Nitrogenous zeolite and preparing method thereof

A zeolite and mordenite technology, applied in chemical instruments and methods, catalyst activation/preparation, molecular sieve catalysts, etc., to achieve the effects of good selectivity, high thermal stability, crystal retention, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

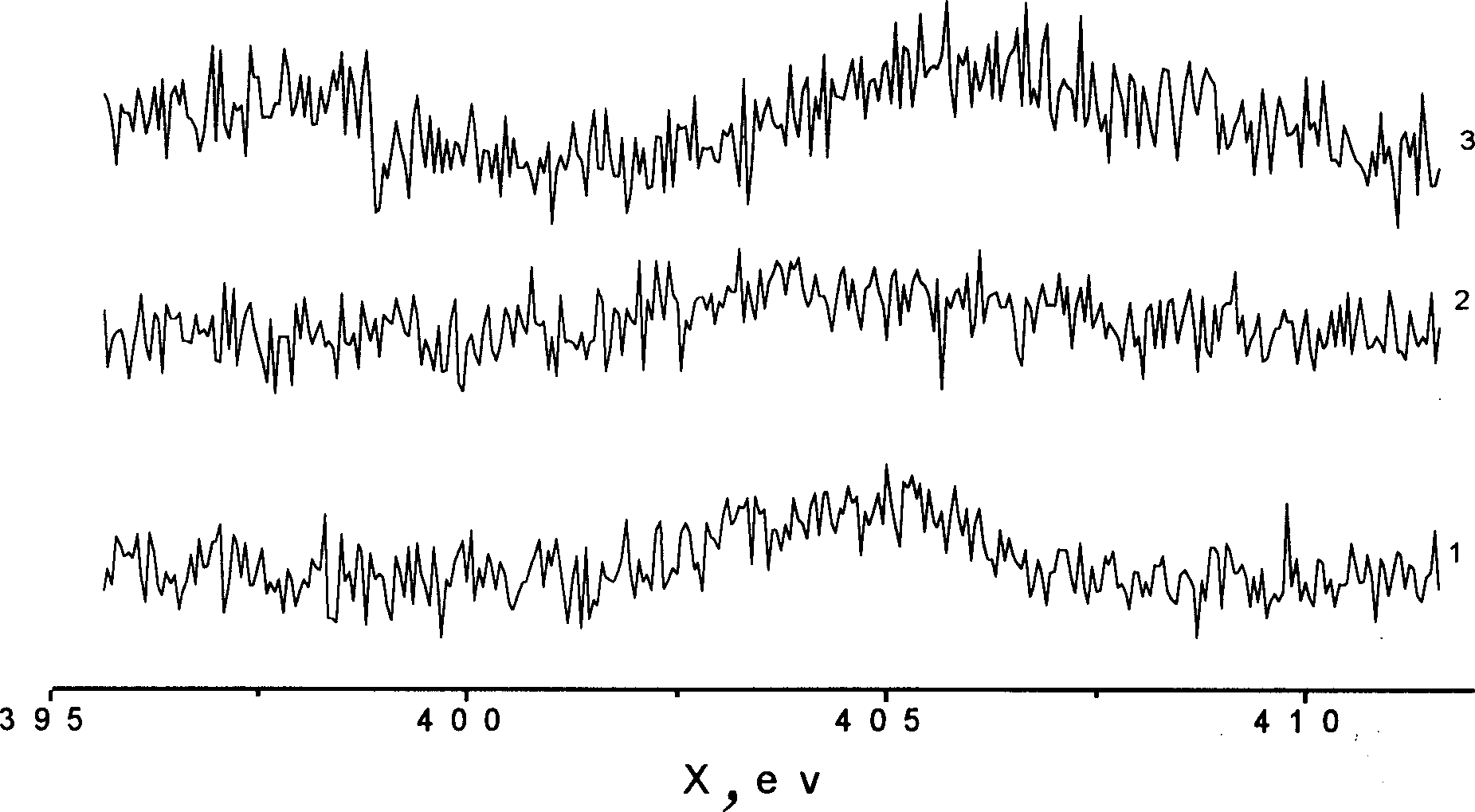

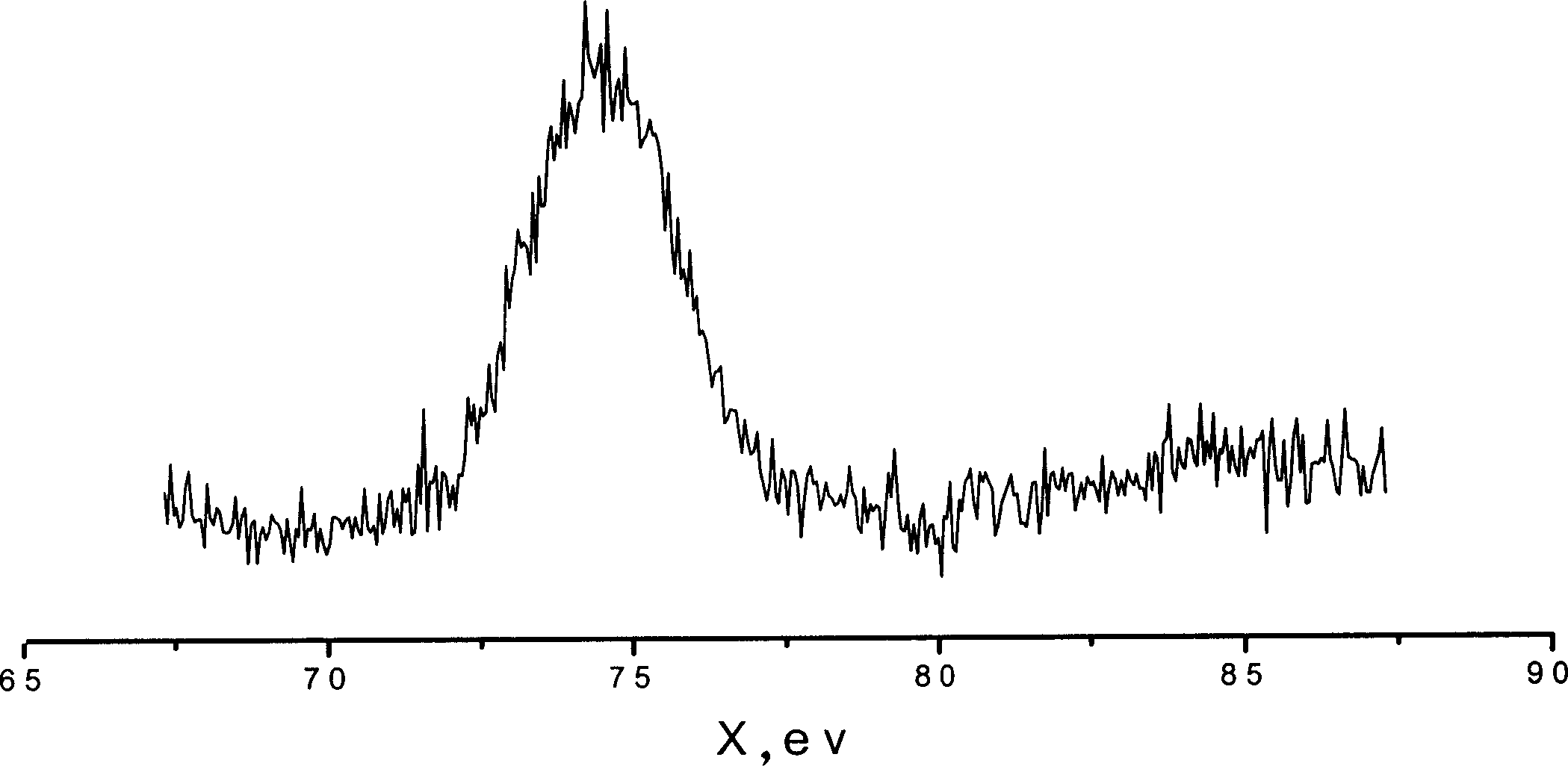

Image

Examples

preparation example Construction

[0015] The preparation method of nitrogen-containing zeolite provided by the present invention comprises the following steps: directly mix ammonium nitrate and zeolite according to the weight ratio of 0.1-30:1, and heat at 50-600° C. for 0.1-15 hours, preferably in airtight Heating at 80-550° C. for 0.5-10 hours under conditions, washing with deionized water, and recovering the obtained zeolite.

[0016] The raw material zeolite can be one or more of the existing aluminosilicate zeolites, can be a zeolite with large pores, such as faujasite, Beta zeolite, omega zeolite, or a zeolite with medium pores, such as Mordenite, ZSM-5, ZSM-11, ZSM-22, ZSM-23, ZSM-35, ZSM-48, ZSM-57 and other zeolites, can also be zeolites with small pores, such as erionite, ZSM-34 zeolite . The raw material zeolite is preferably one or more of Y-type zeolite, mordenite, and zeolite with ZSM-5 structure. The most preferred raw material zeolite is: one or more of HY zeolite, REY zeolite, REHY zeolite, ...

Embodiment 1

[0022] The present invention provides the preparation of nitrogen-containing zeolites.

[0023] (1) take by weighing 200 grams of NaY zeolite (sodium oxide content 12% by weight, unit cell constant 2.468 nanometers) and 2 liters, ammonium sulfate concentration is 0.5 mol / liter, the ammonium sulfate of PH4-5 and the mixed solution of sulfuric acid mix, Perform ion exchange at 80° C. for 1 hour, filter, and wash the solid with deionized water until there is no free acid ion. The ion exchange process was performed twice. The resulting molecular sieve (abbreviated as B) was dried.

[0024] (2) Weigh 150 grams of the above-mentioned molecular sieve B, mix it with 750 grams of ammonium nitrate, and roast it at 300°C for 1 hour under airtight conditions to obtain the nitrogen-containing (elementally, the same below) 0.77 % by weight of Y-type zeolite A1.

Embodiment 2

[0026] Preparation of the nitrogen-containing zeolite provided by the invention.

[0027] Prepared by the same steps as in Example 1, the difference is that the amount of ammonium nitrate in step (2) is 1500 grams, the calcination temperature is 500 ° C, and the calcination time is 0.5 hour to obtain a nitrogen-containing 1.43% by weight Y-type zeolite A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com