Phase-change composite material with photo-thermal conversion function and preparation method thereof

A phase-change composite material and phase-change material technology, applied in the field of phase-change composite materials and their preparation, can solve problems such as the lack of mature reports on advanced photothermal conversion devices and systems, achieve excellent photothermal conversion performance, enhance Light-to-heat conversion effect, good leak-proof performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Preparation of a lightweight flexible carbon foam-based phase-change composite material

[0051] The specific preparation method is as follows:

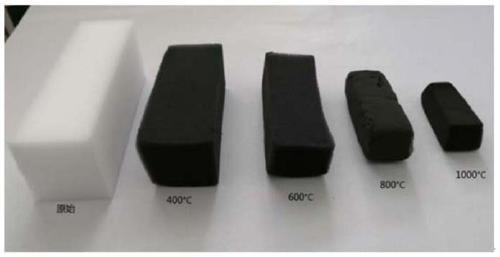

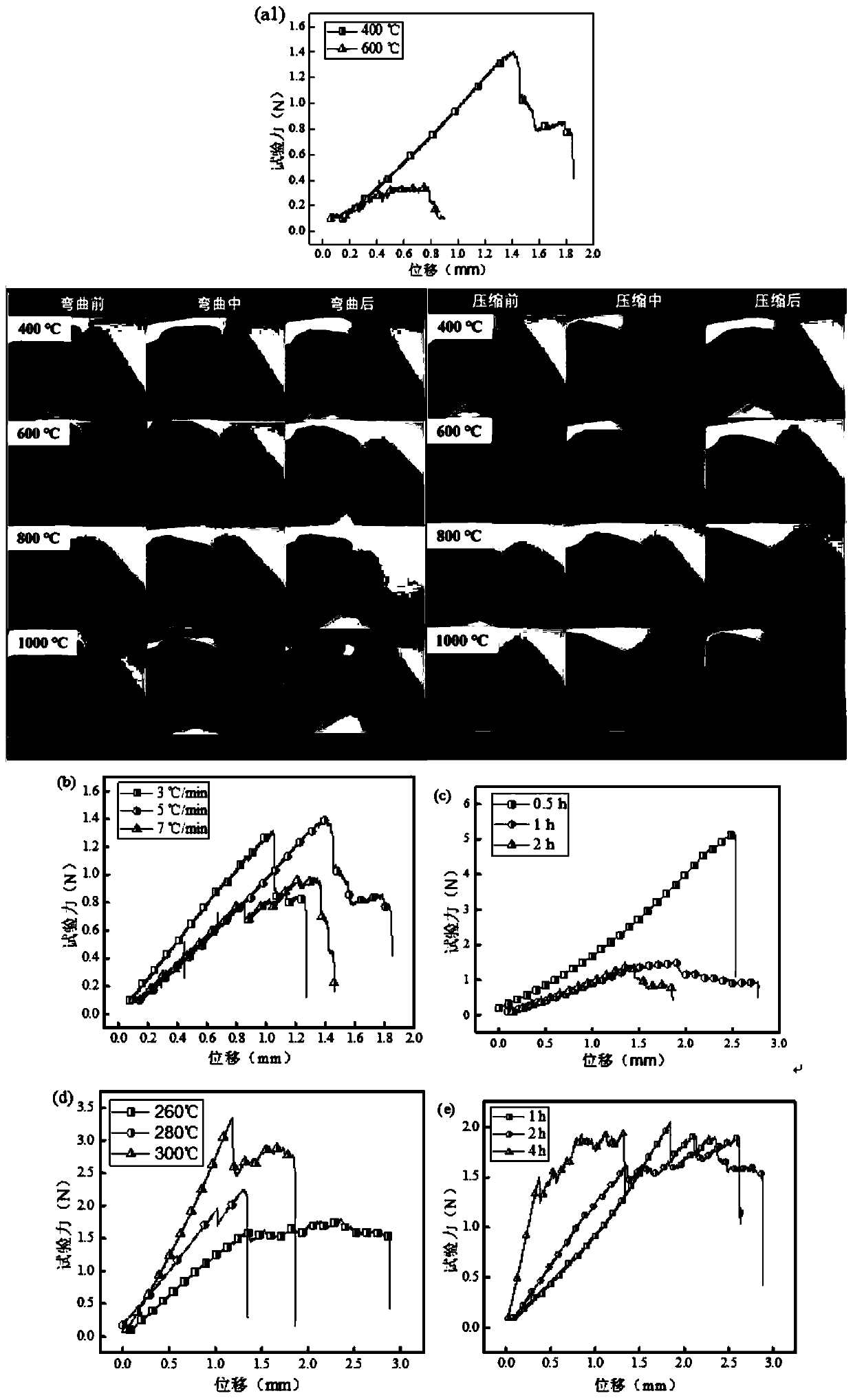

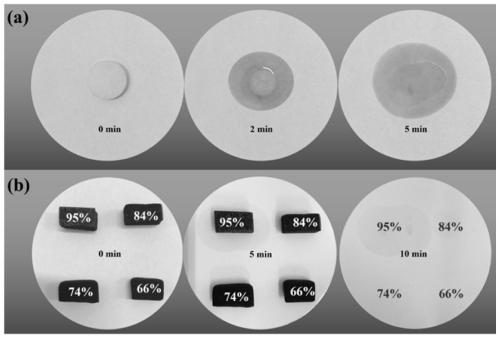

[0052] Preparation of lightweight flexible carbon foam matrix: commercial melamine foam was used as raw material, pre-oxidized and carbonized: the pre-oxidation process was at a temperature of 280°C, and the holding time was 2h; the carbonization process was at 400°C, the holding time was 0.5h, and the heating rate was 5°C / min, to obtain lightweight flexible carbon foam; the density of the resulting carbon foam matrix material is 11.7kg / m 3 , the interior of the matrix is a three-dimensional porous framework connected to each other, and the pore size is 50-200 μm.

[0053] Ti 2 o 3 Nanoparticle modification: Ti 2 o 3 The nanoparticles were mixed with a Tris solution of dopamine (2 mg / mL, pH 8.5) to infiltrate the foam material, and the photothermal conversion nanoparticles Ti were deposited on the surface of ...

Embodiment 2

[0056] Example 2 Preparation of a lightweight flexible carbon foam-based phase-change composite material

[0057] The specific preparation method is as follows:

[0058] The preparation steps of the lightweight flexible carbon foam matrix are the same as in Example 1; secondly, on the basis of the lightweight flexible carbon foam, Ti 2 o 3 Nanoparticles are mixed with a Tris solution of dopamine (2 mg / mL, pH 8.5) to infiltrate the foam material, and the photothermal conversion nanoparticle Ti is deposited on the surface of the carbon foam skeleton by utilizing the excellent adhesion of polydopamine. 2 o 3 , the nanoparticle specification is the same as in Example 1; the nanoparticle Ti 2 o 3 In the mixed system with Tris solution of dopamine, the concentration of nanoparticles was adjusted to 2.5%. The reaction time of the mixed solution was adjusted to 24 hours in a constant temperature oscillating shaker, and the constant temperature was 30°C.

[0059] Finally, the sol...

Embodiment 3

[0061] Example 3 Preparation of a lightweight flexible carbon foam-based phase-change composite material

[0062] The specific preparation method is as follows:

[0063] The preparation steps of the lightweight flexible carbon foam matrix are the same as in Example 1, wherein the pre-oxidation temperature is adjusted to 260°C; secondly, on the basis of the lightweight flexible carbon foam, Ti 2 o 3 Nanoparticles were mixed with a Tris solution of dopamine (2 mg / mL, pH 8.5) to infiltrate the foam material, and the photothermal conversion nanoparticle Ti was deposited on the surface of the carbon foam skeleton by utilizing the excellent adhesion of PDA. 2 o 3 , the Ti 2 o 3 Nanoparticle specification is the same as embodiment 1; Described nanoparticle Ti 2 o 3 In the mixed system with Tris solution of dopamine, the concentration of nanoparticles was adjusted to 5%. The mixed solution was reacted in a constant temperature shaking shaker for 24 hours, and the constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com