Silkworm cocoon separating method

A separation method and silkworm cocoon technology, which is applied in the field of separating bonded silkworm cocoons one by one, which can solve the problems that silkworm cocoons cannot be separated one by one in an orderly manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0022] The method for separating silkworm cocoons comprises using a silkworm cocoon separating device to separate silkworm cocoons one by one.

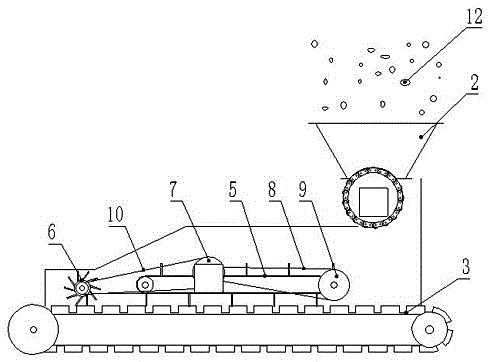

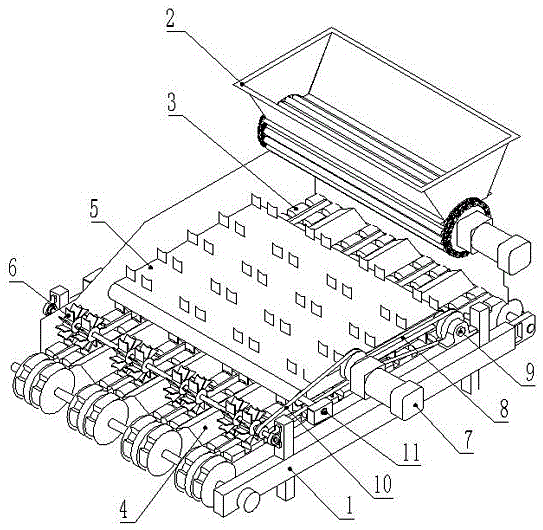

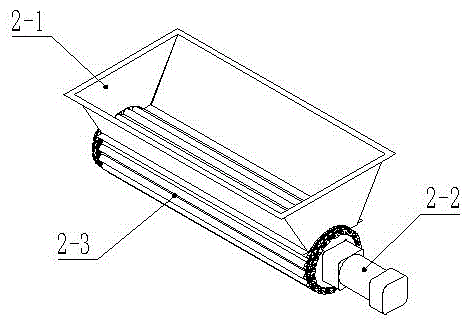

[0023] This silkworm cocoon separation device, such as Figure 2 to Figure 7 As shown, it includes eight conveyor belts 3 with positioning grooves 3-1 arranged at intervals on the bracket 1, and the bracket 1 is equipped with an inverted "V"-shaped intermediate frame 4 on the bracket 1 between two adjacent conveyor belts 3 , the slopes on both sides of the middle frame 4 have a guiding effect on the cocoons; the upper frame of the support 1 equipped with eight conveyor belts 3 is equipped with a separation scraping roller whose travel direction is opposite to the direction of the conveyor belt 3. The scraper roller shaft 9 and the driven scraper roller shaft 11 are surrounded by a separation scraper belt 5 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com