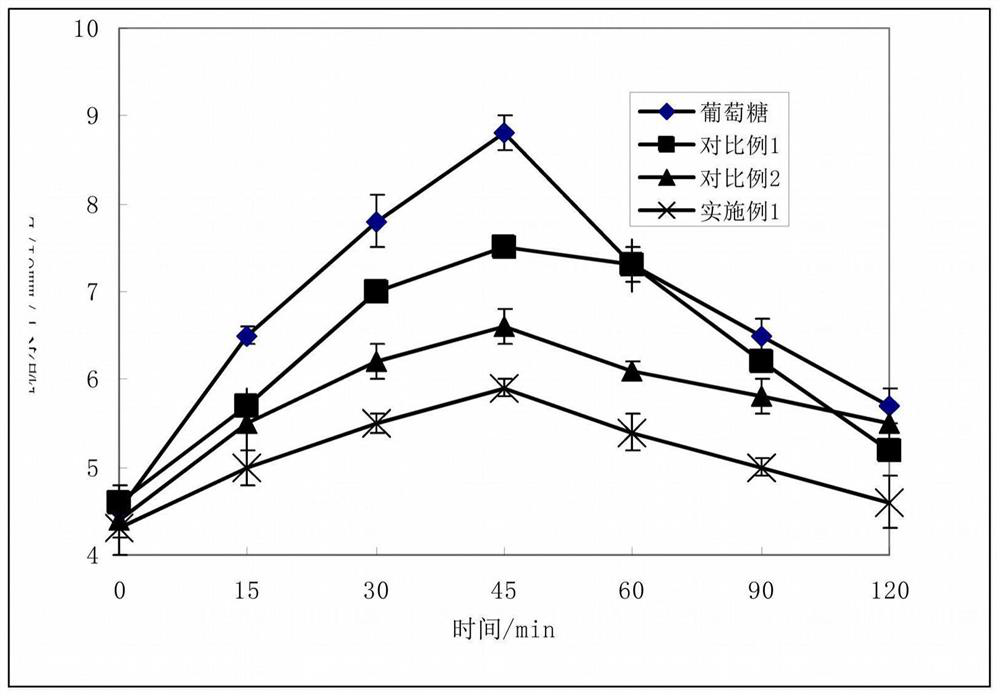

Low-GI konjak noodles and preparation method thereof

A konjac and noodle technology, applied in the functions of food ingredients, food ingredients as gelling agents, climate change adaptation, etc., can solve the problems of high and unsuitable noodles, reduce the glycemic index, hinder digestion, and reduce the degree of gelatinization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a kind of preparation method of low GI konjac noodles, comprising the following steps:

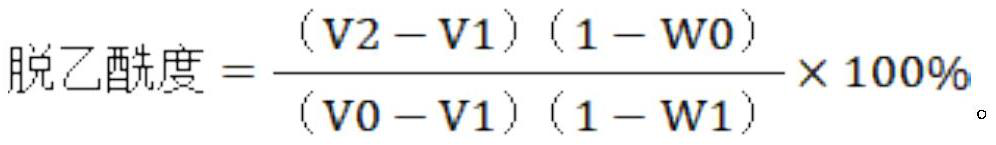

[0029] S1. Preparation of deacetylated konjac powder: adding konjac powder to an ethanol solution with a volume concentration of 25-50%, stirring and reacting at 20-70°C for 5-10min, adding lye and continuing at 20-70°C The reaction is stirred for 10-20 min to obtain crude DKGM; the crude DKGM is washed and dried to obtain deacetylated konjac powder.

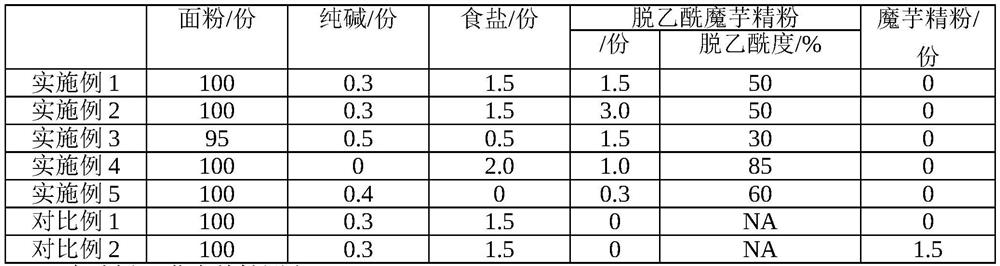

[0030] S2, kneading noodles: dissolve soda ash, table salt and the deacetylated konjac powder obtained in step S1 into water, after mixing and swelling, fully mix with flour to obtain loose granular dough; wherein, the quality of water is 25 to 35%, the water temperature is 20 to 30°C, and the kneading time is 15 to 30 minutes.

[0031] S3, ripening, rolling: the granular dough obtained in step S2 is ripened at room temperature for 10 to 15 minutes, and after ripening, put into a rolling mill for r...

Embodiment 1

[0038] The present embodiment provides a kind of low GI konjac noodles, and its preparation method comprises the following steps:

[0039] S1, prepare deacetylated konjac powder: 6g konjac powder is loaded into a beaker with stirring, and 100 mL of ethanol solution with a volume concentration of 40% is added to the beaker, and the control reaction temperature is 50 ° C, and the stirring reaction is 5min, and the stirring speed is 150rpm. Then, 10 mL of NaOH solution with a concentration of 0.2 mol / mL was added to the beaker, and the reaction temperature was controlled to be 50° C. under microwave heating conditions, and the reaction was continued to be stirred for 10 min at a stirring speed of 150 rpm to obtain a crude DKGM product. After the reaction, 30%, 60% and 90% ethanol solutions were used to carry out gradient washing on the DKGM crude product, respectively, to wash off excess alkali, and then use absolute ethanol to dehydrate the DKGM crude product to obtain a DKGM se...

Embodiment 2

[0048] The difference between the present embodiment and Example 1 is only: in the step S2 in the present embodiment, the consumption of the deacetylated konjac flour is different from the consumption of the deacetylated konjac flour in the step S2 in the embodiment 1, and the rest are the same as the Example 1 is the same. Specifically, in step S2 in this embodiment, the amount of deacetylated konjac powder is 3.0 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com