Dual-pump material feeding method and recombinant Escherichia coli fermentation method based on dual-pump material feeding method

A technology of recombinant Escherichia coli and fermentation method, applied in the field of microbial fermentation, can solve the problems of large dissolved oxygen fluctuation range and low fermentation level, and achieve the effects of large dissolved oxygen fluctuation range, improved fermentation level, and reduced dissolved oxygen fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

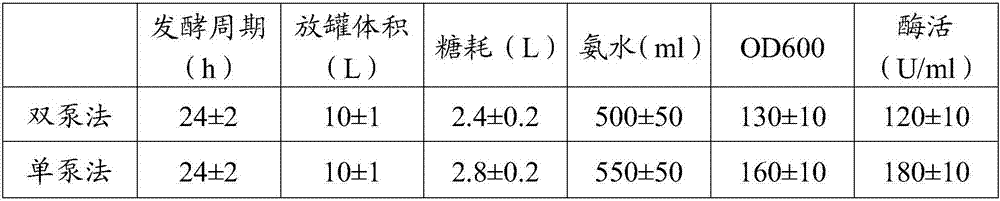

Embodiment 1

[0051] Inoculation: Take out the bacterial solution from the preserved glycerol tube and insert it into a shaker flask containing 150ml LB medium (containing ampicillin 500ug / ml) with a 1% inoculum amount, and culture it on a shaker at 37°C for 4 hours, and wait until the culture solution OD 600 When it grows to 2.5, it starts to be transplanted into the tank.

[0052] Prepare 10L fermentation medium according to the following formula: dodecahydrate and disodium hydrogen phosphate 200g, potassium dihydrogen phosphate 150g, ammonium chloride 200g, sodium sulfate 50g, magnesium sulfate heptahydrate 20g, peptone 200g, yeast powder 100g, glycerol 200g, Polyether type defoamer 10mL, ferric chloride 1.5g.

[0053] Tank elimination: Pour the prepared fermentation medium into the fermenter, and sterilize at 121°C for 30 minutes; after cooling down, control the fermentation temperature to 37°C, the ratio of ventilation to air is 1:1, the speed is 200rpm, and after 20 minutes of stabili...

Embodiment 2

[0060] Inoculation, tank elimination, and tank entry are the same as in Example 1.

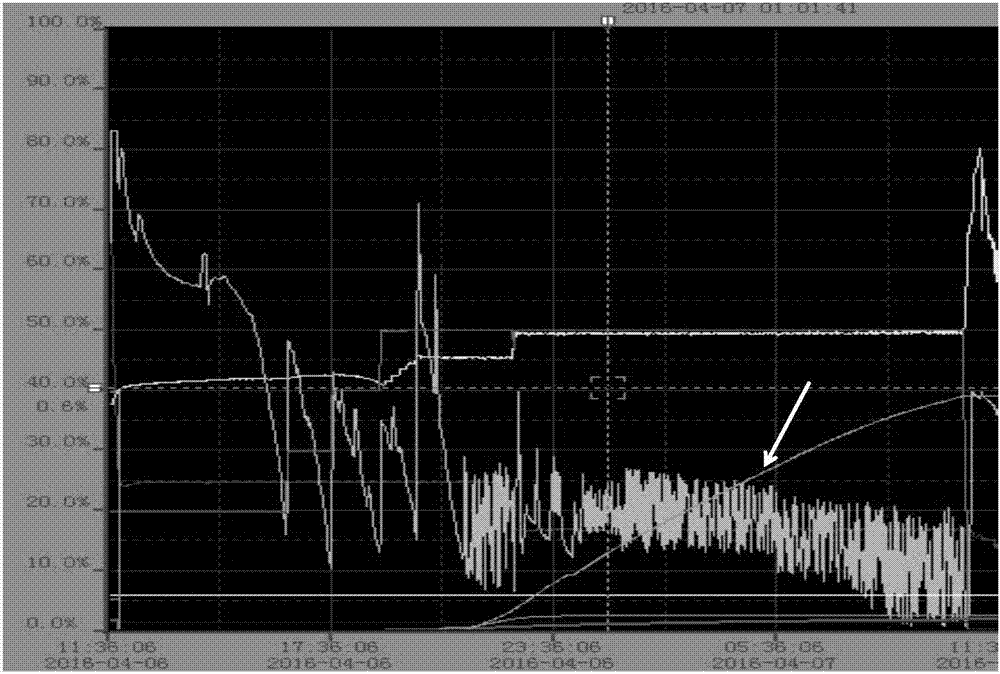

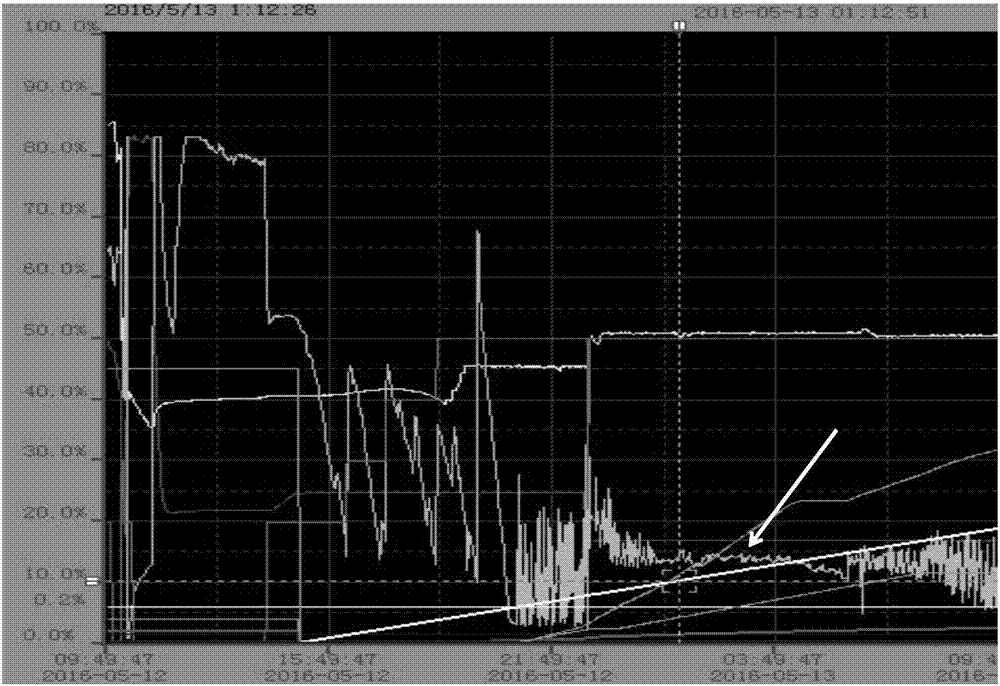

[0061] Fermentation control: Fermentation tank parameters in the early stage of fermentation: 150rpm, 37°C, aeration ratio 1:0.5 (inlet air pressure 0.08MPa), pH of the fermentation broth is not controlled. With the fermentation broth OD 600 Growth, adjust the stirring speed of the fermenter and the air flow, so that the dissolved oxygen of the fermented liquid is controlled above 50%. When the pH starts to drop, add ammonia water to the fermentation broth, and adjust the pH of the fermentation broth to 6.5 in 0.5h; Supplemented with 60% w / v sterile glucose. The electronic switch of the feeding pump is set to be associated with the dissolved oxygen value, and the associated dissolved oxygen value is set to 25%, and the dissolved oxygen value of the fermented liquid is controlled to be 10-50%.

[0062] Induced expression: regular sampling to detect the OD of the fermentation broth 600 , to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com