Low-temperature drying device for high-water-content high-viscosity sludge

A high moisture content, low-temperature drying technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., to achieve enhanced drying effect, high energy efficiency ratio, and improved drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

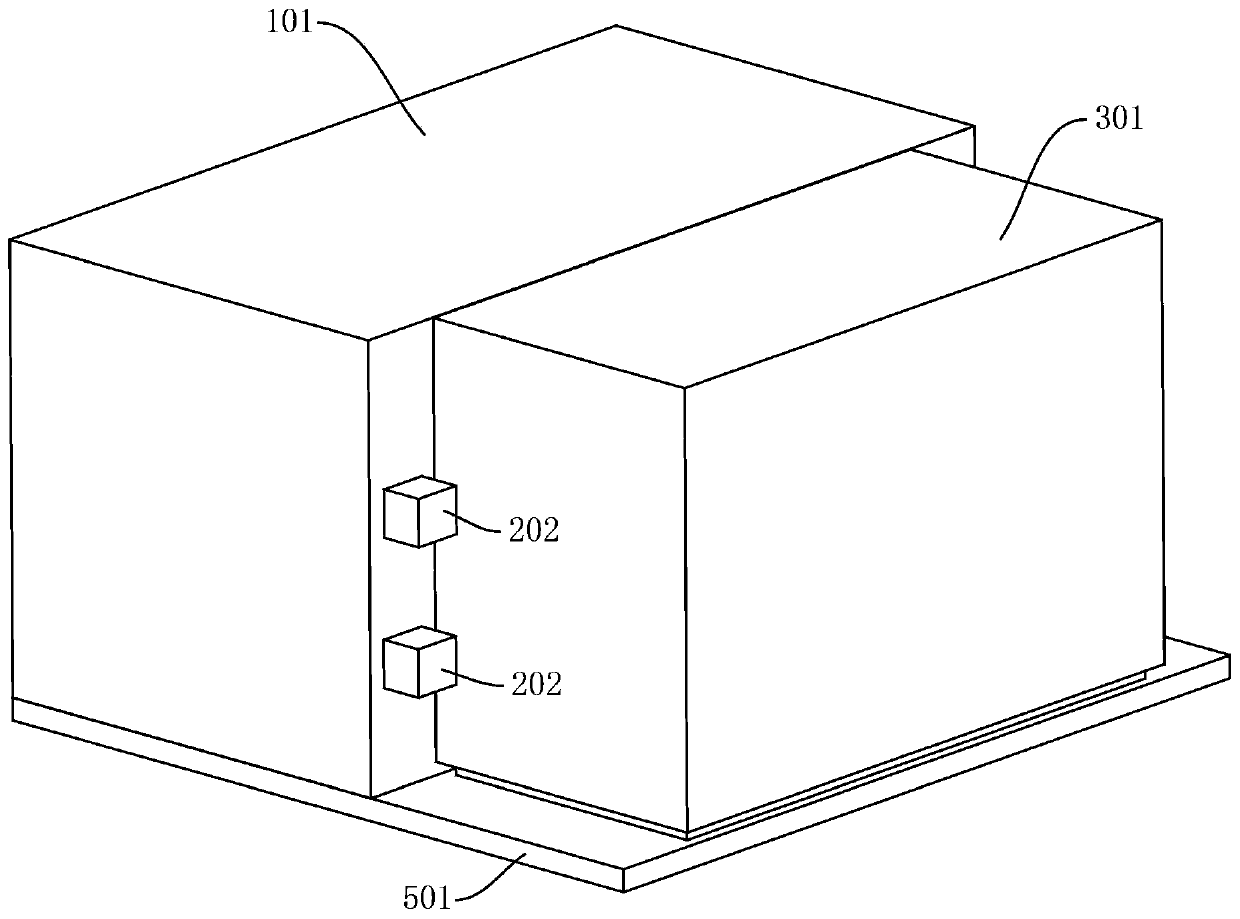

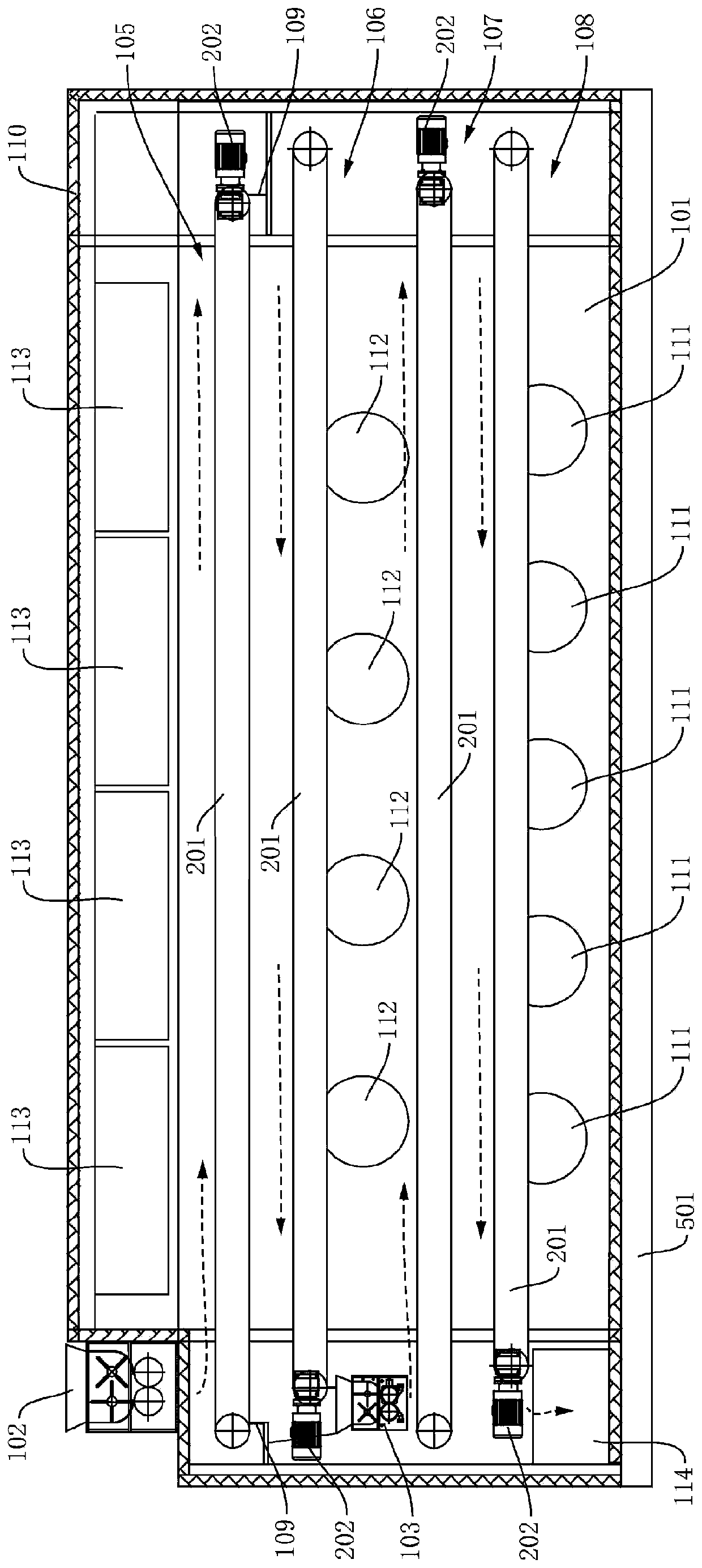

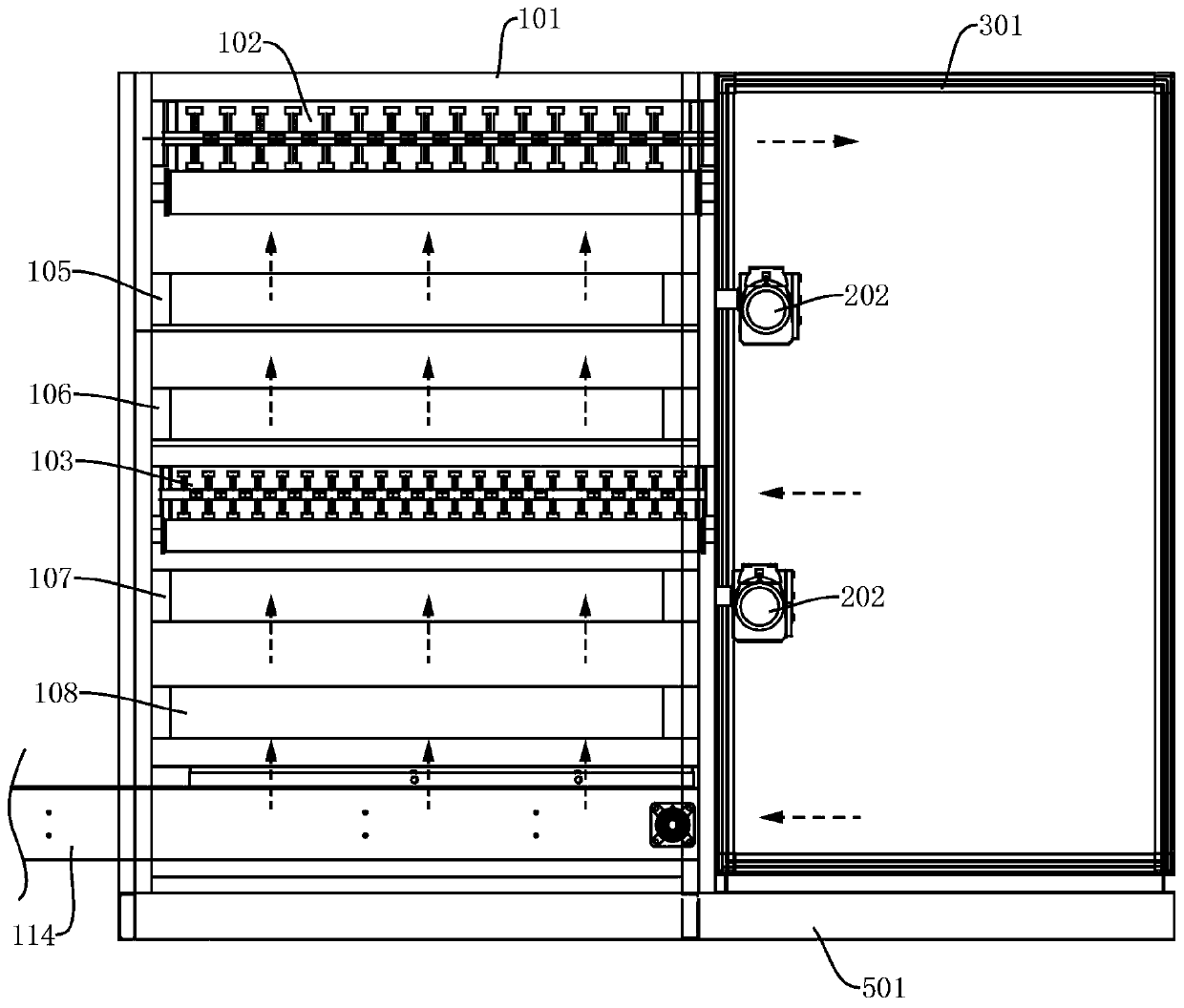

[0048] see figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, a low-temperature (drying temperature lower than 80 degrees Celsius) drying equipment for sludge with high water content and high viscosity is provided, including a drying chamber 101 with a closed cavity, and a drying chamber 101 A connected heat pump system, the drying chamber 101 is provided with a feed cutting machine 102 and a secondary cutting machine 103, wherein,

[0049] The feeding strip cutter 102 is used to cut the sludge input into the drying chamber 101 for the first time, so that the sludge (usually mud cake) input into the drying chamber 101 can become a strip or similar strip structure. The mud strips with a strip-shaped or strip-like structure have a thinner thickness and a larger surface area, and have a larger contact area with the hot air in the drying chamber 101, which is more conducive to drying and rapid dehydration of the sludge;

[0050] The secondary slitting machine 10...

Embodiment 2

[0073] The main difference between this embodiment 2 and the above-mentioned embodiment 1 is that in the drying equipment provided by this embodiment, the heat pump system includes a filter 309, a regenerator 310, an evaporator 311, a first condenser 312, a second Two condensers 313, the first fan 314 and the second fan 315, such as Figure 7 As shown, the first channel 305, the second channel 306 and the third channel 307 are respectively arranged in the box body 301, wherein,

[0074] One end of the first channel 305 communicates with the air return port 304, and the other end communicates with the second channel 306 and the first input end of the regenerator 310 respectively, and the filter 309 is arranged in the first channel 305 ;

[0075] One end of the second channel 306 communicates with the second air outlet 303, and the first condenser 312 and the first fan 314 are respectively arranged in the second channel 306;

[0076] The first output end of the regenerator 310...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com