Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of unstable molecular sieve framework and lower crystal retention, so as to improve hydrothermal stability, reduce reaction dosage, Effect of lowering exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the phosphorus-silicate-aluminum glue is: phosphoric acid and pseudo-boehmite are prepared under acidic conditions, and the phosphorus-aluminum glue is prepared, P 2 o 5 / Al 2 o 3 Mass ratio=2.8-5.0, the reaction temperature is controlled between 55-85°C, the solid content of the slurry is 40% according to phosphorus pentoxide and aluminum oxide during preparation, slowly add silica sol and stir in the phosphorus-aluminum glue, so that The pH of the system is controlled between 2.5-4.0.

[0034] Described silica sol is alkaline silica sol, and it contains SiO 2 20-40wt%, Na 2 O≤0.2wt%, pH 9-10, SiO 2 Colloidal particle diameter 7-13nm.

[0035] A preparation method for catalytic cracking catalyst, comprising the following steps:

[0036] (1) Clay and deionized water are mixed and beaten until fully uniform, and active components and binders are respectively added to the slurry, mixed and stirred, spray-dried and granulated after acidifi...

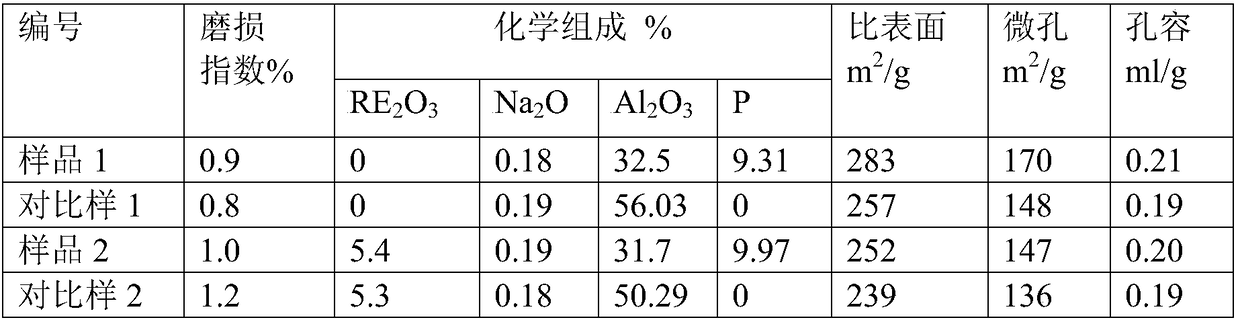

Embodiment 1

[0059] (1) Mix 1658g of kaolin and deionized water for beating, and add 1000g of USY cross-baked molecular sieve and 2027g (calculated as phosphorus pentoxide, aluminum oxide and silicon oxide) of phosphorus-silicon-alumina gel to the slurry and mix and stir 3h, beating evenly and then spray drying to obtain the primary product.

[0060] (2) 1000 g of the obtained primary product was roasted in a muffle furnace at 380° C. for 1.5 h to obtain a roasted product, and after the reaction, the roasted product was taken out and cooled to 300° C.

[0061] (3) Introduce gaseous SiCl with a temperature of 85°C into the reactor containing the roasted product 4 120g.

[0062] (4) The reacted product was beaten with 4500 g of deionized water, washed with 5000 g of deionized water, filtered, and dried to obtain catalyst sample 1.

Embodiment 2

[0064] (1) Mix 1658g of kaolin and deionized water for beating, and add 1000g of REY cross-baked molecular sieve and 2027g (calculated as phosphorus pentoxide, aluminum oxide and silicon oxide) of phosphorus-silicon-aluminum glue to the slurry and mix and stir 3h, beating evenly and then spray drying to obtain the primary product.

[0065] (2) 1000 g of the obtained primary product was roasted in a muffle furnace at 380° C. for 1.5 h to obtain a roasted product, and after the reaction, the roasted product was taken out and cooled to 300° C.

[0066] (3) Introduce gaseous SiCl with a temperature of 85°C into the reactor containing the roasted product 4 120g.

[0067] (4) The reacted product was beaten with 4500g of deionized water, washed with 5000g of deionized water, finally filtered, and dried to obtain catalyst sample 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com