Diffusion rectification flow equalizing structure

A technology of diffuser tube and rectifier plate, applied in the direction of fluid flow, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of high flow velocity in the center of the heating cavity, large impact load of equipment, and reduced heat exchange efficiency, and achieve heat exchange. Efficiency improvement, overcoming large shock loads, and consistent flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

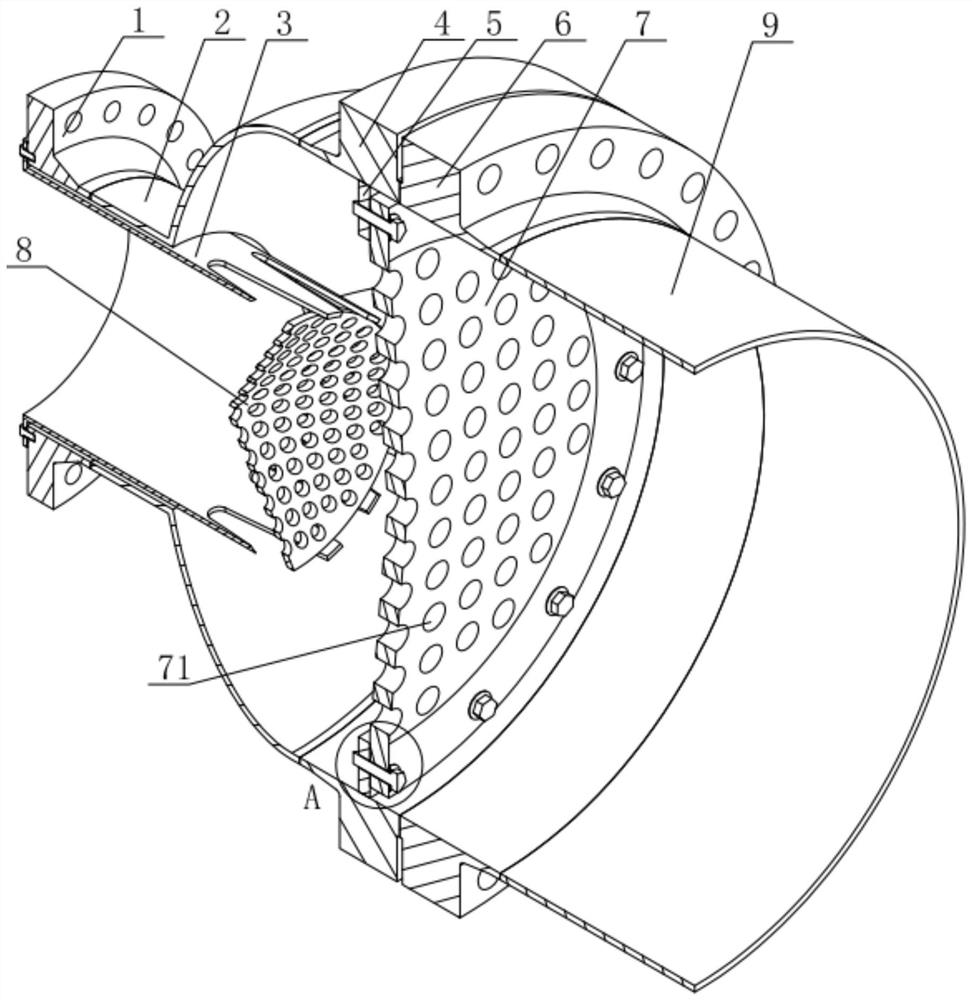

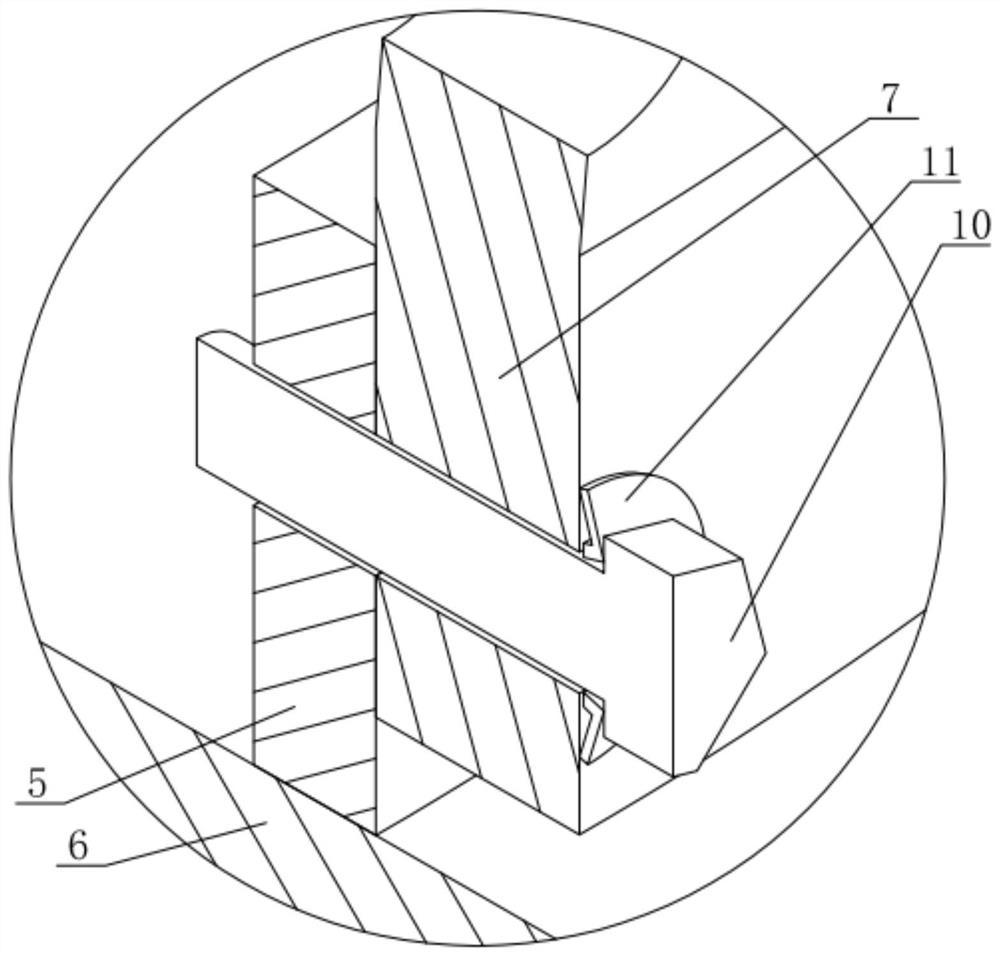

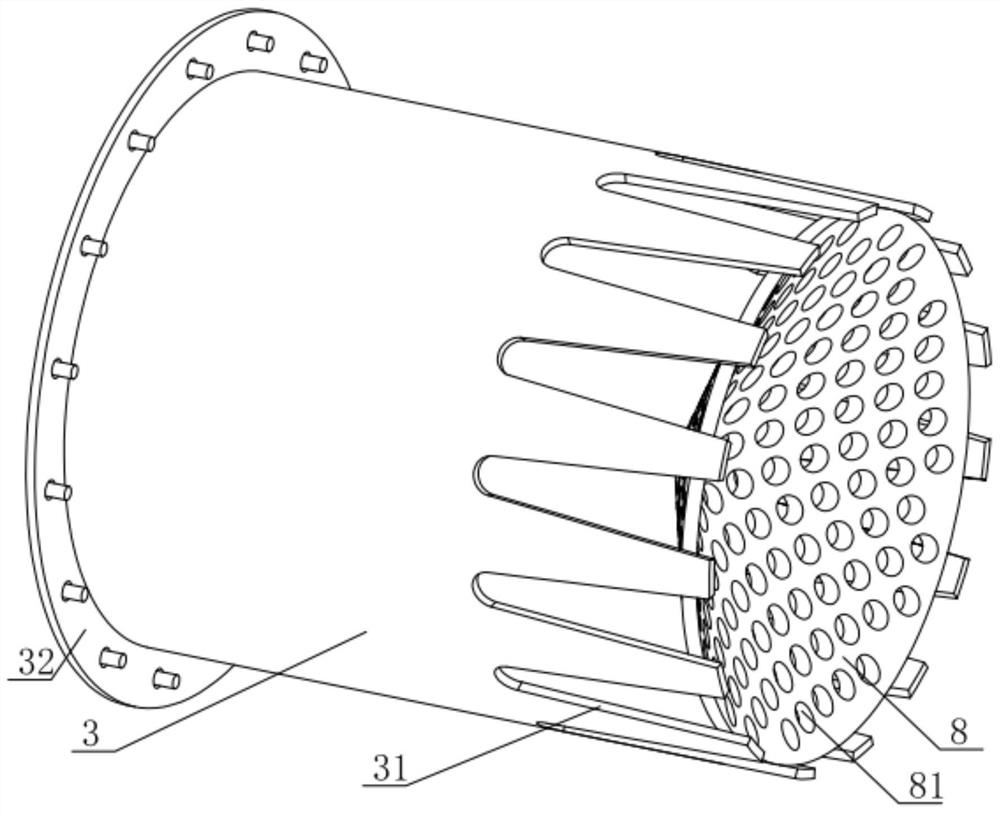

[0028] Such as figure 1 As shown, a diffusion and rectification flow equalization structure of the present embodiment includes a front-to-back through shell, a diffuser tube 3 is installed in the front opening of the shell, and a concave diffuser cone 8 is installed at the rear end of the diffuser tube 3 A rectifying plate 7 is installed on the inner wall of the housing behind the diffuser 3, and the housing behind the rectifying plate 7 is connected with a heating chamber; the edge of the diffuser 3 and the diffuser cone 8, the diffuser 8 and the rectifier 7 are provided with through holes for medium circulation; the middle part of the rectifying plate 7 protrudes into a tapered structure, and the surrounding edges of the rectifying plate 7 are connected to the inner wall of the housing through fasteners arranged at intervals. Disc sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com