Cocoon overturning, stripping and washing integrated machine with ditch groove

An all-in-one machine and cocoon peeling technology, which is applied in mechanical processing, cocoon cleaning/sorting, animal husbandry, etc., can solve the problems of waste cocoon raw material efficiency, cocoon thickness and thickness, easy to break cocoon, etc., and achieve high washing efficiency, High efficiency, not easy to break the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

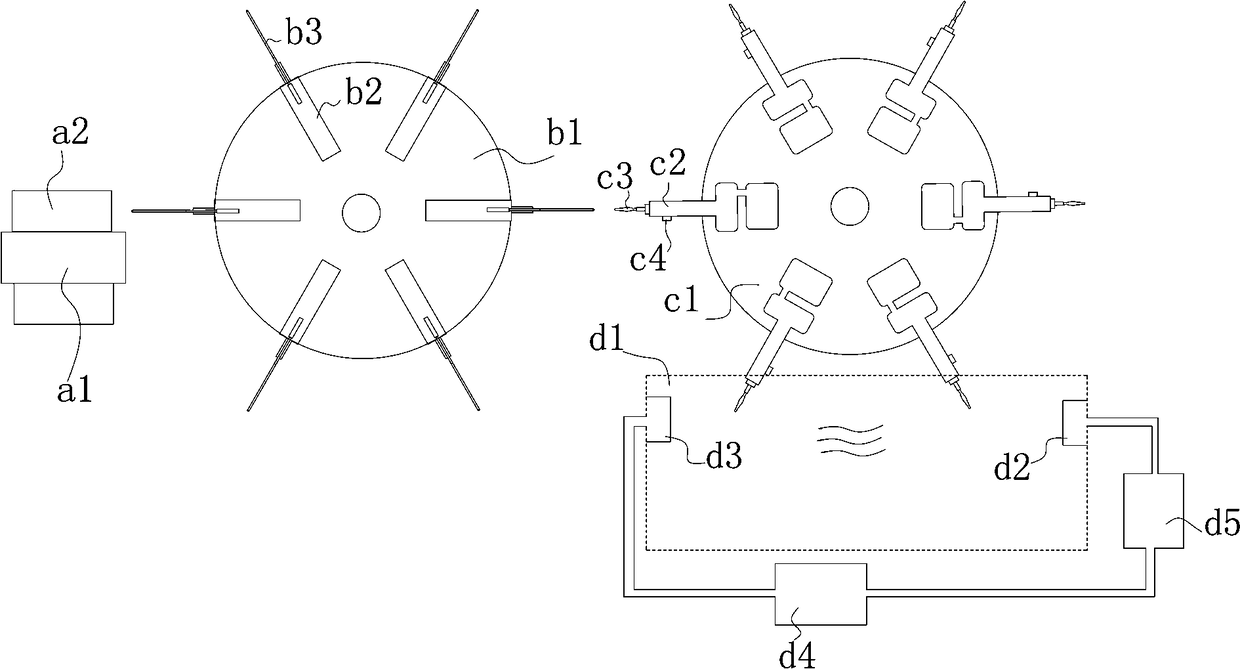

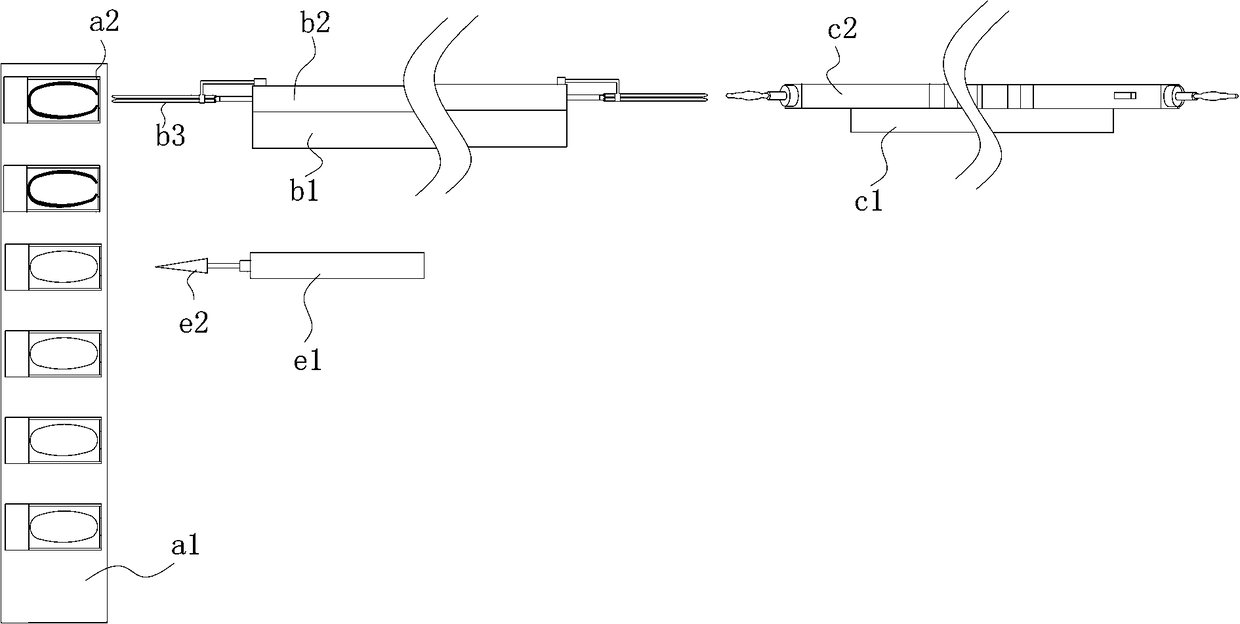

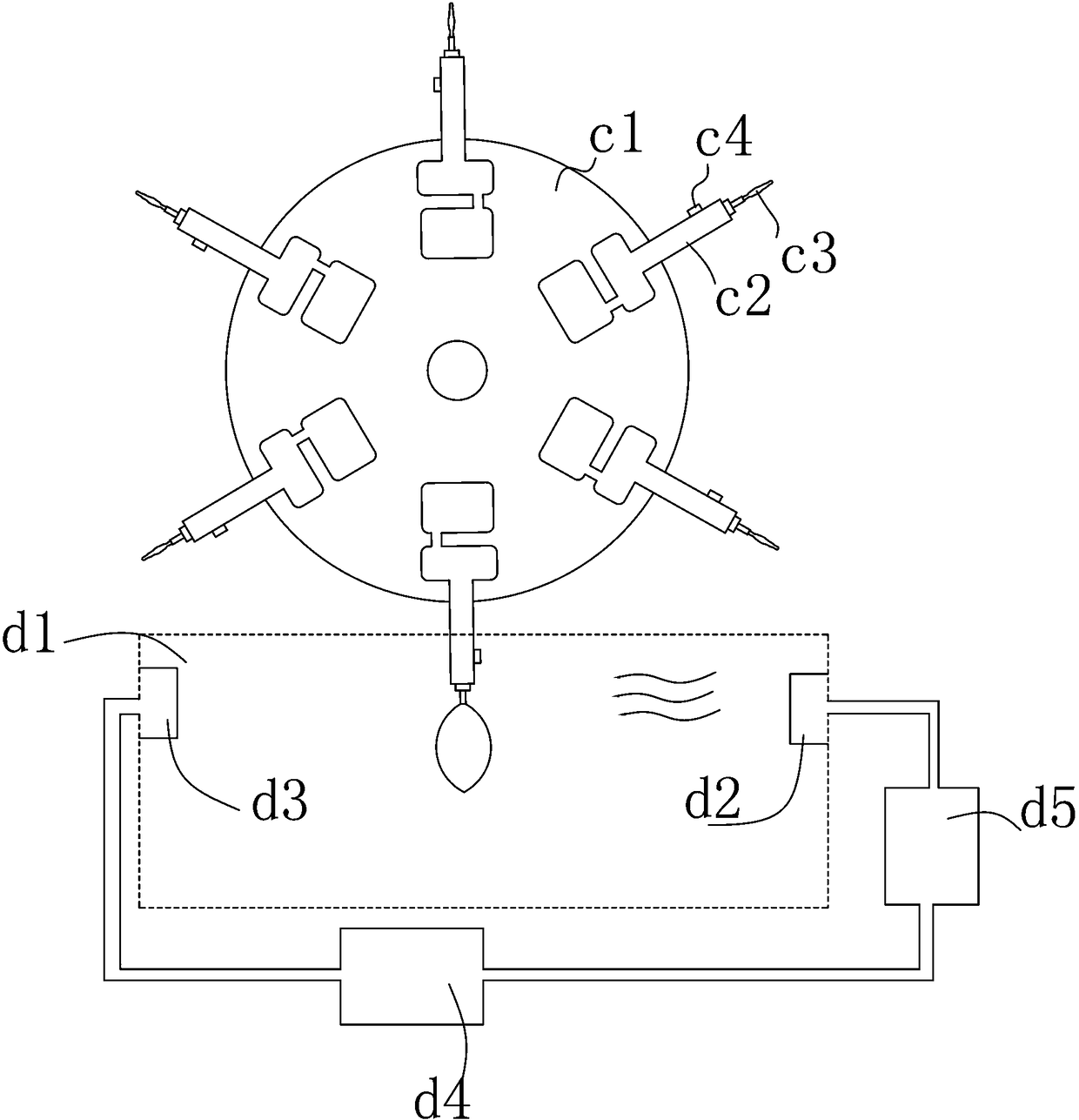

[0036] like Figure 1 to Figure 9 As shown, the integrated cocoon peeling and washing machine with a gully described in this embodiment includes a transmission device for transmitting cocoons, a punching device for punching cocoons, an intake device for taking out cocoons, An expansion device that cooperates with the intake device and expands the cocoon, and a water washing device that washes the cocoon.

[0037] The specific structure is: a transmission device, which is arranged parallel to the ground, and includes a transmission belt a1, the surface of the transmission belt a1 is provided with a cocoon box a2, the top of the cocoon box a2 has no cover, the bottom is fixedly connected to the transmission belt a1, and one side of the cocoon box a2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com