Audio-frequency noise acquisition apparatus arranged at slagging furnace mouth of converter

A collection device and slag furnace technology, applied in the detection of response signals, etc., can solve the problems of reduced sensitivity, unreliable results, interference, etc., to avoid interference from environmental noise, reduce the probability of spattering, and improve steelmaking efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

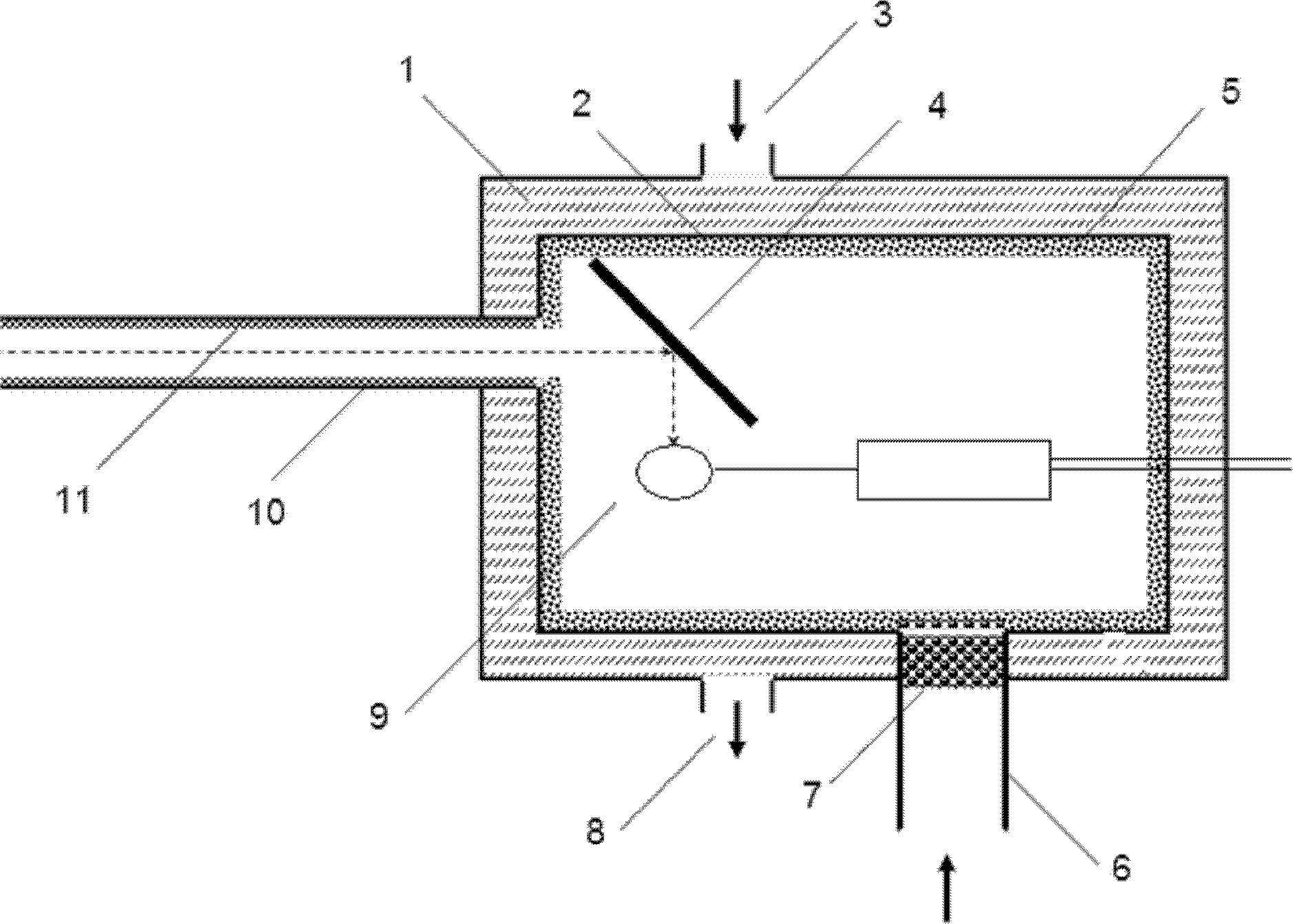

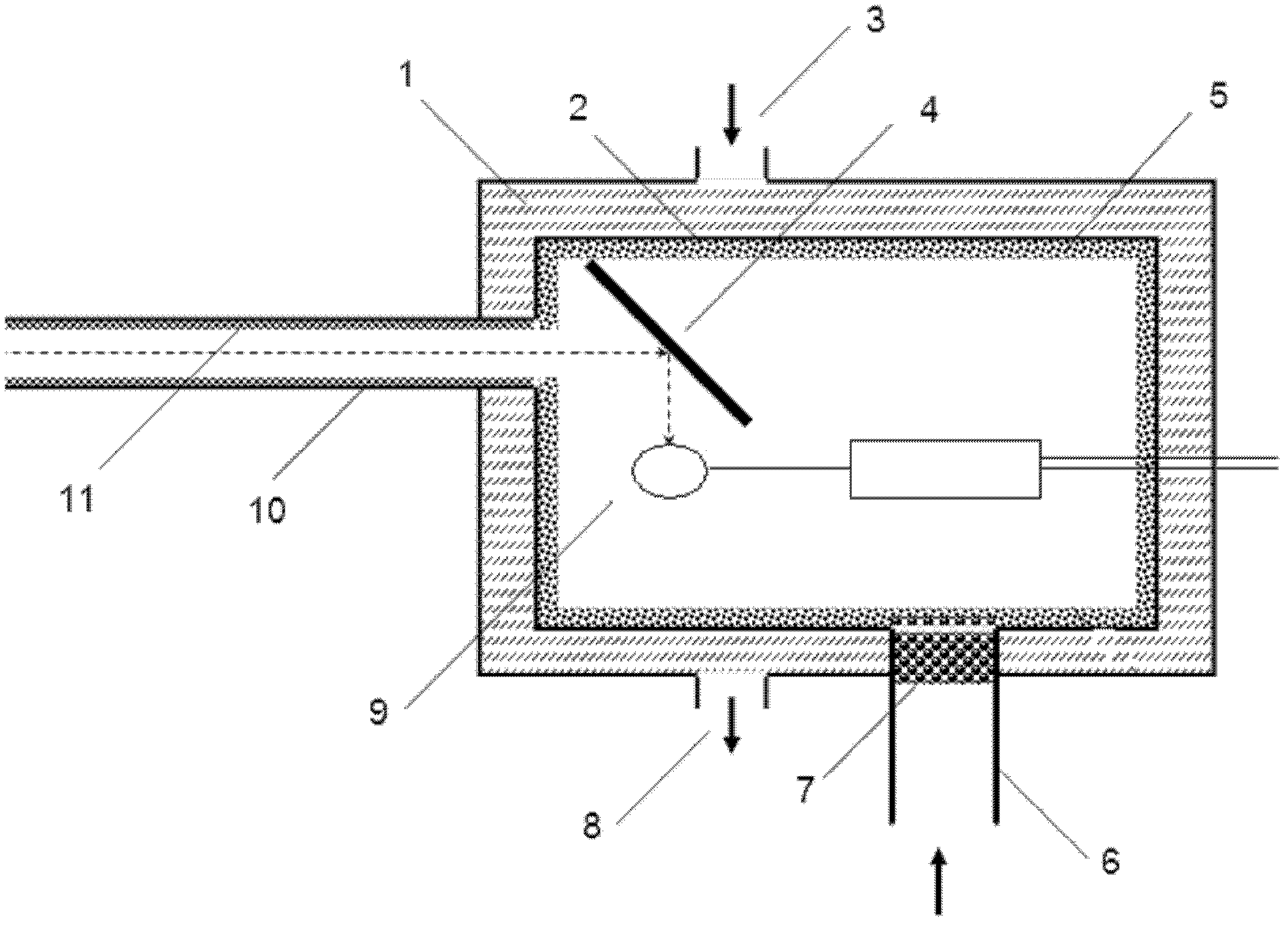

[0022] A converter slag furnace mouth audio noise collection device, as shown in the figure, includes a collection box 2, a circulating water bag 1 is arranged outside the collection box 2, and a water inlet 3 and a water outlet 8 are arranged on the circulating water bag 1. On the upper part of the side wall of the collection box 2, there is a pointing steel pipe 10 communicating with the cavity in the box, and the pointing steel pipe 10 is aligned with the furnace mouth of the converter. , 11. The bottom of the collection box 2 is provided with an air inlet 6, and the air inlet 6 is provided with a sound filter 7 made of porous sound-absorbing material. wind. A black reflector 4 is provided in the collection box facing the nozzle pointing to the centerline of the steel pipe. The reflector 4 has a smooth plane. The normal line of the reflector 4 is at an angle of 45 degrees to the centerline of the steel pipe 10. Directly below the reflector 4, the noise signal enterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com