Dye-sensitized solar cell

A technology for solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of reducing photoelectric conversion efficiency, limiting the industrialization development of dye-sensitized solar cells, reducing the durability of dye-sensitized solar cells, etc., and is beneficial to the development of industrialization. , The effect of improving durability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Preparation of Dye Solution

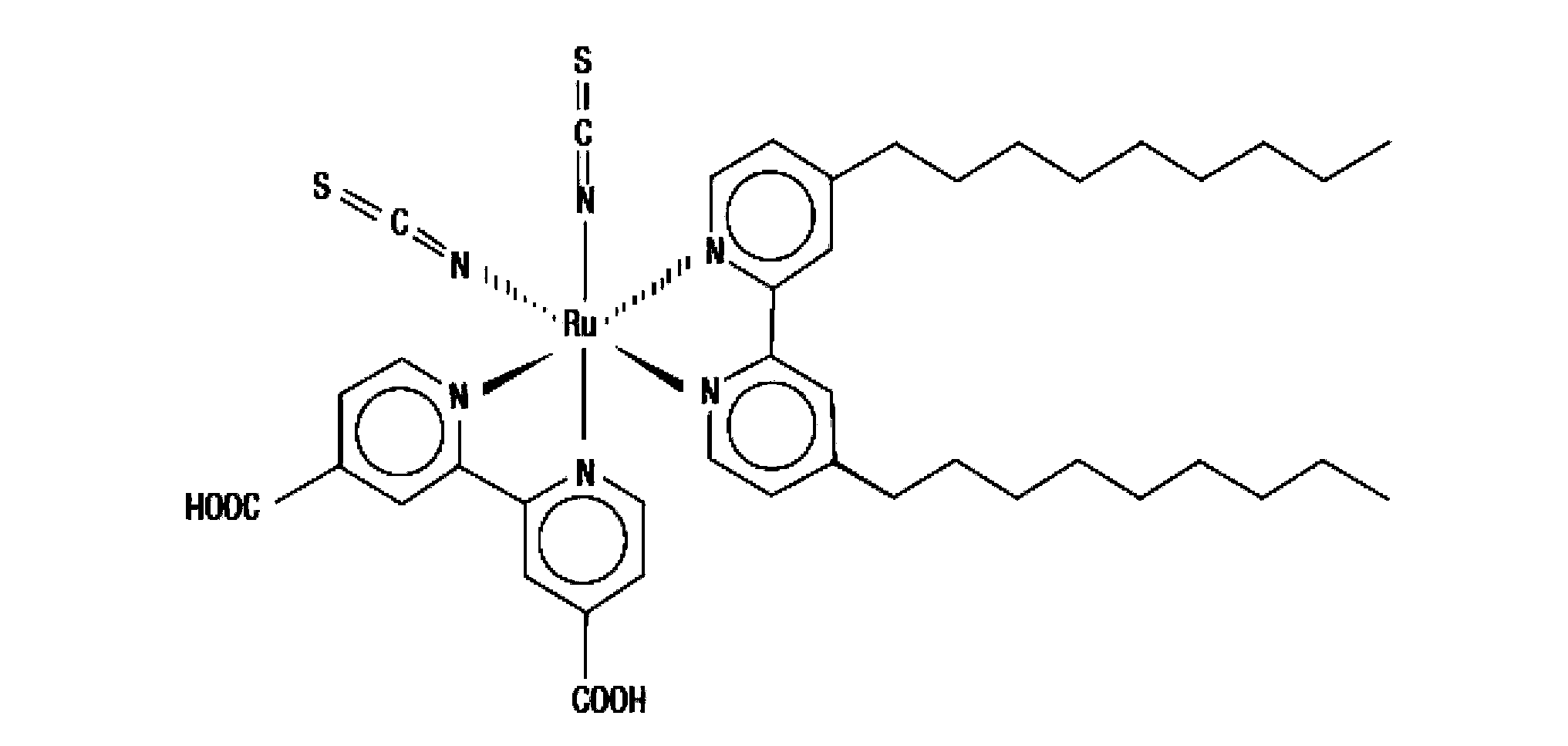

[0051] The commercially available standard Z907 dye (chemical structural formula such as figure 2 shown) after purification, dissolved in acetonitrile: tert-butanol = 1:1 solvent to prepare a 0.4mmol / L dye solution.

[0052] 2. Photoelectrode fabrication

[0053] Commercially available TiO with a particle diameter of 20 nm 2The paste is coated on the surface of FTO conductive glass by screen printing method, placed in a muffle furnace and sintered at 500 °C for 2 hours to obtain 20 μm TiO 2 membrane. TiO 2 The electrodes were soaked in the dye solution for 2 days.

[0054] 3. Counter electrode fabrication

[0055] A commercially available conductive polymer was coated on the titanium counter electrode substrate by screen printing, placed in a muffle furnace for sintering at 300° C. for 0.5 hour, and cooled to room temperature.

[0056] 4. battery production

[0057] Bond the photoelectrode and the counter electrode with hot ...

Embodiment 2

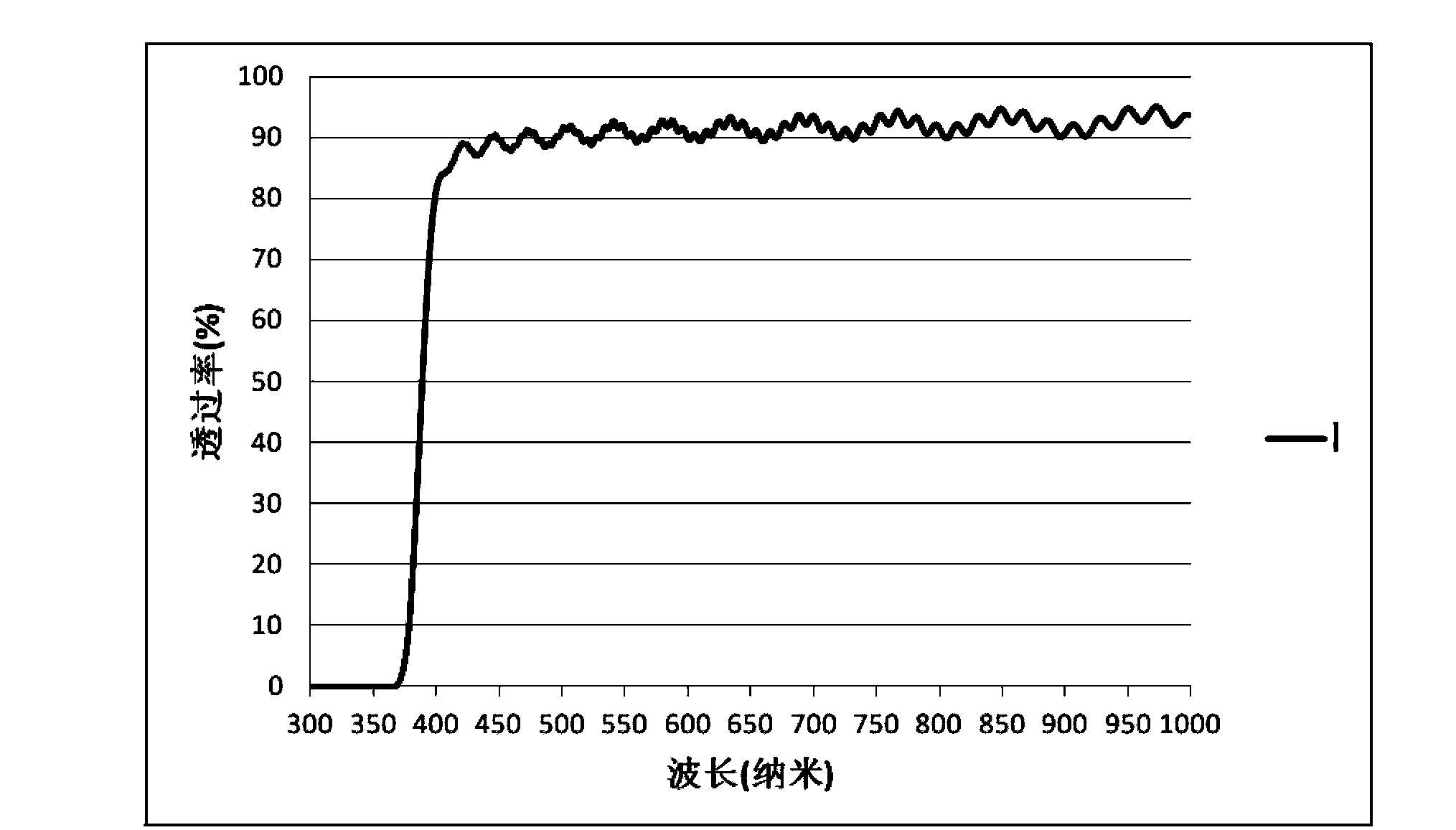

[0061] The preparation process is the same as in Example 1, except that the photoelectrode is covered with a layer of commercially available UV-resistant polymer film on the side away from the electrolyte layer. After testing, the visible light transmittance of the commercially available UV-resistant polymer film is 91%, the transmittance of light with a wavelength of 372 nm is 0%, and the transmittance of light with a wavelength of 391 nm is 50%, such as Image 6 shown.

[0062] The obtained dye-sensitized solar cell performance is tested, and the results are as follows: Figure 7 As shown, the voltage and current did not change significantly, indicating that the initial performance of the dye-sensitized solar cell obtained in Example 1 was the same as that of the control example.

[0063] The performance of the obtained dye-sensitized solar cell was subjected to an accelerated photoaging experiment. The cell efficiency of the control example dropped to 0 after 100 h, while ...

Embodiment 3

[0065] The preparation process is the same as in Example 1, except that a layer of commercially available anti-ultraviolet coating is coated on the side of the photoelectrode away from the electrolyte layer. After testing, the visible light transmittance of the commercially available anti-ultraviolet coating is 90%. The transmittance of light with a wavelength of 372 nm is 0%, and the transmittance of light with a wavelength of 399 nm is 50%, such as Figure 9 shown.

[0066] The obtained dye-sensitized solar cell performance is tested, and the results are as follows: Figure 10 As shown, the voltage and current did not change significantly, indicating that the initial performance of the dye-sensitized solar cell obtained in Example 1 was the same as that of the control example.

[0067] The performance of the obtained dye-sensitized solar cell was subjected to an accelerated photoaging experiment. The cell efficiency of the control example dropped to 0 after 100 h, while the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com