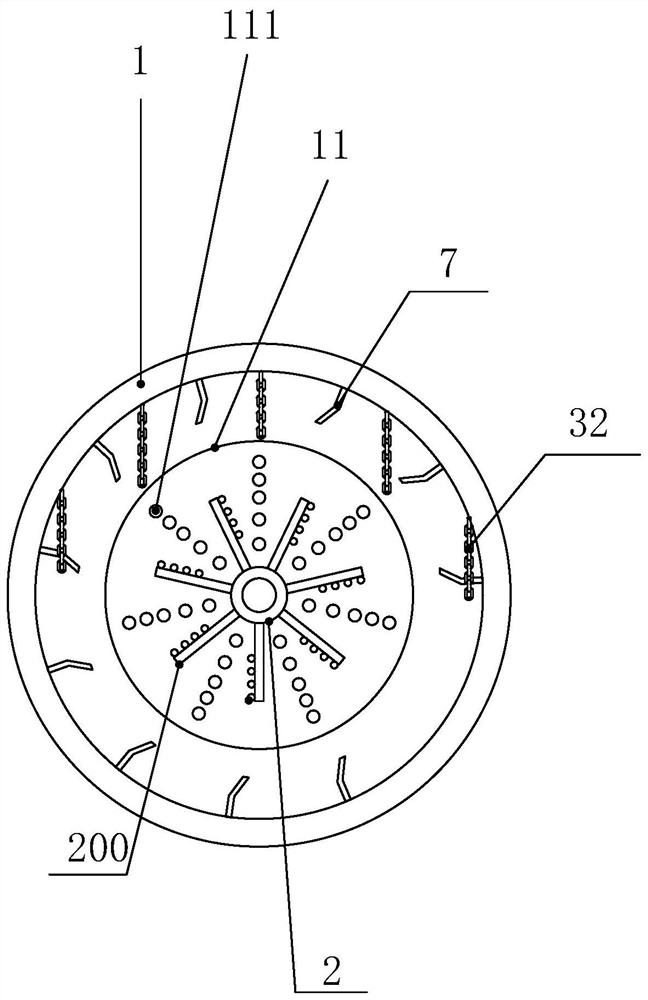

[0029] Such as figure 1 , 2 As shown, a sludge crushing and drying device includes a machine base 100, a drying drum 1 is placed horizontally on the machine base, an inner rotating shaft 2 is arranged inside the drying drum, and a stirring propulsion device is arranged radially on the inner rotating shaft. The rod 200 assembly, the stirring propulsion rod assembly includes a propulsion section 3 and a fine crushing section 4 along the extension direction of the inner rotating shaft, a material inlet 101 is arranged at the end of the drying drum close to the propulsion section, and a hot smoke inlet 103 is arranged above the material inlet, A fine crushing runner is arranged at the tail end of the stirring propulsion rod in the fine crushing section. The stirring propulsion rod sequentially includes a connecting part 201, a crushing part 202 and an extension part 203 along the length direction. The connecting part is connected to the inner rotating shaft. The cross section of ...

Embodiment 2

[0035] The difference from Embodiment 1 is that in this embodiment, the lengths of the crushing rods on both sides of the extension section are not equal, including the long end and the short end. Under this unbalanced structure, no matter the length After the end or the short end collides with the stop rod, the fine crushing rotor can be rotated at a variable speed, which makes the fine crushing rotor effectively assist the high-temperature hot air in the drying drum to form turbulent flow and improve the drying effect. At the same time, since the contact area between the long end and the sludge material is larger, when the short end collides with the blocking rod, since the long end and the short end have the same angular velocity, the free end of the long end has Higher linear velocity, according to the momentum formula, the momentum of the long rod is significantly improved, which can more effectively hit the sludge particles for crushing. Correspondingly, when the long en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com