Low-gelatinization-degree staple food regenerated rice and processing technology thereof

A technology with low degree of gelatinization and processing technology, which is applied in food preparation, food drying, food science, etc., can solve the problems of high elasticity and poor taste, and achieve the effect of good taste, low bursting rate and reduced degree of gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

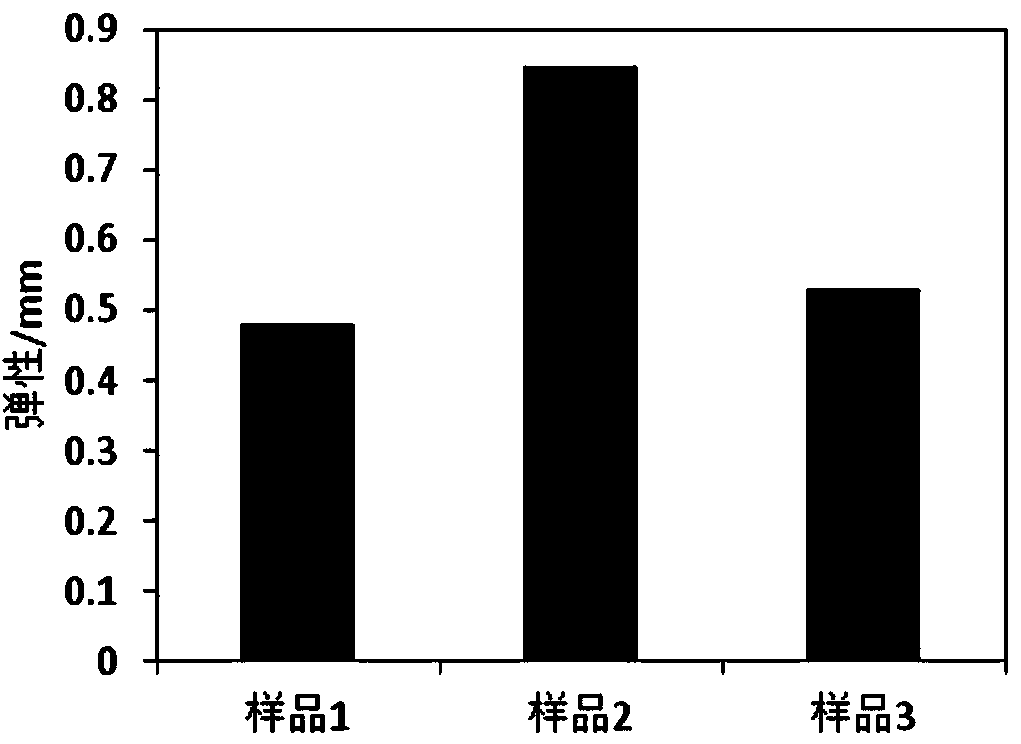

Embodiment 1

[0024] Crush the raw materials separately, pass through an 80-mesh sieve, and set aside. Wherein each raw material is counted as respectively by weight: Broken rice flour 20, potato flour 20, yam powder 1, lotus root powder 1, oat flour 10, add mixer, add water conditioning and tempering while stirring, adjust to final moisture content 25%, fast Stir for 5 minutes; the moisture-adjusted material is sent to a twin-screw extruder for granulation. The extruder screw is traditionally divided into three sections, namely: feeding section (hereinafter referred to as zone Ⅰ), compression section (hereinafter referred to as zone Ⅱ) and metering section (hereinafter referred to as zone Ⅲ). The temperature in Zone II of the machine is controlled at 92°C, the temperature in Zones I and III is controlled at 60°C, and the screw speed is controlled at 240 rpm. The extruded and melted material is shaped by a die and cut into the shape of rice grains by a cutter. The rice grain-shaped materi...

Embodiment 2

[0026] Crush the raw materials separately, pass through an 80-mesh sieve, and set aside. Wherein each raw material is counted by weight part respectively: Broken rice powder 20, potato powder 20, yam powder 1, lotus root powder 1, put into mixer, add water while stirring, adjust to final moisture content 25%, stir rapidly for 5 minutes; The material with adjusted moisture is sent to the twin-screw extruder for granulation. The temperature in Zone II of the extruder is controlled at 92°C, the temperature in Zones I and III is controlled at 60°C, and the screw speed is controlled at 240 rpm. The extruded and melted material is shaped by a die and cut into the shape of rice grains by a cutter. The rice grain-shaped material coming out of the extruder directly falls into the wind conveying device, and the sticky rice grains are initially separated through surface hardening and wind vibration during conveying. Then send it to a three-stage gradient hot air dryer for drying. The a...

Embodiment 3

[0028] Crush the raw materials separately, pass through a 100-mesh sieve, and set aside. Wherein each raw material is respectively by weight: corn flour 30, potato flour 20, yam powder 1, lotus root powder 1, tartary buckwheat powder 5, highland barley powder 5, add mixer, add water while stirring, adjust to final moisture content 26 %, stirring rapidly for 5 minutes; the material with adjusted moisture is sent to the twin-screw extruder for granulation, the temperature in zone II of the extruder is controlled at 90°C, the temperature in zone I and III is controlled at 60°C, and the screw speed is controlled at 240 rpm . The staple food regenerated rice coming out of the extruder directly falls into the wind conveying device, and the sticky rice grains are initially separated through surface hardening and wind vibration during conveying. Then send it to a three-stage gradient hot air dryer for drying. The air temperature in the front section is 35°C, and the drying time is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com