Material supplementing method for reducing viscosity of gentamicin C1a fermentation liquid

A technology of gentamicin and fermentation liquid, which is applied in the field of fermentation engineering, can solve the problems of not being able to relieve glucose repression, and achieve the effects of improving the mixing transfer effect, simple and effective process, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

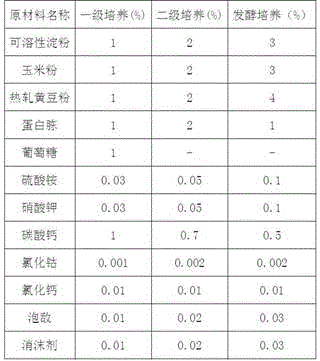

[0026] Primary seed culture: at 2m 3 The seed tanks were fed according to the composition ratio in Table 1. First sterilize the primary seed medium, cool it down, use sterile air to keep the pressure, and then inoculate the 1L cultured shake flask seed solution into the primary seed tank for cultivation on the differential pressure gauge, and the tank pressure during the process is 0.04~0.08Mpa ; tank temperature 33~38 ℃; air flow 0.7:1; rotation speed 150rpm; pH value 6.0-8.0; culture time 45h. The cultured primary seed solution has a cell concentration of 21%, a pH value of 7.0, and no bacterial contamination.

[0027] Secondary seed culture: at 15m 3 The medium was fed according to the ratio of ingredients in Table 1. First, sterilize the secondary seed medium, cool it, and use sterile air to keep the pressure, and then transfer all the cultivated primary seed liquid into the secondary seed tube for cultivation. During the process, the tank pressure is 0.04~0.08Mpa; the...

Embodiment 2

[0038] The primary seed cultivation, secondary seed cultivation and fermentation cultivation process are the same as in Example 1. In the feeding control stage, the carbon sources used for carbon supplementation are: 40% glucose, 5% maltose and 2.0% D-xylose.

[0039] The nitrogen sources used for nitrogen supplementation were: 15% urea, 20% ammonium sulfate, 1.5% corn steep liquor and 1% yeast extract powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com