Method and equipment for coating slurry layer on cellular carrier of ceramics

A technology of ceramic honeycomb and carrier, which is applied to the device and coating of surface coating liquid, which can solve the problem of difficulty in achieving quantitative, uniform and consistent product quality, inability to perform quantitative coating, waste of slurry raw materials, etc. problems, to achieve the effect of improving quality and purification effect, good transformation effect, and convenient production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment: the formula of alumina coating slurry is 2kg monohydrate aluminum oxide powder, add 3250-3650ml H 2 O and 550ml of concentrated nitric acid are put in a ball mill for ball milling for 6-15h to obtain a slurry with a pH of 3-5, a specific gravity of 1.20-1.35, and a viscosity of 40-70 centipoise. There will be no precipitation if the slurry is not stirred within 24 hours.

[0038] The ceramic honeycomb carrier specifications used in this embodiment:

[0039] Φ100×100mm, 400 holes / in 2 ; Wall thickness 0.18-0.21mm; Water absorption 23-26%;

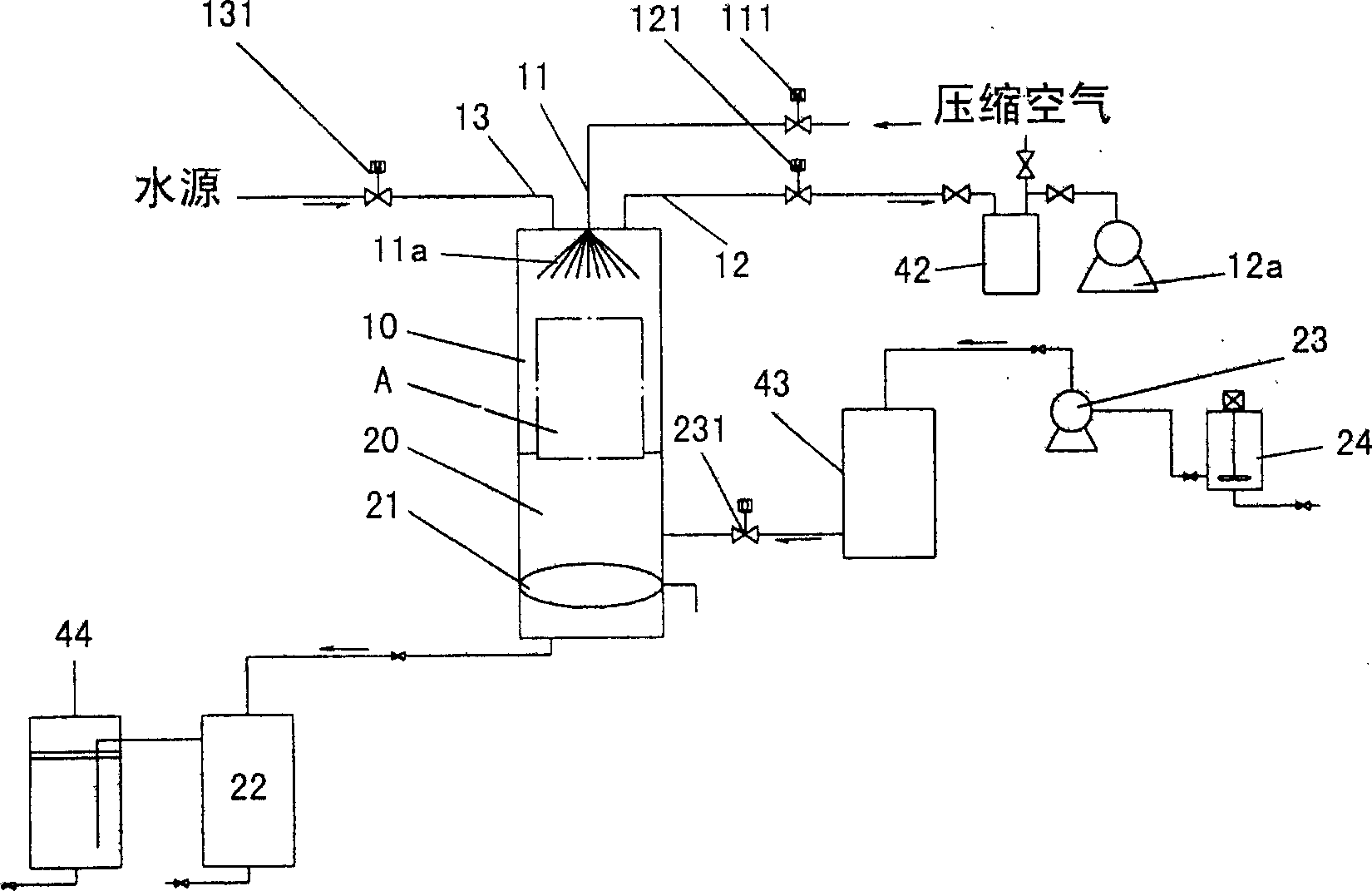

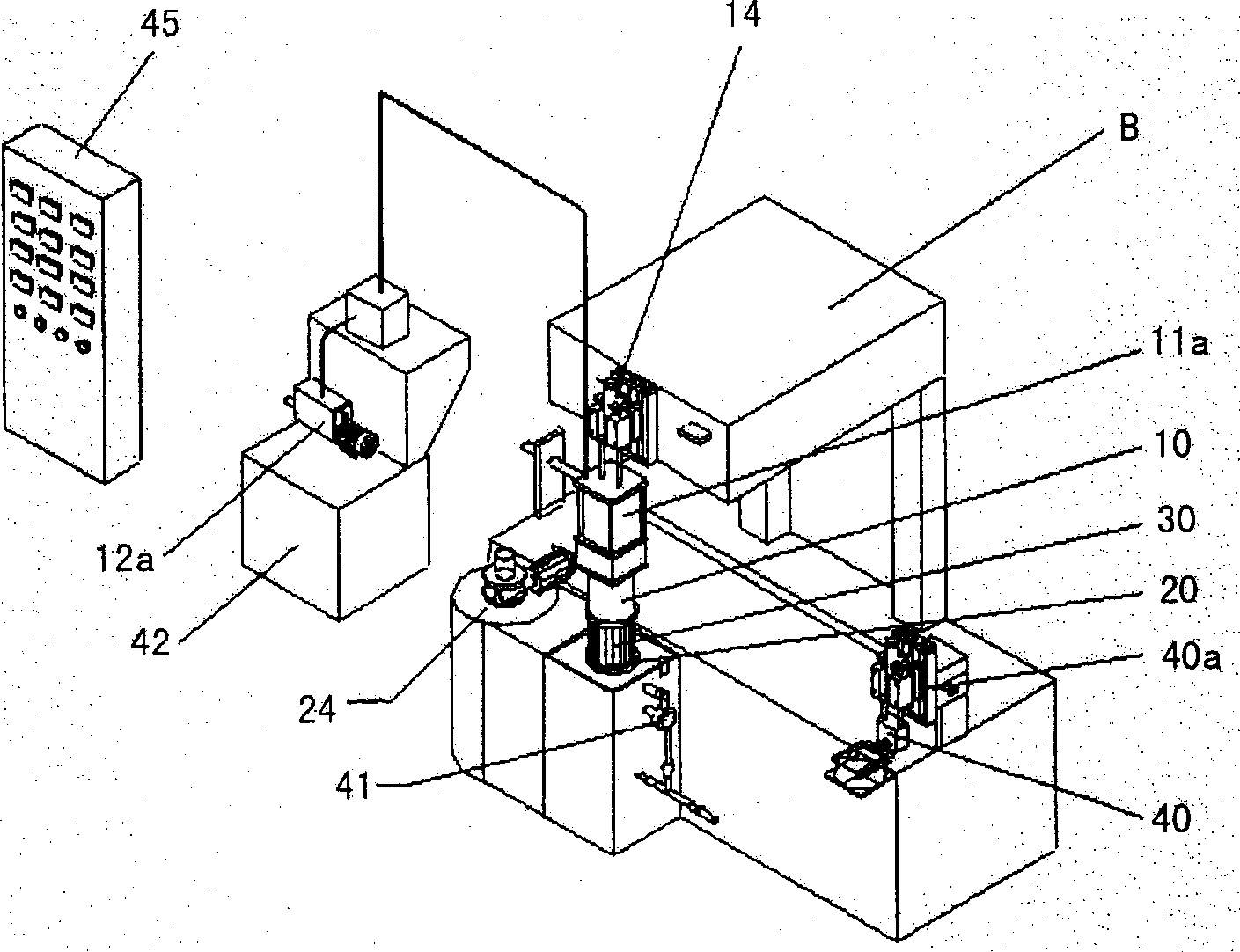

[0040] The basic structure of coating device see figure 1 and figure 2 .

[0041] In the device of the present invention, the connections that need to transmit gas, water and slurry between the components are pipeline connections, and the pipeline can be a metal pipeline, such as stainless steel; it can also be a pipeline made of organic polymer materials, such as polytetrafluoroethylene vinyl etc. The pipe diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com