Method for producing DHA (Docosahexaenoic Acid) by fermenting schizochytrium limacinum via mixed carbon source

A technology of Schizochytrium and mixed carbon source, applied in the field of microbial application, can solve the problems of low efficiency, high production cost of algae oil DHA, high equipment investment and maintenance costs, etc., so as to improve the fermentation level and promote the development of industrialization. , the effect of improving substrate utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

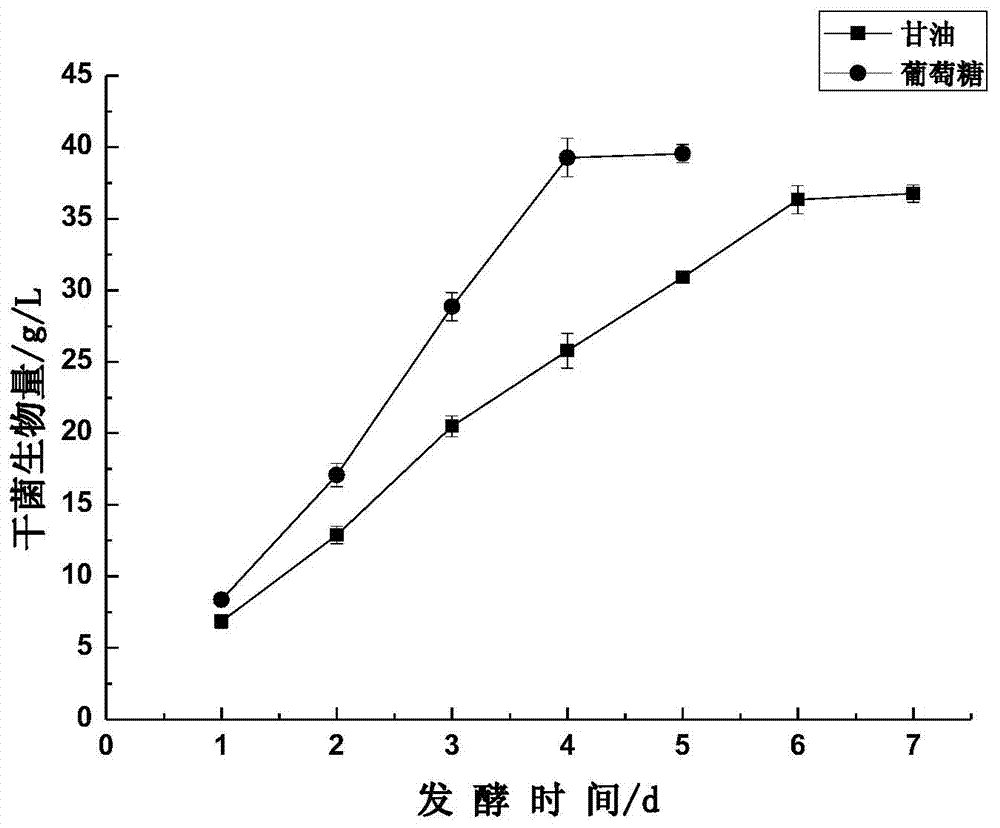

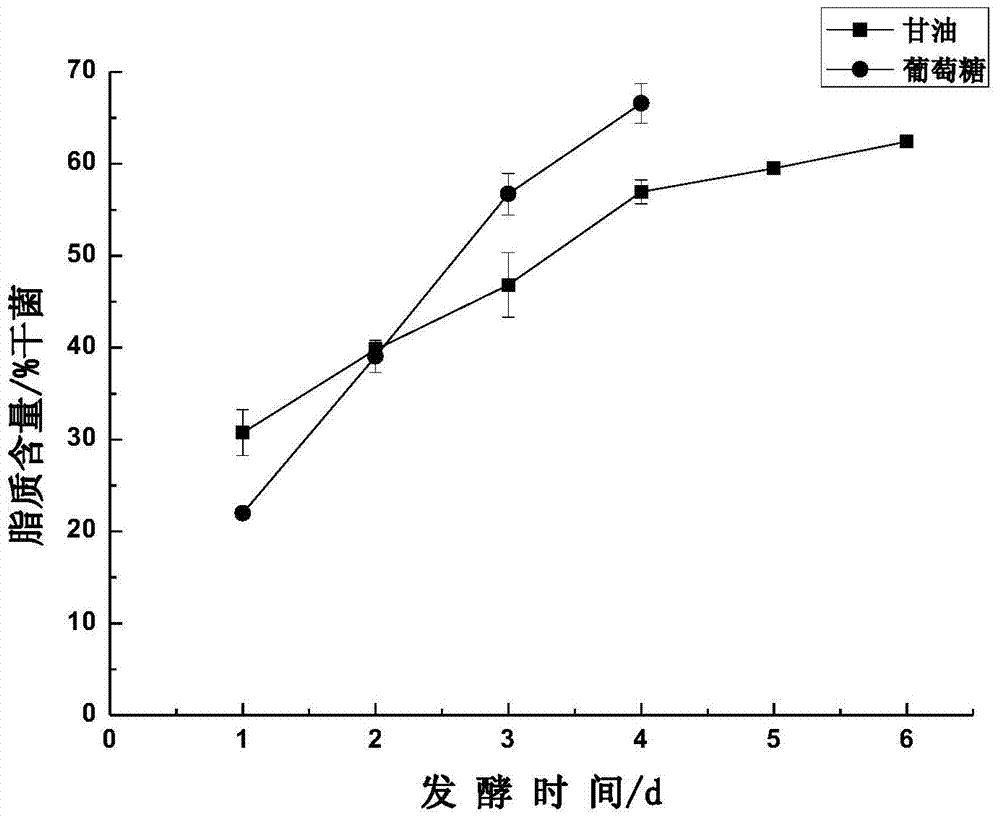

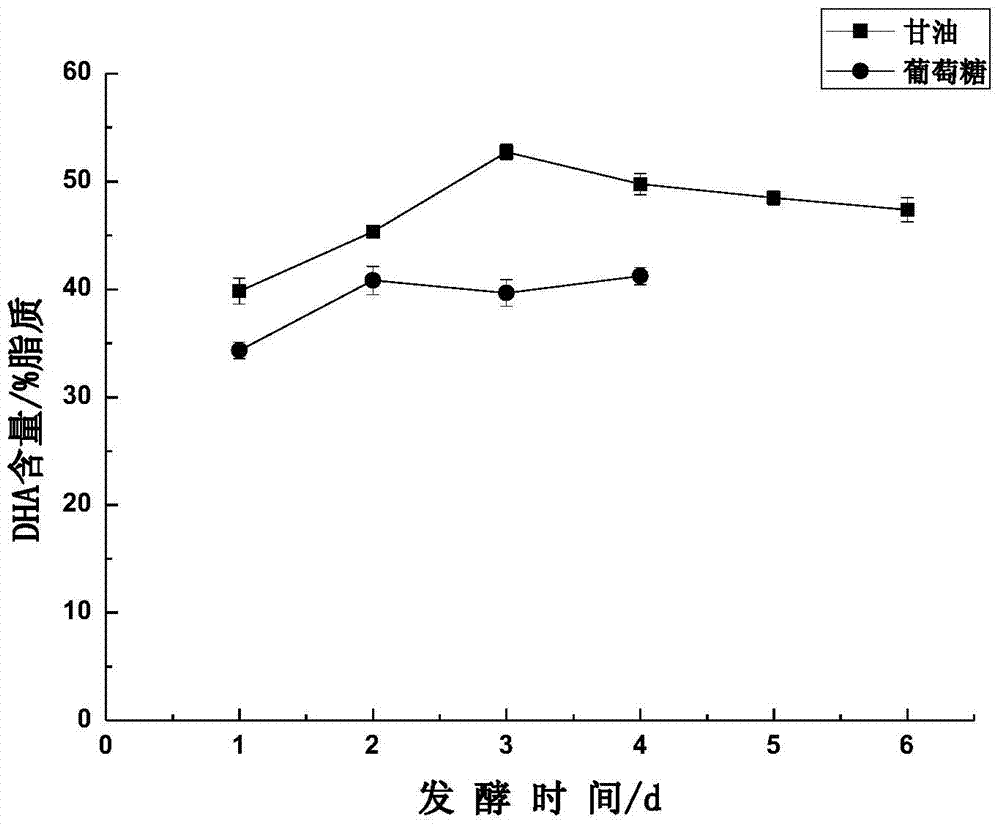

[0021] Embodiment 1: Utilize glucose or glycerol single carbon source fermentation to produce DHA

[0022] Schizochytrium seed medium: glucose 30g / L, yeast extract 5g / L, sodium glutamate 5g / L, Na 2 SO 4 15g / L, KH 2 PO 4 3g / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O3g / L, K 2 SO 4 1g / L, VB 1 0.005g / L, VB 6 0.002g / L, VB 12 0.005g / L.

[0023] Schizochytrium fermentation medium: glucose (or glycerol) 100g / L, yeast extract 10g / L, sodium glutamate 15g / L, Na 2 SO 4 15g / L, KH 2 PO 4 3g / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O3g / L, K 2 SO 4 1g / L, VB 1 0.008g / L, VB 6 0.002g / L, VB 12 0.008g / L.

[0024] The seeds were cultured for two generations, and each generation was carried out in a 50mL / 250mL Erlenmeyer flask with an inoculum volume of 8% (V / V), and cultured on a shaking table at 25°C and 200rpm for 48h. The second-generation seeds were placed into 50mL / 250mL Erlenmeyer flasks with an inoculum volume of 8% (V / V), and the fermentation conditions were 25°C and 200rpm.

[002...

Embodiment 2

[0029] Embodiment 2: Glucose and glycerol mixed carbon source feeding fermentation produces DHA

[0030] Schizochytrium seed culture medium is as described in Example 1.

[0031] In the Schizochytrium fermentation medium, the carbon source is 50g / L glucose and 50g / L glycerol, and the remaining composition is as described in Example 1.

[0032] Schizochytrium culture method as described in Example 1.

[0033]The results showed that the biomass was 42.12g / L with a 1:1 mixed carbon source fed at one time, the fermentation time was 5 days, that is, the substrate utilization rate was improved, the total fat accounted for 61.84% of the dry bacteria content, and the DHA accounted for the total The fatty acid content is 45.67%, and the resulting DHA yield is 11.90g / L, which is about 10% higher than that of single carbon source fermentation.

Embodiment 3

[0034] Embodiment 3: DHA is produced by glucose feed glycerol fed-feed fermentation

[0035] Schizochytrium seed culture medium is as described in Example 1.

[0036] In the Schizochytrium fermentation medium, the composition is as described in Example 1 except for the carbon source.

[0037] Schizochytrium culture method as described in Example 1.

[0038] In this example, 4 sets of fermentation experiments were carried out. The first two were to add glycerin when the residual sugar content was 50% to 70%, and the latter two were to add glycerin when the residual sugar content of glucose was 1% to 5%.

[0039] Experiment No. A used 50g / L glucose as the initial carbon source, and added 50g / L glycerin when the residual sugar content was 50%.

[0040] In experiment number B, 75g / L glucose was used as the initial carbon source, and 25g / L glycerol was added when the residual sugar content was 70%.

[0041] Experiment No. C used 25g / L glucose as the initial carbon source, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com