Hydrocracking method for preparation of high-octane naphtha

A hydrocracking and hydrogenation activity technology, applied in chemical instruments and methods, petroleum industry, hydrotreating process, etc., can solve the problems of high yield, harsh operating conditions, influence of catalyst service life, etc., and achieve the adaptability of raw materials Strong, good product quality, high octane effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

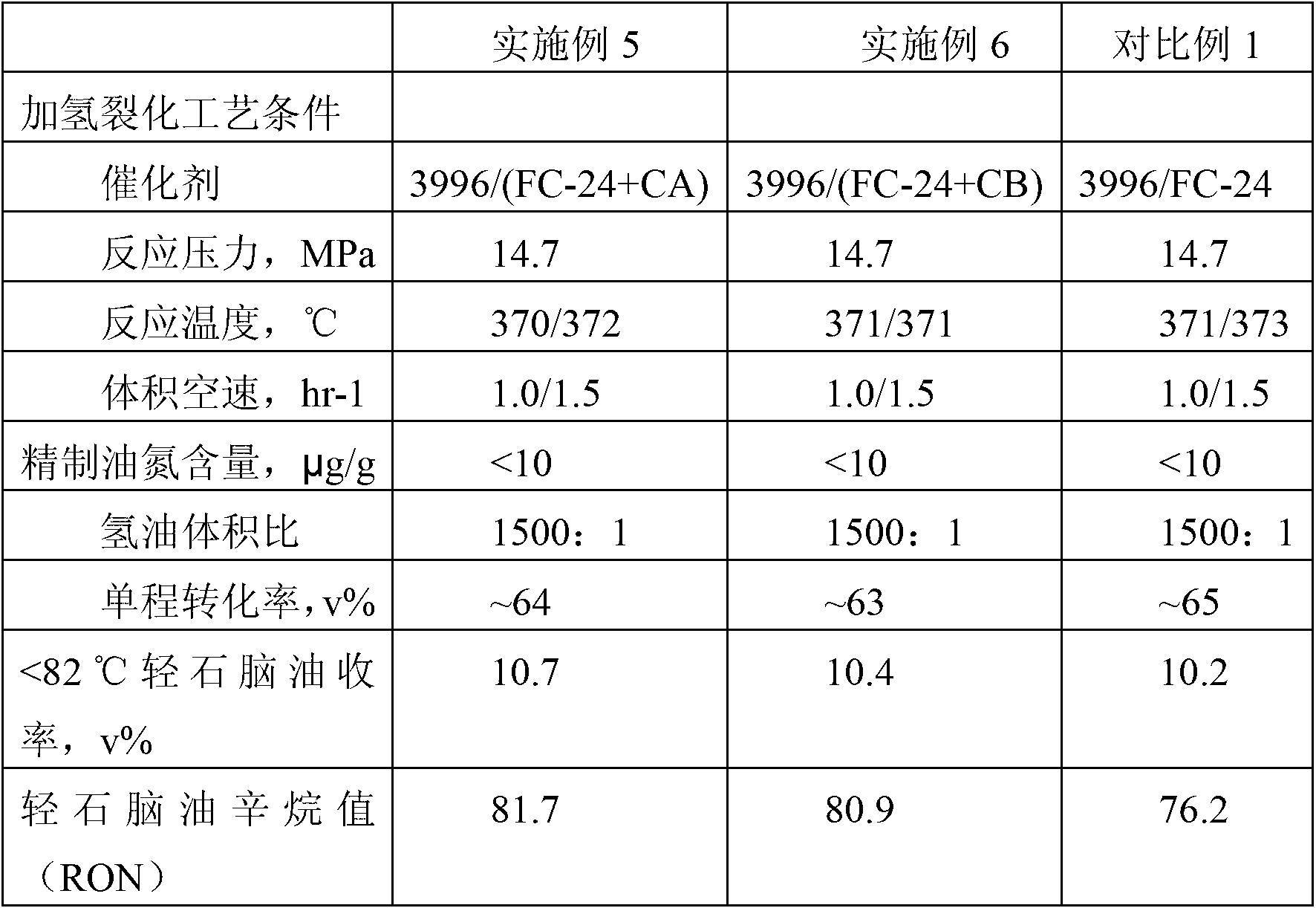

Examples

Embodiment 1

[0050] Embodiment 1, preparation contains the catalyst CA of composite molecular sieve

[0051] The modified Y molecular sieve NTY (relative crystallinity is 97%, unit cell parameter is 2.432nm, specific surface area is 781m 2 / g, SiO 2 / Al 2 o 3 The molar ratio is 12.9, the total infrared acid is 1.06mmol / g) and SAPO-11 molecular sieve (the pore volume is 0.18ml / g, the specific surface area is 223m 2 / g) according to the mass ratio of 1:1 mixed to obtain a composite molecular sieve, take 200 grams of composite molecular sieve, MoO 3 (Based on the mass of molybdenum oxide) 37.5 grams, Ni(NO 3 ) 2 ·6H 2 O (based on the mass of nickel oxide) 145 grams, amorphous silicon aluminum (SiO 2 Content 50wt%, pore volume 0.85ml / g, specific surface area 370m 2 / g, dry basis 75wt%) 35 grams, macroporous alumina (pore volume 1.0ml / g, specific surface area 400m 2 / g, 75wt% on a dry basis) 80 grams, binder (30wt% on a dry basis, the molar ratio of nitric acid to small-pore alumina is...

Embodiment 2

[0054] Embodiment 2, preparation contains the catalyst CB of composite molecular sieve

[0055] NTY (relative crystallinity is 97%, unit cell parameter is 2.432nm, specific surface area is 781m 2 / g, SiO 2 / Al 2 o 3 The molar ratio is 12.9, the total infrared acid is 1.06mmol / g) and SAPO-11 molecular sieve (the pore volume is 0.18ml / g, the specific surface area is 223m 2 / g) according to the mass ratio of 3:1 mixed to obtain a composite molecular sieve, take 200 grams of composite molecular sieve, MoO 3 37.5 grams, Ni(NO 3 ) 2 ·6H 2 O145 grams, amorphous silicon aluminum (SiO 2 Content 50wt%, pore volume 0.85ml / g, specific surface area 370m 2 / g, dry basis 75wt%) 35 grams, macroporous alumina (pore volume 1.0ml / g, specific surface area 400m 2 / g, 75wt% on a dry basis) 80 grams, binder (30wt% on a dry basis, the molar ratio of nitric acid to small-pore alumina is 0.3, the pore volume of small-pore alumina is 0.46ml / g, and the specific surface area is 280m 2 / g) 66.5 g...

Embodiment 3

[0058] Embodiment 3, preparation contains the catalyst CC of composite molecular sieve

[0059] NTY (relative crystallinity is 97%, unit cell parameter is 2.432nm, specific surface area is 781m 2 / g, SiO 2 / Al 2 o 3 Molar ratio is 12.9, total infrared acid is 1.06mmol / g) and SAPO-11 molecular sieve (pore volume is 0.18ml / g, specific surface area is 223m 2 / g) by mass ratio 3:1 mixed to obtain a composite molecular sieve, get 160 grams of composite molecular sieve, MoO 3 37.5 grams, Ni(NO 3 ) 2 ·6H 2 O145 grams, amorphous silicon aluminum (SiO 2 Content 50wt%, pore volume 0.85ml / g, specific surface area 370m 2 / g, dry basis 75wt%) 35 grams, macroporous alumina (pore volume 1.0ml / g, specific surface area 400m 2 / g, dry basis 75wt%) 133 grams, binder (dry basis 30wt%, the mol ratio of nitric acid and small-pore alumina is 0.3, the pore volume of small-pore alumina is 0.46ml / g, specific surface area is 280m 2 / g) 66.5 grams are placed in a roller compactor for kneading a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com