Method for efficiently producing cellulase

A cellulase and high-efficiency technology, applied in the field of high-efficiency production of cellulase, to achieve the effects of improved degradation performance, increased activity, and improved fermentation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

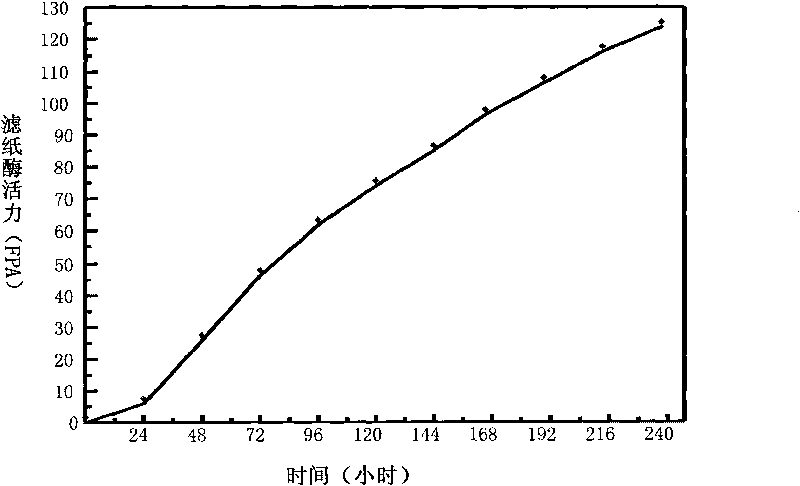

Embodiment 1

[0029] Inject the liquid bacteria into 50M at a ratio of 10% (V / V) 3 Fermentation tank, initial pH 4.8, stirring speed 150rpm, 0-72 hours: fermentation temperature 32°C, ventilation 1.0vvm; after 72 hours: fermentation temperature 28°C, ventilation 0.6vvm. The fermentation medium formula is as follows:

[0030] Soluble carbon source (87.5% of which is glucose, 12.5% is sophorose) 15g / L, insoluble carbon source (microcrystalline cellulose) 30g / L, magnesium sulfate 0.8g / L, potassium dihydrogen phosphate 6g / L, soil temperature 802g / L, yeast powder 15g / L, peptone 10g / L, ammonium sulfate 2.5g / L, calcium chloride 0.5g / L, FeSO 4 ·7H 2 O5mg / L, ZnSO 4 ·7H 2 O 1.4mg / L, MnSO 4 ·H 2 O 1.6mg / L, CoCl 2 ·6H 2 O 3.7mg / L, H 3 BO 3 0.4mg / L, ammonium molybdate 1.6mg / L.

[0031]Start fed-batch culture after 72 hours of fermentation, the flow rate is 3.5L / h m 3 fermentation broth. When the pH value of the fermentation broth rose to 4.8, start feeding fresh medium; when the pH value...

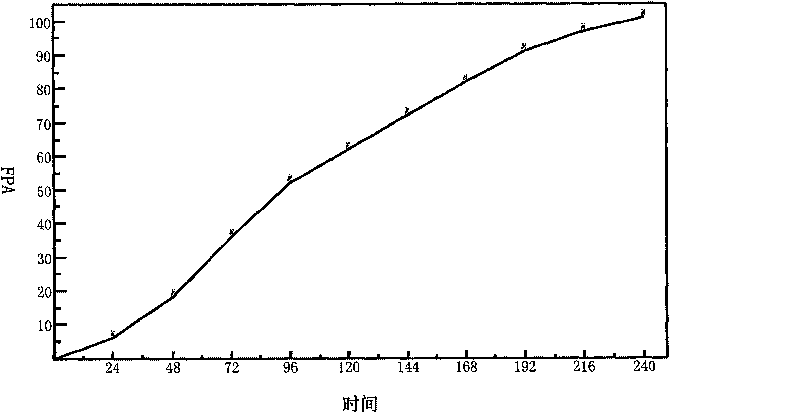

Embodiment 2

[0037] Inject the liquid bacteria into 50M at a ratio of 10% (V / V) 3 Fermentation tank, initial pH 4.8, stirring speed 150rpm, 0-90 hours: fermentation temperature 31°C, ventilation 1.2vvm; after 90 hours: fermentation temperature 29°C, ventilation 0.8vvm. The fermentation medium formula is as follows:

[0038] Soluble carbon source (93.5% of which is glucose, 6.5% is sophorose) 15g / L, insoluble carbon source (microcrystalline cellulose) 40g / L, magnesium sulfate 1.0g / L, potassium dihydrogen phosphate 8g / L, soil temperature 804g / L, yeast powder 20g / L, peptone 15g / L, ammonium sulfate 3.5g / L, calcium chloride 0.7g / L, FeSO 4 ·7H 2 O7mg / L, ZnSO 4 ·7H 2 O 1.6mg / L, MnSO 4 ·H 2 O 1.8mg / L, CoCl 2 ·6H 2 O 3.4mg / L, H 3 BO 3 0.5mg / L, ammonium molybdate 1.2mg / L.

[0039] Start fed-batch culture after 90 hours of fermentation, the flow rate is 1.5L / h m 3 fermentation broth. When the pH value of the fermentation broth rose to 4.8, start feeding fresh medium; when the pH value o...

Embodiment 3

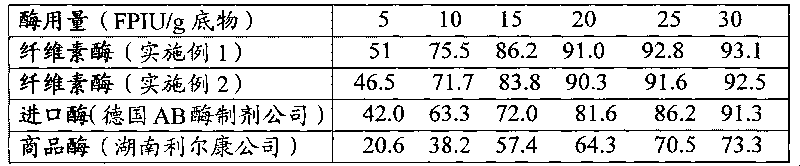

[0044] Using xylose residue (the cellulose waste residue obtained from xylose after hydrolyzing corn cob cores with 10g / L sulfuric acid at 110°C for 6 hours) as raw material, cellulase preparations from different sources were added respectively, and at 50°C and pH 4.8 The enzymolysis reaction was carried out under the following conditions, the concentration of xylose residue was 100g / L, and the dosage of cellulase was: 5-30 FPIU (international unit of filter paper enzyme activity) per gram of xylose residue. After 48 hours of reaction, the concentration of reducing sugar in the hydrolyzate was measured. , Calculate the enzymatic hydrolysis yield (Table 1).

[0045] Table 1 Comparison of enzymatic hydrolysis yields of xylose residues from different sources of cellulase preparations

[0046]

[0047] The chemical composition of xylose residue is: 60.9% cellulose, 5.1% hemicellulose, 18.7% lignin, and 15.3% other.

[0048] Enzyme hydrolysis yield (%) = (mass concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com