Positioning module and packaging box

A technology for positioning modules and packaging boxes, applied in the directions of packaging, transportation and packaging, packaging of fragile items, etc., can solve the problems of collision, movement, and rupture of liquid crystal display panels, and achieve the effect of preventing scratches or ruptures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

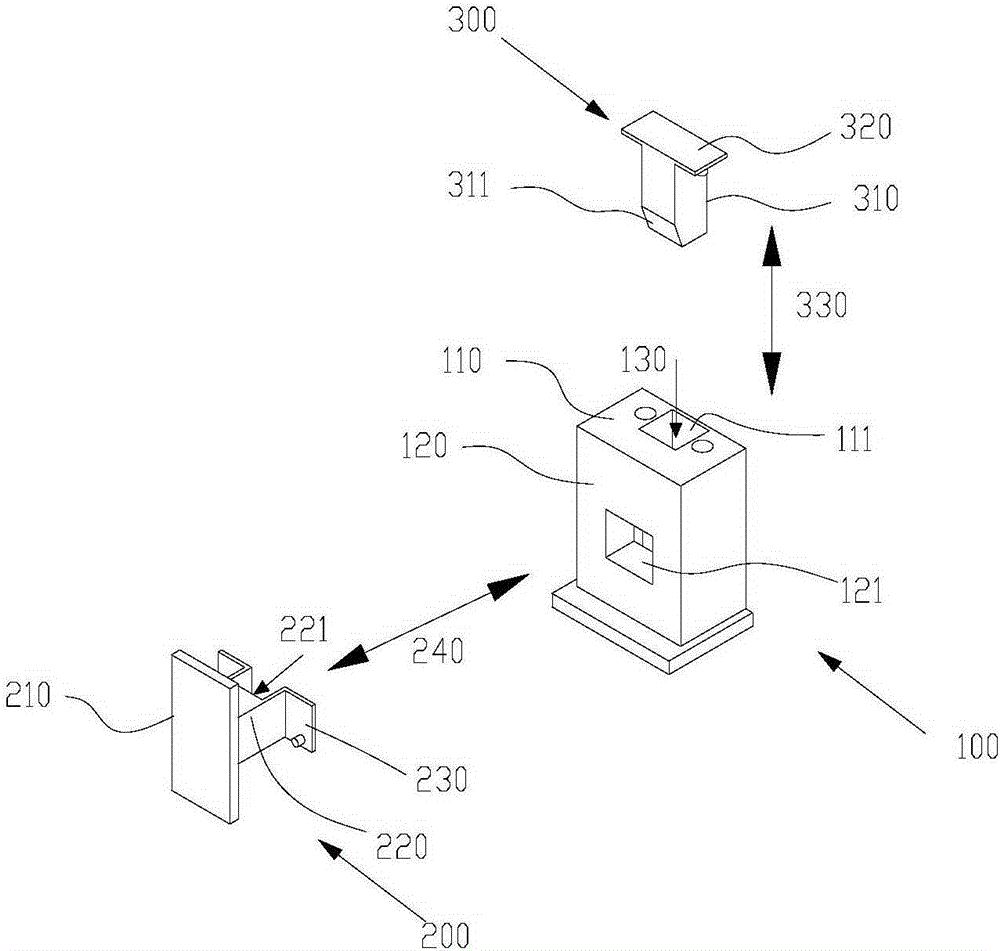

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

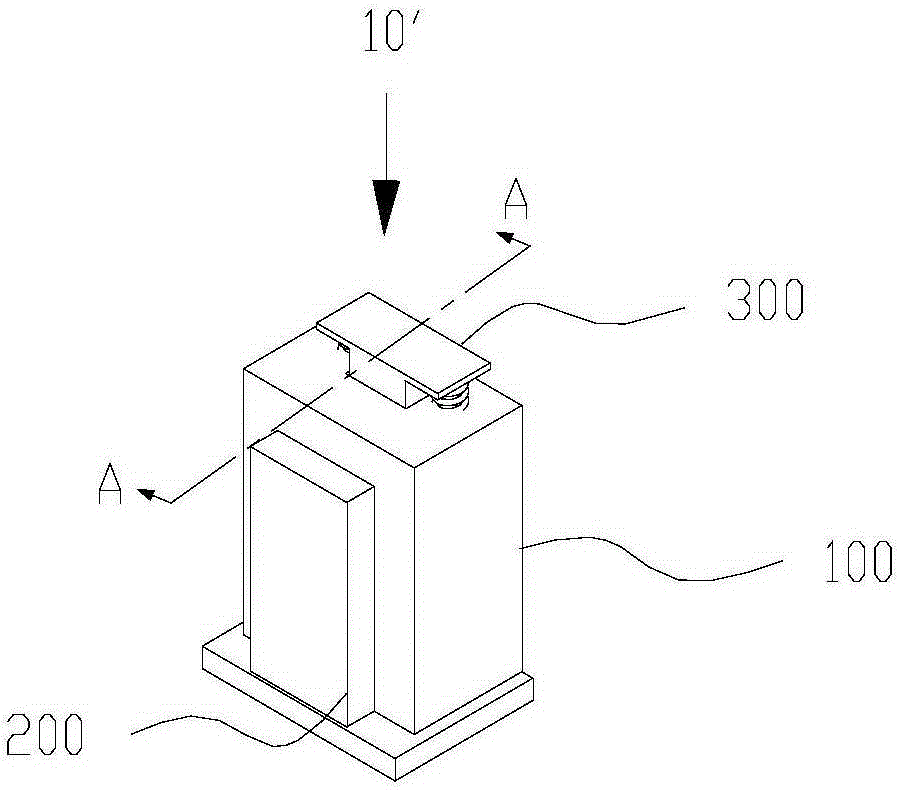

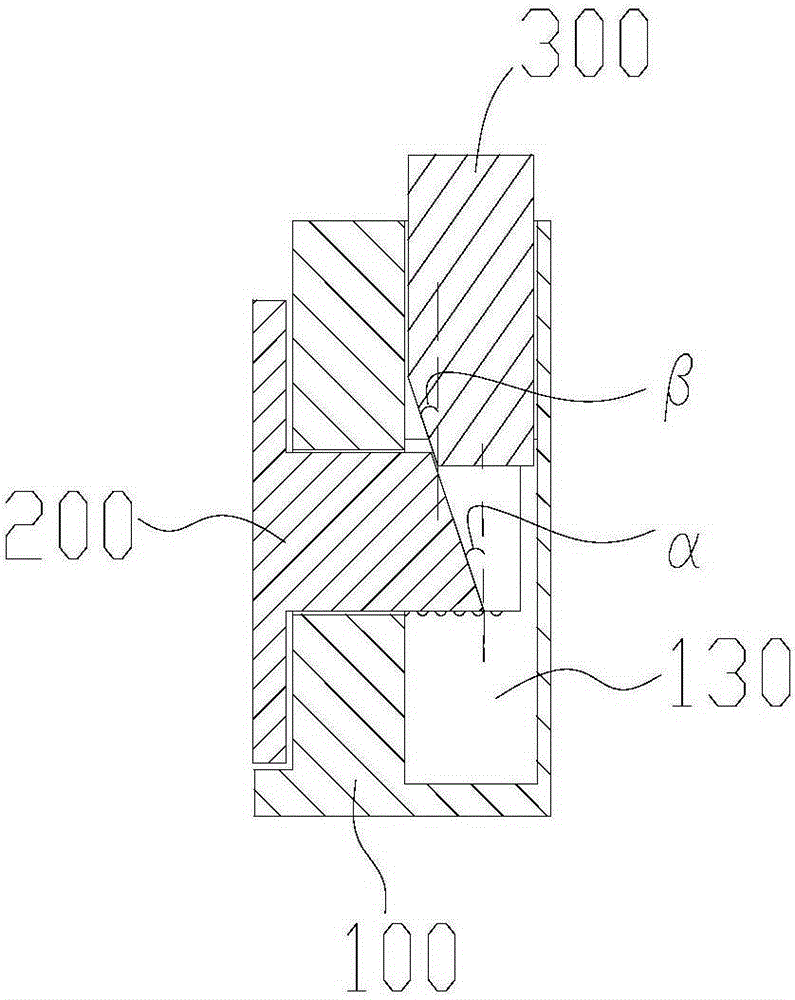

[0033] Please also see figure 1 , figure 2 with image 3 , figure 1 , figure 2 with image 3 It is a schematic diagram of the relevant structure of the positioning module in the first embodiment of the present invention. In the first embodiment of the present invention, a positioning module is provided, including:

[0034] The base 100, the base 100 has a first mounting surface 110, a second mounting surface 120 and an inner cavity 130, the second mounting surface 120 has a second opening 121, the first mounting surface 110 has a first opening 111, and the second opening 121 and the first opening 111 communicates with the inner cavity 130;

[0035] The pressure piece 300, the pressure piece has an inserting plate 310 and a baffle plate 320, the baffle plate 320 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com