Intelligent multilevel inverter microwave and optical wave crawler speed-regulating tunnel type coal drying device

A drying equipment and tunnel-type technology, which is applied in the field of industrial clean and productive briquette drying equipment, can solve the problems of large occupied space, high production cost, easy ignition, etc., and achieve small footprint and fast heating speed , the effect of short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

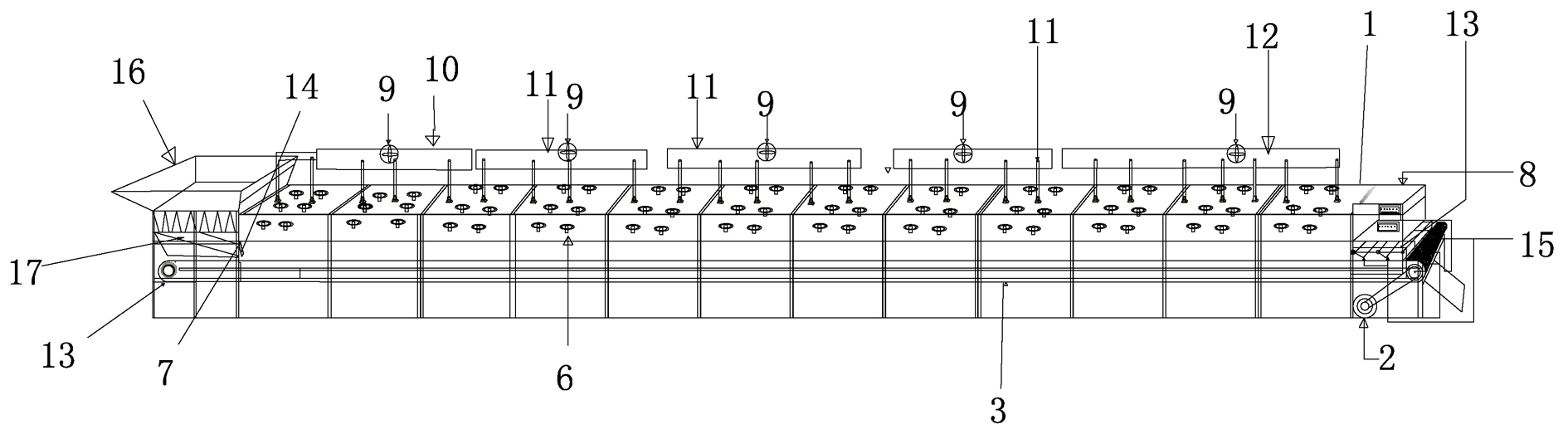

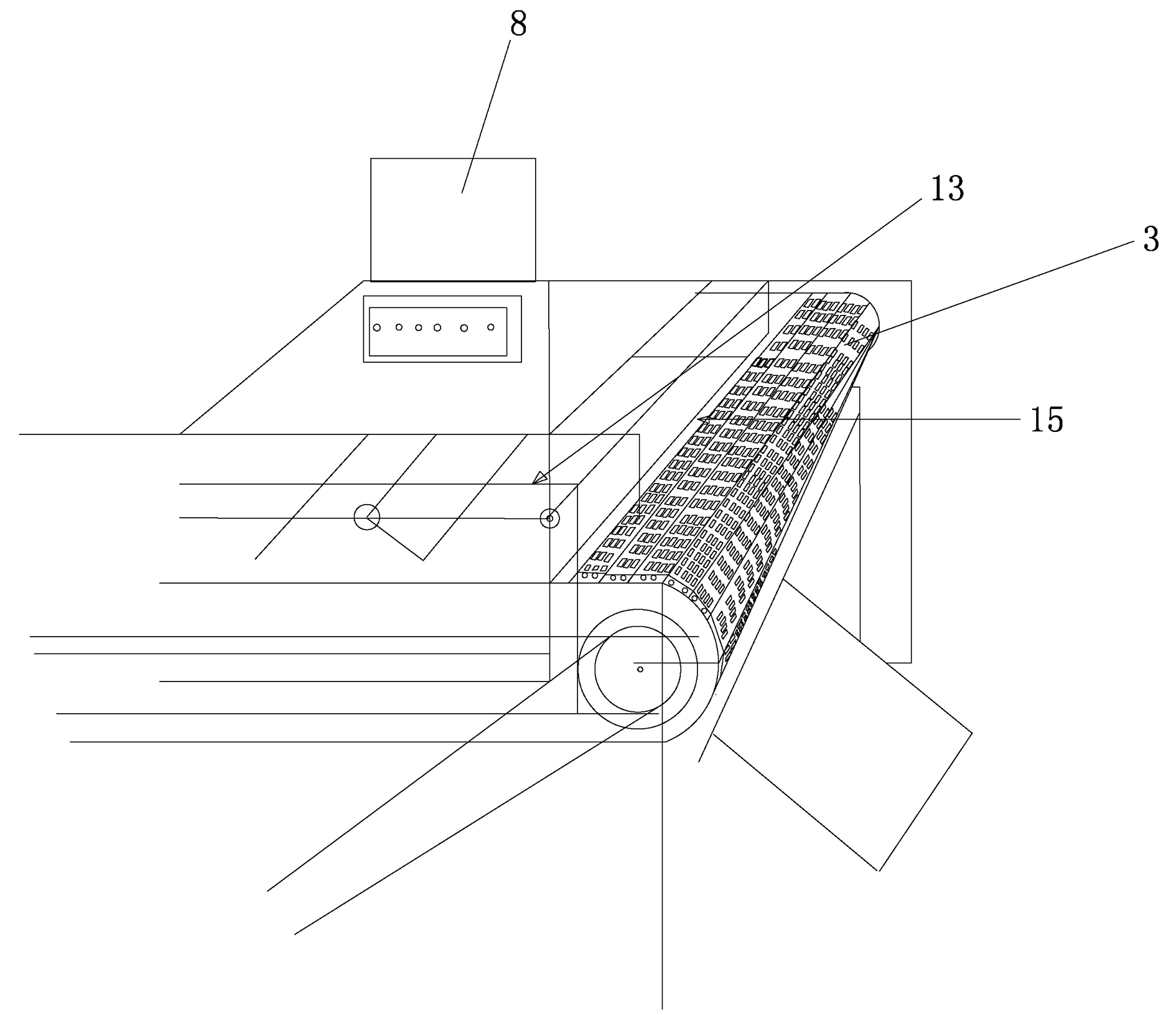

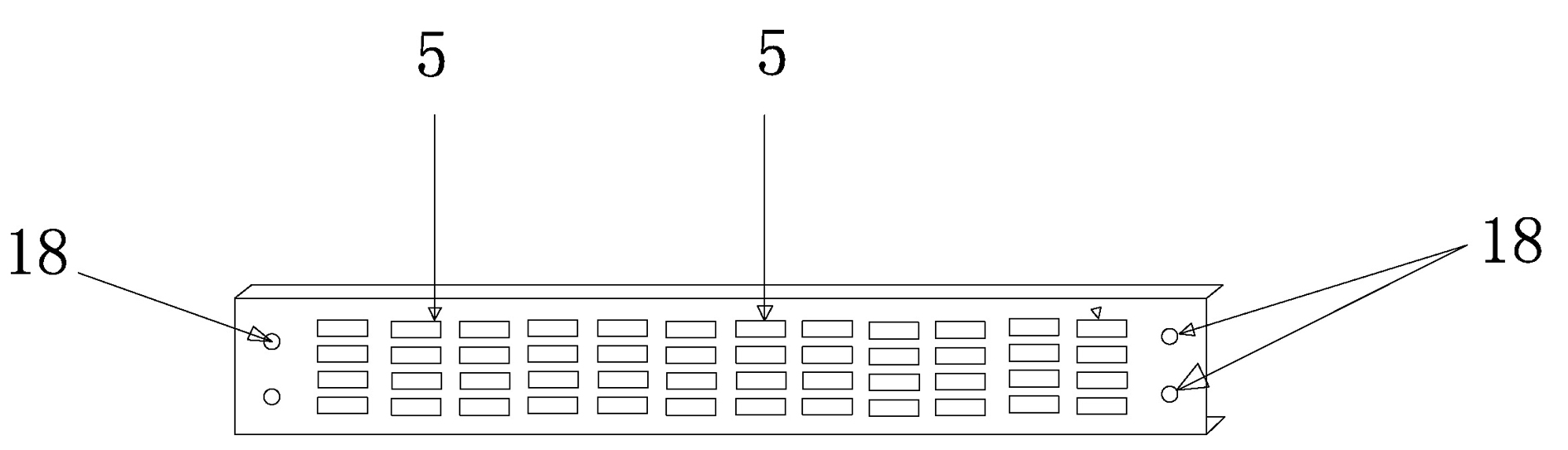

[0013] The intelligent multi-stage frequency conversion microwave and light wave crawler speed regulating tunnel type coal drying equipment described in the present invention, such as figure 1 , 2 , 3, and 4, it includes a tunnel-type box 1, a metal crawler 3 connected to the frequency conversion motor 2, the metal crawler 3 is formed by splicing several crawler grooves 4, and each crawler groove 4 is neatly arranged. Breathing holes 5; a microwave magnetron group and a light wave metal halide lamp group 6 are arranged above the metal track 3 in the tunnel type box.

[0014] In the present invention, a microcomputer automatic induction control switch 7 is provided at the briquette entrance of the tunnel box 1, and a microcomputer control system 8 is provided at the briquette exit; The motor 9 is connected to the low-temperature zone moisture discharge lead-out conduit 10, the medium-temperature zone moisture discharge lead-out conduit 11, and the high-temperature zone moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com