Phosphorus-modified ZSM-5 molecular sieve and preparation method thereof

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as unsatisfactory hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

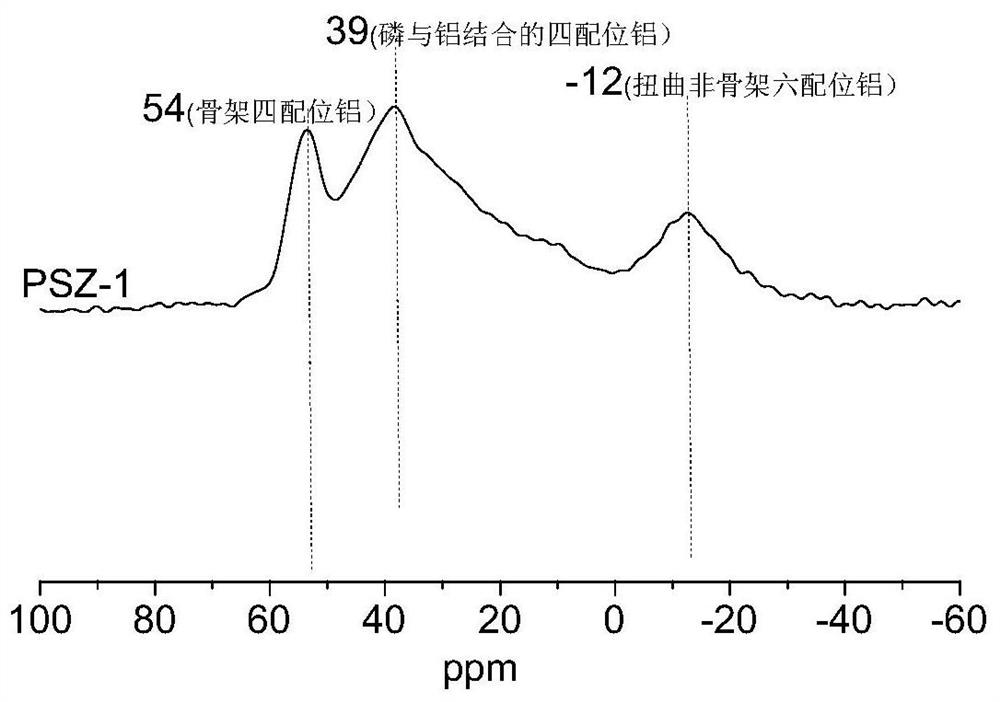

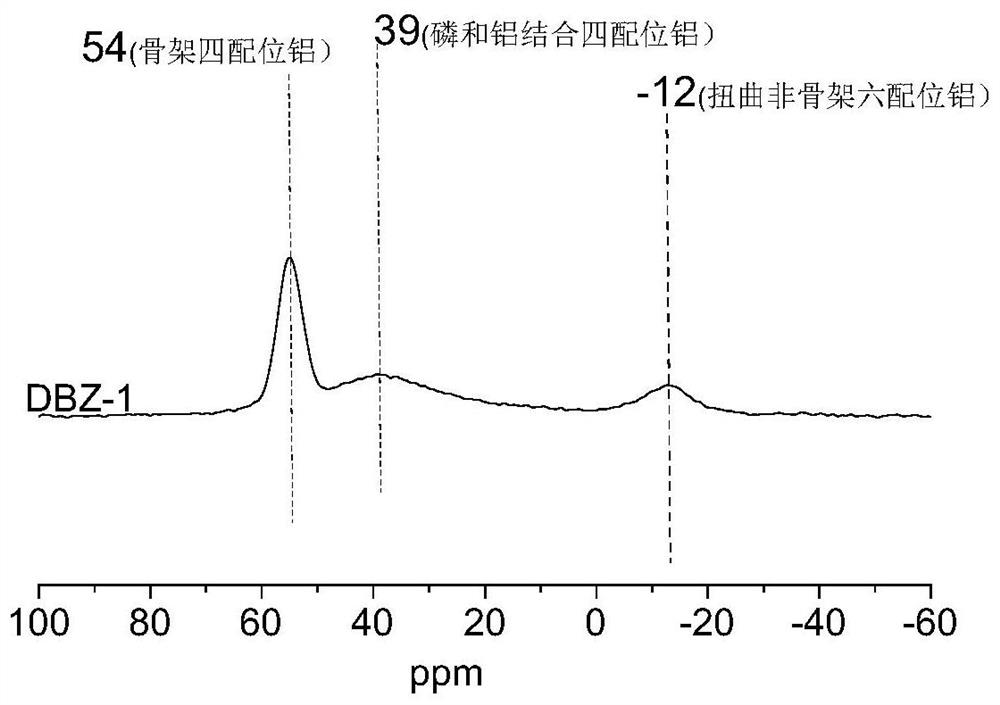

[0033] Example 1-1 illustrates the phosphorus-modified ZSM-5 molecular sieve and process of the present invention.

[0034] Get 16.2g diammonium hydrogen phosphate (Tianjin Guangfu Science and Technology Development Co., Ltd., analytically pure, the same below) and dissolve it in 60g deionized water, stir for 0.5h to obtain a phosphorus-containing aqueous solution, add 113g HZSM-5 molecular sieve (Sinopec catalyst company Qilu Provided by the branch company, the relative crystallinity is 91.1%, the silica / alumina molar ratio is 24.1, and the Na 2 The O content is 0.039% by weight and the specific surface area is 353m 2 / g, the total pore volume is 0.177ml / g, the same below), modified by impregnation, impregnated at 20°C for 2 hours, dried in an oven at 110°C, applied external pressure and added water, at 500°C, The phosphorus-modified ZSM-5 molecular sieve sample obtained by treating under 0.5Mpa and 50% water vapor atmosphere for 0.5h is designated as PSZ1-1.

Embodiment 1-2

[0036] Examples 1-2 illustrate the phosphorus-modified ZSM-5 molecular sieves and methods of the present invention.

[0037] The materials, proportioning, drying and roasting are the same as those in Example 1-1, except that diammonium hydrogen phosphate, HZSM-5 molecular sieve and water are mixed and beaten into a slurry, and the temperature is raised to 100° C. for 2 hours. The obtained phosphorus-modified ZSM-5 molecular sieve sample is denoted as PSZ1-2.

Embodiment 2-1

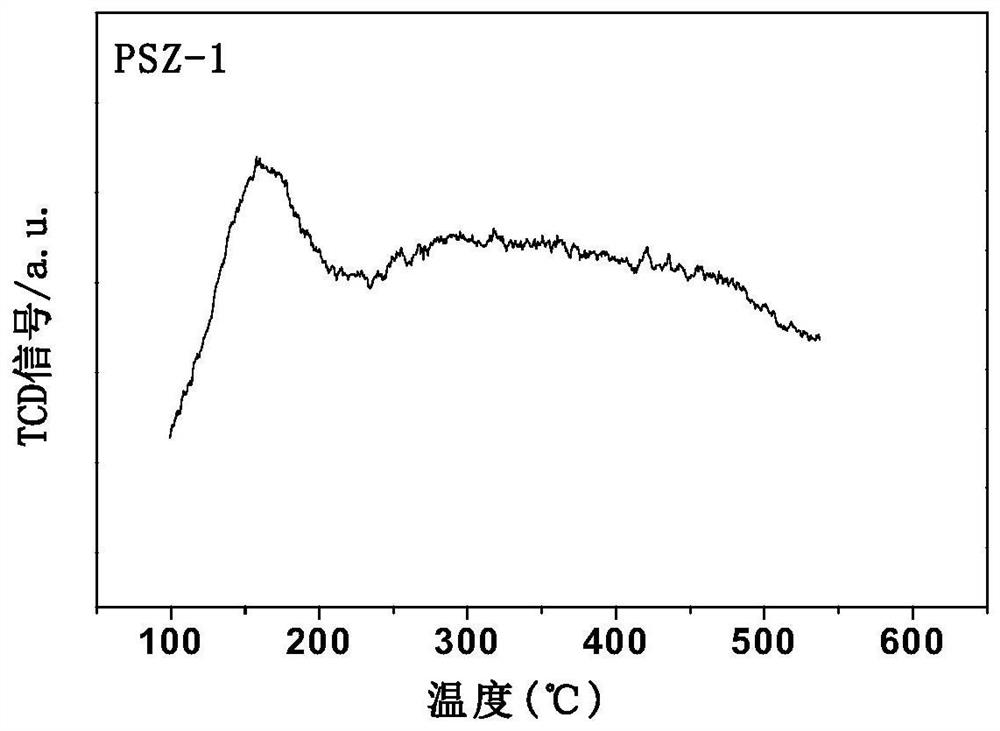

[0061] Example 2-1 illustrates the phosphorus-modified ZSM-5 molecular sieve and process of the present invention.

[0062] Dissolve 16.2g of diammonium hydrogen phosphate in 120g of deionized water at 50°C, stir for 0.5h to obtain a phosphorus-containing aqueous solution, add 113g of HZSM-5 molecular sieve, modify it by impregnation, soak it at 20°C for 2 hours, and then soak it at 110°C Dry it in a lower oven, apply external pressure and add water, pressurize hydrothermal calcination at 600°C, 0.5Mpa, and 30% water vapor atmosphere for 2 hours, and obtain a phosphorus-modified ZSM-5 molecular sieve sample, which is designated as PSZ-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com