Dual-purpose automatic wire feeding machine

A feeder and wire technology, which is applied in the field of dual-purpose automatic wire feeders, can solve the problems of unsteady conveying, instability and jitter of the wire, and achieve the effect of overcoming the unsteady conveying, reasonable design and perfect function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

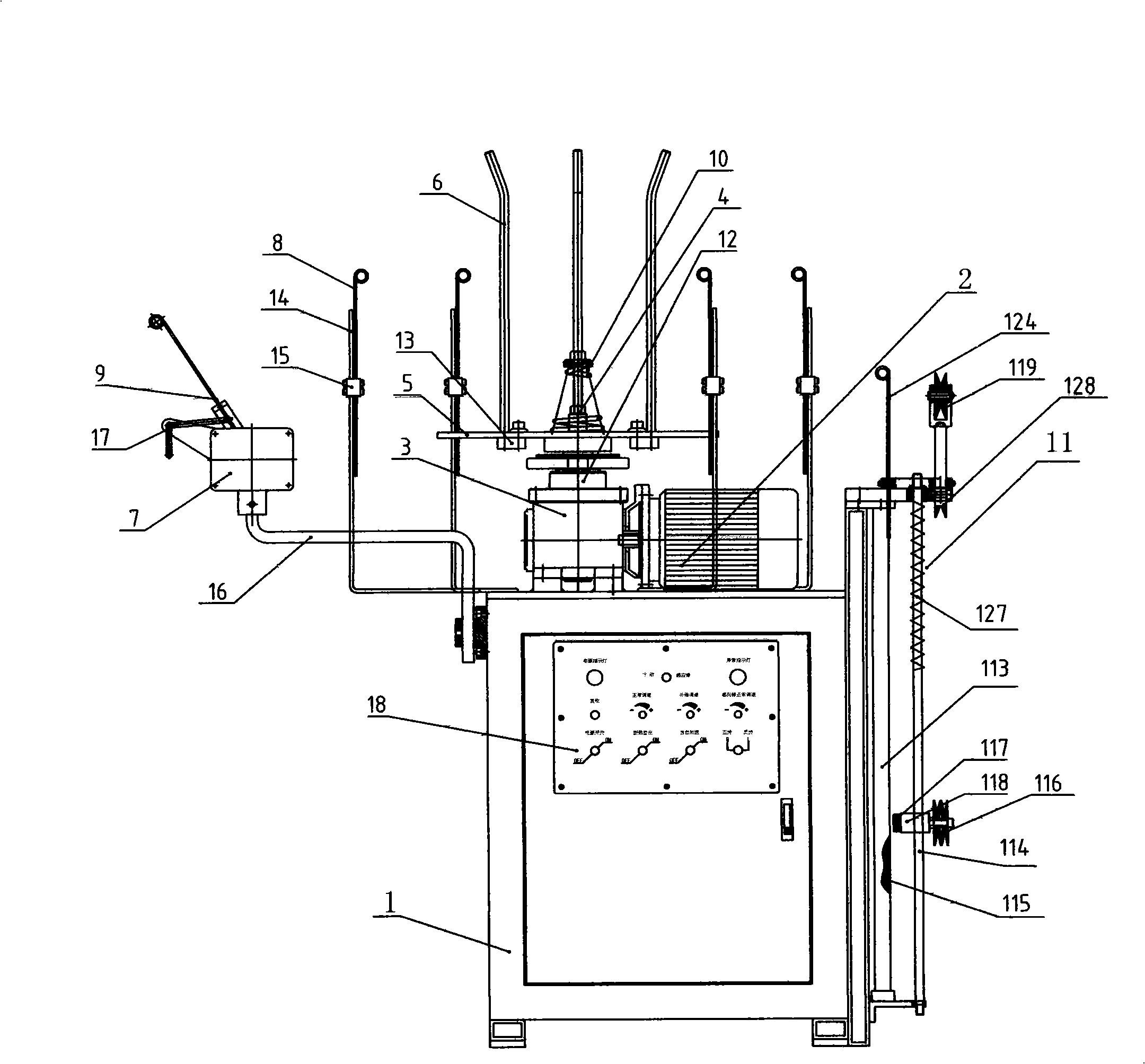

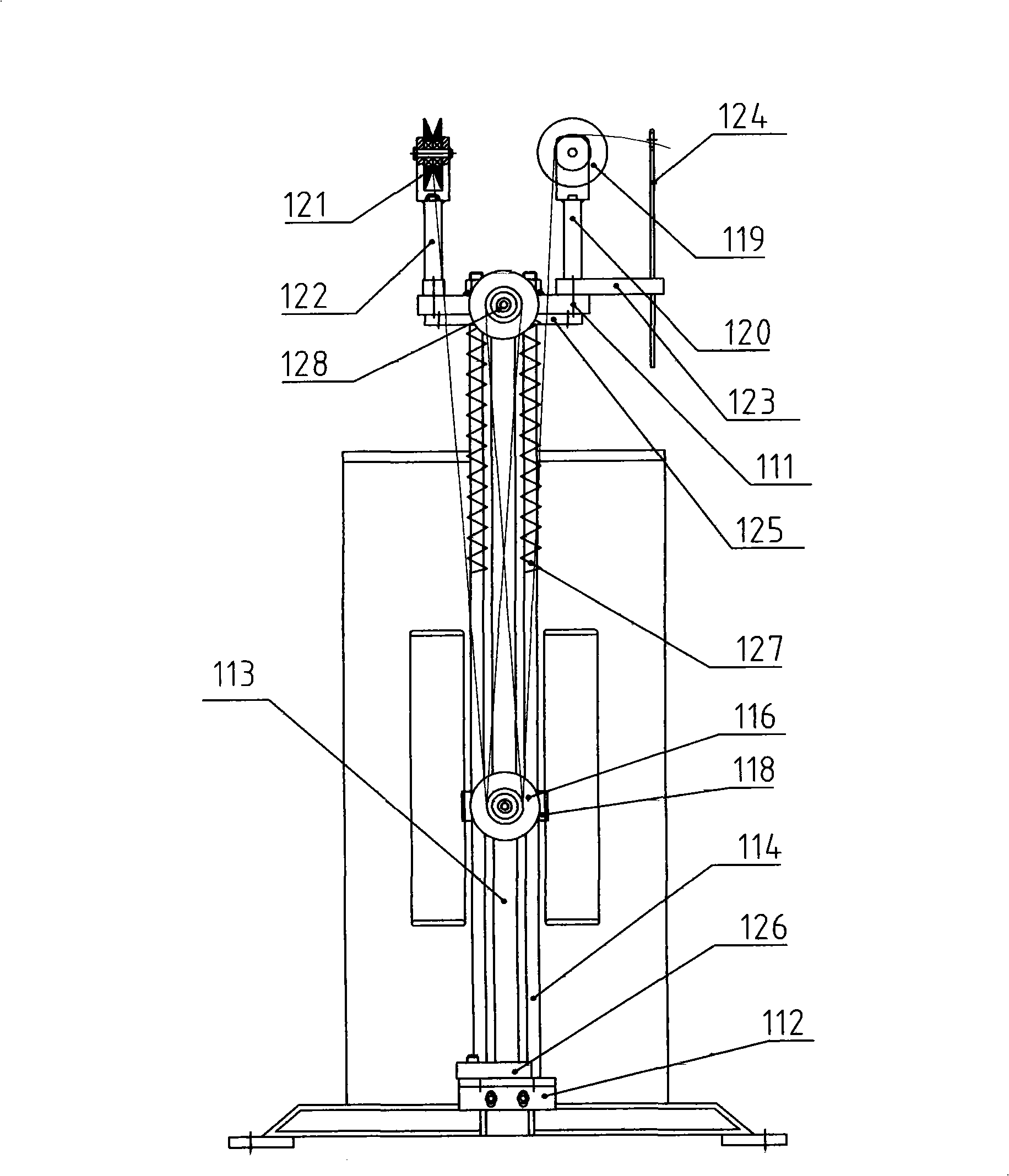

[0019] refer to figure 1 , figure 2 As shown, a dual-purpose automatic wire material feeder includes a box body 1, a motor 2 installed on the box body 1, and a control panel 18 installed on the front of the box body 1. The motor 2 is connected to the reducer 3, and the reducer 3 is meshed with a main shaft 4, on the main shaft 4 is installed a material tray 5 for placing wires, between the material tray 5 and the reducer 3 there is a flange plate 12, the flange plate 12 is mainly used to support the material tray 5 , on the tray 5 is installed a wire retaining rod 6, the retaining rod 6 with the main shaft 4 as the center along its circumferential direction at least three, specifically with the main shaft 4 as the center along its circumferential direction around the main shaft 4 Each is provided with a wire retaining rod 6, and the lower end of each wire retaining rod 6 is also provided with an adjustment fixing block 13. The effect of the wire retaining rod 6 is mainly to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com