Capsule production line equipment

A production line and production line technology, applied in the direction of conveyors, roller tables, mechanical conveyors, etc., can solve the problems of high impact and noise of the rubber sheet turning mechanism, low efficiency of the rubber sheet lifting mechanism, and large footprint of the drying equipment. Achieve the effects of improving processing efficiency, saving the time of conveying rubber sheets, and having a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The capsule production line equipment of this embodiment will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

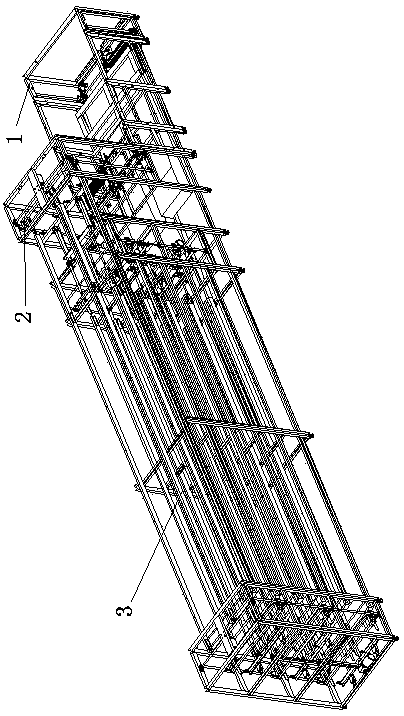

[0047] A kind of capsule production line equipment of the present embodiment, such as figure 1 As shown, it includes the rubber sheet turning mechanism for lifting the dried rubber sheet from the lower part of the production line to the upper part of the production line and realizing the 180° flip of the rubber sheet, the circulating capsule drying equipment and the lifting of the rubber sheet that has been dipped in glue and turned over To the rubber plate lifting mechanism of the circulating capsule drying equipment.

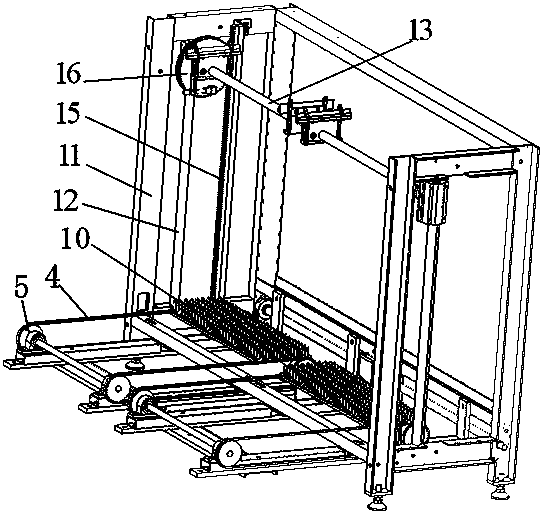

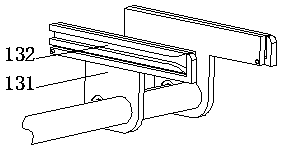

[0048] The above-mentioned rubber sheet turnover mechanism, such as figure 2 As shown, it includes a bracket 11, a column 12 fixedly arranged on both sides of the bracket 11, a lifting mechanism 13 slidingly connected with the column 12, and a gear 16 and a rack 15 for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com