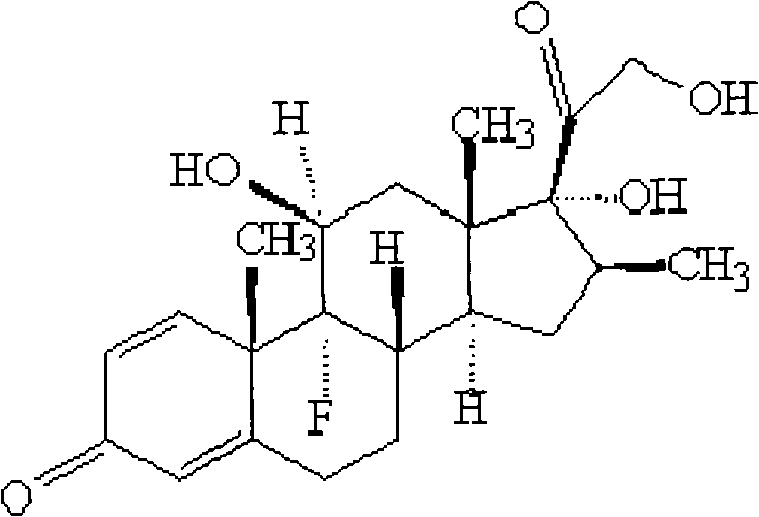

Preparation process of betamethasone intermediate

A technology of preparation process and volume of fermentation liquid, applied in the field of preparation technology of betamethasone intermediates, can solve the problems of low feeding concentration, ineffectiveness, limited conversion effect, etc., and achieves the improvement of fermentation mode, reduction of production cost, and cost saving of auxiliary materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Fermentation broth culture medium (mass percentage): glucose 0.4%, corn steep liquor 0.1%, peptone 0.1%, KH 2 PO 4 0.20%, the rest is water; pH 7.0, filter to remove the sediment, each 500ml shake flask is filled with 200ml fermentation medium, the bottom of the shake flask is covered with 50ml thick ceramic beads with a diameter of 4mm, and sterilized at 121°C for 30 minutes.

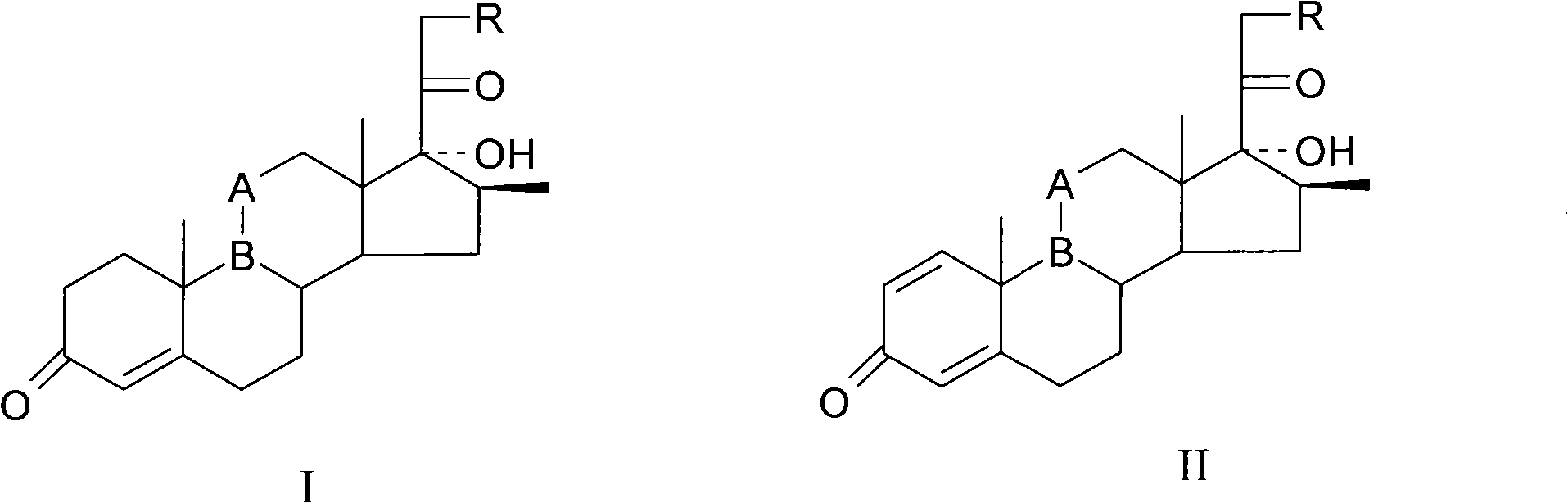

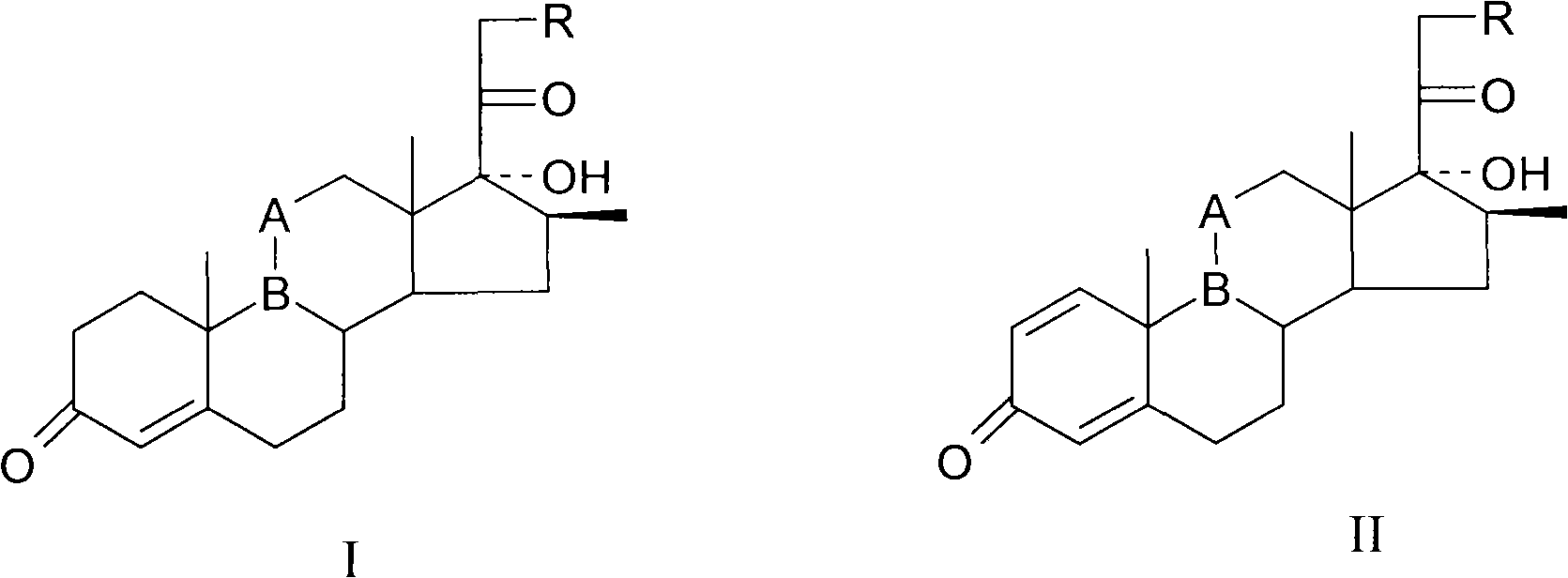

[0032] b. 16β-Methyl-17α,21-dihydroxy-pregna-4-ene-3,20-dione, through ordinary mechanical crushing or grinding, the particle size reaches about 100 mesh.

[0033] Operation process: Inoculate the simple Arthrobacter bacteria that has grown on the slope into a sterilized fresh fermentation medium, the rotation speed of the shaker is 200r / min, and the culture temperature is 30°C. After culturing for 22 hours, 1.0 g (feeding concentration of 0.5%) mechanically crushed 16β-methyl-17α,21-dihydroxy-pregn-4-ene-3,20-dione was introduced. The rotating speed of the shaker is 200r / min, and the culture temp...

Embodiment 2

[0036] a. Fermentation broth medium (mass percentage): glucose 0.8%, corn steep liquor 0.6%, peptone 0.5%, KH 2 PO 4 0.10%, the rest is water; pH 7.2, filter to remove the sediment, each 500ml shake bottle with a volume of 200ml, cover the bottom with 40mm thick glass beads with a diameter of 6mm, and sterilize at 121°C for 30 minutes.

[0037] b. 16β-Methyl-17α,21-dihydroxy-pregna-4,9(11)-diene-3,20-dione, through ordinary mechanical crushing or grinding, the particle size reaches about 120 mesh.

[0038] Operation process: Scrape three full loops of simple Arthrobacter cells that have grown on the inclined surface, and inoculate them into sterilized fresh fermentation medium. The rotation speed of the shaker is 200r / min, and the culture temperature is 30℃. After culturing for 20 hours, 1 g (feeding concentration of 0.5%) mechanically crushed 16β-methyl-17α,21-dihydroxy-pregna-4,9(11)-diene-3,20-dione was added. After casting, the shaker rotates at 200r / min and the culture tempera...

Embodiment 3

[0041] a. Fermentation broth medium (mass percentage): glucose 0.6%, corn steep liquor 0.8%, peptone 0.3%, KH 2 PO 4 0.15%, the rest is water; pH 7.1, filter to remove the sediment, each 500ml shake bottle with 200ml, 25ml thick ceramic beads with a diameter of 2mm on the bottom, and sterilize at 121°C for 30min.

[0042] b. 16β-Methyl-17α,21-dihydroxy-pregn-4-ene-3,11,20-trione, through ordinary mechanical crushing or grinding, the particle size reaches about 140 mesh.

[0043] Operation process: Scrape three full loops of simple Arthrobacter cells that have grown on the inclined surface, and inoculate them into sterilized fresh fermentation medium. The rotation speed of the shaker is 200r / min, and the culture temperature is 30℃. After culturing for 22 hours, 1 g (feeding concentration of 0.5%) mechanically crushed 16β-methyl-17α,21-dihydroxy-pregna-4-ene-3,11,20-trione was added. After casting, the shaker rotates at 200r / min and the culture temperature is 33°C. After 65 hours of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com