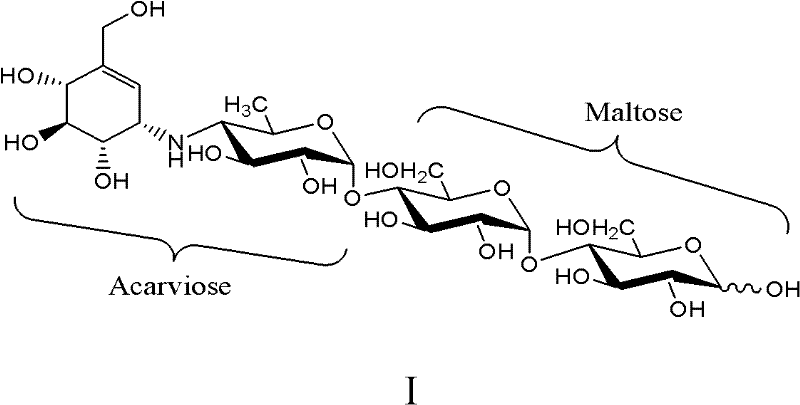

Method for synthesizing acarbose through microbial fermentation

A technology for microbial fermentation and acarbose, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of low acarbose production, achieve the promotion of biomass formation, increase production, The effect of promoting the consumption of carbohydrate substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of medium:

[0041] Prepare solid plate culture medium, its medium composition is as follows: sucrose 25g / L, peptone 2g / L, tyrosine 1g / L, K 2 HPO 4 0.1g / L, KCl 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, FeSO 4 ·7H 2 O 0.1g / L, agar 20g / L, prepared with tap water, initial pH 7.0. Sterilize at 121°C for 30 minutes.

[0042] Prepare seed culture medium, its culture medium composition is as follows: cornstarch 15g / L, soybean cake powder 40g / L, glycerol 20g / L, K 2 HPO 4 0.1g / L, CaCO 3 2g / L, prepared with tap water, initial pH 7.0. Sterilize at 121°C for 30 minutes.

[0043] Prepare the fermentation medium, the composition of which is as follows: maltose 80g / L, glucose 20g / L, soybean cake powder 10g / L, corn steep liquor 5g / L, CaCO 3 6g / L, FeCl 3 0.1g / L, CaCl 2 2g / L, prepared with tap water, pH 7.0. Sterilize at 121°C for 30min.

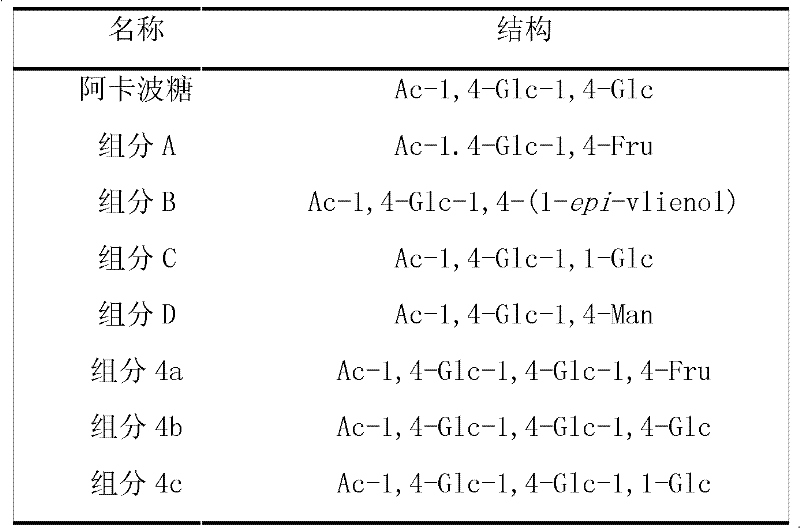

[0044] (2) Preparation of SAM aqueous solution:

[0045] SAM solutions with SAM concentrations of 0.25mM, 0.5mM, 1mM, 2mM, 4mM, 7mM ...

Embodiment 2

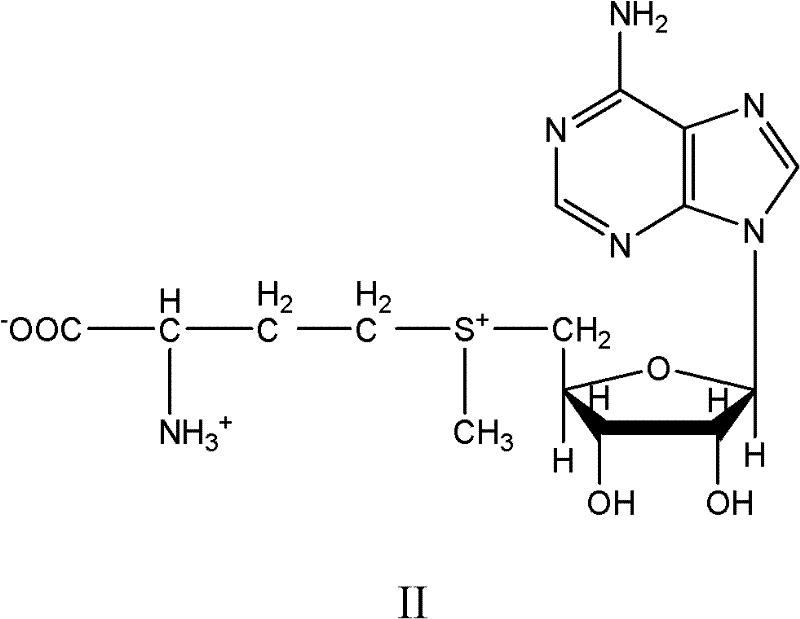

[0053] According to the results of Example 1, the concentration of SAM in the fermented liquid was selected to be 20 μM and 100 μM respectively, and according to the culture method of Example 1, the impact of adding SAM on the acarbose output in the fermented liquid was investigated at different times when the fermentation was carried out, At the same time, the shake flask fermentation without adding SAM solution but adding an equal volume of sterile water was used as a control, and the concentration of acarbose in the fermentation broth was detected by HPLC, and the results are shown in Table 3.

[0054] Table 3: Effect of SAM addition time on acarbose yield

[0055]

[0056] It can be seen from the above table that adding an appropriate amount of SAM in the early stage of fermentation, that is, from 0h to 60h, can significantly increase the fermentation yield of acarbose, especially adding an appropriate amount of SAM between 0h and 36h of fermentation can significantly in...

Embodiment 3

[0058] According to the results of Examples 1 and 2, SAM was added to the fermentation broth at the 12th hour of fermentation, and the SAM concentration in the fermentation broth was selected to be 10 μM and 20 μM respectively. According to the cultivation method of Example 1, the effect of adding SAM on Aka The influence of wave sugar fermentation process and yield, fermentation carries out 168 hours altogether, meanwhile, with the shaking flask fermentation that does not add SAM solution, but adds equal volume sterile water as contrast, HPLC detects the concentration of acarbose in the fermented liquid, the result As shown in Table 4.

[0059] Table 4: Effects of adding / not adding SAM on the process and yield of acarbose formed by fermentation

[0060]

[0061] It can be seen from the above table that adding an appropriate amount of SAM to the culture medium at the 12th hour of fermentation can promote the fermentation yield of acarbose in the whole fermentation process. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com