Drying device for drum printing machine

A drying device and printing machine technology, applied in printing machines, general parts of printing machinery, printing, etc., can solve the problem of small adjustable range of temperature control and air volume, inability to meet different drying requirements from top to bottom, and distance cannot be adjusted, etc. problems, to achieve the effect of ensuring drying requirements, improving labor productivity, and reducing drying intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

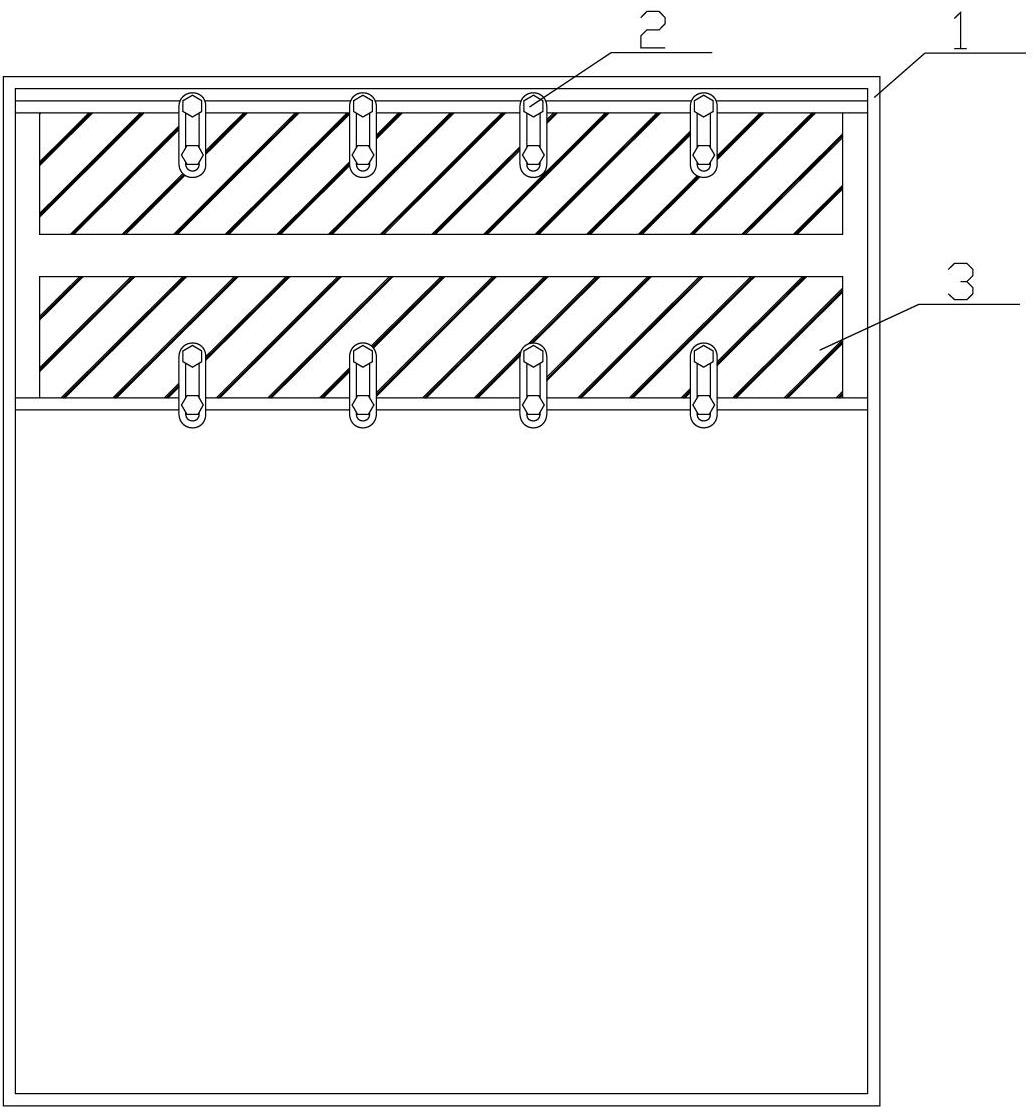

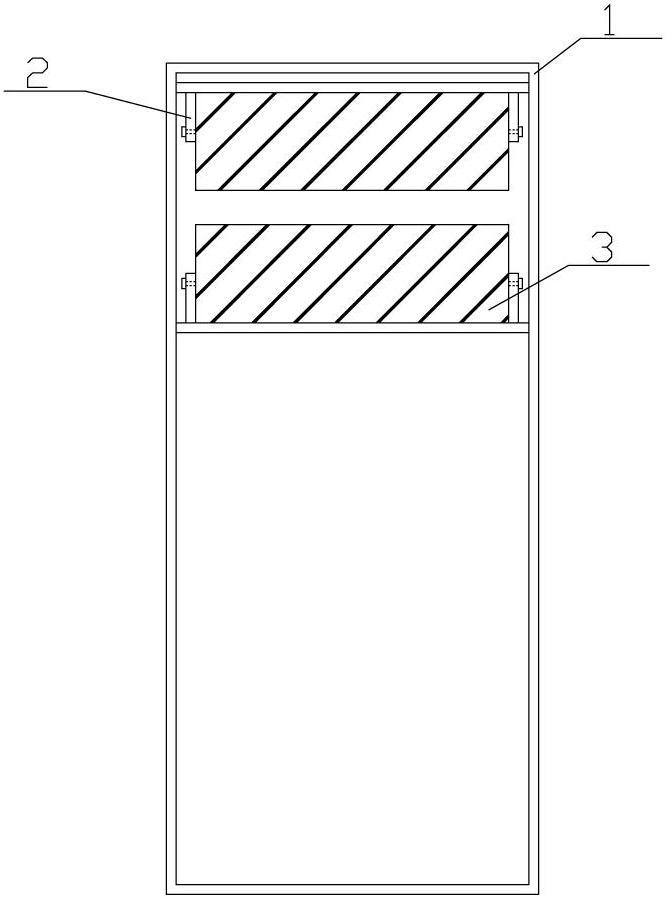

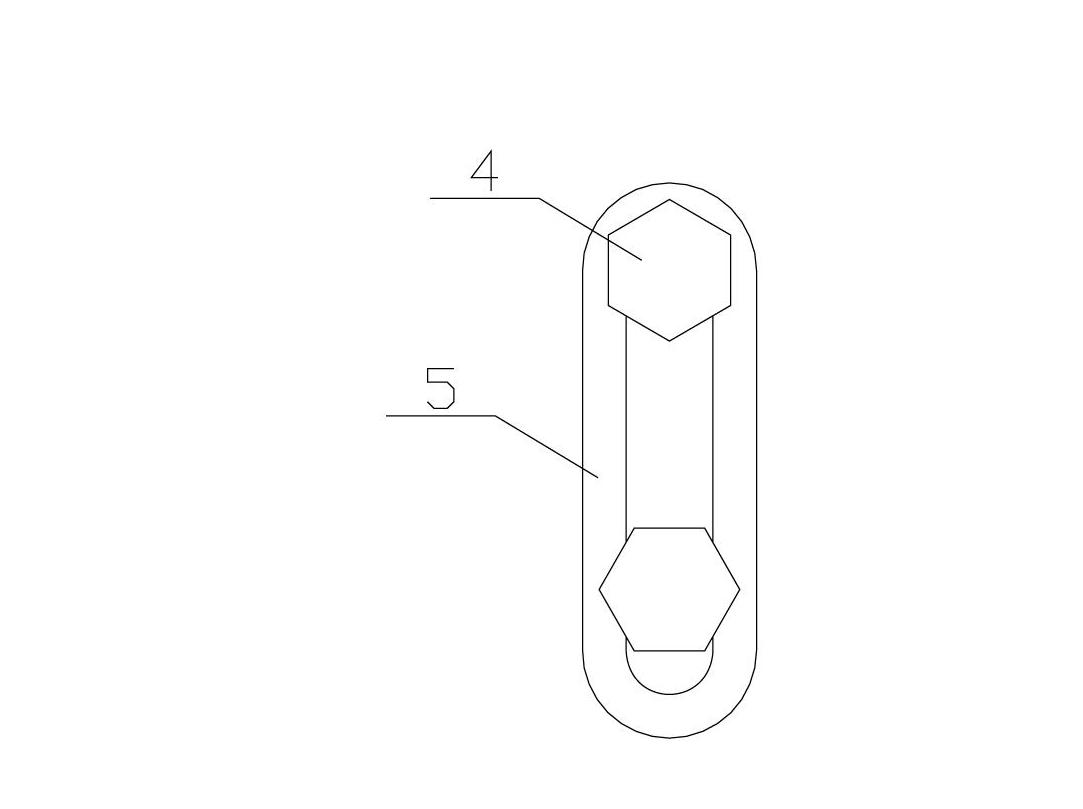

[0015] Such as Figure 1 to Figure 4 As shown, a drying device for a cylinder printing machine provided by the present invention includes an oven 3, a bracket 1 for fixing and supporting the oven 3, and a track assembly 2 that can adjust the position of the oven. The bracket 1 is fixed on the There is a track assembly 2, and an oven 3 is fixed on the track assembly 2. The rail assembly 2 is composed of fixing bolts 4 and adjusting rails 5 , and the adjusting rails 5 are respectively connected with the bracket 1 and the oven 3 through the fixing bolts 4 . There are at least two ovens (3), which are fixed in the support (1) in a horizontally parallel and top-to-top manner through track assemblies (2), and heating pipes and exhaust fans are arranged inside the ovens 3.

[0016] The dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com