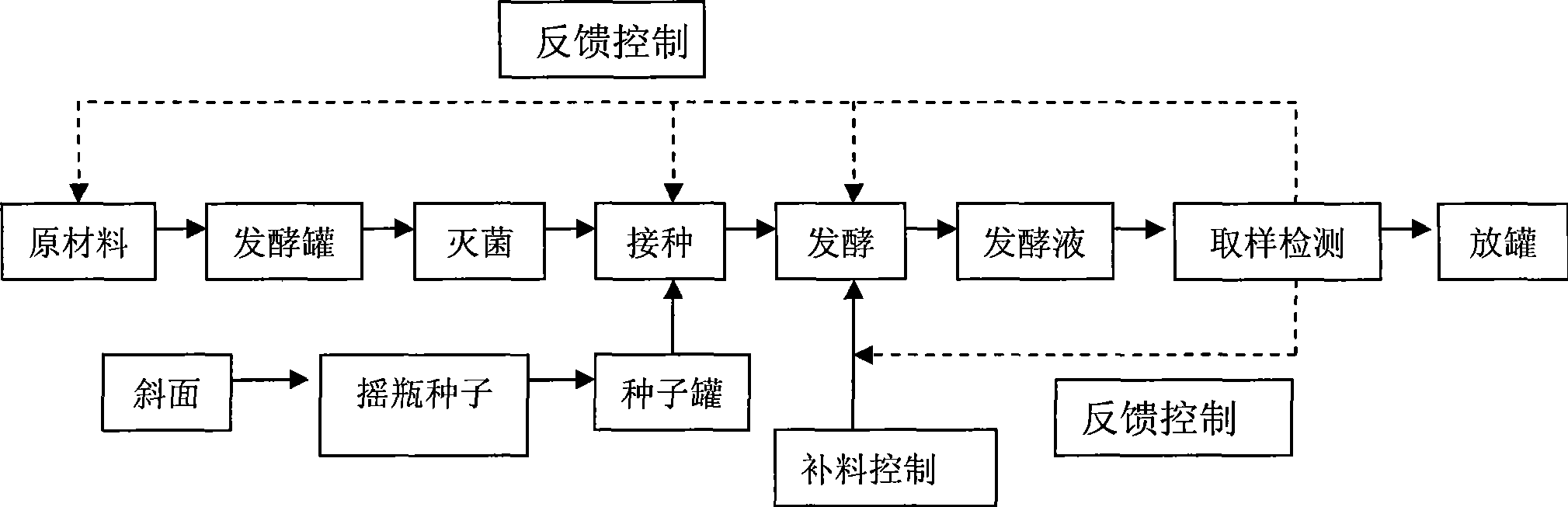

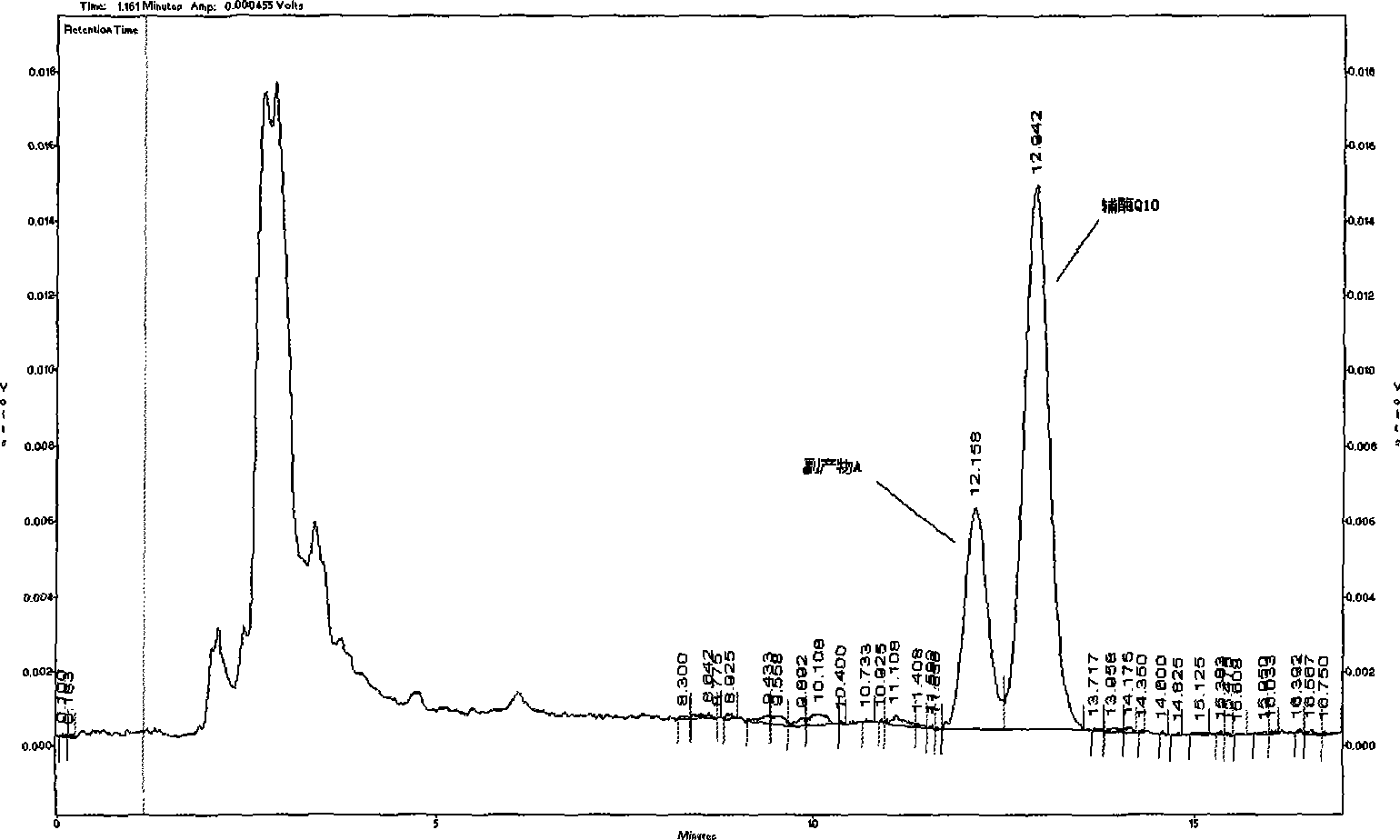

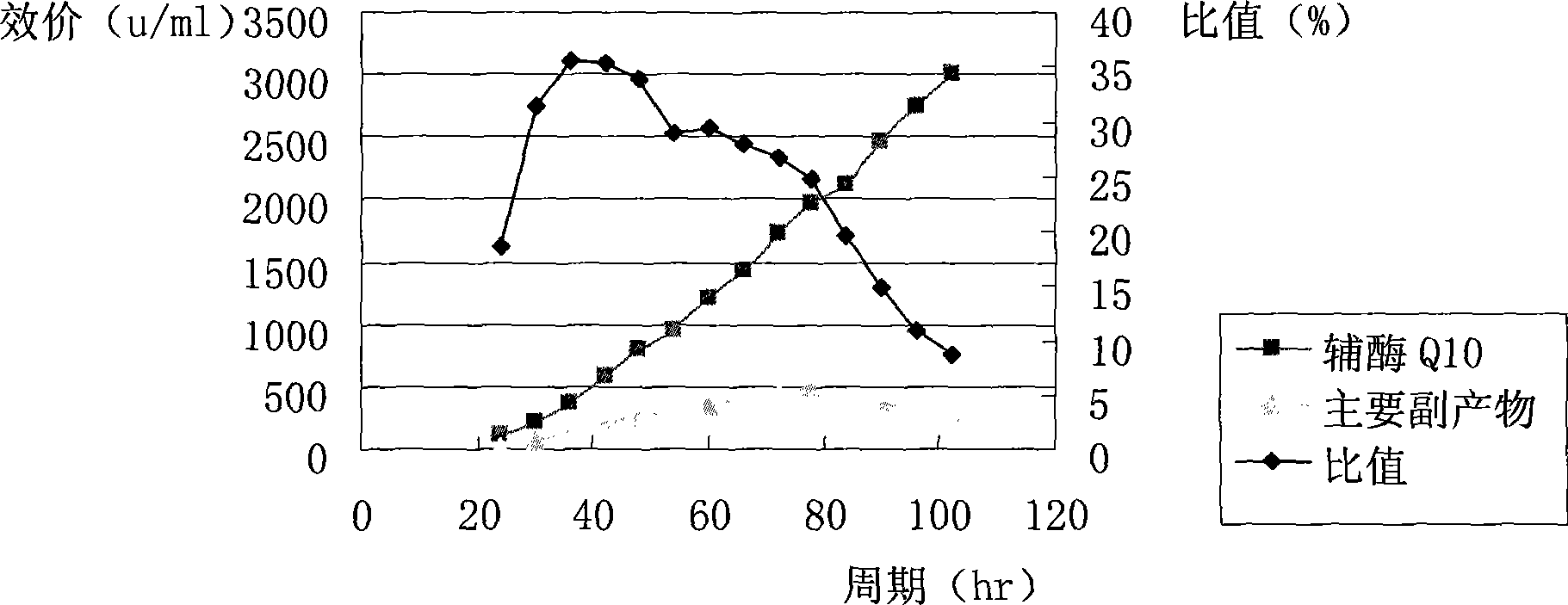

Production and fermentation process of coenzyme Q10

A fermentation process and coenzyme technology, which is applied in the direction of fermentation, microorganisms, and methods based on microorganisms, can solve problems such as high cost, inability to meet actual production, and low production level, so as to reduce fermentation cost, improve time utilization, and fermentation level Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] On the slant of the broth culture medium test tube, inoculate Rhodopseudomonas capsulatum on the culture medium under sterile conditions, control the culture temperature at 30°C, and cultivate for 96 hours to grow pale yellow Single colony, the length of the colony is 1-1.5mm, and then the above-mentioned strains are inserted into the sterilized primary seed tank with 7.5L medium under aseptic conditions, and the stirring is controlled under the condition of no need of light The rotation speed is 400rpm, the cultivation temperature is 33°C, the pressure is 0.04Mpa, and the cultivation time is 24 hours, and then transferred to the sterilized secondary seed tank containing 37.5L medium. The temperature is 33°C, the pressure is 0.04Mpa, and the incubation time is 24 hours. The medium formula (by mass ratio) of the primary seed tank and the secondary seed tank is: ammonium sulfate 0.30%, magnesium sulfate 0.25%, potassium dihydrogen phosphate 0.08%, glucose 0.50%, corn stee...

Embodiment 2

[0079] On the slant of the broth culture medium test tube, inoculate Rhodopseudomonas capsulatum on the culture medium under sterile conditions, control the culture temperature at 30°C, and cultivate for 96 hours to grow pale yellow Single colony, the length of the colony is 1-1.5mm, and then the above-mentioned strains are inserted into the sterilized primary seed tank with 1.0 tons of medium under aseptic conditions, and the stirring is controlled under the condition of no need of light The rotation speed is 250rpm, the cultivation temperature is 33°C, the pressure is 0.04Mpa, and the cultivation time is 24 hours; then it is transferred into a sterilized secondary seed tank containing 5.0 tons of medium, and the stirring speed is controlled at 200rpm under the condition of no light, and the cultivation The temperature is 33°C, the pressure is 0.04Mpa, and the incubation time is 24 hours. The medium formula (by mass ratio) of the primary seed tank and the secondary seed tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com