Rotary disk type air jet impact drying machine

A gas jet and dryer technology, applied in the direction of dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of complex structure, cumbersome operation, and large quantity of rotating racks, so as to ensure the quality of dried products, The effect of ensuring product quality and reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

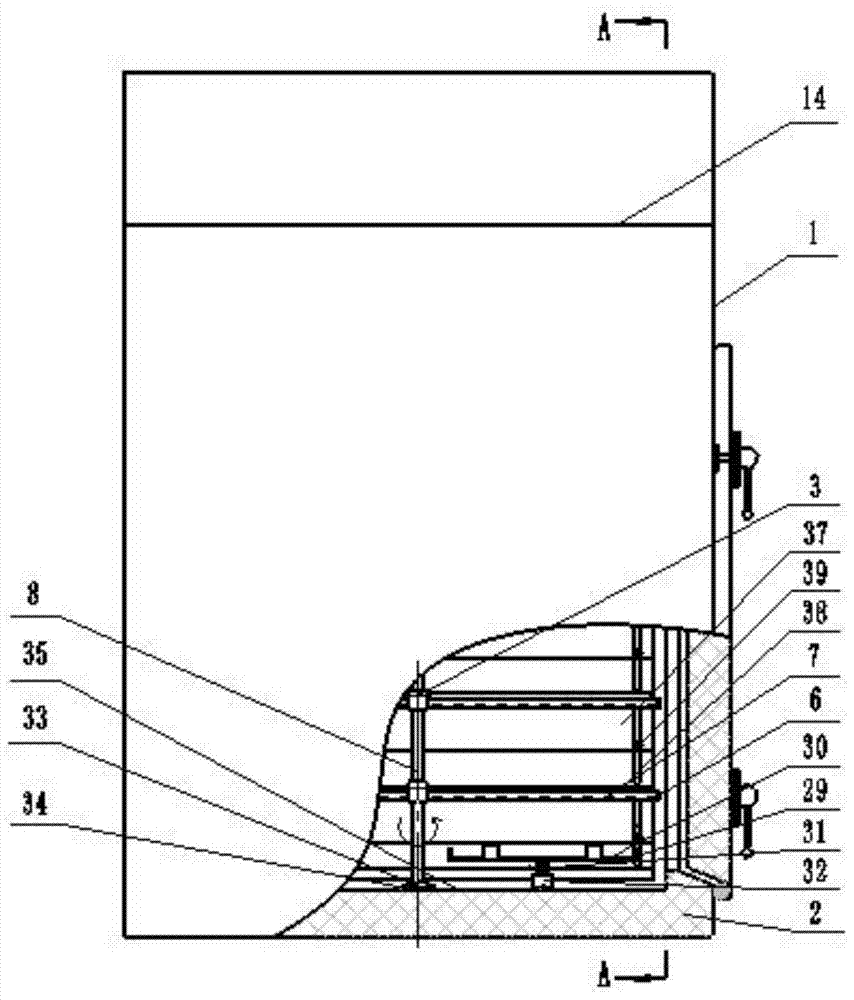

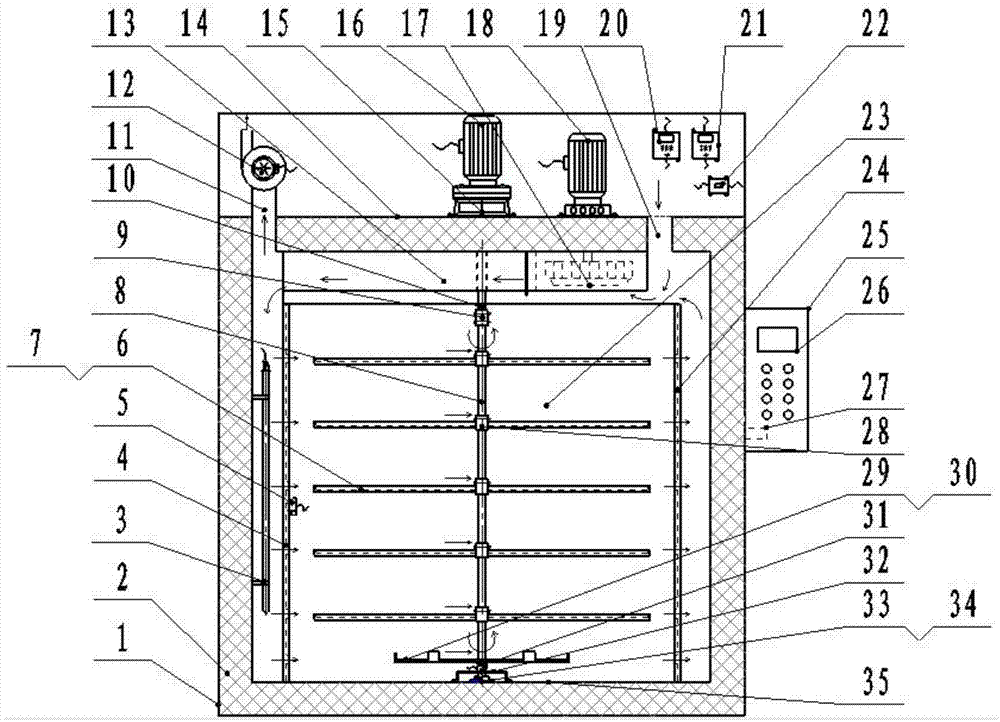

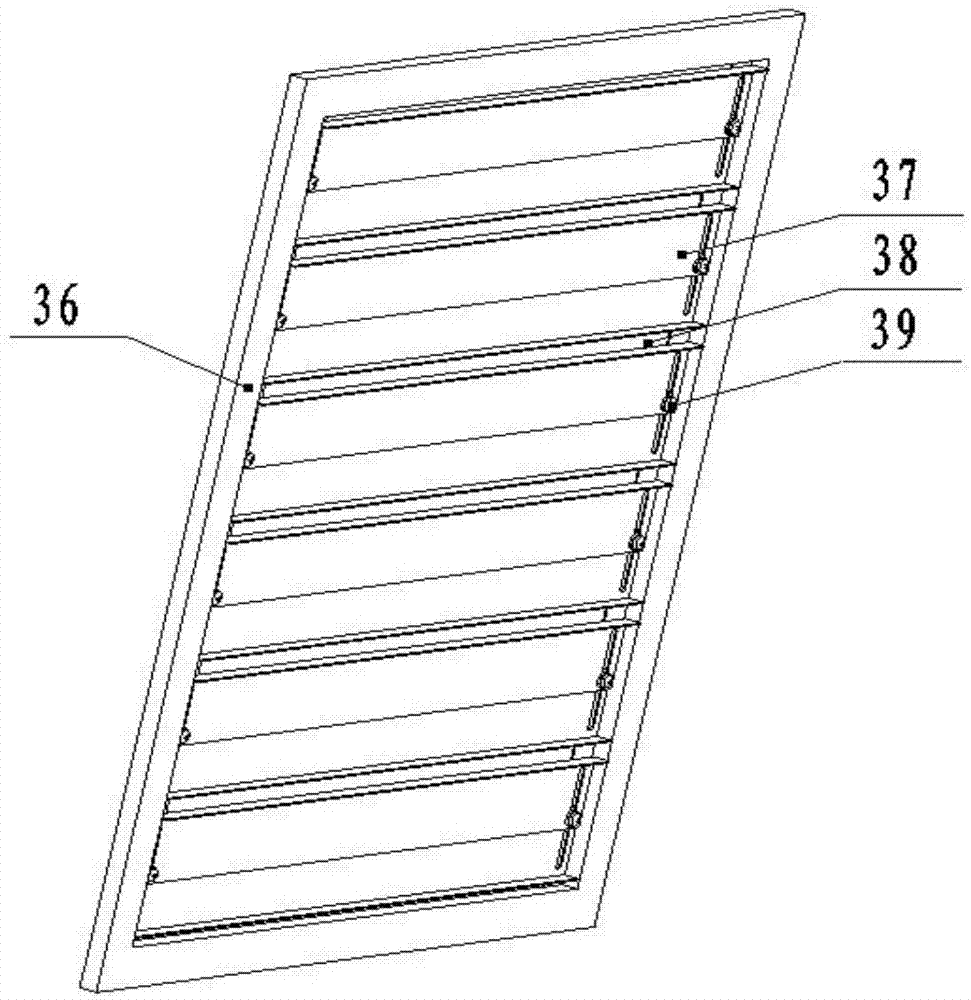

[0038] like figure 2 As shown, the rotary disc type gas jet impingement dryer of the present invention is composed of an air circulation system, a rotary disc system, a weighing system, an automatic control system and a body 1 . The drying chamber top plate 14 in the body 1 divides the body 1 into two parts, the top of the machine and the lower cabinet. The body 1 around the drying chamber 23 is filled with thermal insulation material 2. The air circulation system includes a centrifugal fan 18, a fan outlet duct 13, a moisture exhaust pipe 11, a moisture exhaust fan 12, an air inlet airflow adjustment device 4, and an electric heating device. 3. The drying chamber 23, the return air flow regulating device 24 and the air inlet pipe 19, the centrifugal fan 18 is vertically installed on the top plate 14 of the drying chamber, the air outlet of the centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com