Method and equipment of cultivated silkworm fresh cocoon quick-freezing for cocoon suffocation

A technology for fresh cocoons and silkworms, which is applied in cocoon cleaning/classification, silk fiber production, textiles and papermaking, etc. It can solve the problems of poor quality of cocoons, high requirements for equipment conditions, rancidity of pupa oil, etc., and shorten the production of pupa killing Cycle time, no risk of explosion and leakage, and the effect of improving the quality of raw silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

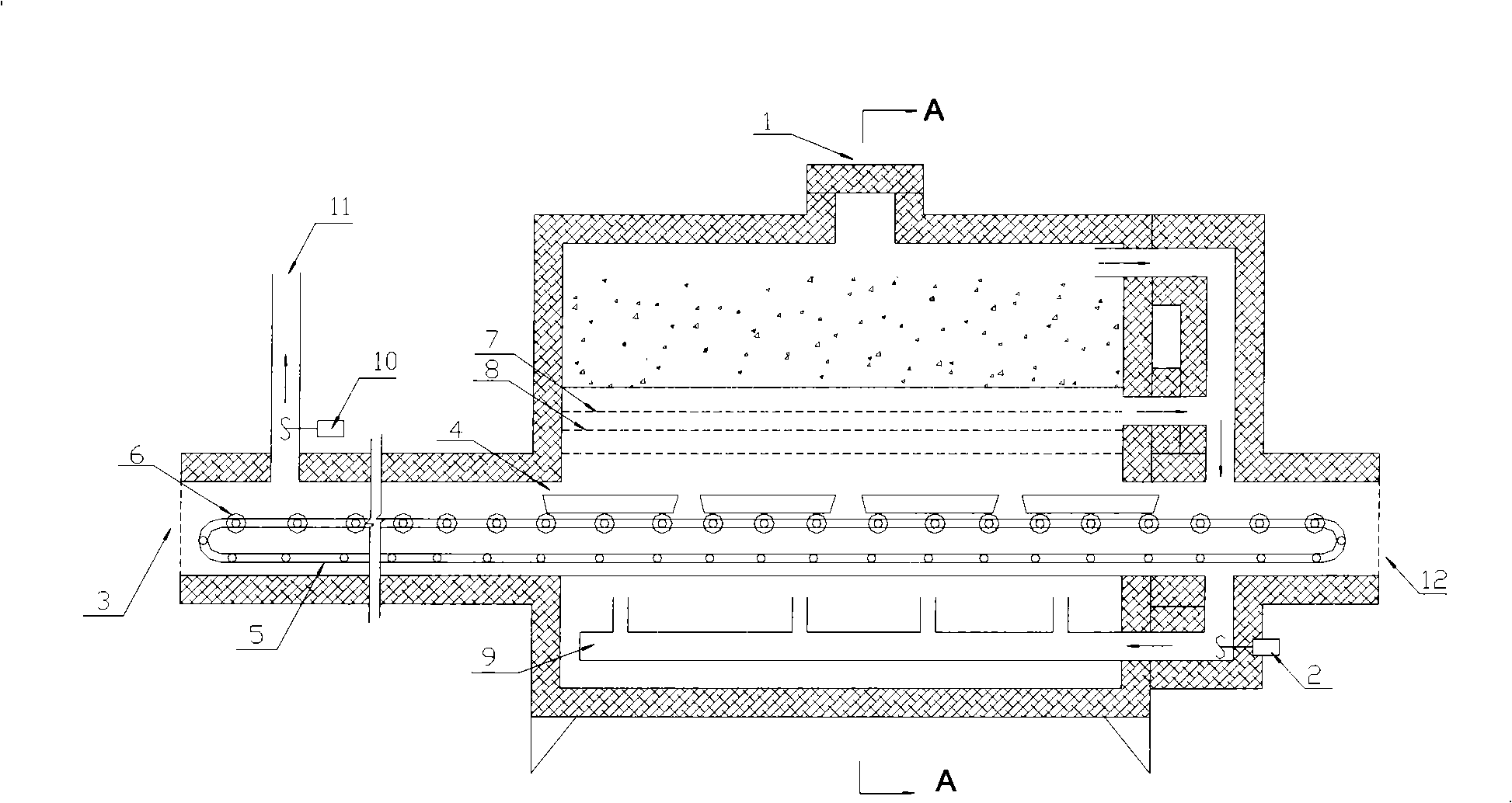

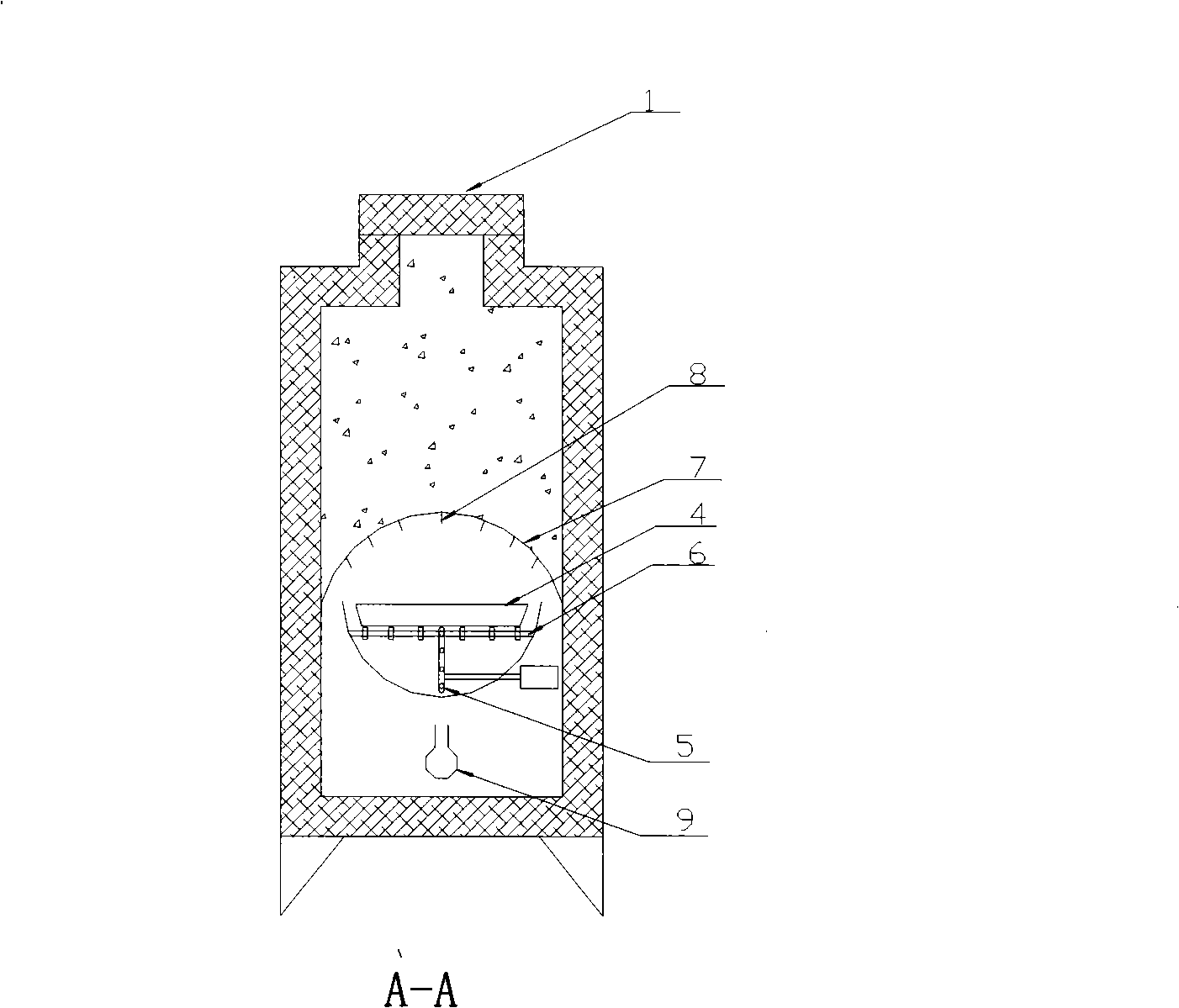

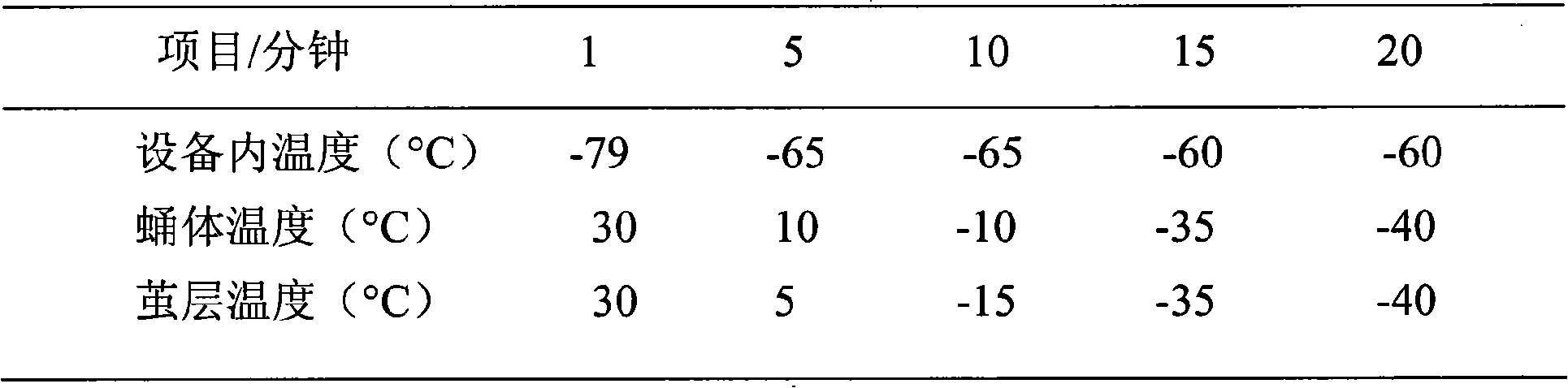

[0034] figure 1 and figure 2 shows the concrete structure of the present invention, by figure 1 and figure 2 It can be seen that the silkworm fresh cocoon quick-freezing and pupal killing equipment comprises an insulated box body, a circulating conveyor belt 5 arranged between the insulated box body inlet 3 and the outlet 12, and a cold source box body is set on the top of the insulated box body, and the insulated box body The upper part of the cold source box is provided with a feed port 1, and dry ice (-79° C.) is sent into the cold source box from the feed port 1; the bottom of the cold source box is provided with a heat exchange plate 7, so that The heat exchange plate 7 is located on the upper side of the circulating conveyor belt 5, and the lower surface of the heat exchange plate 7 is provided with cooling fins 8 to enhance the heat transfer effect; the lower side of the circulating conveyor belt 5 is provided with a cold air pipe 9, and the cold air pipe 9 The ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com