Automobile A-pillar structure, vehicle and manufacturing method of A-pillar structure

A manufacturing method and column structure technology, applied in the connection between superstructure sub-assemblies, superstructure, vehicle components, etc., can solve the problems of secondary damage to the passenger compartment, insufficient impact energy absorption, and no support for A-pillars, etc. Achieve the effect of not easy slipping, improving stiffness and dispersing collision energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

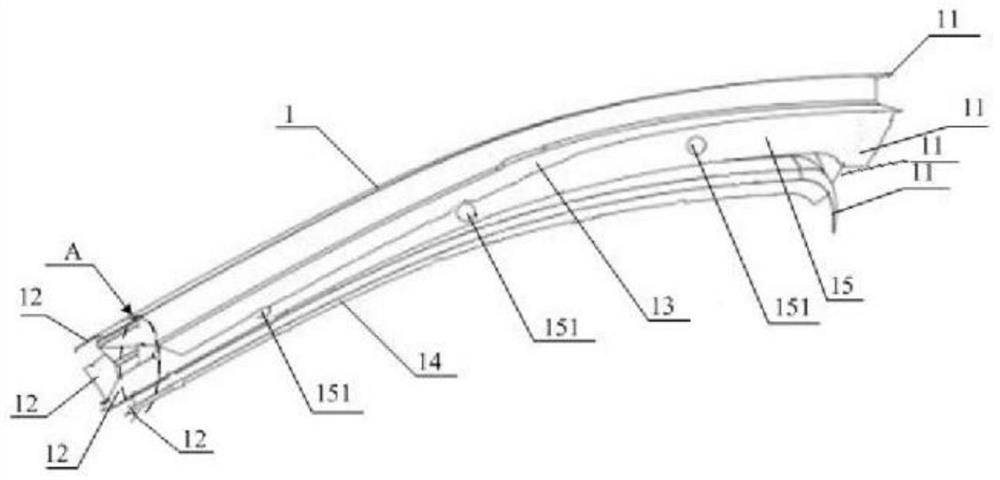

[0037] Figure 1-2 It shows the automobile A-pillar structure of the present invention, which is an integrally extruded cavity structure, the cavity is distributed axially along the A-pillar body 1, and pipe fittings 2 are arranged in the cavity, and the pipe fittings 2 are distributed axially along the cavity, The A-pillar body 1 and the pipe fitting 2 are in a bending fit.

[0038] One-piece extrusion molding can ensure the overall rigidity and prevent the A-pillar from collapsing during the collision. The pipe fitting 2 is arranged in the cavity of the A-pillar body 1 to further improve the rigidity. The column body 1 is more tightly connected and is not easy to slip off. The curved A-pillar body 1 and the pipe fitting 2 have an arched structure with better impact resistance when subjected to a collision.

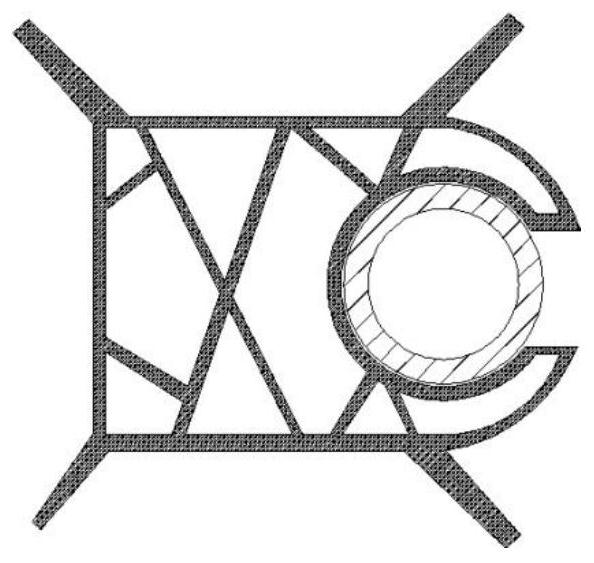

[0039] In this embodiment, the A-pillar structure of the automobile forms a network-like cross-section during extrusion molding.

[0040] The network-like cross-sectio...

Embodiment 2

[0049] The invention discloses a method for manufacturing an automobile A-pillar structure, which specifically includes the following steps:

[0050] S1: Connect the extrusion die to the port of the extrusion equipment through bolts;

[0051] S2: heating the aluminum alloy ingot to 360°C to 380°C, and putting it into the extrusion cylinder of the extrusion equipment;

[0052] S3: The extrusion device in the extrusion equipment advances to the extrusion die at a predetermined extrusion speed, extrudes the aluminum alloy ingot, and passes the aluminum alloy ingot from the die hole of the extrusion die Extrude to form an extrusion;

[0053] S4: Fix one end of the extruded piece formed by the traction equipment, and complete the traction with the work of the extrusion equipment;

[0054] S5: The aluminum alloy ingots inside the extrusion cylinder are all converted into extrusions, and the extrusions are cut according to the preset size by cutting equipment.

[0055] S6: Insert ...

Embodiment 3

[0060] The present invention provides an automobile A-pillar structure, including an A-pillar body, and the A-pillar body should have a cavity inside; wherein, a pipe fitting is arranged in the cavity of the A-pillar body; implementing the embodiment of the present invention is beneficial to the safety of the vehicle body The performance is improved to solve the problem that the A-pillar in the prior art is prone to solder joint cracking and sheet metal bending during the collision due to insufficient rigidity and insufficient impact energy absorption, resulting in secondary damage to the passenger compartment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com