Low-temperature methane steam reforming catalyst and preparation method thereof

A technology of methane steam and reforming catalyst, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor catalytic effect, long production cycle and high preparation cost, and achieve shortened time, improve production efficiency, and avoid the effects of high preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

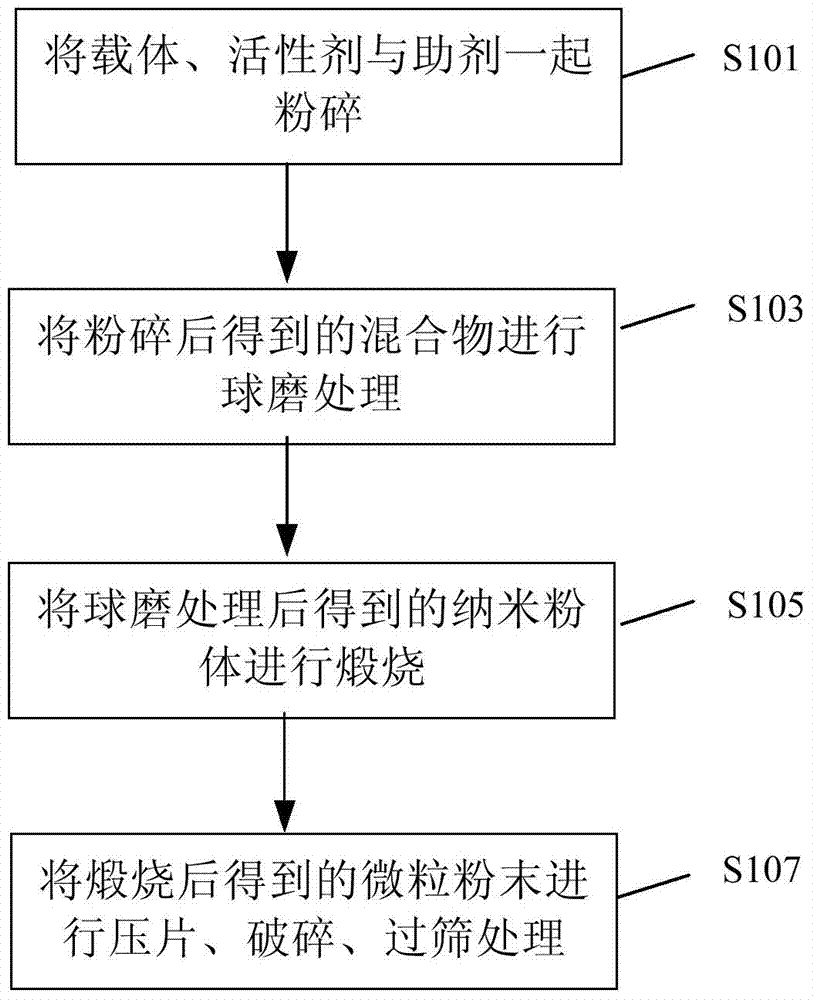

[0028] Catalyst preparation method

[0029] Such as figure 1 As shown in step S101, the carrier, active agent and auxiliary agent are put into a pulverizer together for pulverization. The pulverizer used is a small laboratory frequency conversion speed regulation pulverizer (model RT-08SC). In some embodiments, the amount of filler in the pulverizer is 30% to 70%, and the rotational speed of the controller is in the range of about 10000r / m to about 25000r / m. In some embodiments, the crushing time is controlled within the range of 10 minutes to 20 minutes. In a preferred embodiment, the carrier includes nano-Al 2 o 3 , cordierite nano powder and nano SO 2 etc.; the active agent is a nickel-containing compound including one of nickel hydroxide, nickel nitrate, nickel carbonate, nickel chloride and nickel acetate or any combination thereof, and the auxiliary agent includes zirconium nitrate, potassium nitrate, magnesium nitrate, nitric acid Nitrates of calcium, cerium nit...

Embodiment 1

[0035] Nano Al 2 o 3, nickel nitrate and additives are put into the grinder at a mass ratio of 10:2:0.5, wherein the additives include cerium nitrate and zirconium nitrate, and their mass ratio is 3:2. The filler content of the pulverizer is 40%, the speed of the pulverizer is controlled to be 10000r / m, and the pulverization time is 10 minutes. Then put the pulverized mixture into a high-energy ball mill, control the speed of the ball mill to 400r / m, and control the ball milling time to 25 minutes. The obtained particle mixture is the catalyst precursor powder. The precursor powder obtained in the ball milling process was calcined at a temperature of 400° C. for 3 hours to obtain particle powder. The obtained catalyst powder is pressed into tablets and pulverized into 60-80 mesh particles to finally obtain catalyst particles.

Embodiment 2

[0037] Nano Al 2 o 3 , nickel nitrate and additives are put into the grinder at a mass ratio of 10:1.5:0.2, wherein the additives include cerium nitrate, zirconium nitrate and manganese nitrate, and their mass ratio is 2:1:1. The filler content of the pulverizer is 45%, the speed of the pulverizer is controlled to be 15000r / m, and the pulverization time is 12 minutes. Then put the pulverized mixture into a high-energy ball mill, control the speed of the ball mill to 500 r / m, and control the ball milling time to 20 minutes, and the obtained particle mixture is the catalyst precursor powder. The precursor powder obtained in the ball milling process was calcined at a temperature of 500° C. for 3 hours to obtain particle powder. The obtained catalyst powder is pressed into tablets and pulverized into 60-80 mesh particles to finally obtain catalyst particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com