Solar vertical circulation dying room

A technology of three-dimensional circulation and solar energy, applied in the field of solar energy, can solve the problems of small capacity, large energy consumption, long drying cycle, etc., and achieve the effects of large capacity, increased volume ratio, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

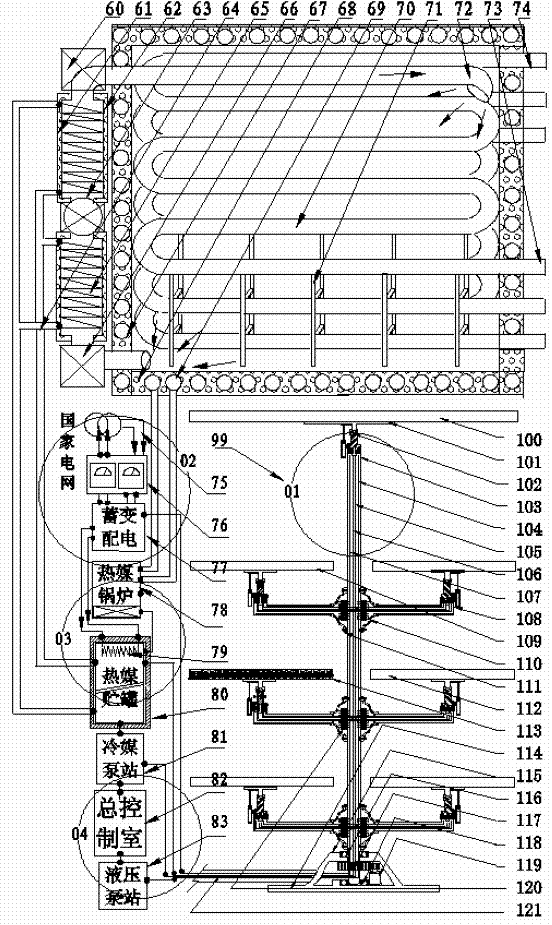

[0017] figure 1The marking names are: energy harvesting system (01), transmission system (02), energy regulation system (03), monitoring system (04), dehumidifier A (60), heating box (61), heating box insulation layer (62) , heat pump fan (63), heat medium circuit (64), heat medium coil (65), dehumidifier B (66), drying room insulation layer (67), steam coil (68), steam circuit (69), Three-dimensional curved conveyor (70), hot air nozzle (71), drying material inlet (73), circulation drying room (72), drying material outlet (74), State Grid (75), automatic power switch (76), storage, transformation, power distribution room (77), heat medium boiler (78), heater (79), heat medium storage tank (80), refrigerant pump station (81), general control room (82) and Hydraulic pump station (83), refrigerant type solar cantilever tower (99), top solar panel (100), rotating bracket (101), sag tracker (102), tower column (103), cryogenic pipeline (104), High temperature pipeline (105), hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com