Process for producing pravastatin on large scale

A pravastatin and process technology, applied in the field of drug preparation, can solve the problems of operating temperature and time affecting product yield and quality, restricting the large-scale production and application of pravastatin, microorganisms that cannot tolerate addition, etc., to achieve improved drug resistance performance and transformation ability, improve production efficiency and output, and realize the effect of resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

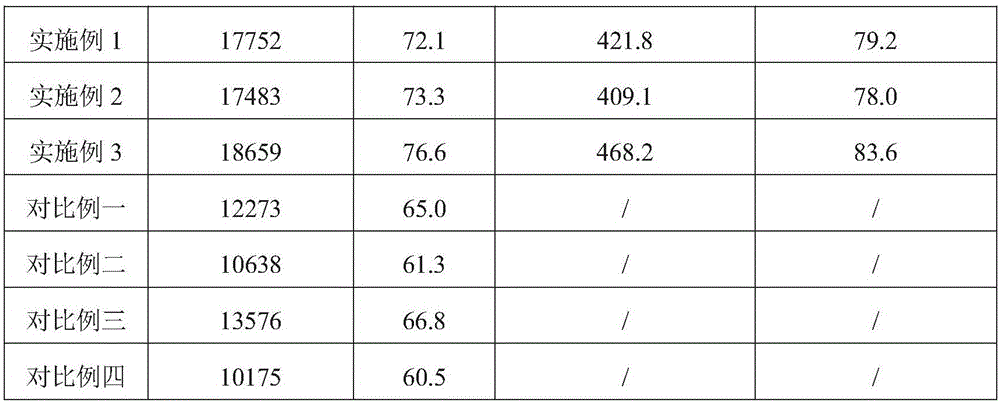

Embodiment 1

[0041] Embodiment 1, the technique of large-scale production of pravastatin of the present invention

[0042] Specific steps are as follows:

[0043] S1. Fermentation:

[0044] A1. Seed culture: Use a 5L shaker flask to prepare 3L seed medium. The formulation of the seed medium is as follows: glucose 24g / L, yeast extract 22g / L, soybean peptone 6g / L, K 2 HPO 4 ·3H 2 O2g / L, MgSO 4 ·7H 2 00.5g / L and defoamer 1.0g / L, adjust pH7.0; Inoculate Actinomyces madurai in the seed culture medium, cultivate 48 hours at 33~35 DEG C on a shaker after the inoculation, obtain seed liquid;

[0045] A2. Fermentation culture: Prepare 30L fermentation medium with a 50L automatic fermentation tank. The formula of the fermentation medium is as follows: glucose 56g / L, yeast extract 20g / L, soybean peptone 6g / L, K 2 HPO 4 ·3H 2 O1g / L, MgSO 4 ·7H 2 O1g / L, (NH 4 ) 2 SO 4 1g / L, plant extract 4ml / L and defoamer 1.0g / L, adjust the pH to 7.0; inoculate 2.5L of the seed solution obtained from A1 i...

Embodiment 2

[0059] Embodiment 2, the technique of large-scale production of pravastatin of the present invention

[0060] Specific steps are as follows:

[0061] S1. Fermentation:

[0062] A1. Seed culture: Use a 5L shaker flask to prepare 3L seed medium. The formulation of the seed medium is as follows: glucose 26g / L, yeast extract 20g / L, soybean peptone 8g / L, K 2 HPO 4 ·3H 2 O1g / L, MgSO 4 ·7H 2 O1g / L and defoamer 1.0g / L, adjust pH7.2; Inoculate Actinomyces madurai in the seed culture medium, after the inoculation, cultivate at 33~35 DEG C on a shaker for 72 hours to obtain the seed liquid;

[0063] A2. Fermentation culture: Prepare 30L fermentation medium with a 50L automatic fermentation tank. The formula of the fermentation medium is as follows: glucose 60g / L, yeast extract 24g / L, soybean peptone 8g / L, K 2 HPO 4 ·3H 2 O2g / L, MgSO 4 ·7H 2 O0.5g / L, (NH 4 ) 2 SO 4 2g / L, plant extract 8ml / L and defoamer 1.0g / L, adjust the pH to 7.2; inoculate 2.5L of the seed solution obtaine...

Embodiment 3

[0077] Embodiment 3, the technique of large-scale production of pravastatin of the present invention

[0078] Specific steps are as follows:

[0079] S1. Fermentation:

[0080] A1. Seed culture: Use a 5L shaker flask to prepare 3L seed medium. The formula of the seed medium is as follows: glucose 25g / L, yeast extract 20g / L, soybean peptone 7g / L, K 2 HPO 4 ·3H 2 O1g / L, MgSO 4 ·7H 2 00.5g / L and defoamer 1.0g / L, adjust pH7.0; Inoculate Actinomyces madurai in the seed culture medium, cultivate 72 hours in shaking table at 33~35 ℃ after the inoculation, obtain seed liquid;

[0081] A2. Fermentation culture: prepare 30L fermentation medium with 50L automatic fermentation tank, the formula of fermentation medium is as follows: glucose 58g / L, yeast extract 22g / L, soybean peptone 7g / L, K 2 HPO 4 ·3H 2 O1g / L, MgSO 4 ·7H 2 O0.5g / L, (NH 4 ) 2 SO 4 1g / L, plant extract 6ml / L and antifoaming agent 1.0g / L, adjust the pH to 7.0; inoculate 2.5L of the seed solution obtained from A1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com