Coenzyme Q10 fermentation process and control strategy

A technology of coenzyme and fermentation method, applied in the field of coenzyme Q10 fermentation process and control strategy, can solve the problems of long microbial fermentation process, influence judgment, low repeatability, etc., and achieve the effects of reducing fermentation cost, stabilizing production level, and improving fermentation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

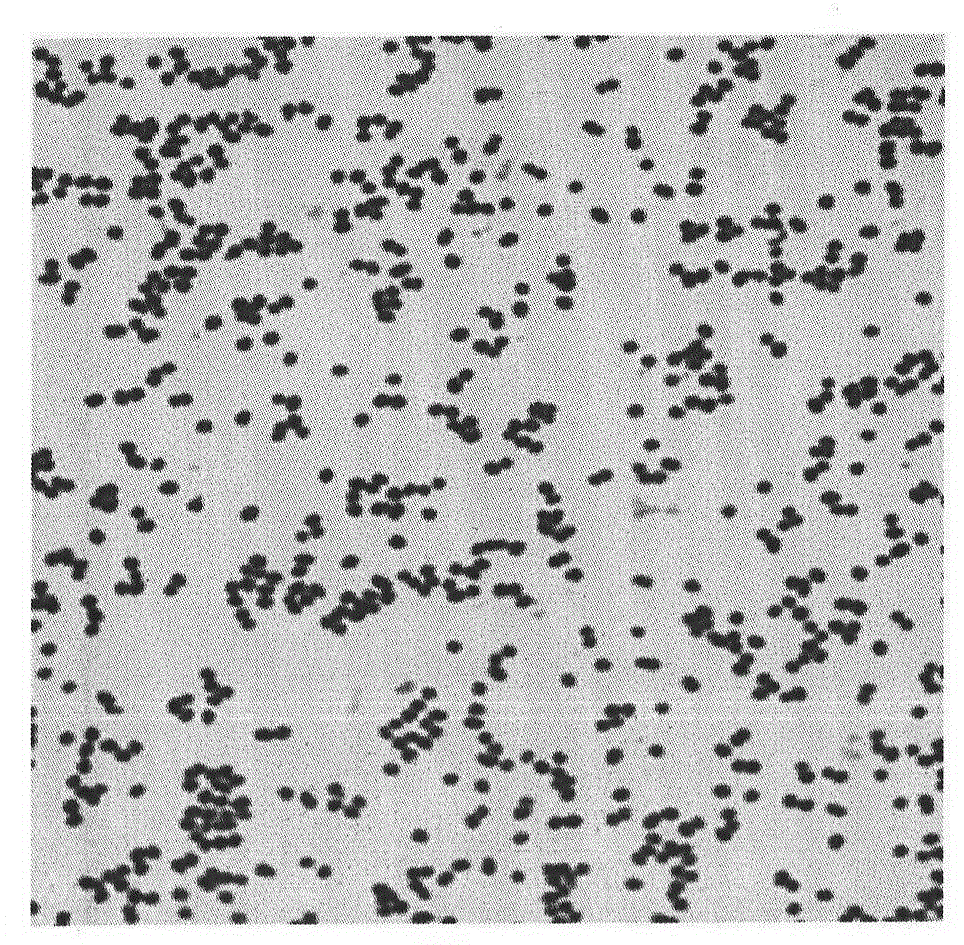

[0035] After the coenzyme Q10 preserved strain CGMCCNo.4497 was activated for three generations, a single colony with a round and full appearance, smooth edges and darker color on the plate was picked and diluted and spread on the plate medium for culture. The plate medium components are: glucose 2g / L, yeast powder 1g / L, peptone 1g / L, agar powder 2g / L, pH 6.8, and the culture conditions are 32°C for 5 days, until the appearance of the colonies on the plate is round and the edges are smooth , When the color is darker, it can be inserted into the mother bottle for cultivation.

[0036] Mother bottle medium components are: ammonium chloride 1.7g / L, peptone 0.7g / L, monosodium glutamate 0.4g / L, corn steep liquor 0.4g / L, glucose 2g / L, disodium hydrogen phosphate 0.35g / L, phosphoric acid Sodium dihydrogen 0.35g / L, ferric chloride 0.08g / L, magnesium sulfate 1.4g / L, potassium chloride 1.4g / L, copper sulfate 0.02g / L, zinc chloride 0.0006g / L, calcium bicarbonate 5.6g / L, auxiliary liquid...

Embodiment 2

[0047] After the coenzyme Q10 preserved strain CGMCCNo.4497 was activated for three generations, a single colony with a round and full appearance, smooth edges and darker color on the plate was picked, diluted and spread, and then inoculated on the plate medium for culture. The plate medium components are: glucose 3g / L, yeast powder 2g / L, peptone 2g / L, agar powder 2.5g / L, pH 7.0. The culture condition is 32°C for 6 days, and when the appearance of a single colony is round, the edge is smooth, and the color is dark, it can be inserted into the mother bottle for culture.

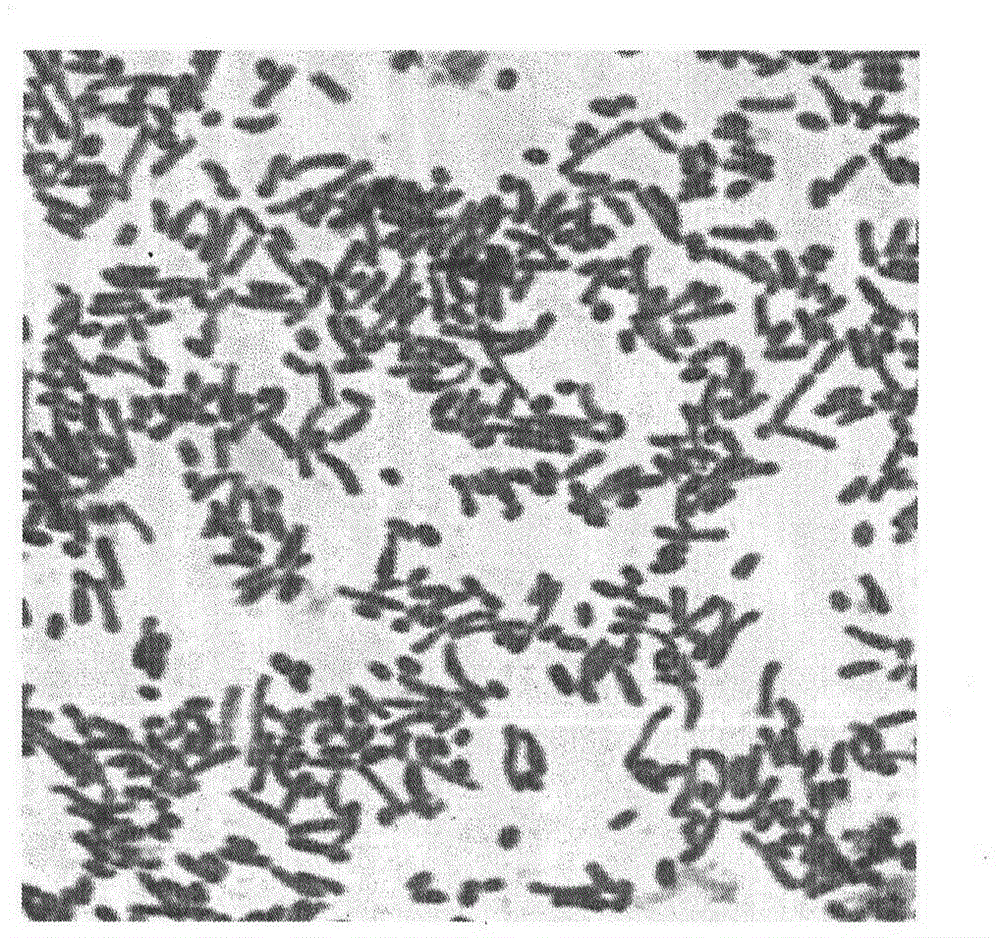

[0048] Mother bottle medium components are: ammonium chloride 2.1g / L, peptone 0.11g / L, monosodium glutamate 0.8g / L, corn steep liquor 0.8g / L, glucose 4g / L, disodium hydrogen phosphate 0.45g / L, phosphoric acid Sodium dihydrogen 0.45g / L, ferric chloride 0.1g / L, magnesium sulfate 1.8g / L, potassium chloride 1.8g / L, copper sulfate 0.04g / L, zinc chloride 0.001g / L, calcium bicarbonate 6.4g / L, auxiliary liquid I. Am...

Embodiment 3

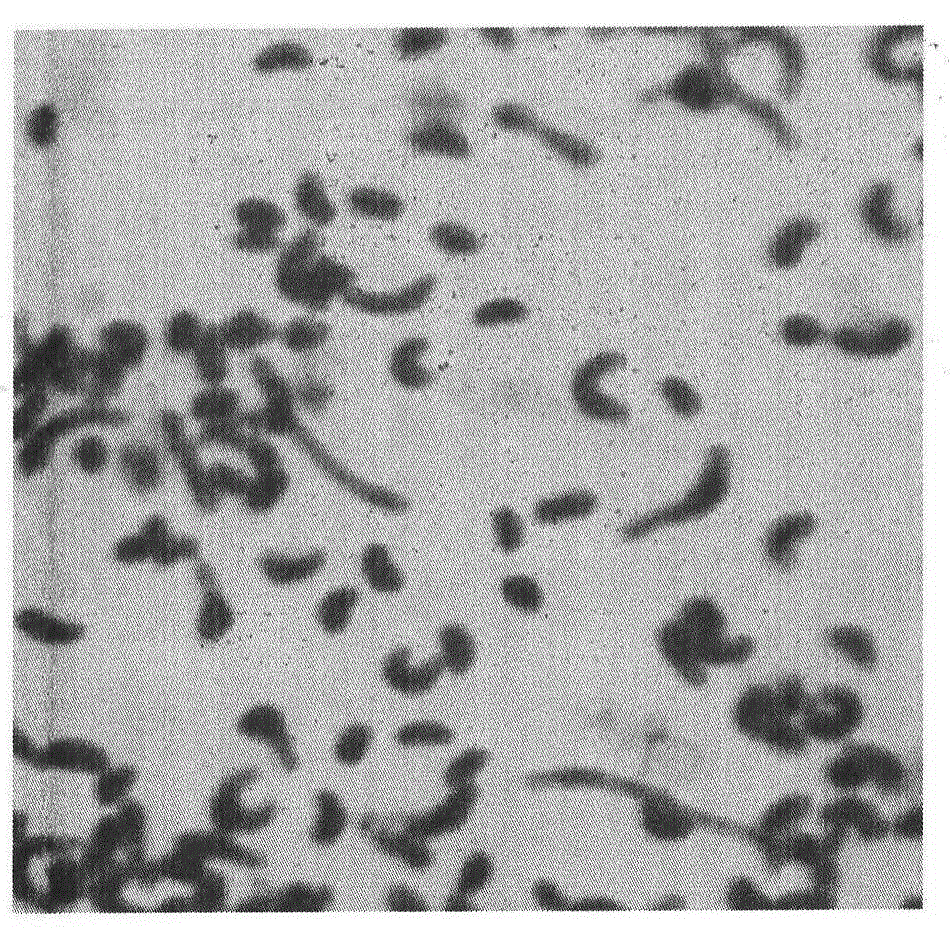

[0059] After the coenzyme Q10 preserved strain CGMCCNo.4497 was activated for three generations, a single colony with a round and full appearance, smooth edges and darker color on the plate was picked and diluted and spread on the plate medium for culture. The plate medium components are: glucose 4g / L, yeast powder 3g / L, peptone 3g / L, agar powder 3g / L, pH 7.2. The culture condition is 32°C for 5 days, and when the appearance of a single colony is round and full, the edges are smooth, and the color is dark, it can be inserted into the mother bottle for culture.

[0060] Mother bottle medium components are: ammonium chloride 2.5g / L, peptone 1.5g / L, monosodium glutamate 1.2g / L, corn steep liquor 1.2g / L, glucose 6g / L, disodium hydrogen phosphate 0.55g / L, phosphoric acid Sodium dihydrogen 0.55g / L, ferric chloride 0.12g / L, magnesium sulfate 2.2g / L, potassium chloride 2.2g / L, copper sulfate 0.06g / L, zinc chloride 0.0014g / L, calcium bicarbonate 7.2g / L, auxiliary liquid I. Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com