Catalyst suitable for processing tail gas of lean-burn natural gas vehicle and preparation method thereof

A technology for exhaust gas treatment and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as affecting catalyst performance, and achieve easy control of preparation process conditions. , the preparation method is simple, the practicability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

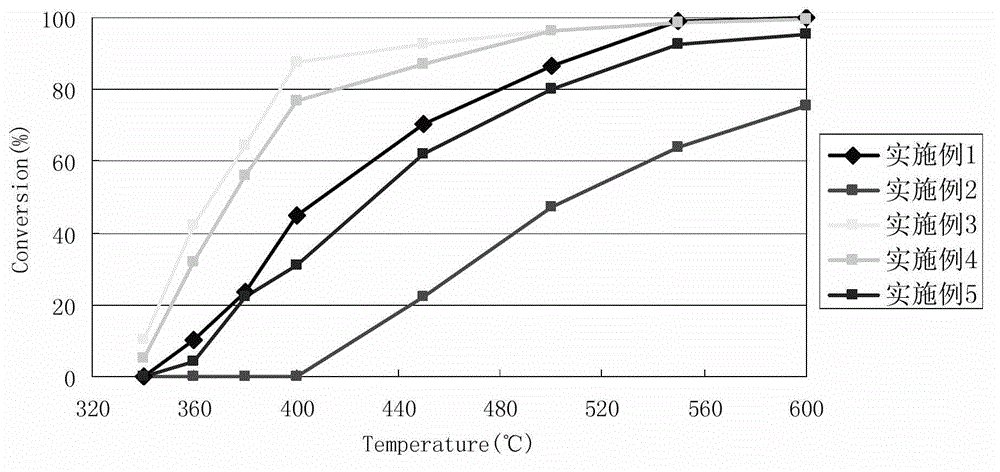

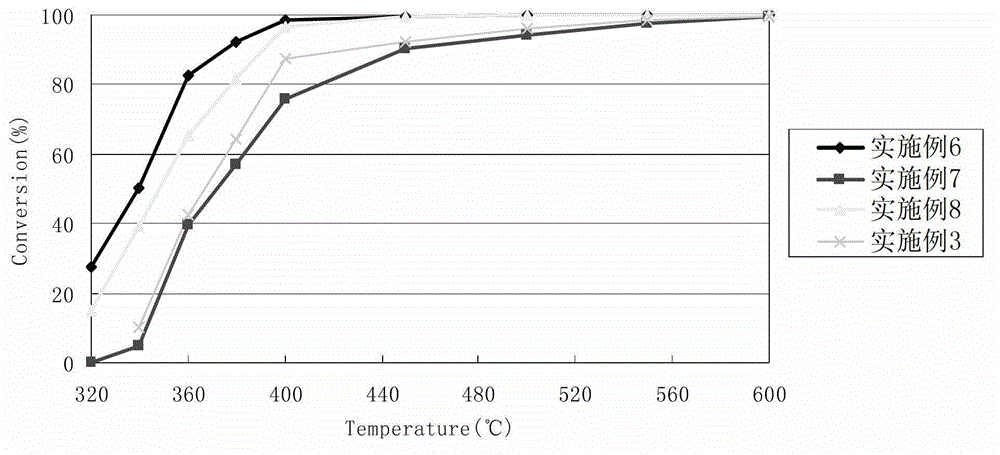

Embodiment 1

[0027] 10%Ce / γ-Al 2 o 3 Preparation of Supported Catalyst Containing 2.0%Pd

[0028] Weigh cerium nitrate [Ce(NO 3 ) 3 .6H 2 O]251.28g, γ-Al 2 o 3 880.00g. [Ce(NO 3 ) 3 .6H 2 O] 251.28g was dissolved in 600g deionized water, stirred and dissolved to a clear solution. γ-Al 2 o 3 Add 880.00g into the dissolved cerium nitrate solution, stir evenly and let stand for 1 hour, then vacuum dry at 80°C for 8 hours, and calcinate at 600°C for 3 hours to obtain Ce / γ-Al 2 o 3 pink. Weigh palladium nitrate [Pd(NO 3 ) 2 ]127.15g was added to 533.33g deionized water, stirred evenly, and the Ce / γ-Al 2 o 3 Add the powder into the palladium nitrate solution, stir rapidly and place it for 1 hour. Then vacuum dry at 80°C for 8 hours, and calcined at 550°C for 2 hours to obtain Pd / Ce / γ-Al 2 o 3 powder (for earthy yellow powder). A binder is added to the khaki powder to prepare a slurry, which is coated on a hole with a mesh number of 400cell / in 2 , with a volume of 2.5ml on ...

Embodiment 2

[0030] 10%Ce / γ-Al2 o 3 Preparation of Supported Catalyst Containing 2.0%Pt

[0031] Ce / γ-Al 2 o 3 The preparation is the same as in Example 1. Weigh palladium nitrate [Pt(NO 3 ) 2 ]65.57g was added to 533.33g deionized water, stirred evenly, and the Ce / γ-Al 2 o 3 Add the powder into the palladium nitrate solution, stir rapidly and place it for 1 hour. Then vacuum-dried at 80°C for 8 hours and calcined at 550°C for 2 hours to obtain Pt / Ce / γ-Al 2 o 3 powder (for earthy yellow powder). A binder is added to the khaki powder to prepare a slurry, which is coated on a hole with a mesh number of 400cell / in 2 , with a volume of 2.5ml on a cordierite ceramic honeycomb carrier, dry and calcined, that is, the precious metal content is 80g / ft 3 single platinum catalyst.

Embodiment 3

[0033] 10%Zr / γ-Al 2 o 3 Preparation of Supported Catalyst Containing 2.0%Pd

[0034] Weigh zirconium nitrate [Zr(NO 3 ) 4 .3H 2 O]333.33g, γ-Al 2 o 3 880.00g. [Zr(NO 3 ) 4 .3H 2 O] 333.33g was dissolved in 600g deionized water, stirred and dissolved to a clear solution. All the other steps are the same as in Example 1, and the available precious metal content is 80g / ft 3 single palladium catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com