Wear-resisting food mechanical material and preparation method thereof

A technology of food machinery and raw materials, which is applied in the field of wear-resistant food machinery materials and their preparation, can solve the problems of tool wear, small shedding, and mixing, and achieve the effect of improving hardness, good internal toughness, plasticity and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

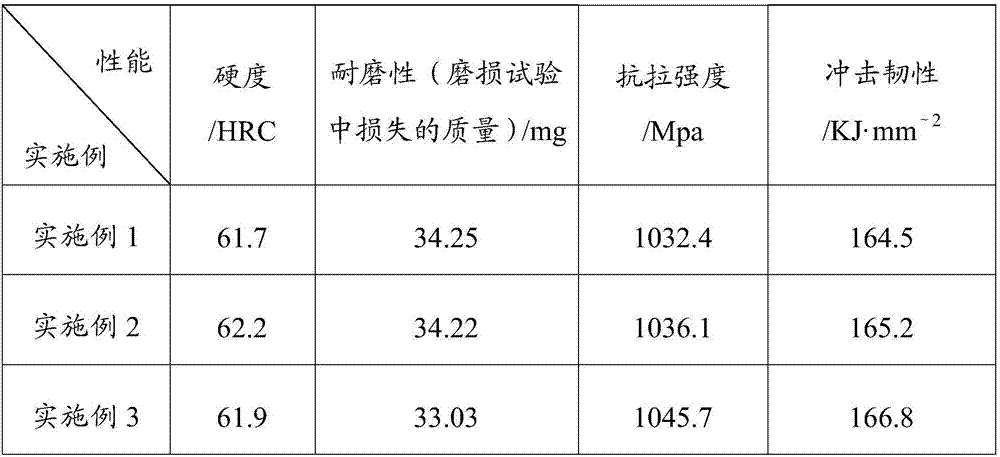

Examples

Embodiment 1

[0023] A wear-resistant food machinery material, characterized in that its raw materials are composed of the following components in mass percentage: C: 3.0%, Si: 1.0%, Cr: 2.0%, V: 0.8%, Mn: 0.8%, Ni: 0.7%, B: 0.05%, W: 0.05%, Ce: 0.08%, the balance is made up to 100% with Fe;

[0024] Specifically follow the steps below:

[0025] Step 1, weigh C: 3.0%, Si: 1.0%, Cr: 2.0%, V: 0.8%, Mn: 0.8%, Ni: 0.7%, B: 0.05%, W: 0.05%, Ce: 0.08%, the balance is made up 100% with Fe;

[0026] Step 2, put the raw materials weighed in step 1 into a vacuum of 1.5×10 -3 In a vacuum medium frequency induction furnace of Pa, stir to make it evenly mixed, and then carry out the initial smelting. During the smelting process, argon protection is introduced, the smelting temperature is 1450°C, and the smelting time is 2h. After the smelting is completed, the primary smelted alloy is obtained;

[0027] Step 3, breaking the primary smelted alloy in step 2 into fragments with a particle size of 1 cm, ...

Embodiment 2

[0031] A wear-resistant food machinery material, characterized in that its raw materials are composed of the following components in mass percentage: C: 3.2%, Si: 0.8%, Cr: 1.8%, V: 0.9%, Mn: 0.6%, Ni: 0.5%, B: 0.08%, W: 0.08%, Ce: 0.07%, the balance is made up to 100% with Fe;

[0032] Specifically follow the steps below:

[0033] Step 1, weigh C: 3.2%, Si: 0.8%, Cr: 1.8%, V: 0.9%, Mn: 0.6%, Ni: 0.5%, B: 0.08%, W: 0.08%, Ce: 0.07%, the balance is made up 100% with Fe;

[0034] Step 2, put the raw materials weighed in step 1 into a vacuum of 1.5×10 -3 In a vacuum medium frequency induction furnace of Pa, stir to make it evenly mixed, and then carry out the primary smelting. During the smelting process, argon protection is introduced, the smelting temperature is 1480°C, and the smelting time is 1.5h. After the smelting is completed, the primary smelted alloy is obtained;

[0035] Step 3, breaking the primary smelted alloy in step 2 into fragments with a particle size of 2 cm...

Embodiment 3

[0039] A wear-resistant food machinery material, characterized in that its raw materials are composed of the following components in mass percentage: C: 3.5%, Si: 0.5%, Cr: 1.5%, V: 1.0%, Mn: 0.5%, Ni: 0.4%, B: 0.1%, W: 0.1%, Ce: 0.06%, the balance is made up to 100% with Fe;

[0040] Specifically follow the steps below:

[0041] Step 1, weigh C: 3.5%, Si: 0.5%, Cr: 1.5%, V: 1.0%, Mn: 0.5%, Ni: 0.4%, B: 0.1%, W: 0.1%, Ce: 0.06%, the balance is made up 100% with Fe;

[0042] Step 2, put the raw materials weighed in step 1 into a vacuum of 1.5×10 -3In a vacuum medium-frequency induction furnace of Pa, stir to make it evenly mixed, and then carry out the initial melting, and pass through the argon protection during the melting process, the melting temperature is 1500°C, the melting time is 1h, and the first melting alloy is obtained after the melting is completed;

[0043] Step 3, breaking the primary smelted alloy in step 2 into fragments with a particle size of 3 cm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com