Device and method for generating clean coal by means of quick total sulfur treatment of coal

A processing device and fast technology, applied in the field of vacuum negative pressure drying, physical desulfurization of raw coal, low-temperature drying, can solve the problems of affecting the effect of microwave irradiation treatment, the effect of organic sulfur removal is not obvious, and hindering the escape of sulfur components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

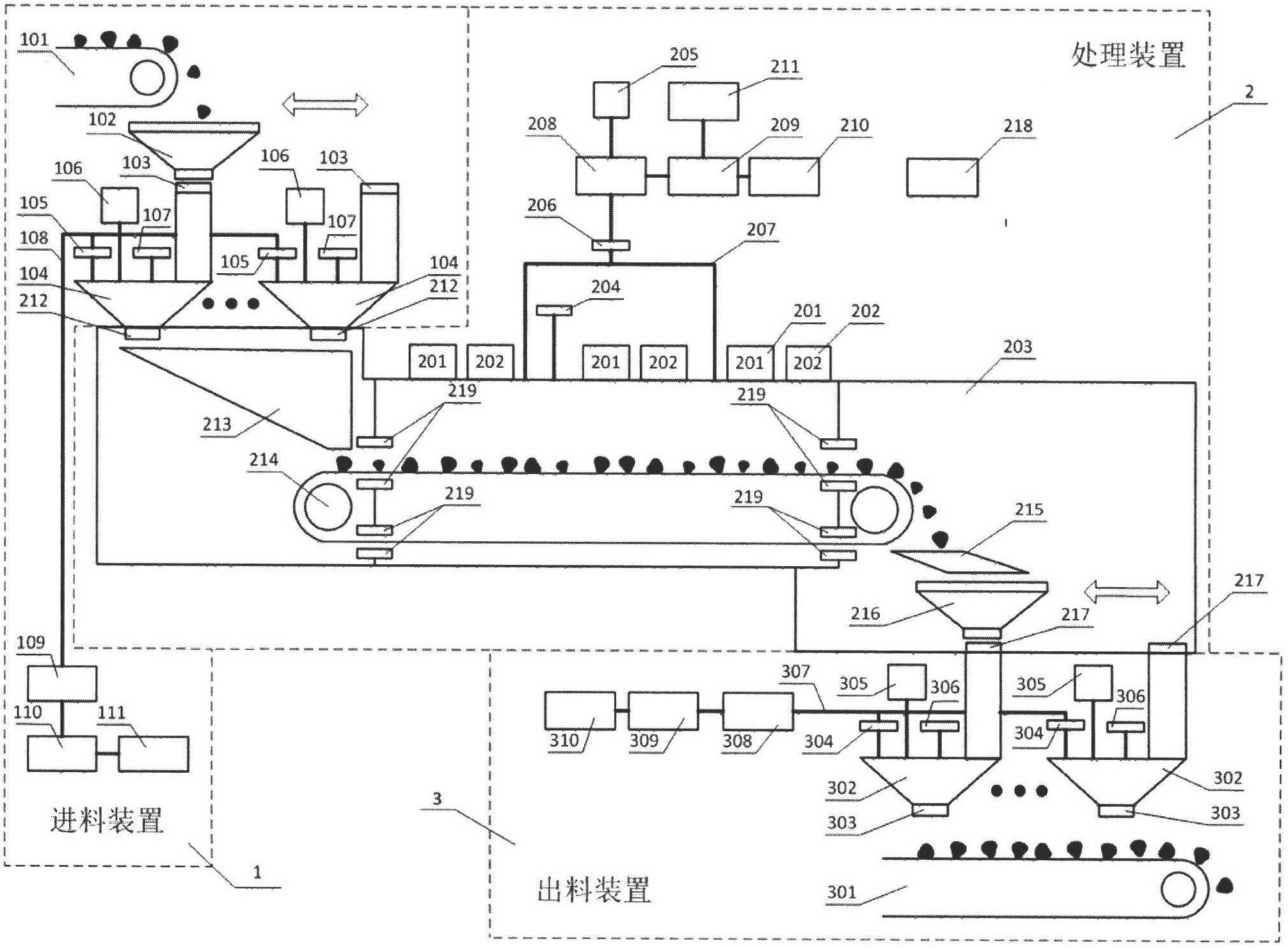

[0069] see figure 1 , the described device for generating clean coal by rapid processing of full sulfur of raw coal of continuous processing type comprises a feeding device 1, a processing device 2, and a discharging device 3; the raw coal is evacuated to a set processing barometric pressure Then it is sent to the processing device 2, where the gas pressure is processed and processing temperature Under the conditions of microwave irradiation, the treatment time is T, and then sent to the discharge device 3, and then sent to the subsequent process after the treated coal returns to atmospheric pressure.

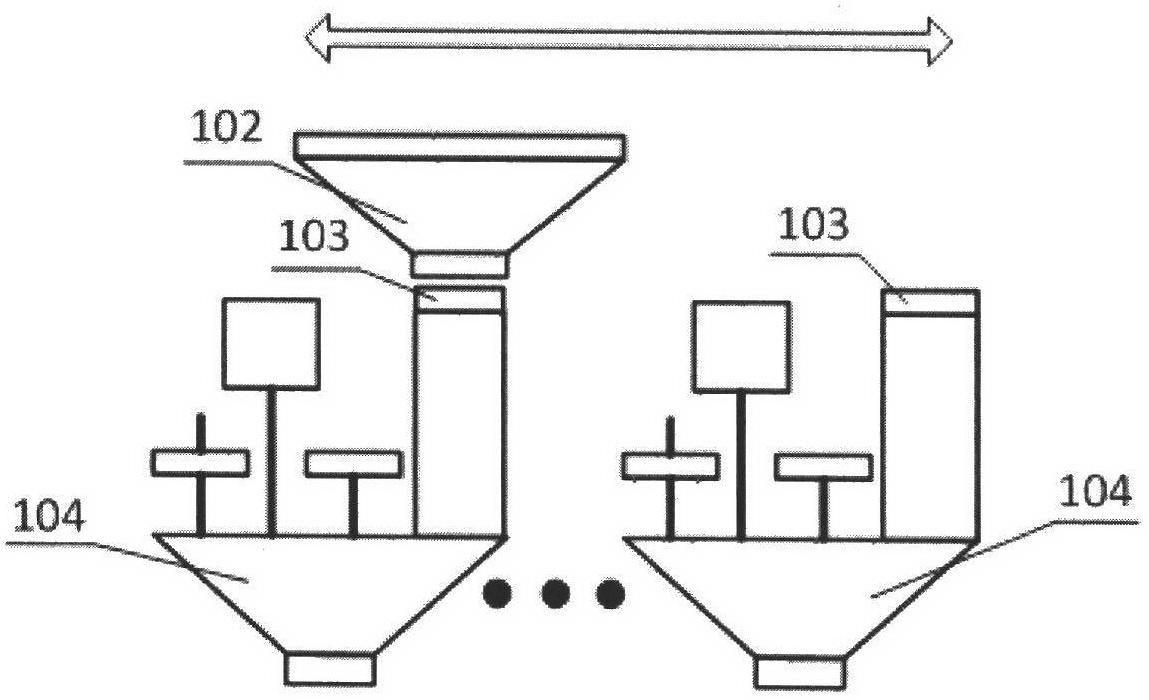

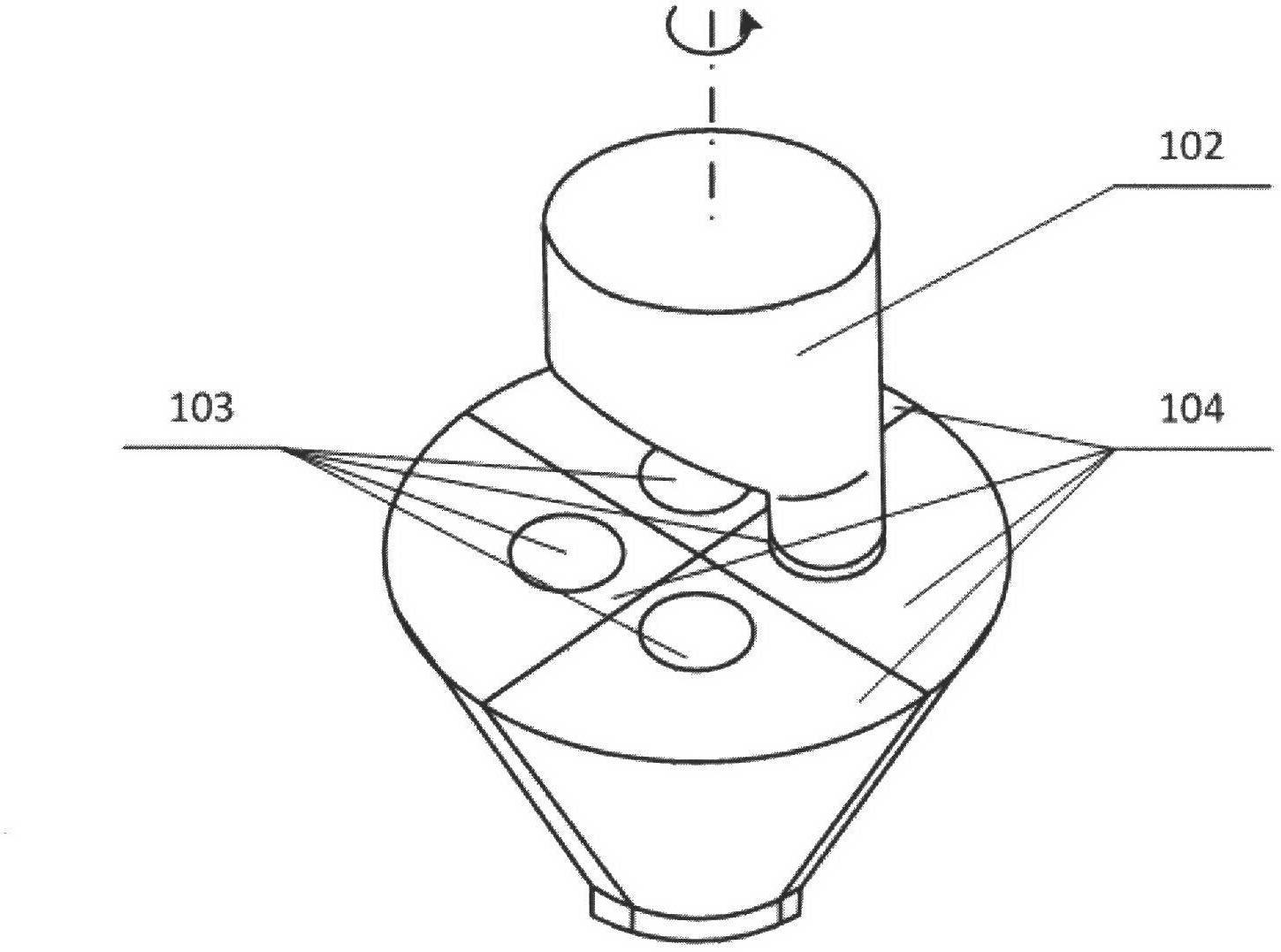

[0070] Described feeding device 1 comprises feeding conveying mechanism 101, feeding distributor 102, several feeding chambers 104, several feeding chamber sealing doors 103 equivalent to feeding chamber 104 quantity, several feeding chambers Air extraction valve 105, several feed chamber vacuum sensors 106, several feed chamber deflation valves 107, and feed chamber suct...

Embodiment 2

[0093] see Figure 14, the described batch processing type raw coal full sulfur rapid processing device to generate clean coal includes several temperature sensors 201, several microwave sources 202, a processing chamber 203, a processing chamber purge valve 204, and a processing chamber vacuum sensor 205, processing chamber exhaust valve 206, processing chamber exhaust pipe 207, processing chamber gas storage tank 208, processing chamber vacuum pump 209, processing chamber vacuum pump motor 210, waste gas treatment device 211, processing chamber sealing screen door 220, processing chamber transmission mechanism 214, controller 218; several microwave sources 202 composed of small and medium power magnetrons, excitation chambers, waveguides, microwave feeders or antennas, and power supplies are distributed on the wall of the processing chamber 203, forming a temperature field together with the processing chamber 203 A uniform microwave heating device, and under the control of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com