Rolling water-spray cocoon cooking machine

A technology of a cocoon cooking machine and a cooking chamber, which is applied in the field of textile machinery, can solve problems such as widening temperature difference, poor cleanliness, failure, etc., and achieve the effects of reducing silk failures, improving cleanliness, and evenly spitting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

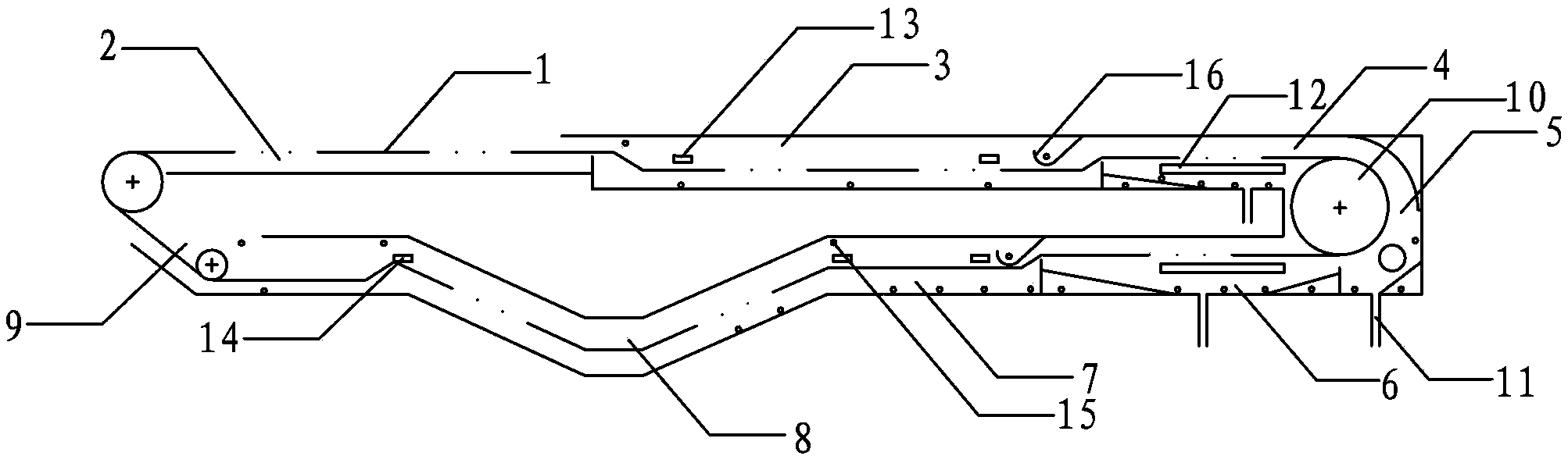

[0028] Such as figure 1 As shown, a tumbling cocoon spitting machine includes a conveyor belt 1 for conveying cocoon cages, and a casing that wraps part of the conveyor belt 1. The casing has an internal space that can accommodate objects. The casing is divided into Cocoon adding part 2, preheating part 3, cooking part, adjusting part, cocoon-out part 9, the cooking part is located at one end of the conveyor belt 1, the cooking chamber wraps the roller 10 at the end of the conveyor belt 1, and the cooking chamber is divided according to the structure of the end of the conveyor belt It is an upper cooking chamber 4, a middle cooking chamber 5 and a lower cooking chamber 6, and each cooking chamber is provided with a steam port.

[0029] Upper cooking chamber 4 is equipped with 4 empty pipes and 1 blind pipe, middle cooking chamber 5 is equipped with 3 empty pipes, and lower cooking chamber 6 is equipped with 3 empty pipes and 2 blind pipes.

[0030] The bottoms of the upper co...

Embodiment 2

[0043] Such as figure 1 As shown, a tumbling cocoon spitting machine includes a conveyor belt 1 for conveying cocoon cages, and a casing that wraps part of the conveyor belt 1. The casing has an internal space that can accommodate objects. The casing is divided into Cocoon adding part 2, preheating part 3, cooking part, adjusting part, cocoon-out part 9, the cooking part is located at one end of the conveyor belt 1, the cooking chamber wraps the roller 10 at the end of the conveyor belt 1, and the cooking chamber is divided according to the structure of the end of the conveyor belt It is an upper cooking chamber 4, a middle cooking chamber 5 and a lower cooking chamber 6, and each cooking chamber is provided with a steam port.

[0044] Upper cooking chamber 4 is equipped with 4 empty pipes and 1 blind pipe, middle cooking chamber 5 is equipped with 3 empty pipes, and lower cooking chamber 6 is equipped with 3 empty pipes and 2 blind pipes.

[0045] The bottoms of the upper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com