Slope vibrating separator

A vibrating and separating machine technology, applied in the field of silk reeling machinery, can solve the problem of inconspicuous separation effect, and achieve the effect of simple structure and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

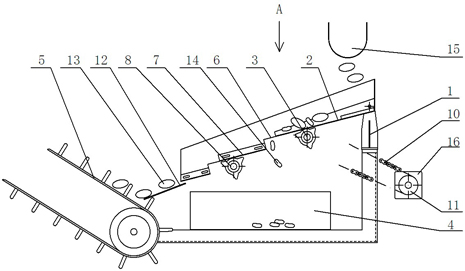

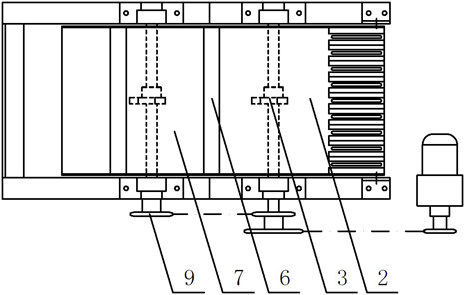

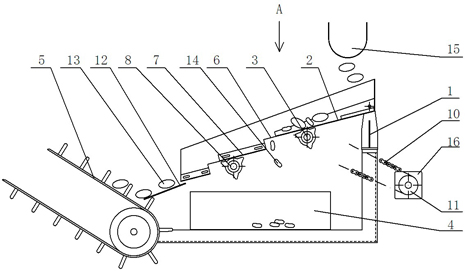

[0017] Embodiment: the slope vibration type separator of this example, as figure 1 , figure 2 , there is a frame 1, the frame is provided with a first vibrating plate 2 and a second vibrating plate 7 inclined downwards in a stepped distribution, the second vibrating plate is located at the lower end of the first vibrating plate, and the first vibrating plate 2 A gap 6 allowing the thin cocoon 14 to fall is left between the second vibrating plate 7 and the length of the gap is 20 mm. Below the first vibrating plate 2 and the second vibrating plate 7, there is a recovery box 4 that can hold thin skin cocoons, and the frame in front of the second vibrating plate is provided with a guide plate 12, and the outlet of the guide plate is provided with a conveying device 5. The frame below the first vibrating plate 2 and the second vibrating plate 7 is respectively provided with a first cam 3 and a second cam 8, and the first cam 3 and the second cam 8 are coaxially connected with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com