Delayed-boosting electric pressure cooker control method and delayed-boosting electric pressure cooker

A control method and technology of electric pressure cooker, which can be applied to pressure cookers, cooking utensils, household utensils, etc., and can solve problems such as poor cooking effect of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A control method for a time-delay boost electric pressure cooker, characterized in that: comprising:

[0028] (1) Temperature setting control steps: set the delayed start temperature and safe start temperature, wherein the delayed start temperature is lower than the safe start temperature;

[0029] (2) Delay time control step: set the delay start temperature control unit, detect the temperature of the temperature sensor, and after reaching the delay start temperature, the delay start temperature control unit starts to count the delay time, and sends a delay time when the delay time is reached. end signal;

[0030] (3) Delay boost control step: After receiving the delay end signal from the delay start temperature control unit, the controller controls to close the air outlet channel of the electric pressure cooker.

[0031] In the above temperature setting control step, the delayed start temperature is the temperature measured by the temperature sensor after the rice boi...

Embodiment 2

[0035] A method for controlling a time-delay boost electric pressure cooker, comprising:

[0036] (1) Steps for setting the boiling time of commonly used rice: set the boiling time of commonly used rice according to the maximum capacity of the pot;

[0037] (2) Delay time setting step: set the delay time so that the delay time is greater than the usual rice boiling time;

[0038] (3) Delay time control step: Once the pressure cooker is powered on, the controller starts to count the delay time, and sends a delay end signal when the delay time is reached. After receiving the delay end signal from the delay start temperature control unit , controlled by the controller to close the air outlet channel of the electric pressure cooker.

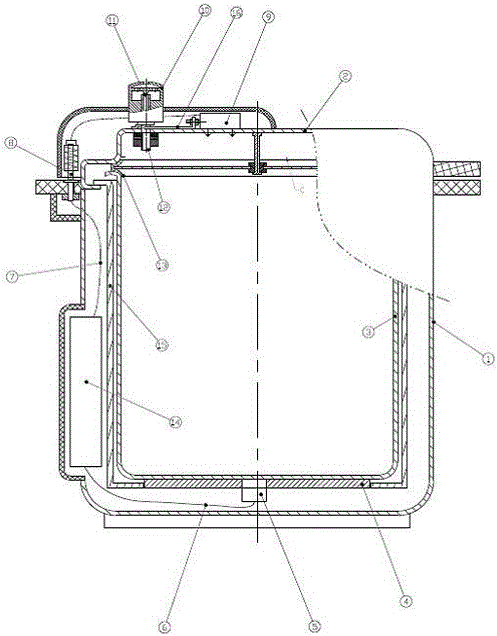

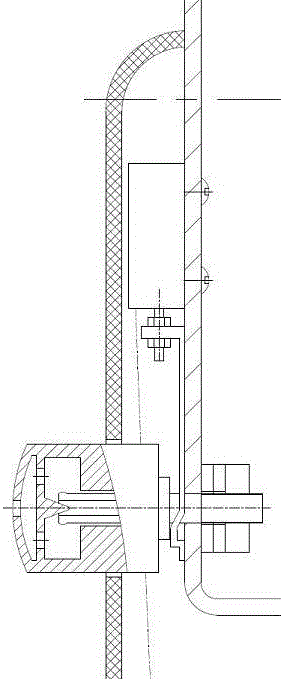

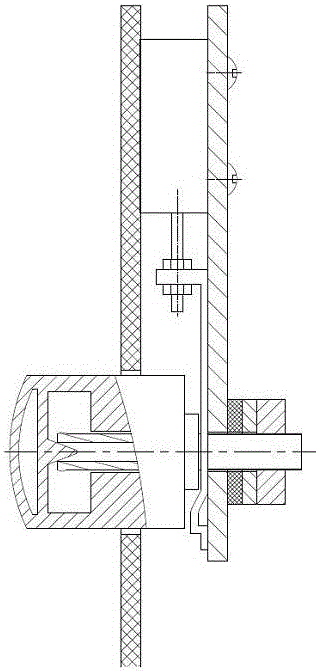

[0039] The delay boost electric pressure cooker adopting the above two control methods is as follows: figure 1 , 2 , 3, including pot body (1), pot cover (2), pot liner (3), heating plate (4), temperature sensor (5), temperature sensing line (6), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com