Mineral source soil conditioner granulation process and device

A technology of soil conditioner and granulation device, which is applied in the direction of fertilization device, fertilizer mixture, static tank/trough granulation, etc., which can solve the problems of poor mixing uniformity, increased circulation load of screening equipment and drying heat load, process Problems such as complex process, to achieve the effect of increasing mixing uniformity, improving the production environment, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

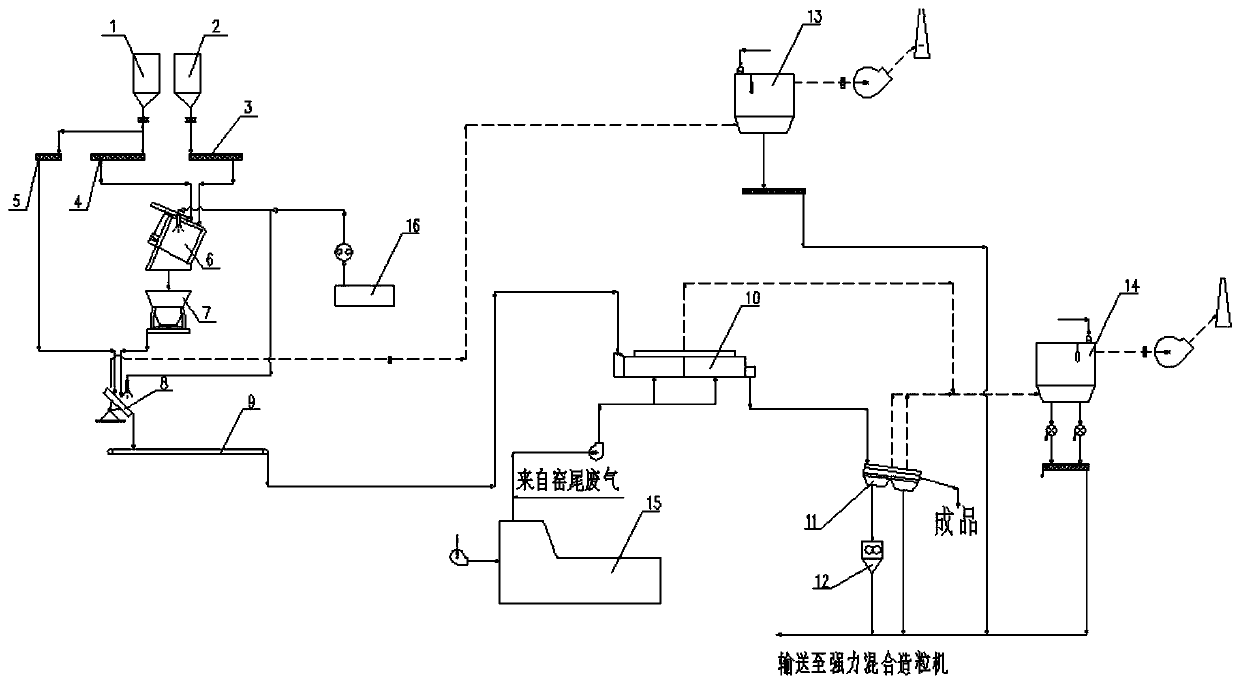

[0059] see figure 1 , the embodiment of the present invention provides a kind of mineral source soil conditioner granulation process, comprises the steps:

[0060] ① Raw material batching: The powdered mineral fertilizer and granulation additives are measured and batched separately according to a certain proportion.

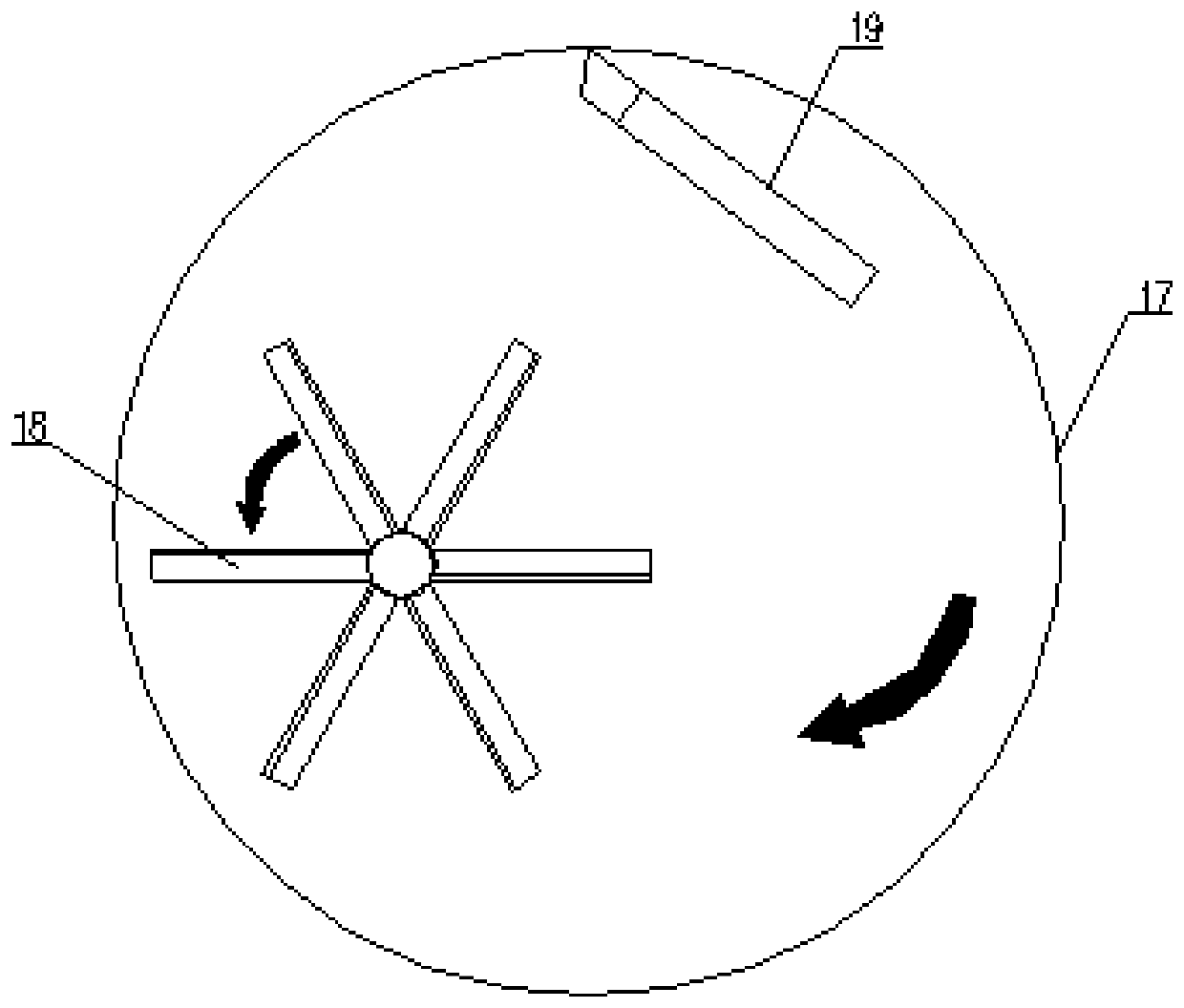

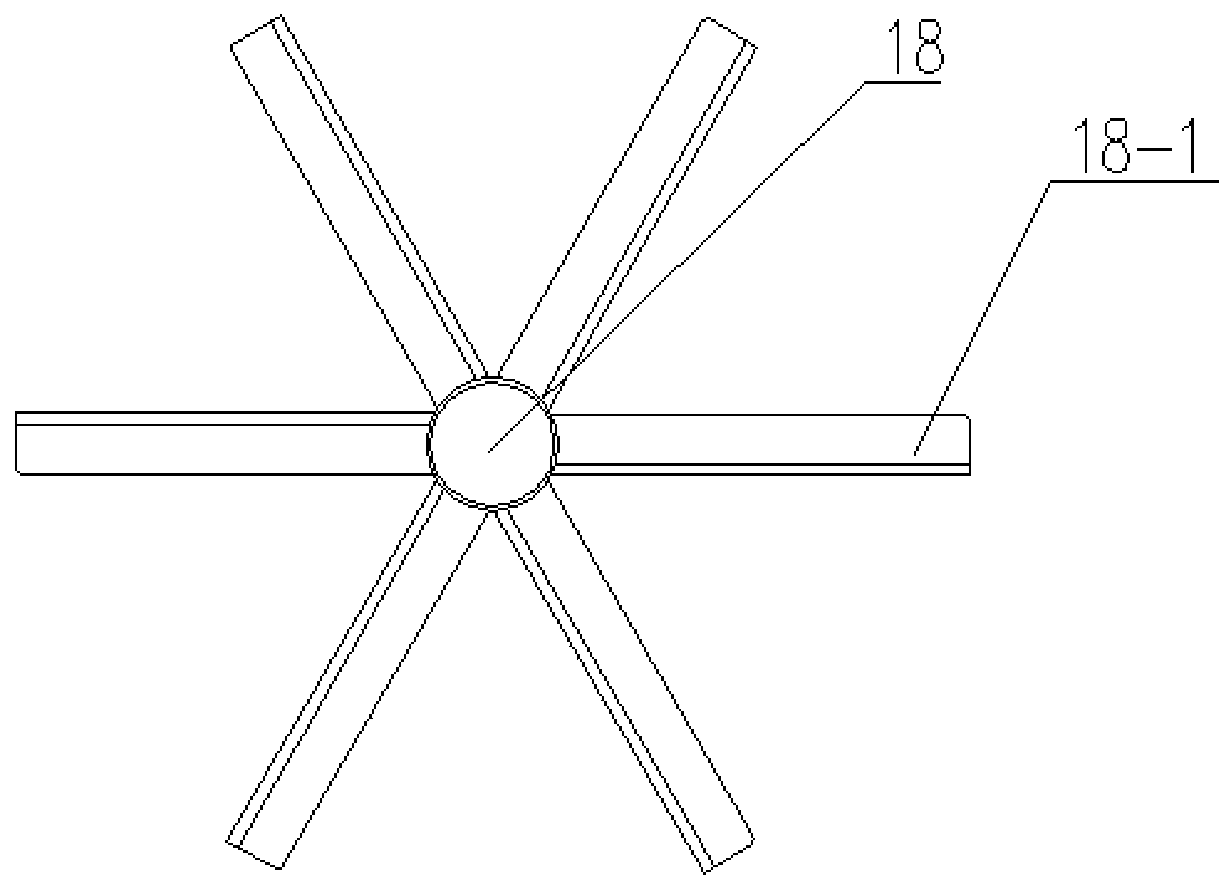

[0061] ②Micro-granulation: After the prepared mixture is measured, it is transported to the intensive mixing granulator 6; in the completely closed granulator barrel, adjust the speed of the stirring device to 4500-5000r / min, carry out vigorous stirring and mixing for 2 minutes, and then The speed of the stirring device is adjusted to 400-500r / min by a frequency converter, and intelligent quantitative water spraying and granulation are carried out to form uniform micro-particles with a water content of 10-12% and a particle size of 0.2-0.5mm. A large number of test results have proved that when the water content of the micro-particles is controlled at about 10-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com