Silkworm cocoon sorting device

A sorting device and silkworm cocoon technology, applied in the textile field, can solve the problems of visual fatigue, large damage to the eyes of workers, low efficiency, etc., and achieve the effect of solving the labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

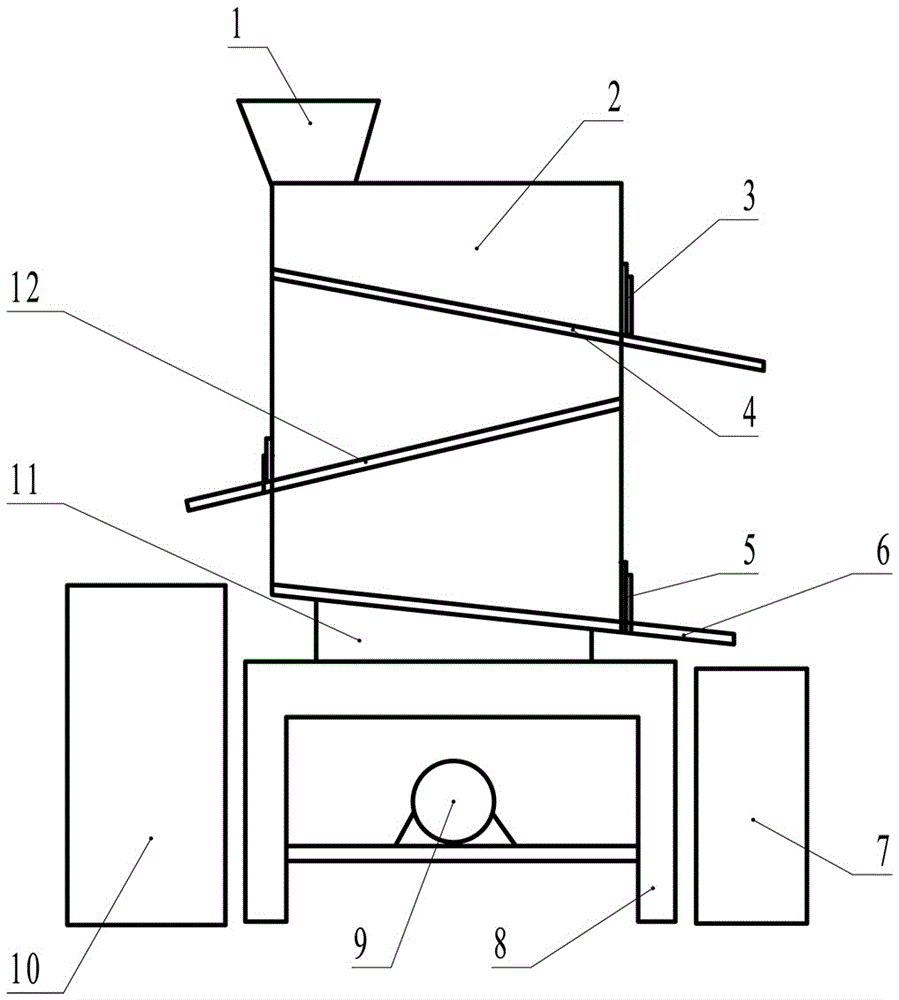

[0012] figure 1 The silkworm cocoon sorting device comprises a frame 8, the vibrator 7 with the vibrating box 2 above is installed on the frame 8, and the vibrator 7 is driven by a motor 9 located on the bottom frame of the frame 8; the vibrating box 2 top is provided with The feeding hopper 1 and the bottom plate 6 are arranged obliquely, and the large-hole sieve plate 4 and the small-hole sieve plate 12 are arranged obliquely from top to bottom in the vibrating box 2; The oversized cocoon discharge port 3 is provided with a qualified size cocoon discharge port at the lower part of the small hole sieve plate 12 and the vibration box 2, and the oversized cocoon discharge port 5 is provided at the bottom of the vibration box 2. An oversized cocoon discharge chute extending along the inclination direction of the large-hole sieve plate 4 is arranged at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com