Patents

Literature

49results about "Heads with composite cores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

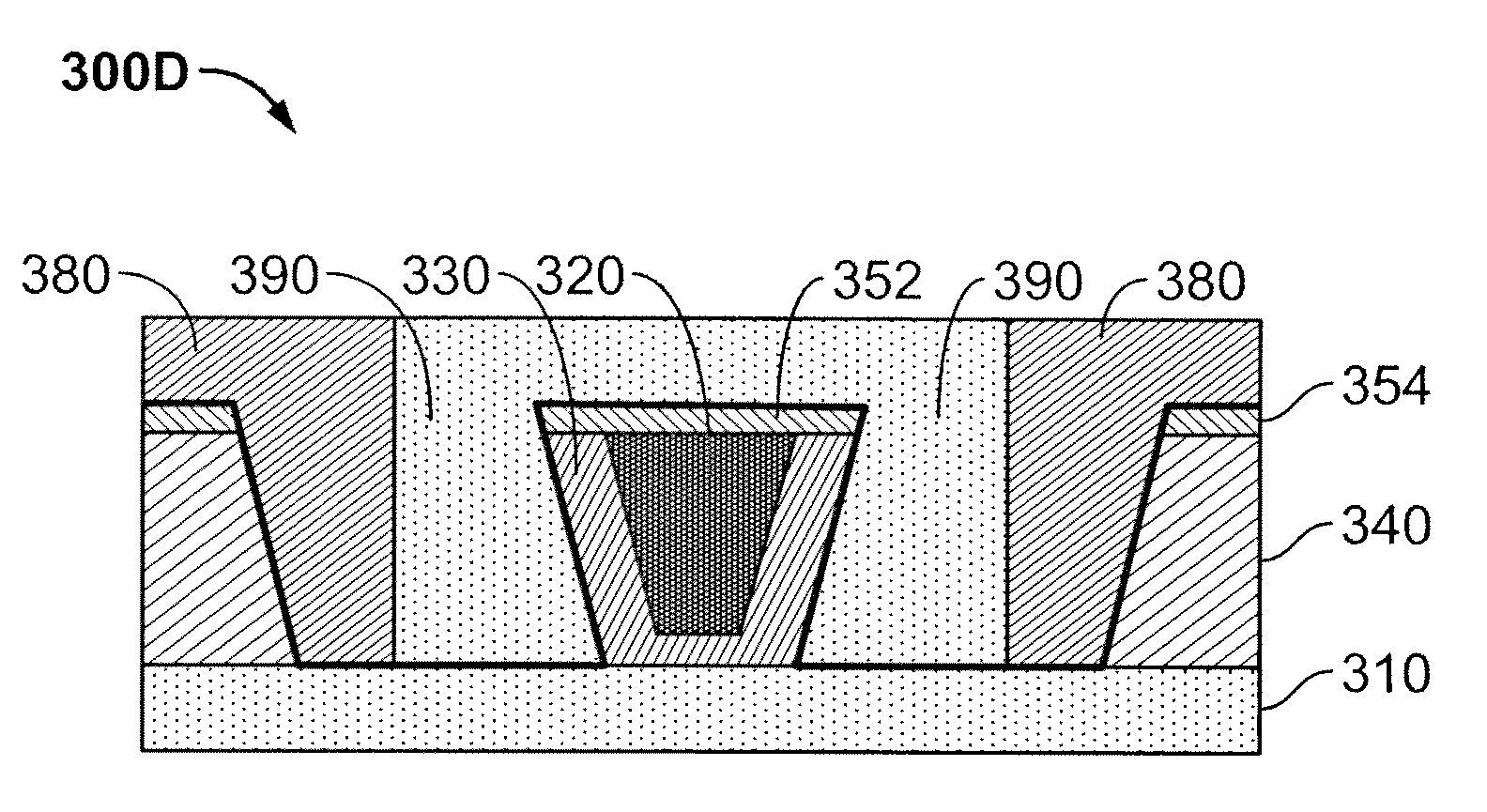

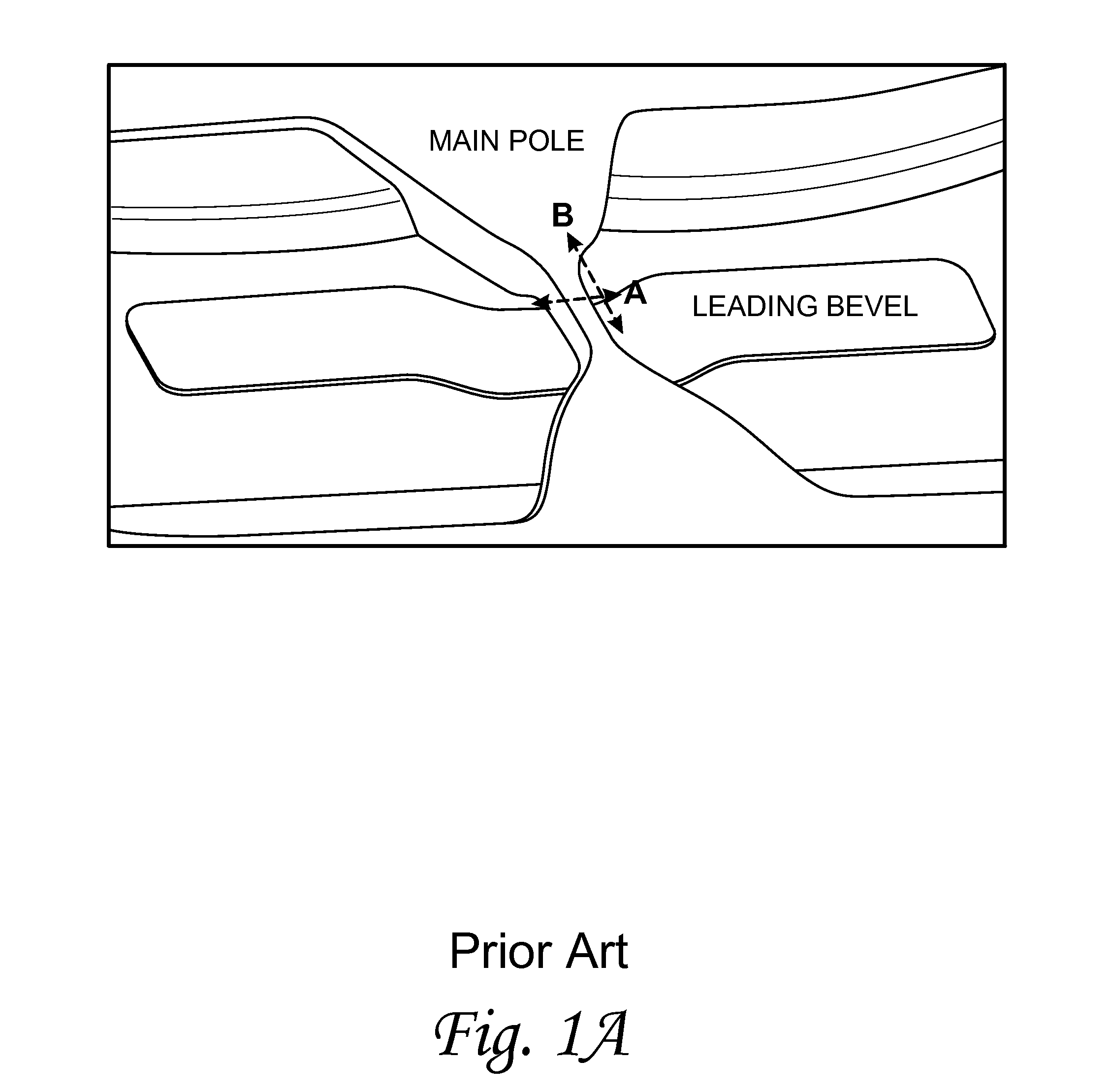

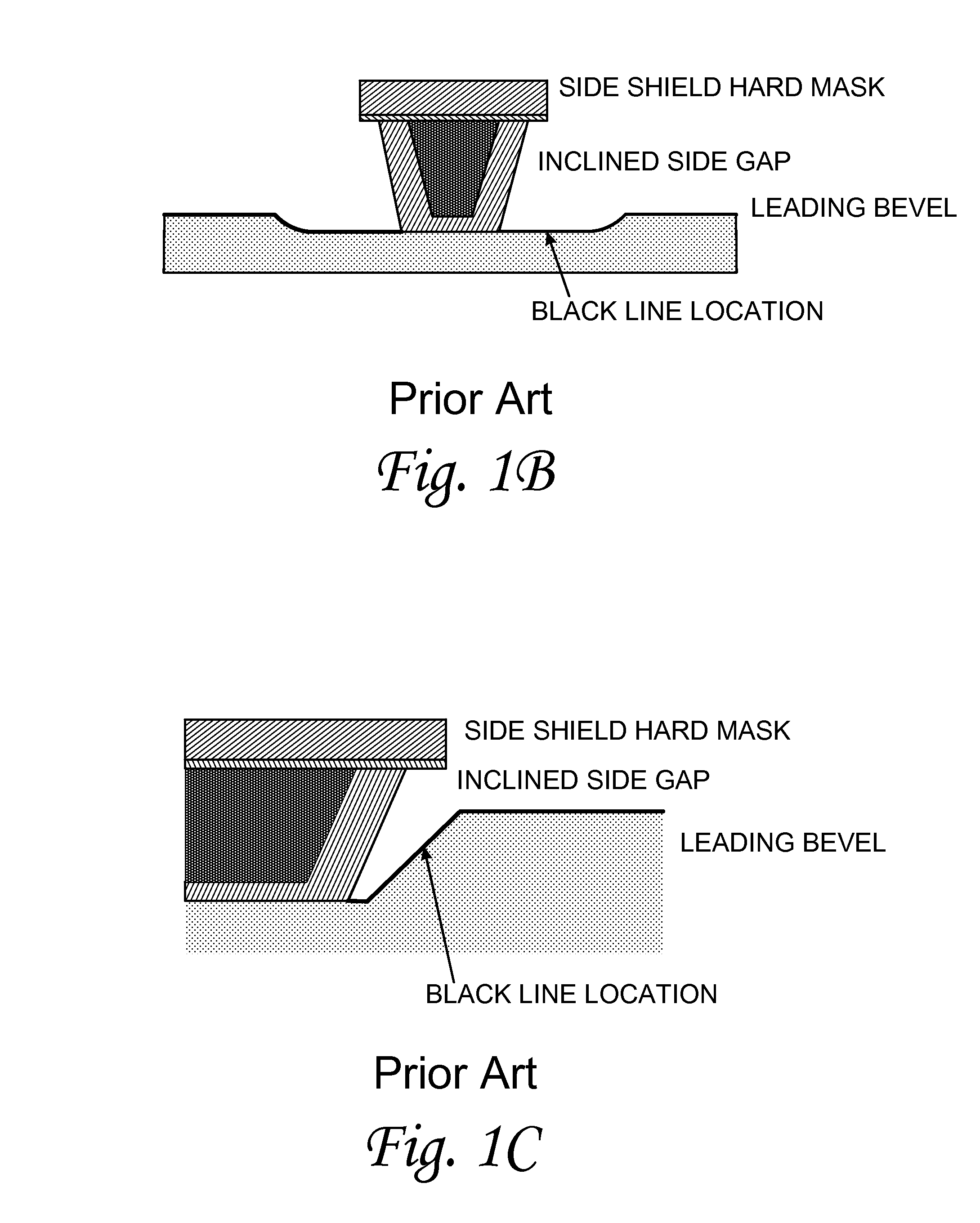

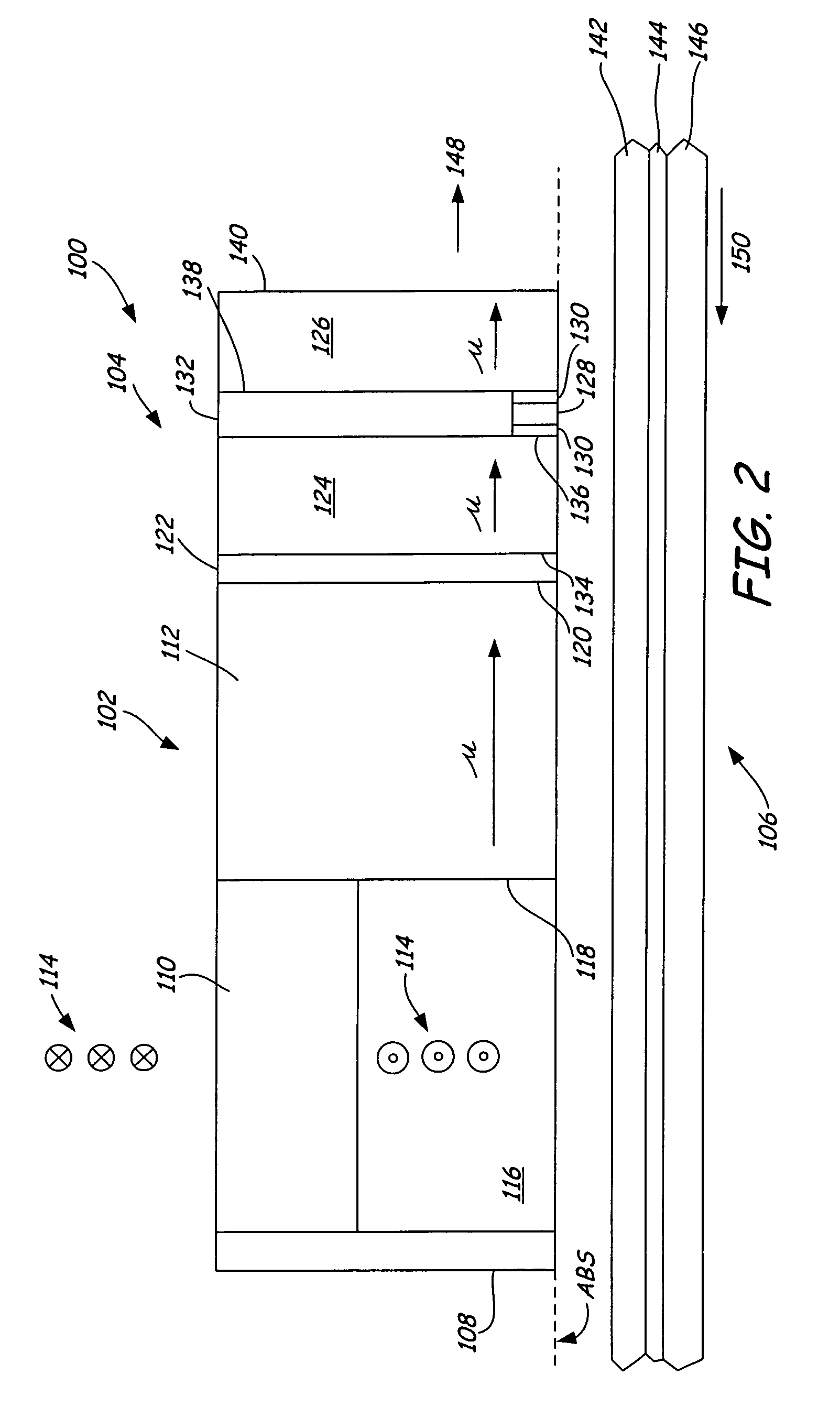

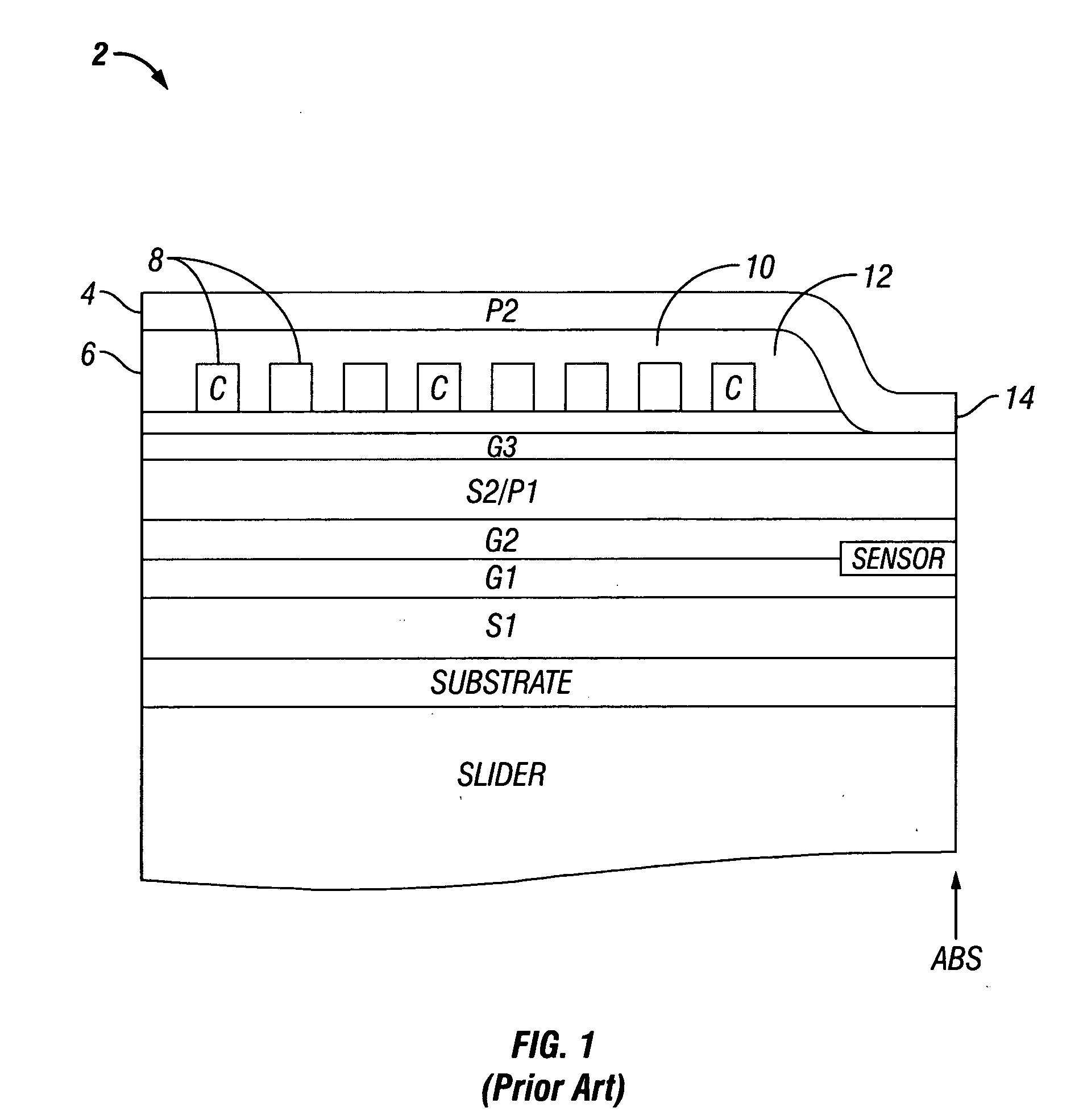

Method of forming a fully wrapped-around shielded PMR writer pole

InactiveUS8533937B1Reduce and eliminate shadowing effectGood deposition coverageElectrical transducersManufacture head surfaceEngineeringNon magnetic

A method or forming a wrapped-around shielded perpendicular magnetic recording writer pole is disclosed. A structure comprising a leading shield layer and an intermediate layer disposed over the leading shield layer is provided, the intermediate layer comprising a pole material and a dielectric material. A trench is formed in the dielectric material. A non-magnetic layer in the trench is removed via an ion beam etching process. A seed layer is deposited in the trench and over the pole material. A magnetic material comprising a side shield layer is deposited on at least a portion of the seed layer.

Owner:WESTERN DIGITAL TECH INC

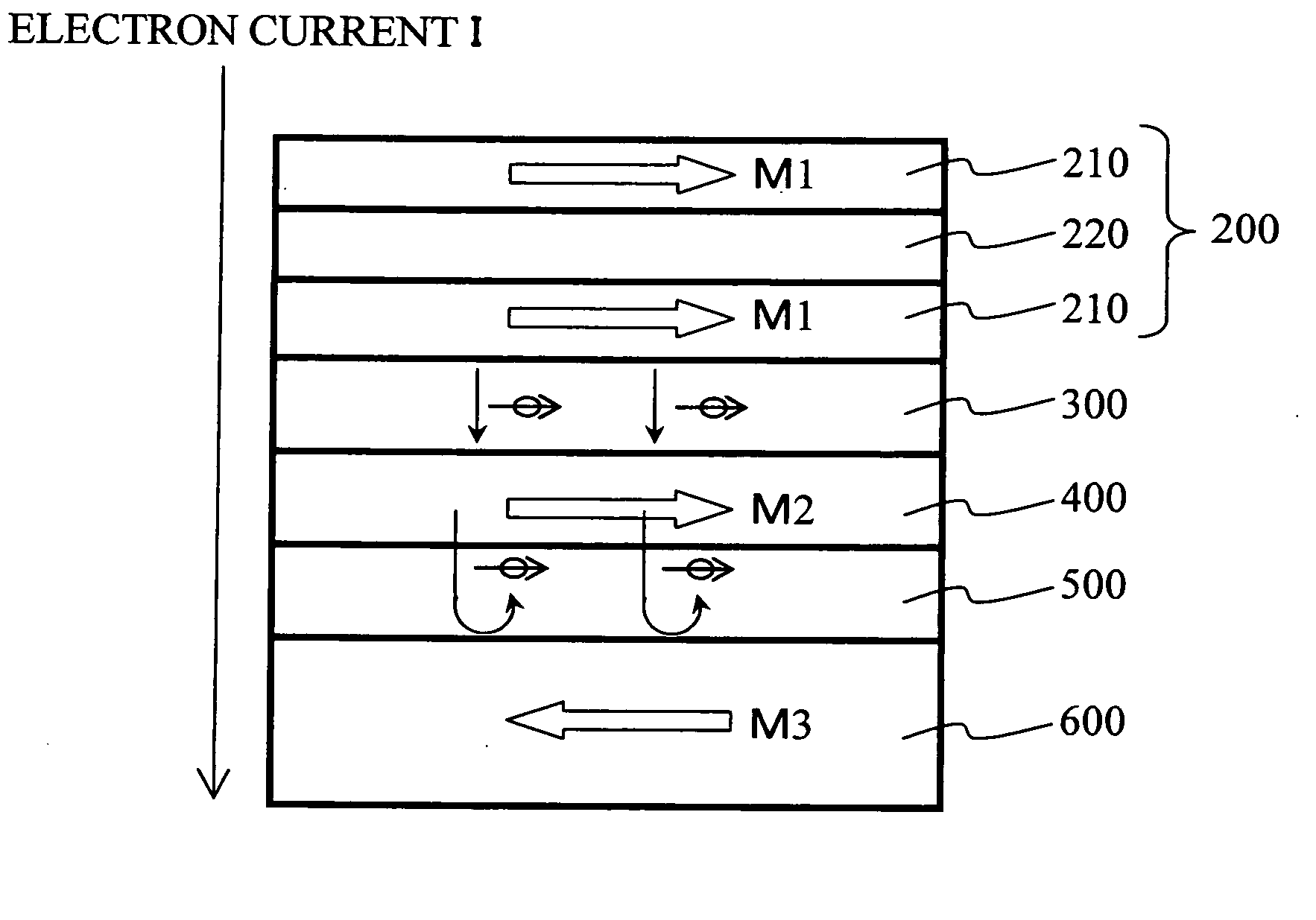

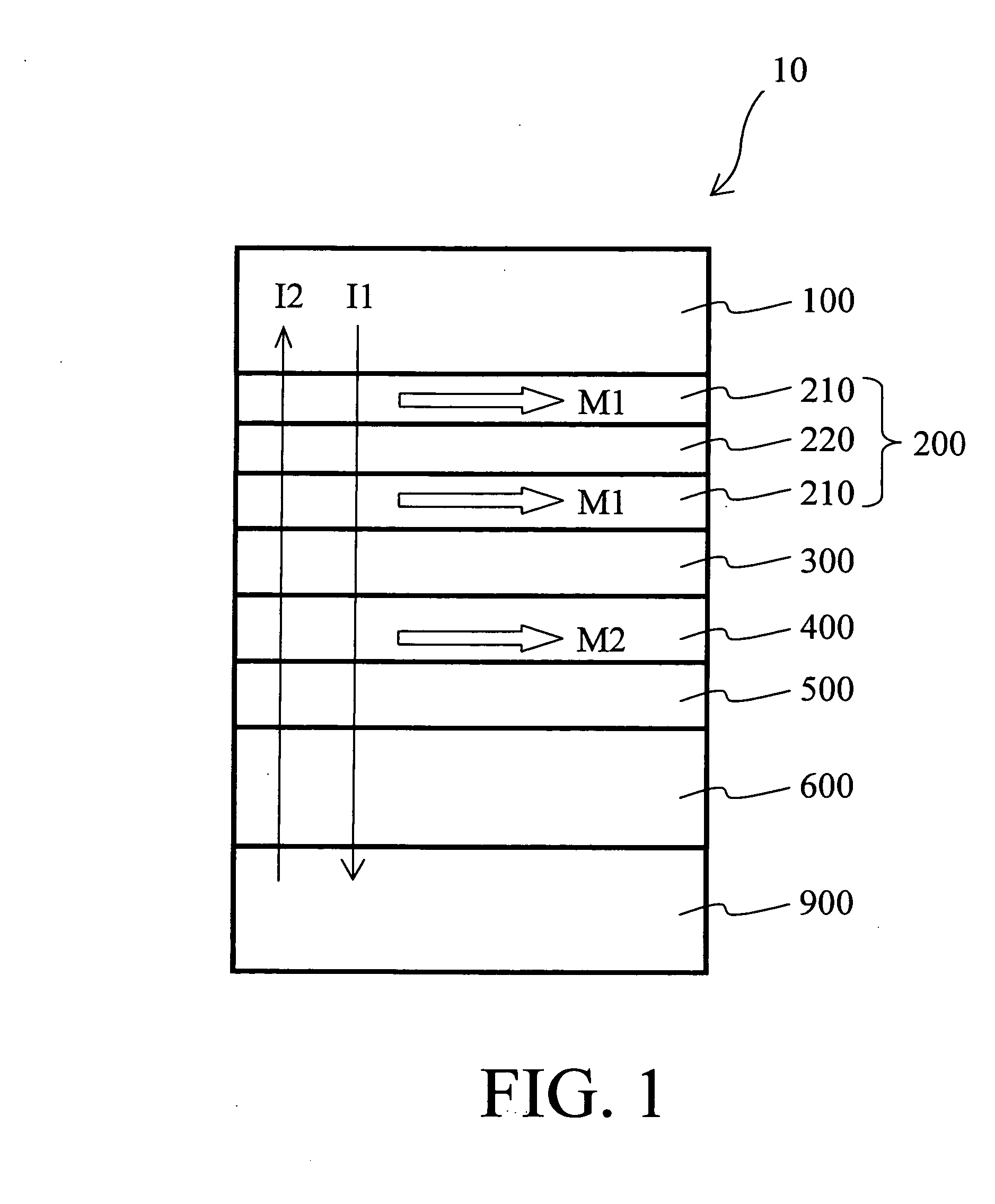

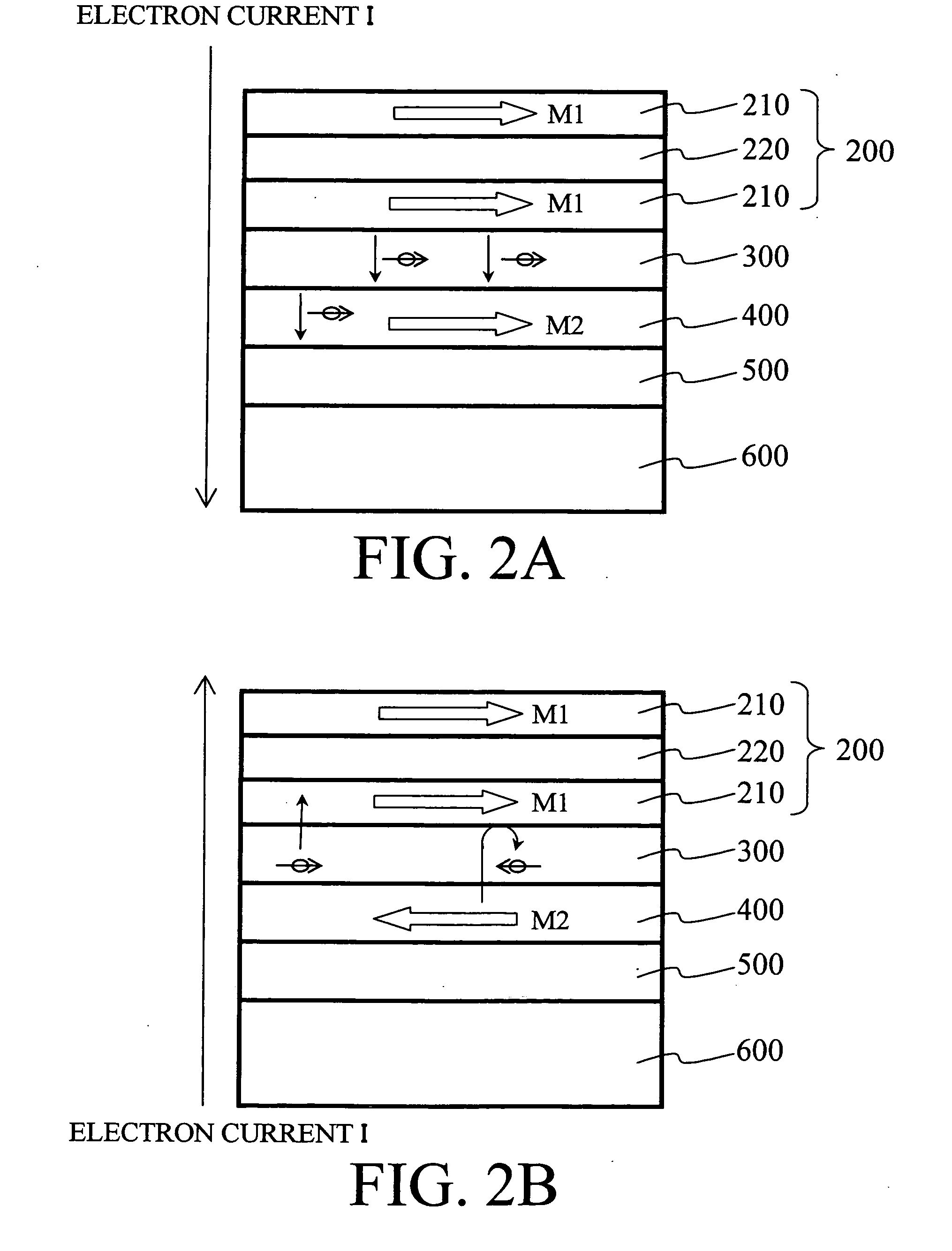

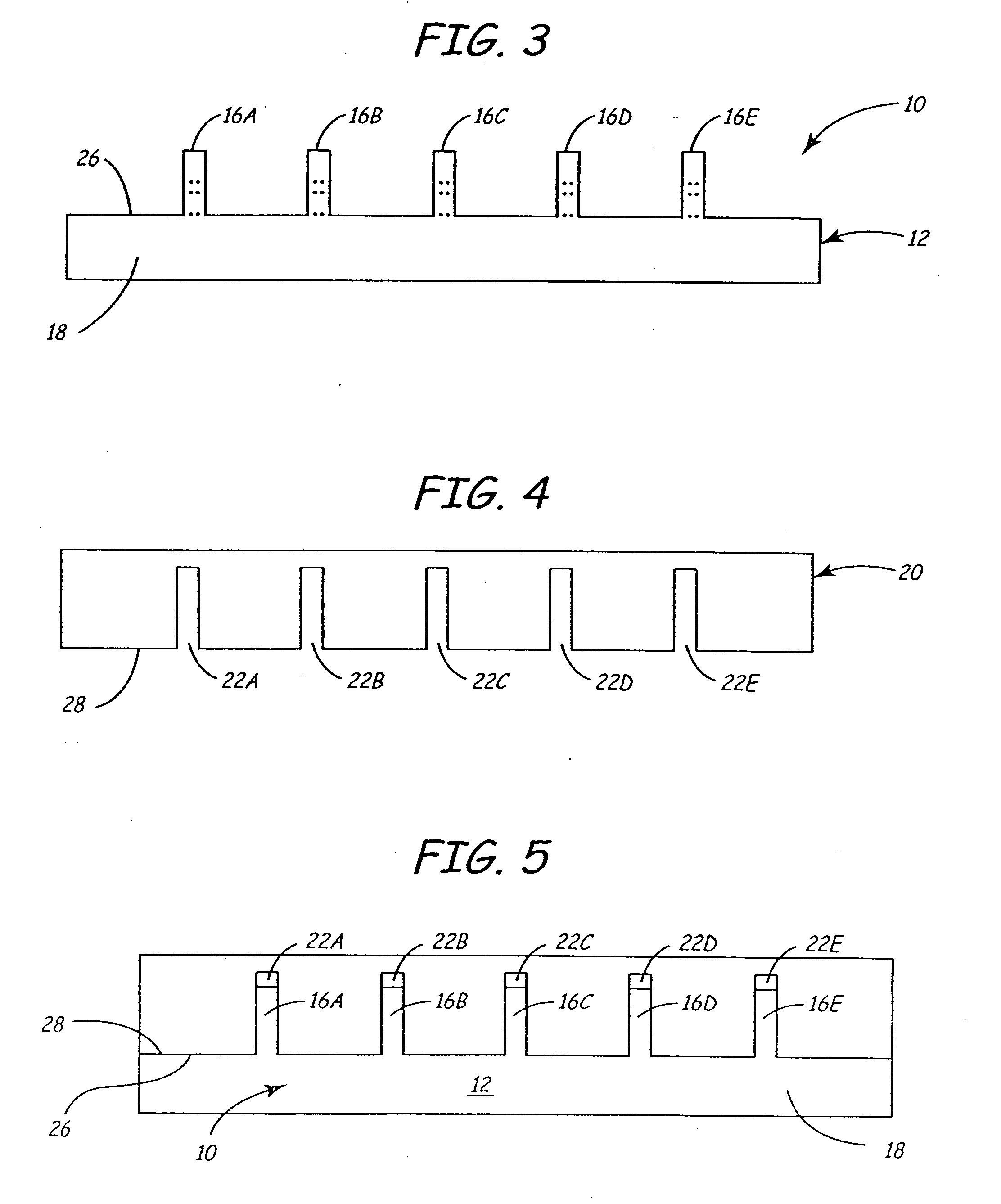

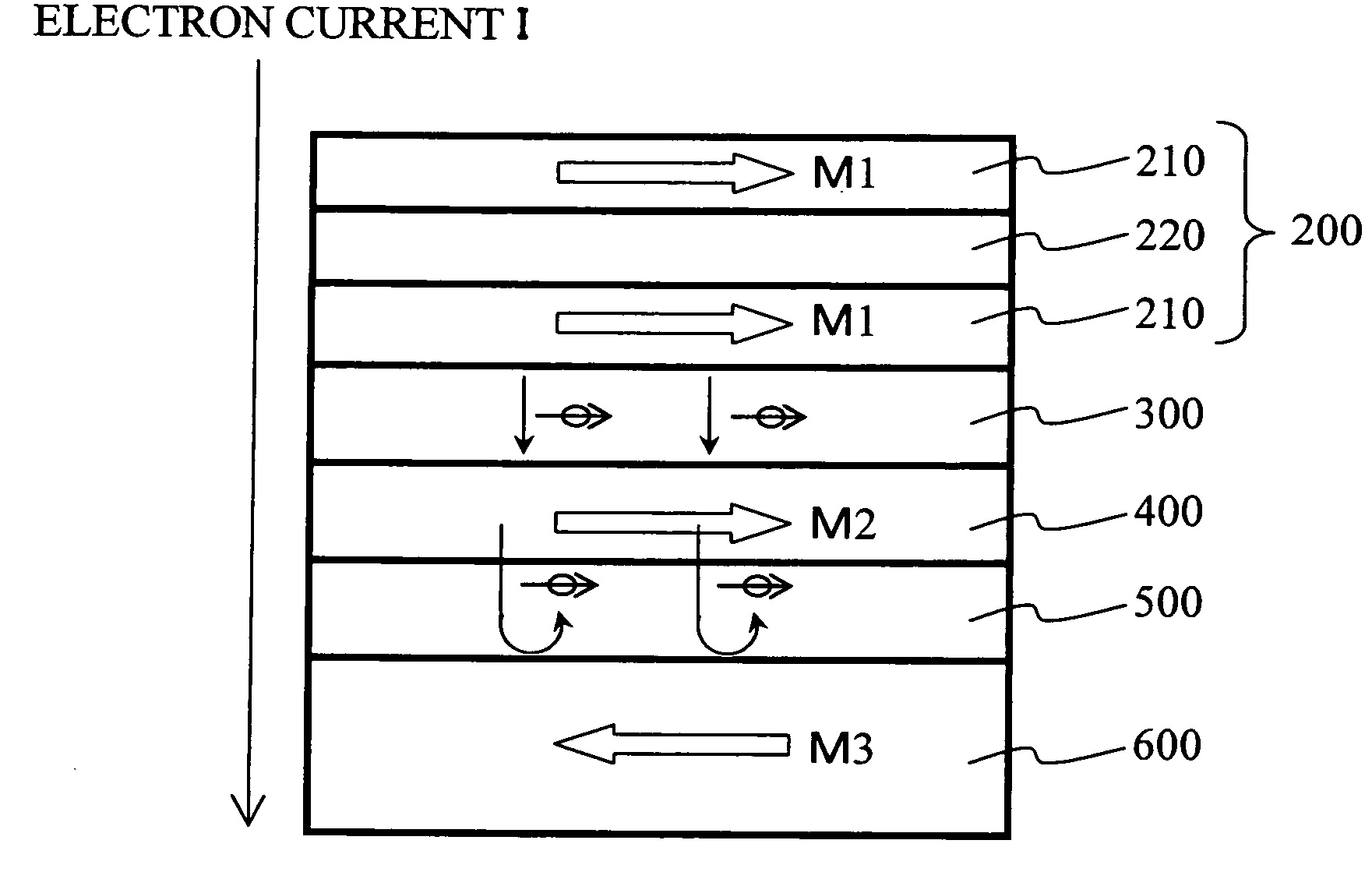

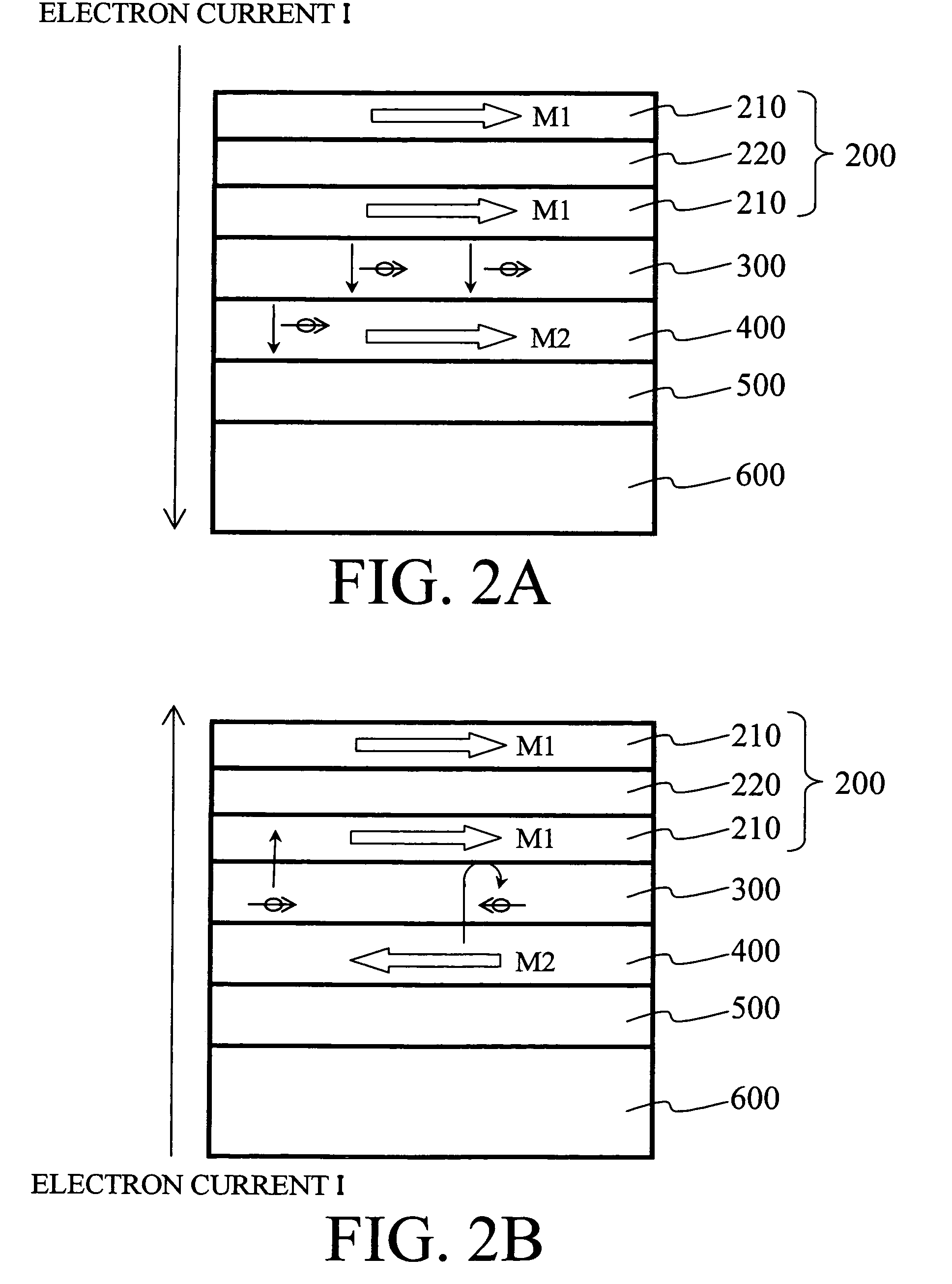

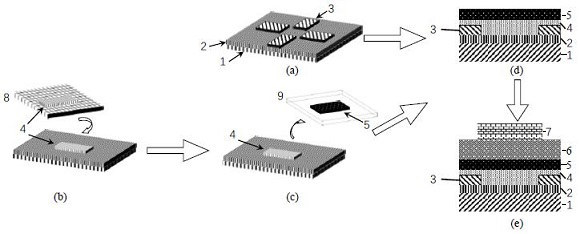

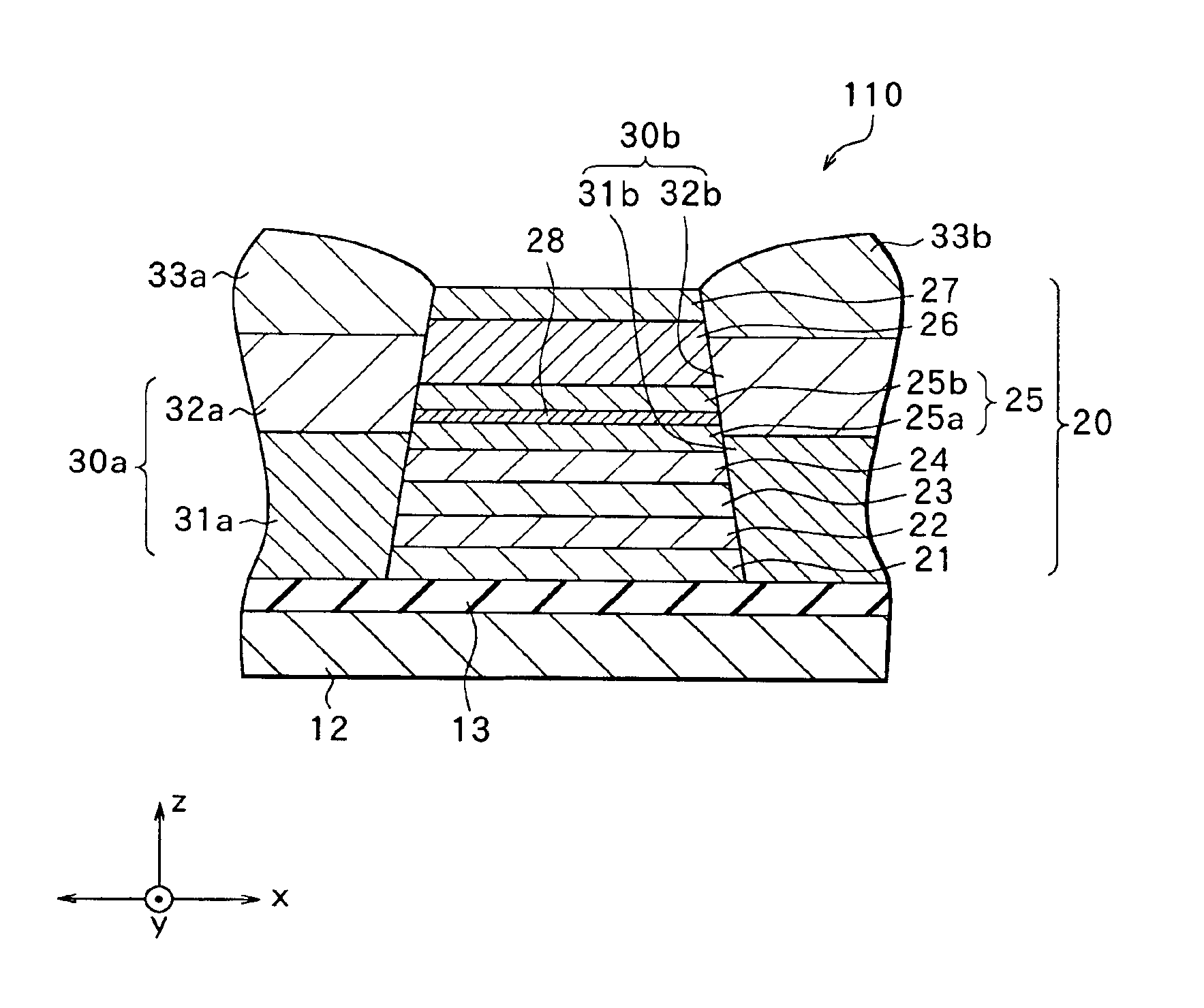

Magnetic device and magnetic memory

ActiveUS20050099724A1Maintain alignmentMagnetic-field-controlled resistorsSolid-state devicesMagnetic memoryMagnetization

A magnetic device comprises first through third ferromagnetic layers, first and second intermediate layers and a couple of electrodes. The first ferromagnetic layer includes magnetic layers and one or more nonmagnetic layers which are alternately stacked, at least one layer of the magnetic layers has magnetization substantially fixed to a first direction, and two or more layers of the magnetic layers are ferromagnetically coupled via the nonmagnetic layers while having easy axes of magnetization parallel to a film plane. The second ferromagnetic layer has magnetization substantially fixed to a second direction. The third ferromagnetic layer is provided between the first ferromagnetic layer and the second ferromagnetic layer. The third ferromagnetic layer has a variable direction of magnetization. The first and second intermediate layers are provided between the ferromagnetic layers. The electrodes are configured to provide write current between the first and second ferromagnetic layers to cause spin-polarized electrons to act on the third ferromagnetic layer so that the direction of magnetization of the third ferromagnetic layer is determined depending on a direction of the current. The ferromagnetic coupling has a strength such that a parallel magnetic alignment of the magnetic layers is maintained when the write current.

Owner:KATANA SILICON TECH LLC

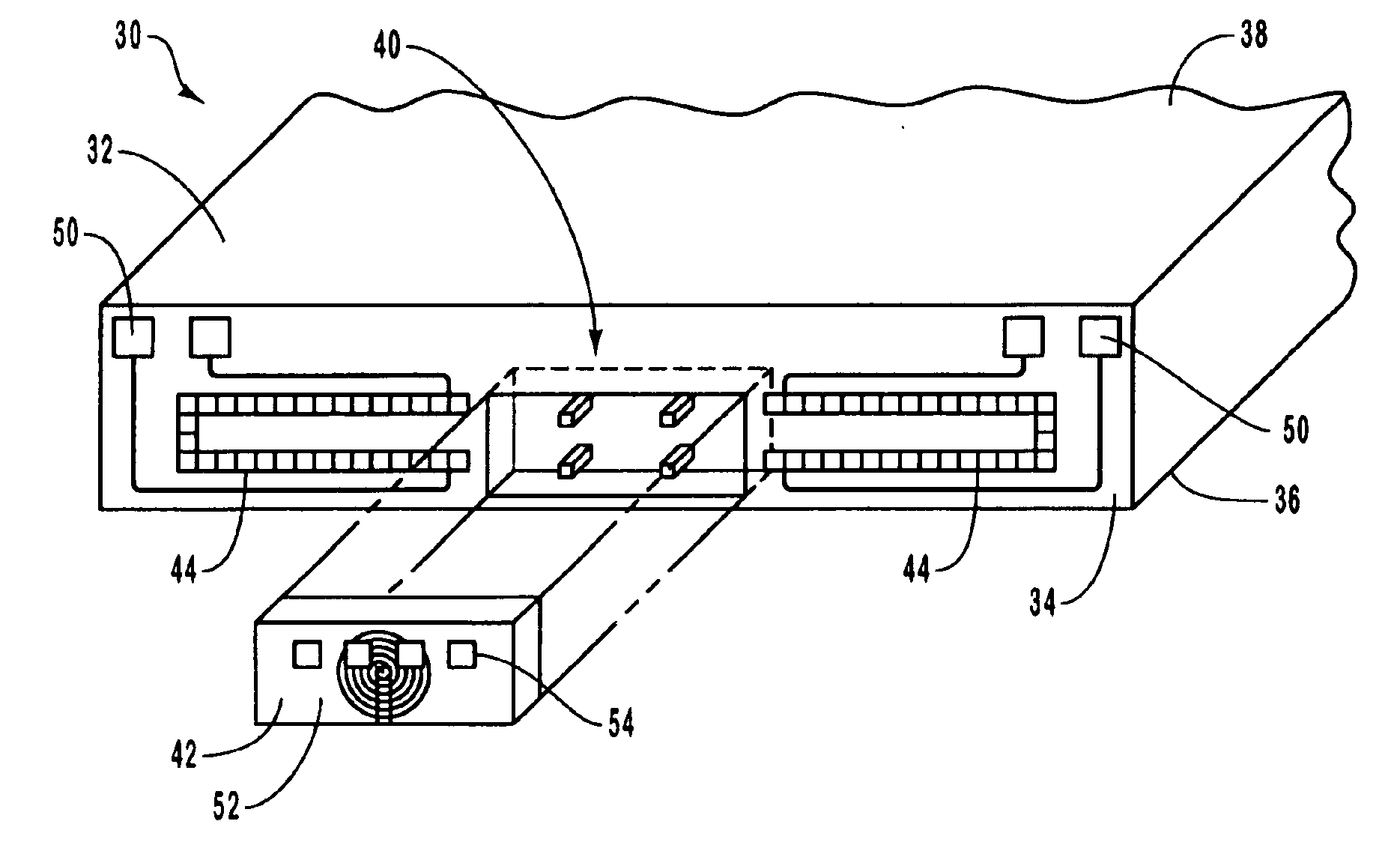

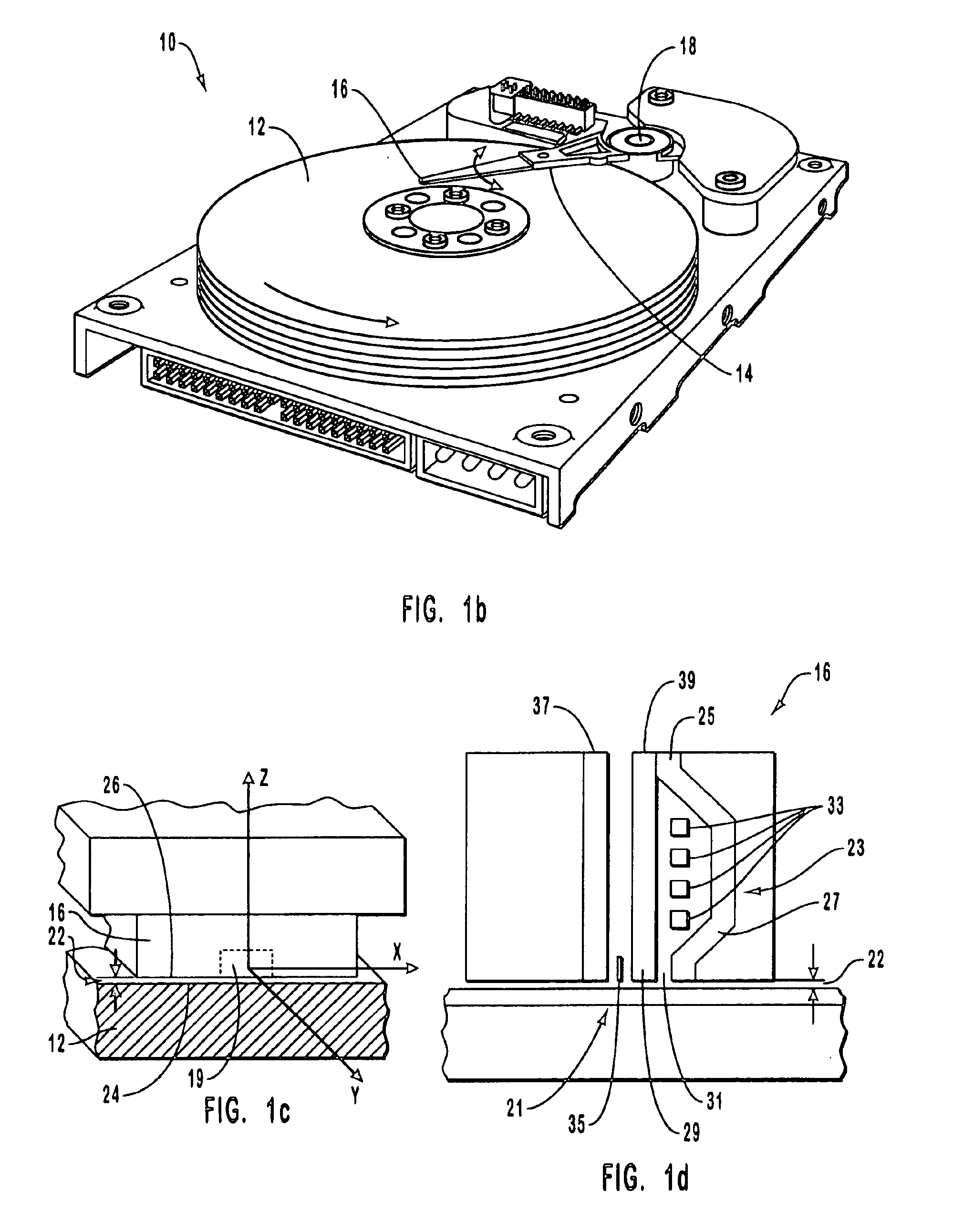

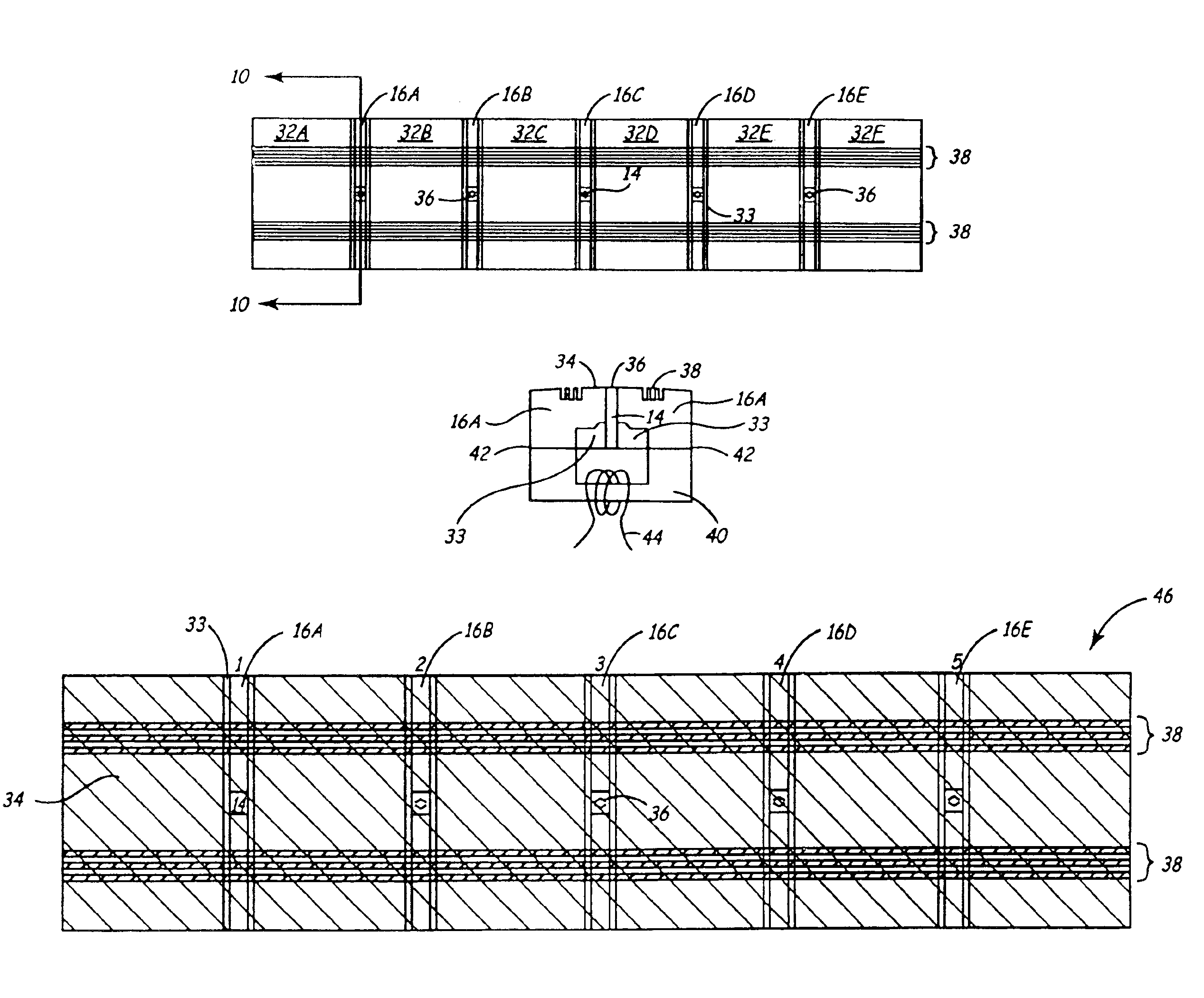

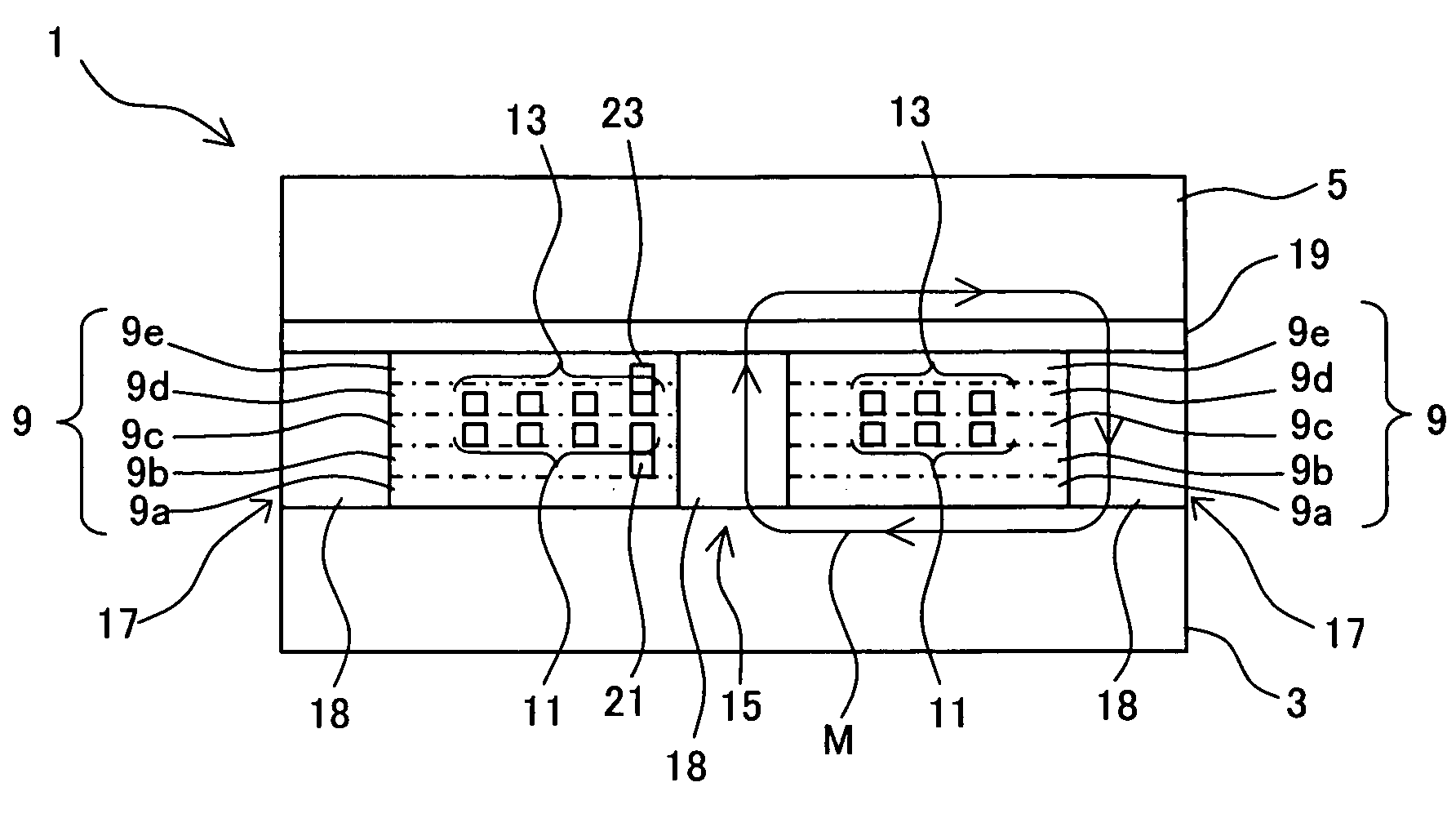

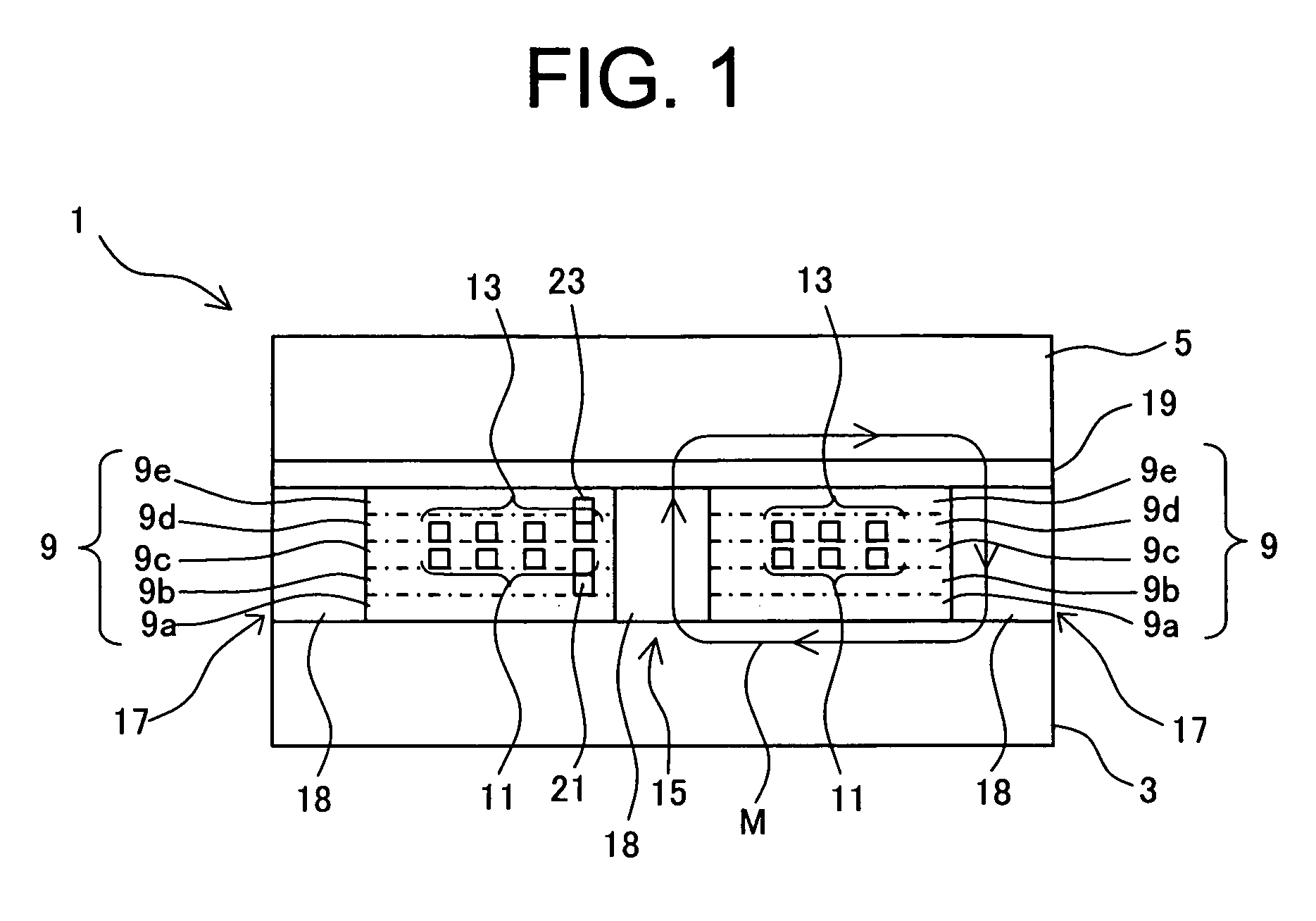

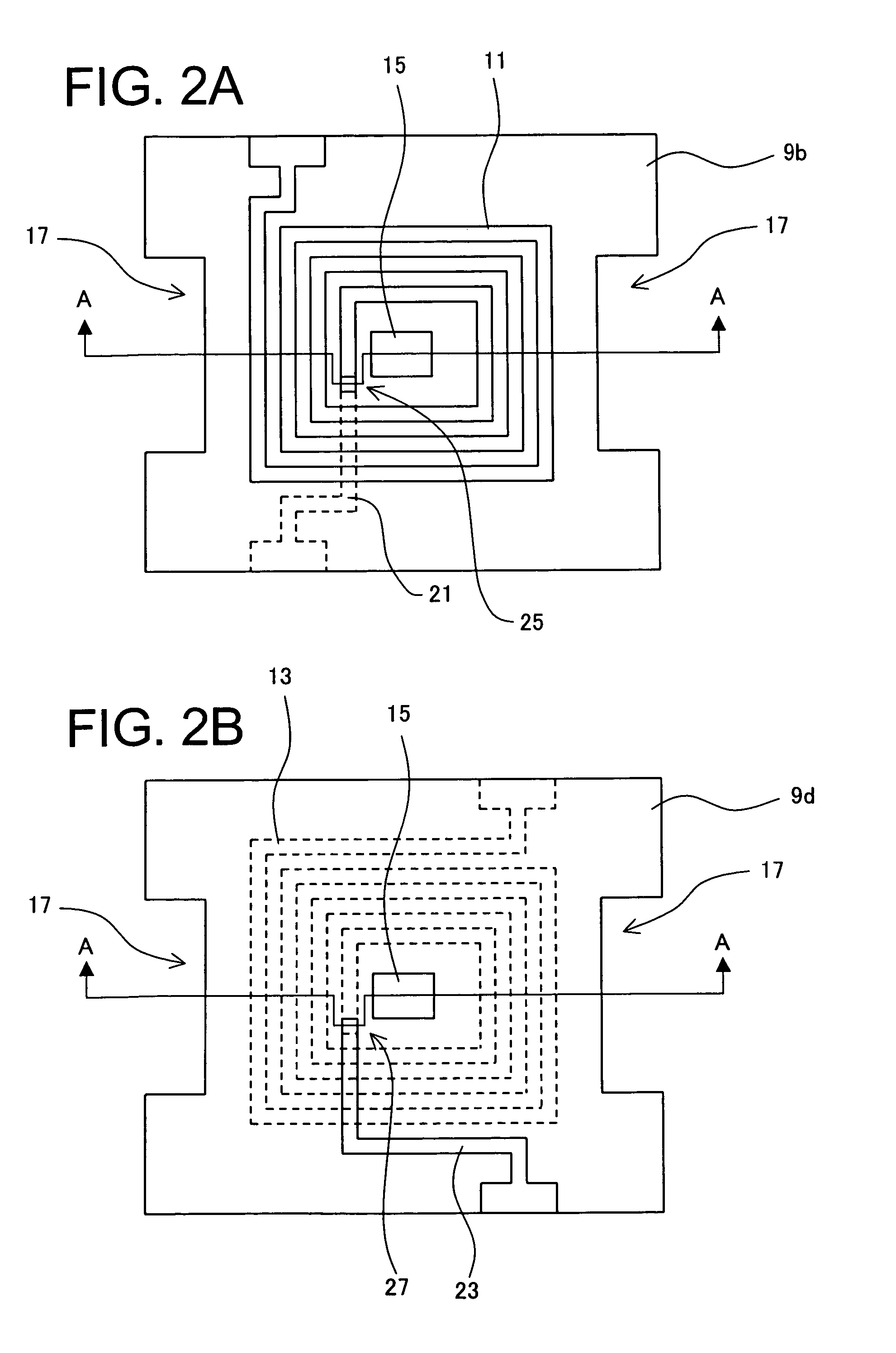

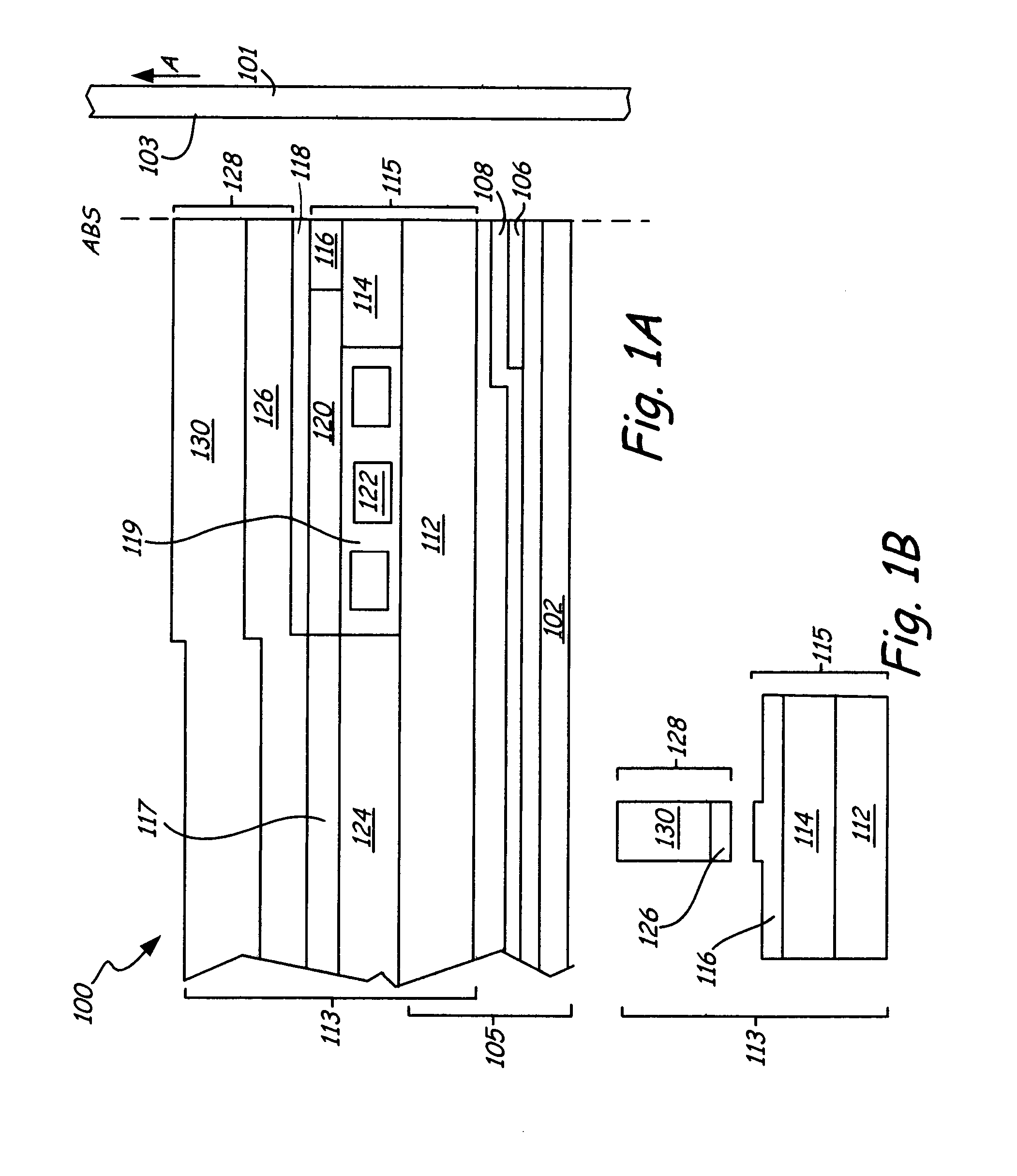

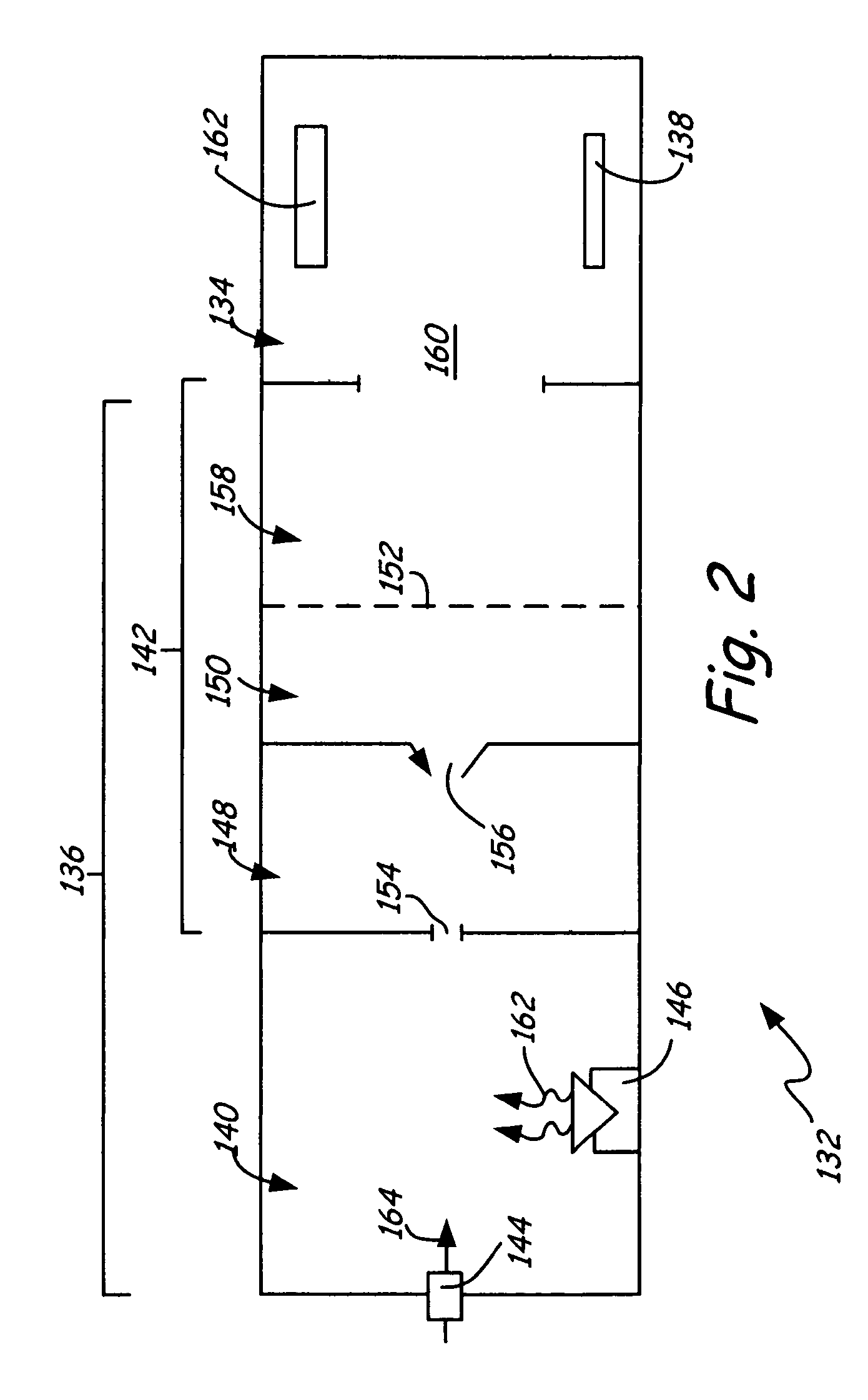

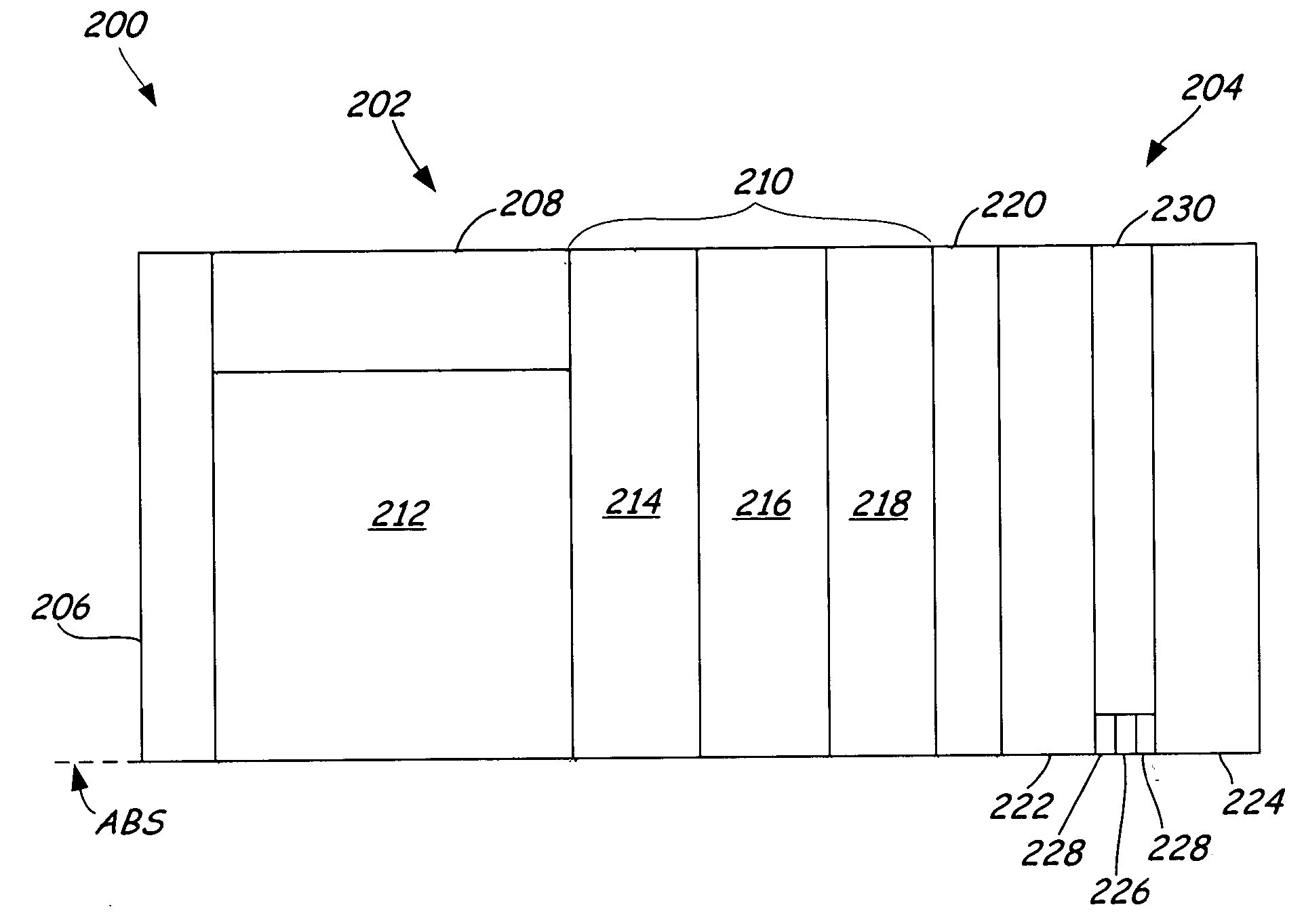

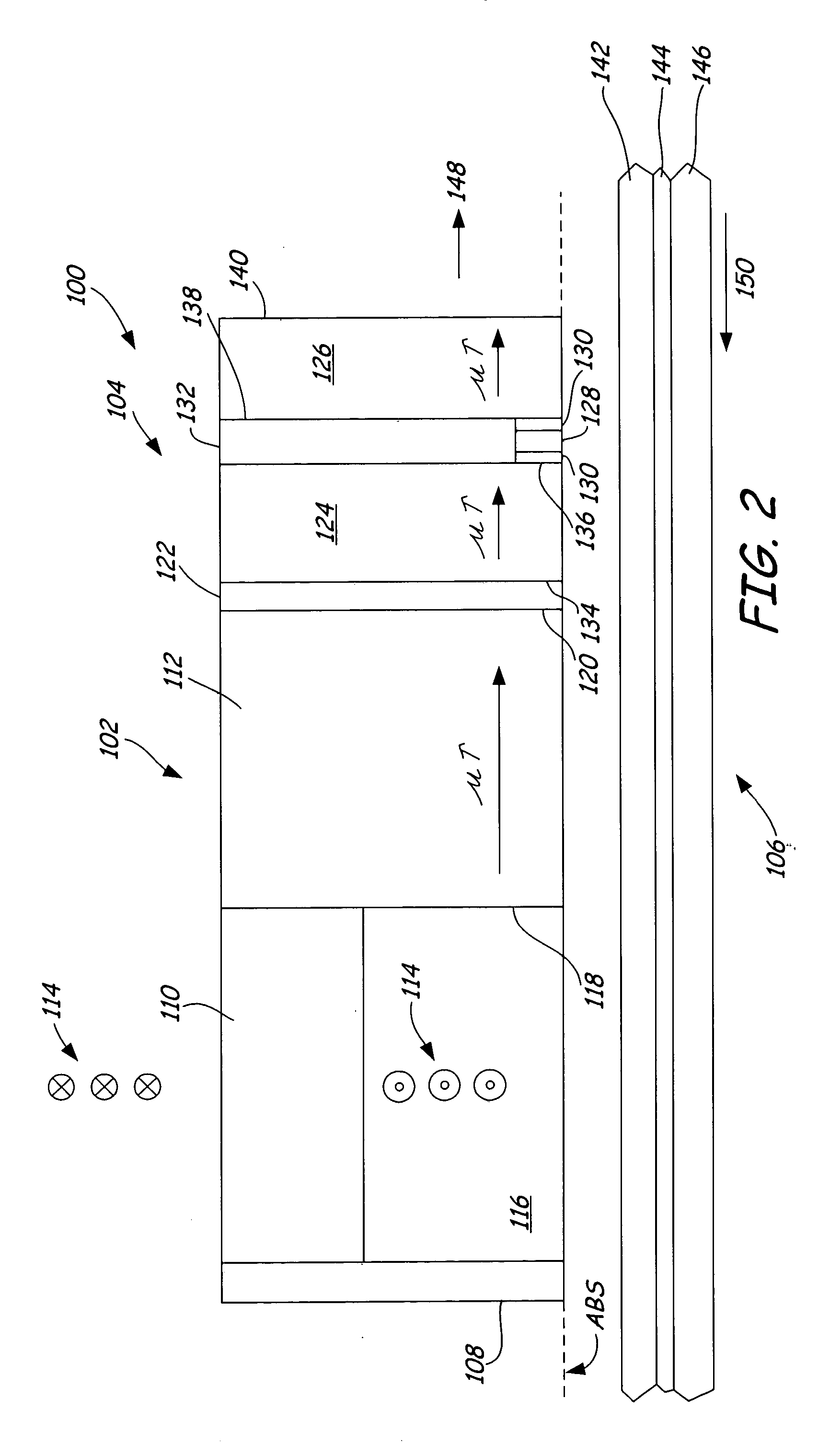

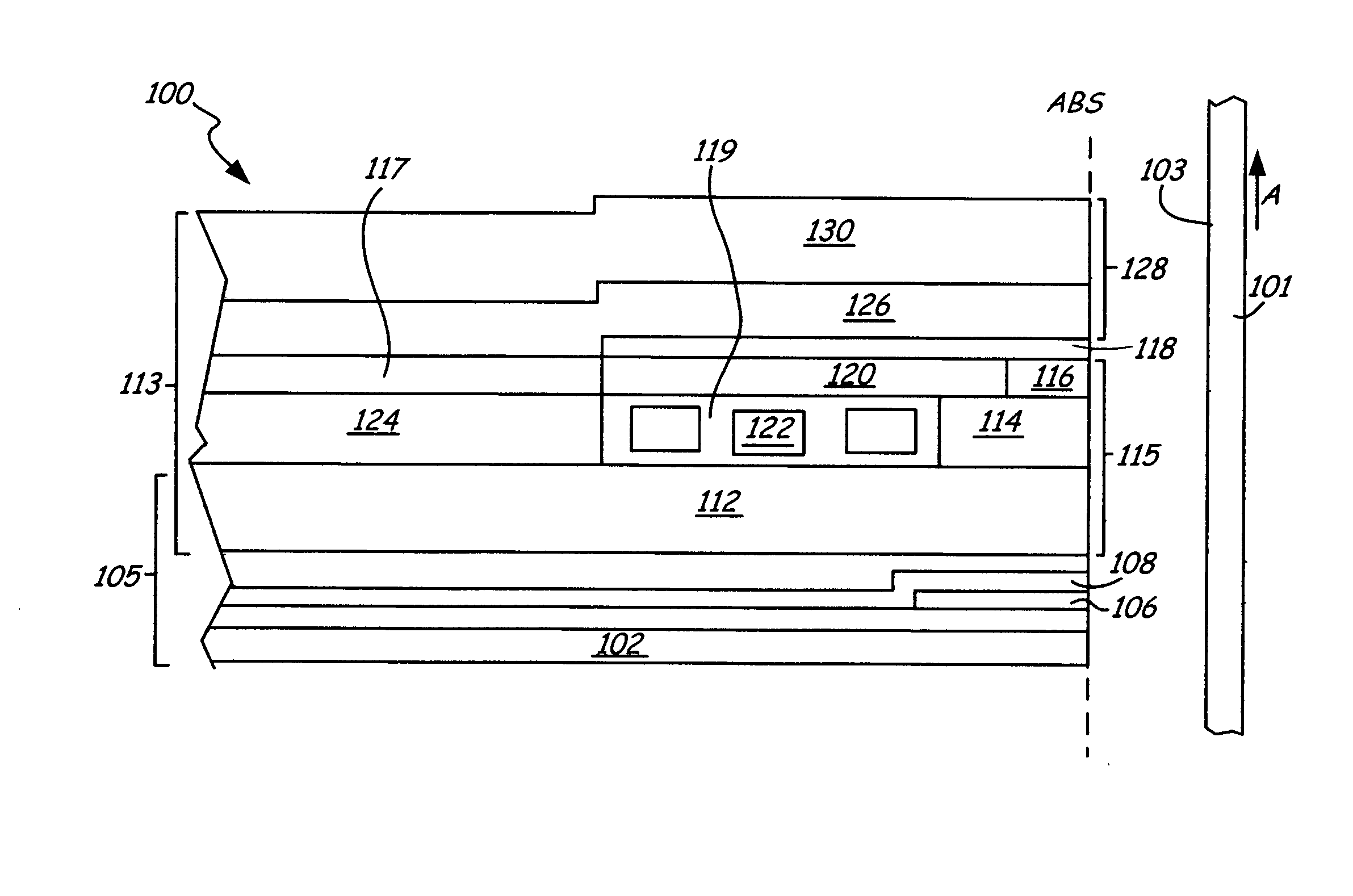

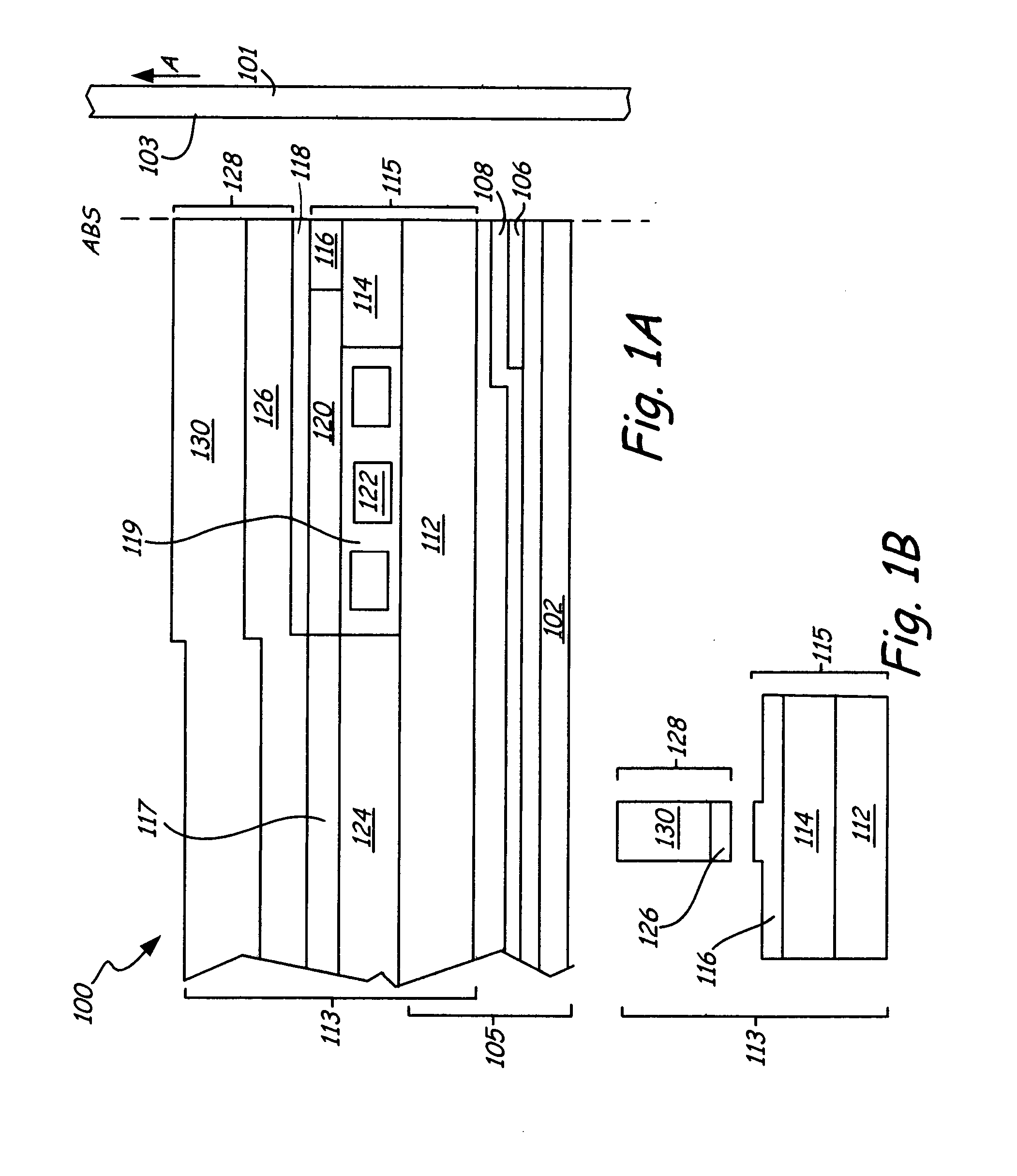

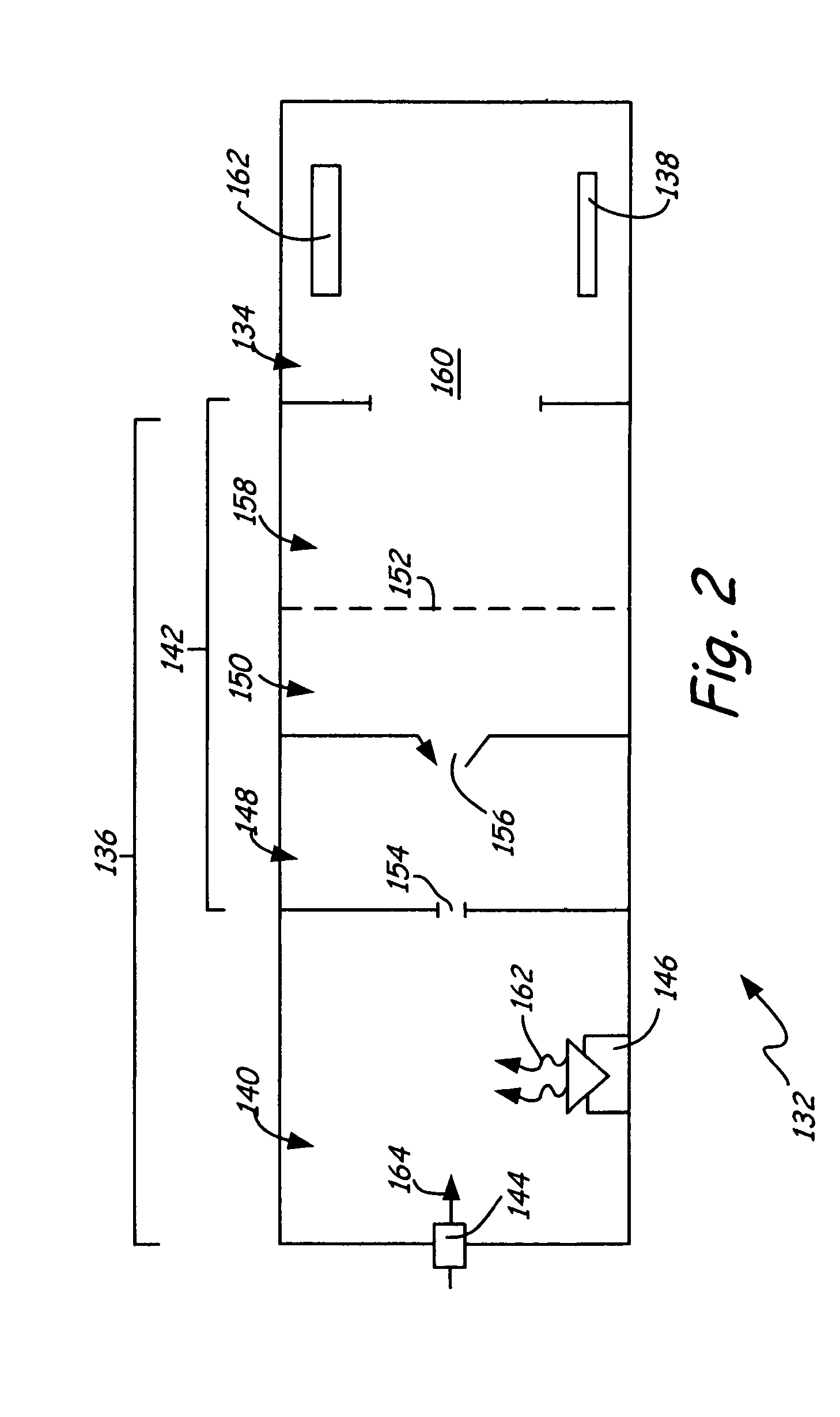

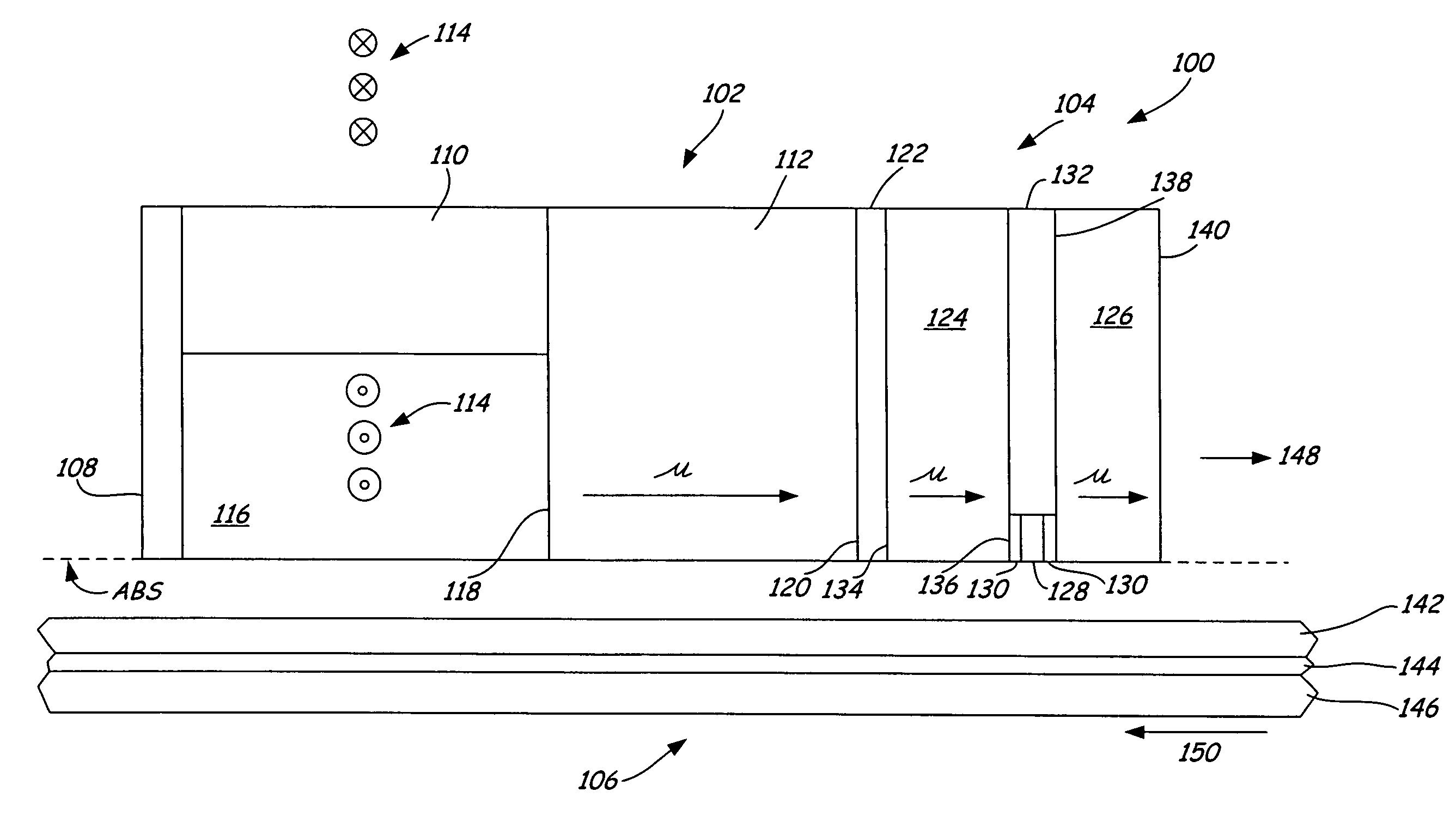

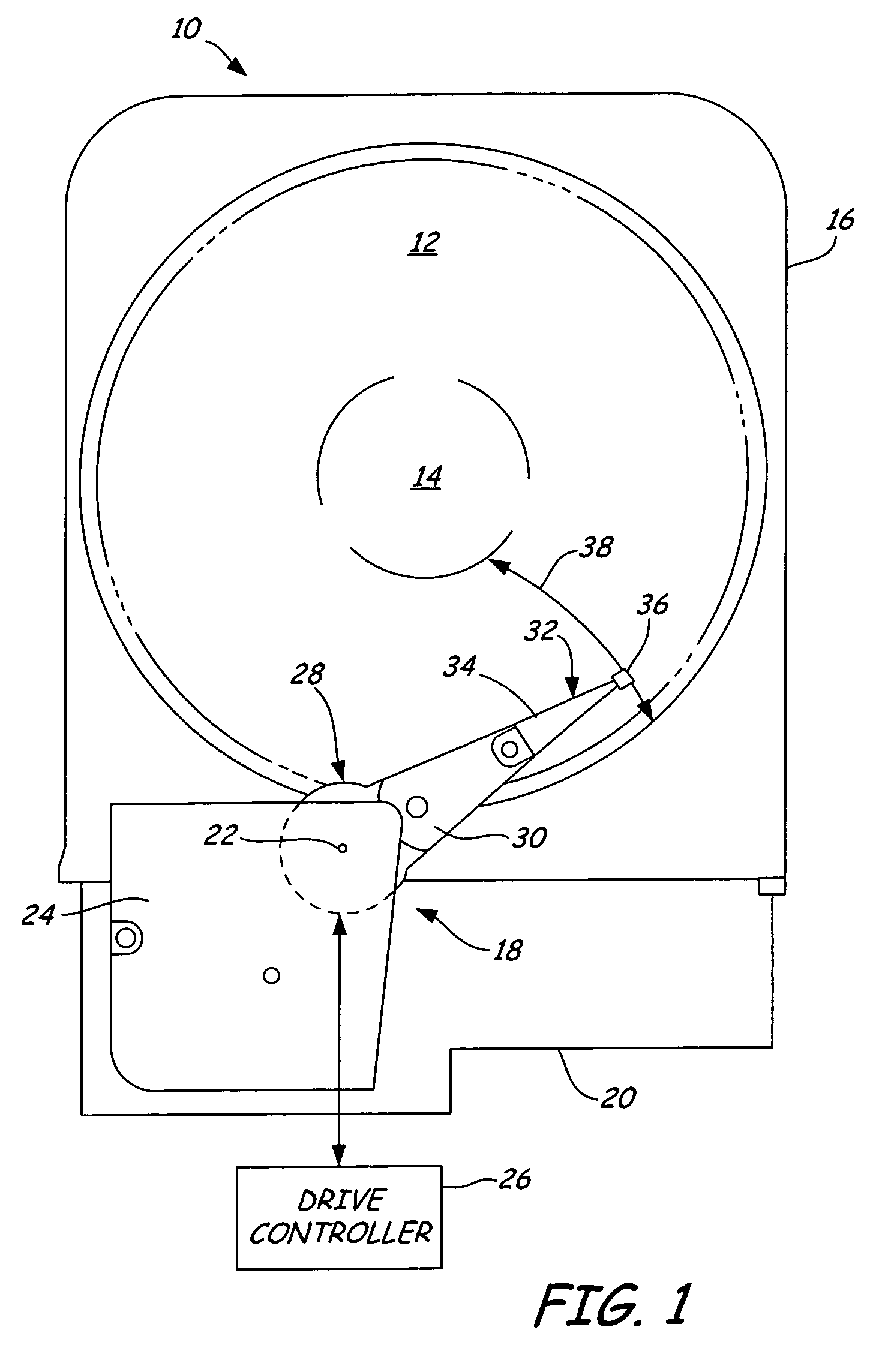

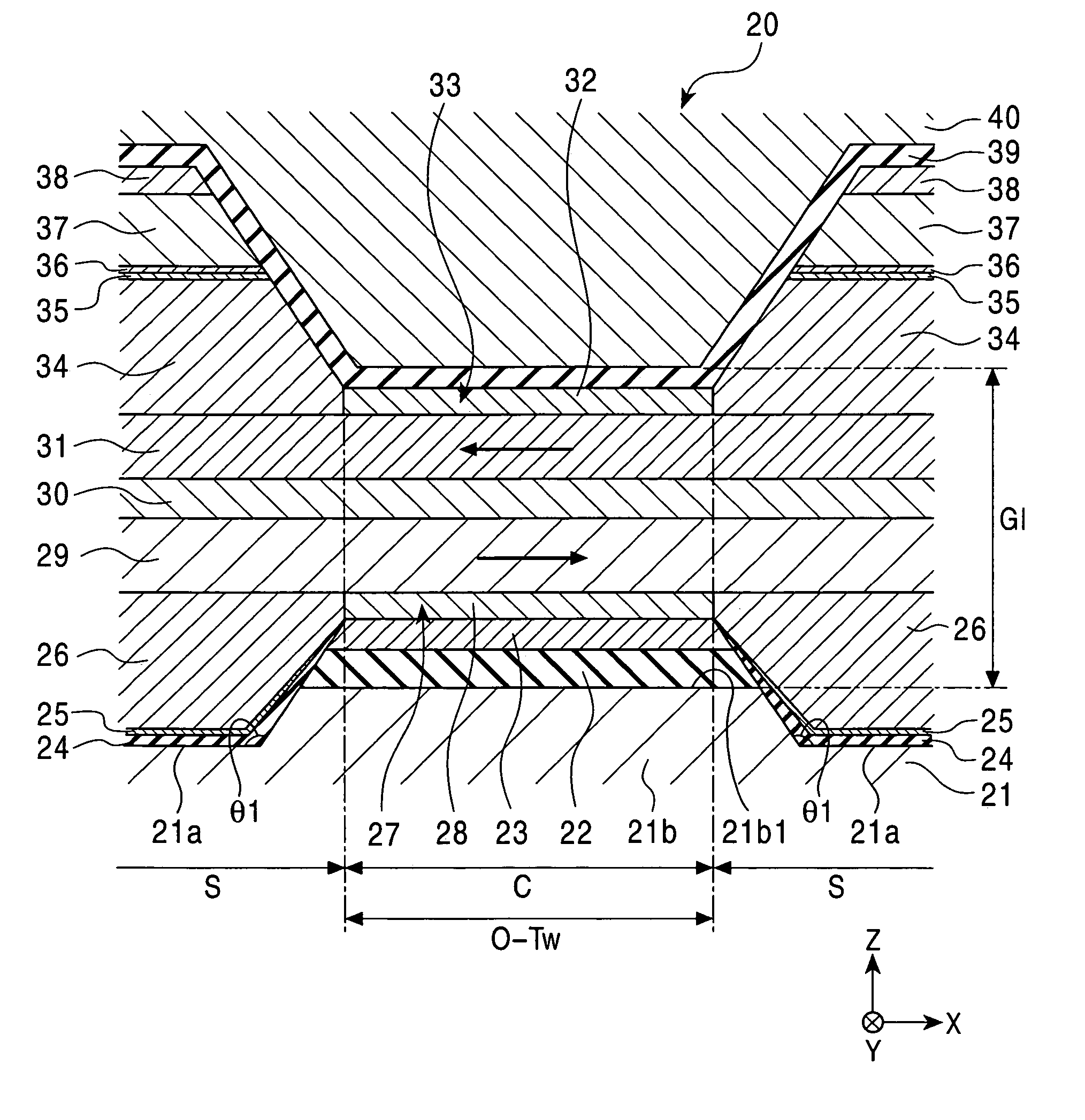

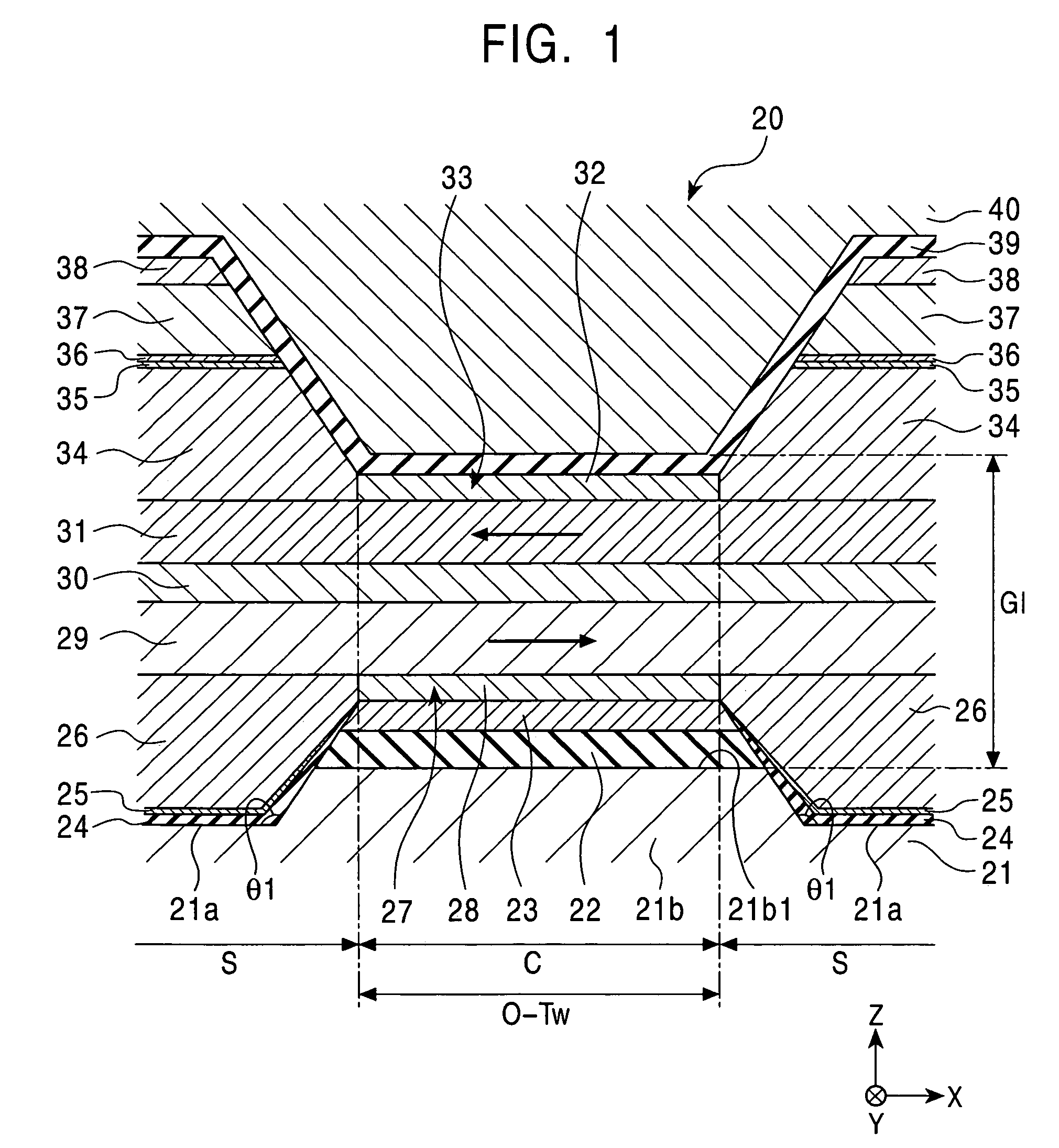

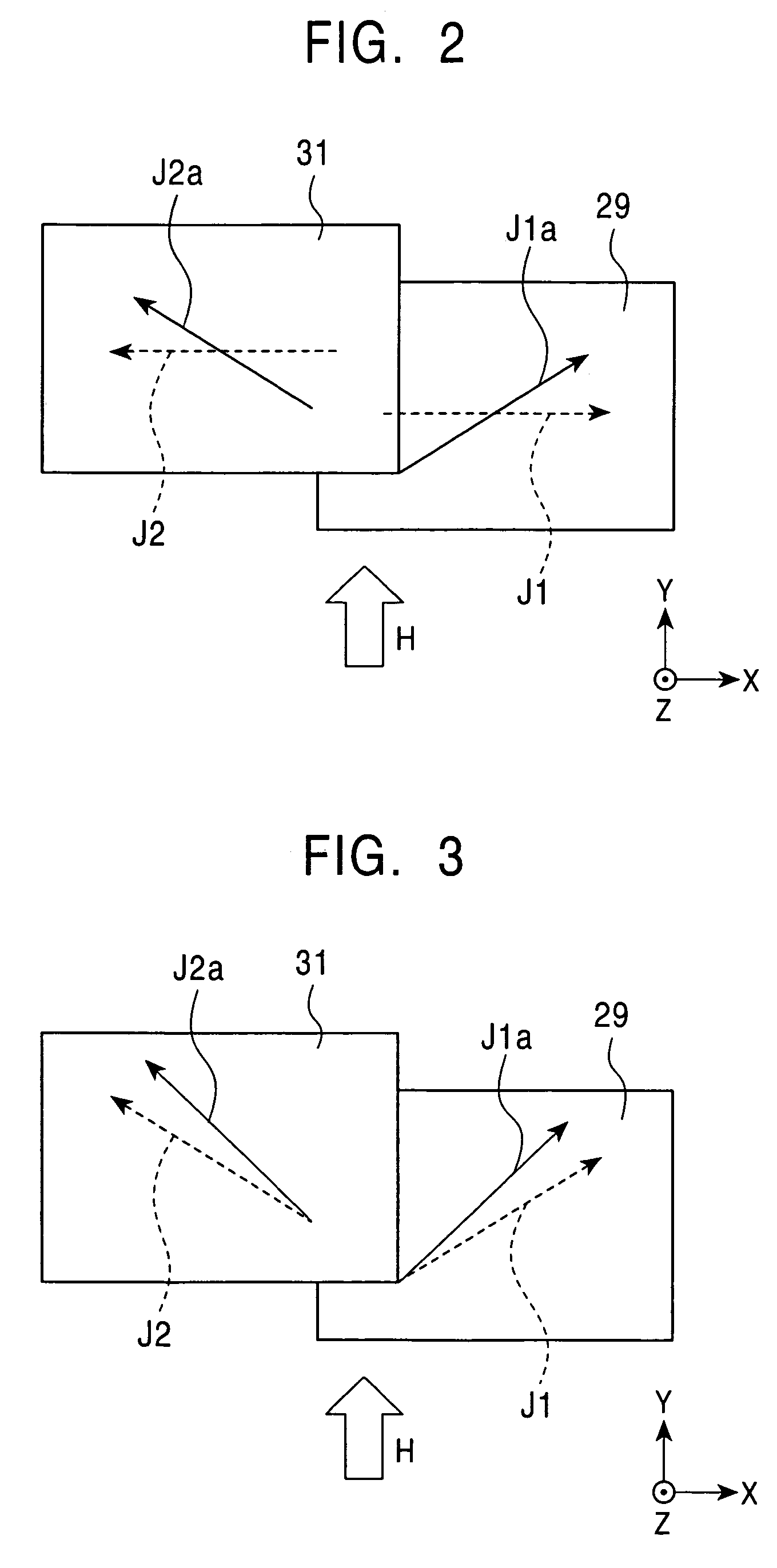

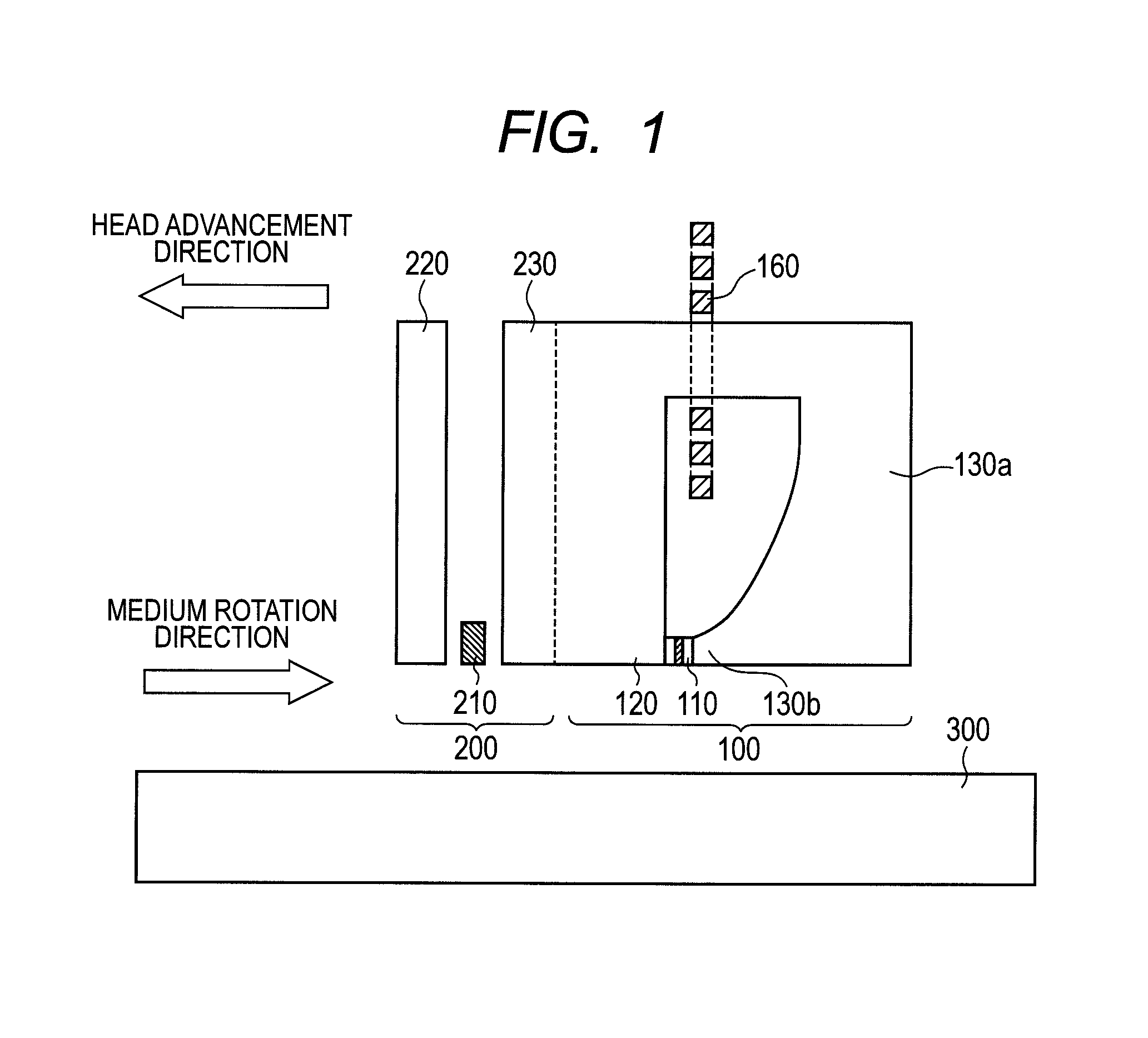

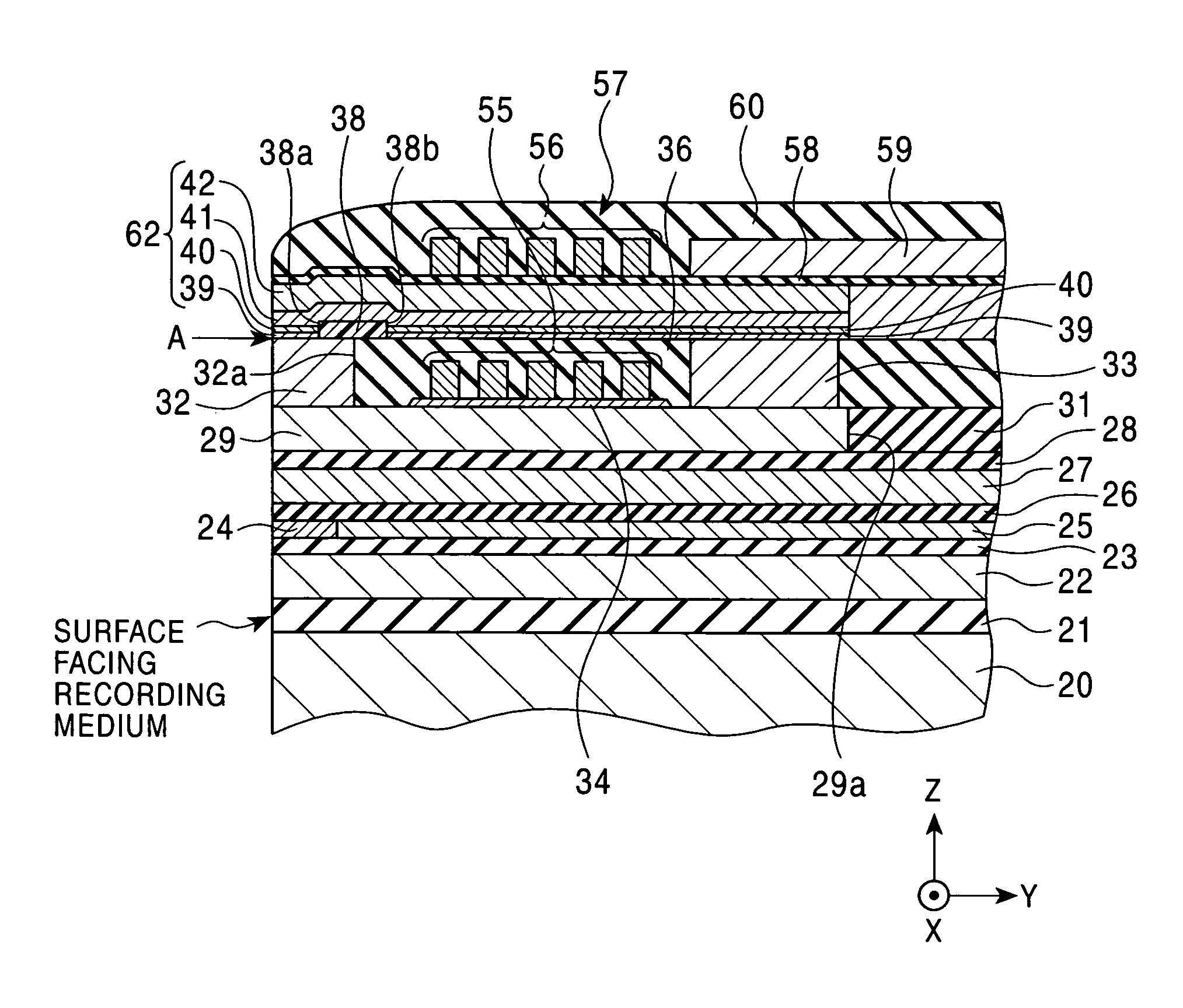

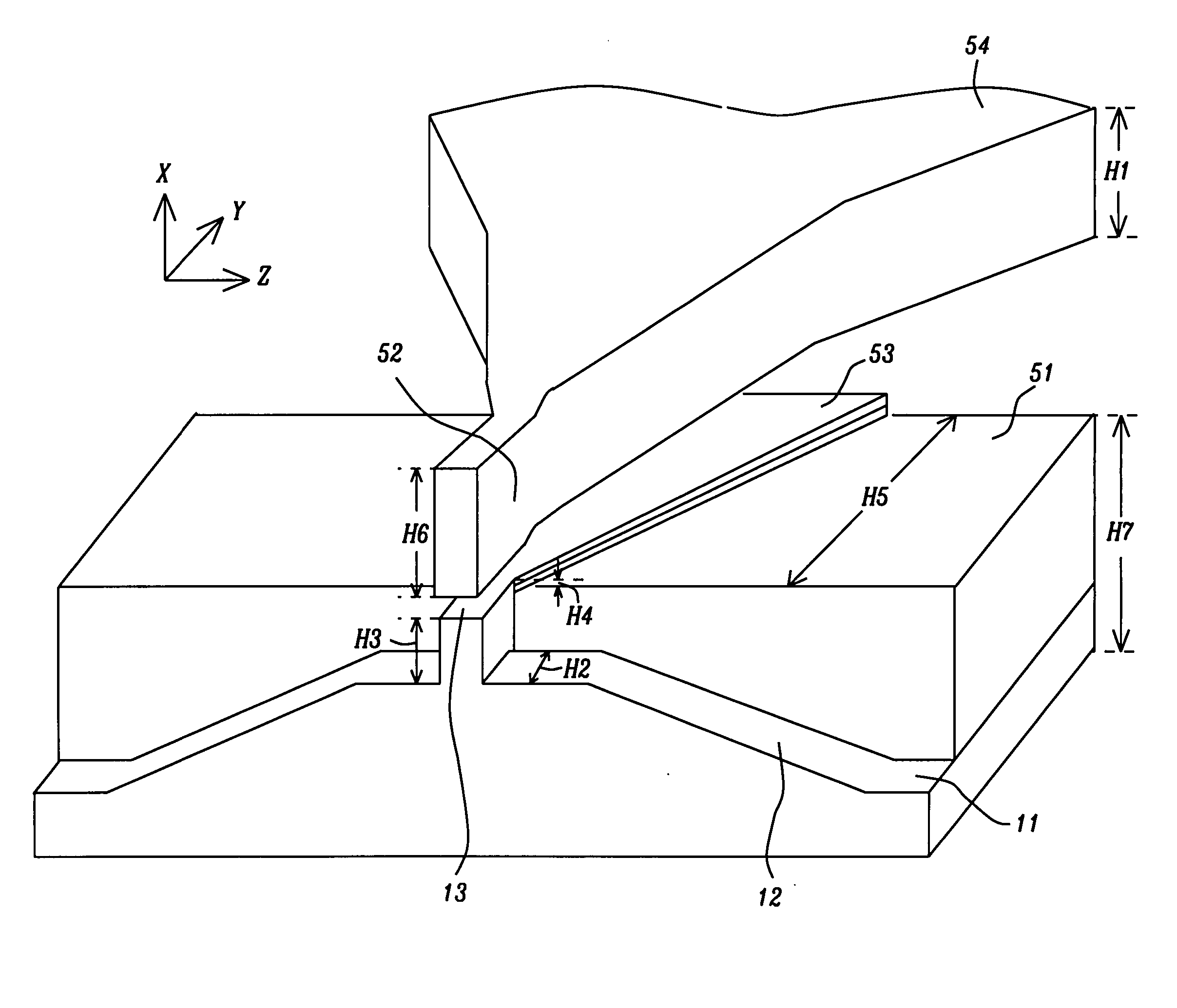

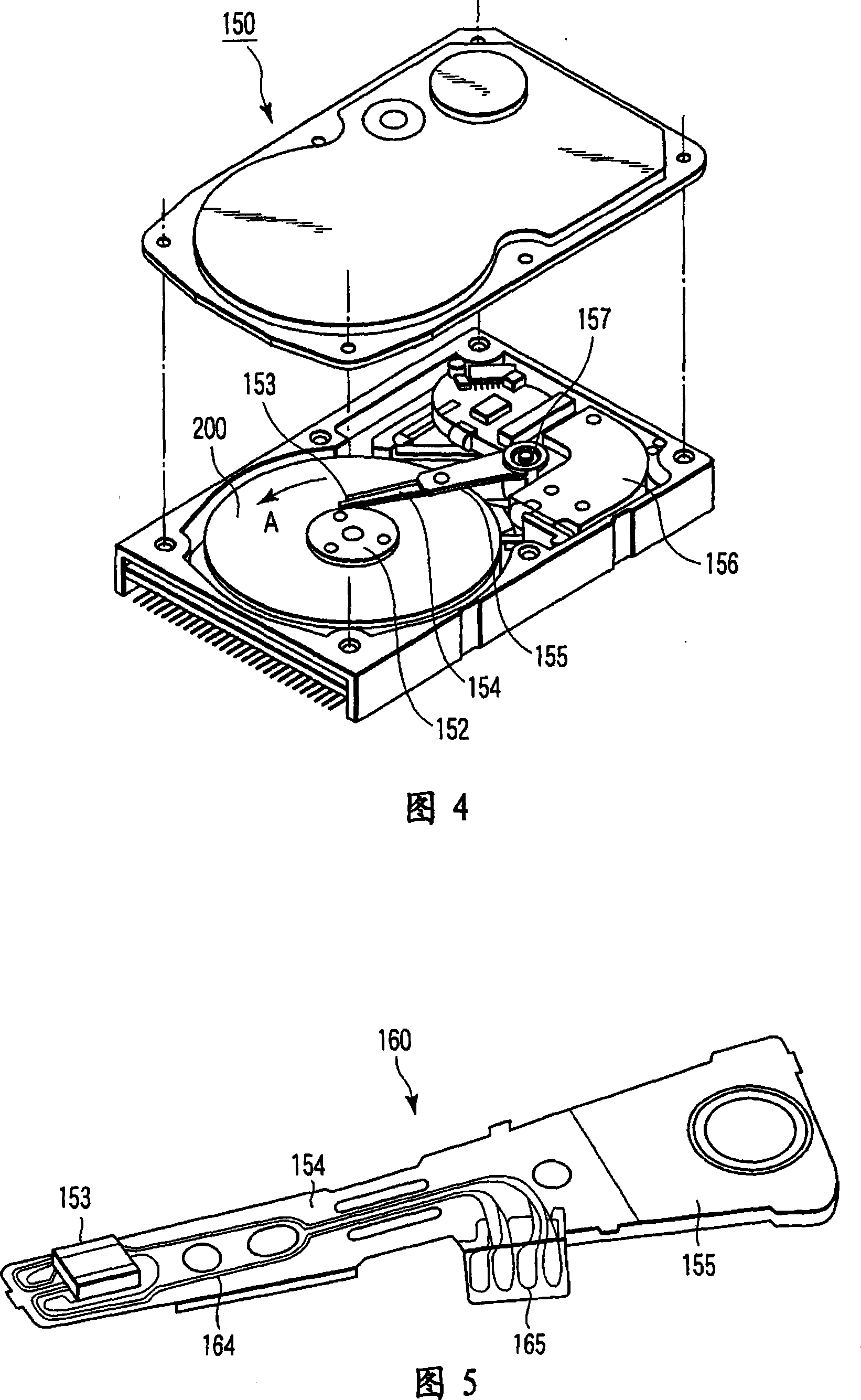

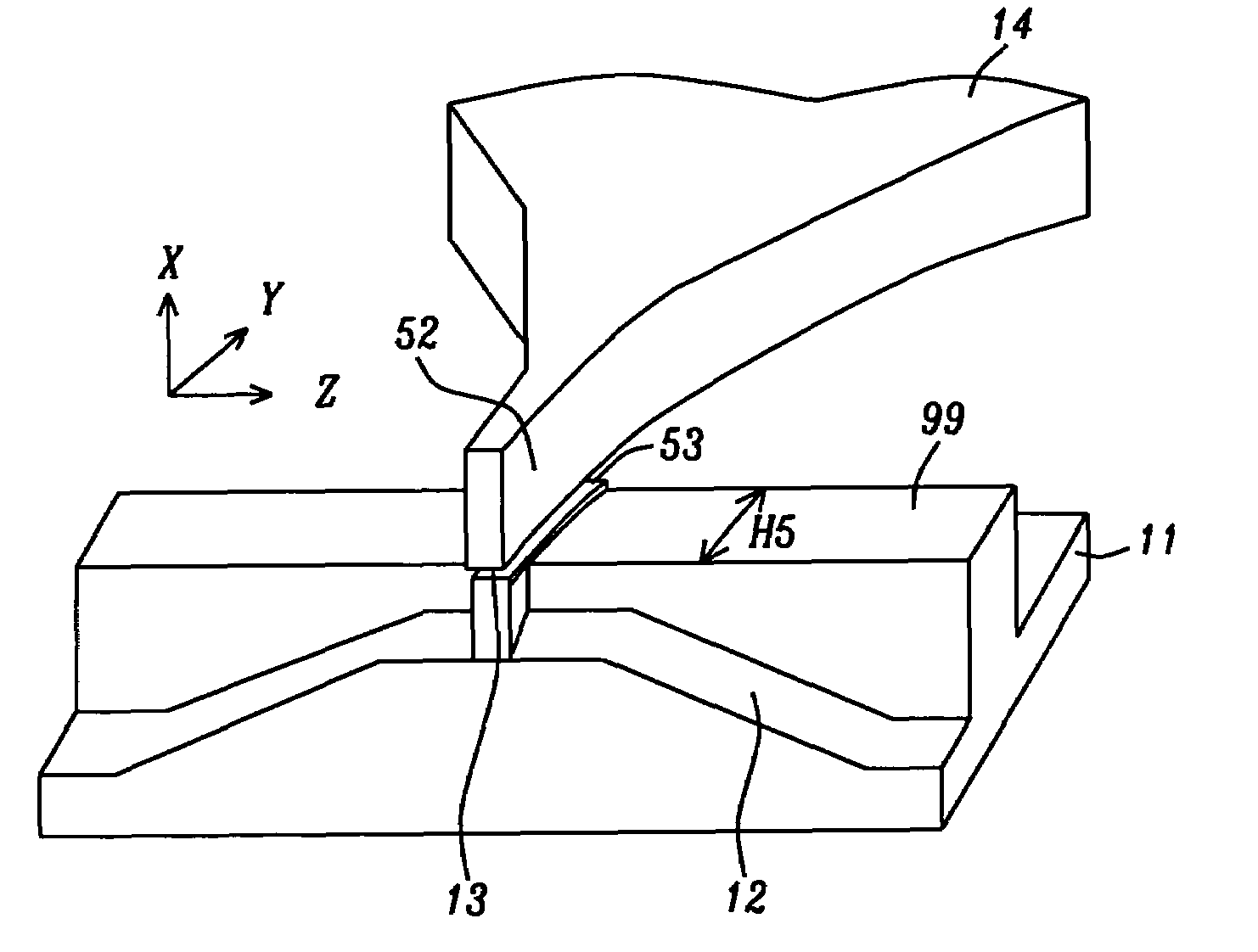

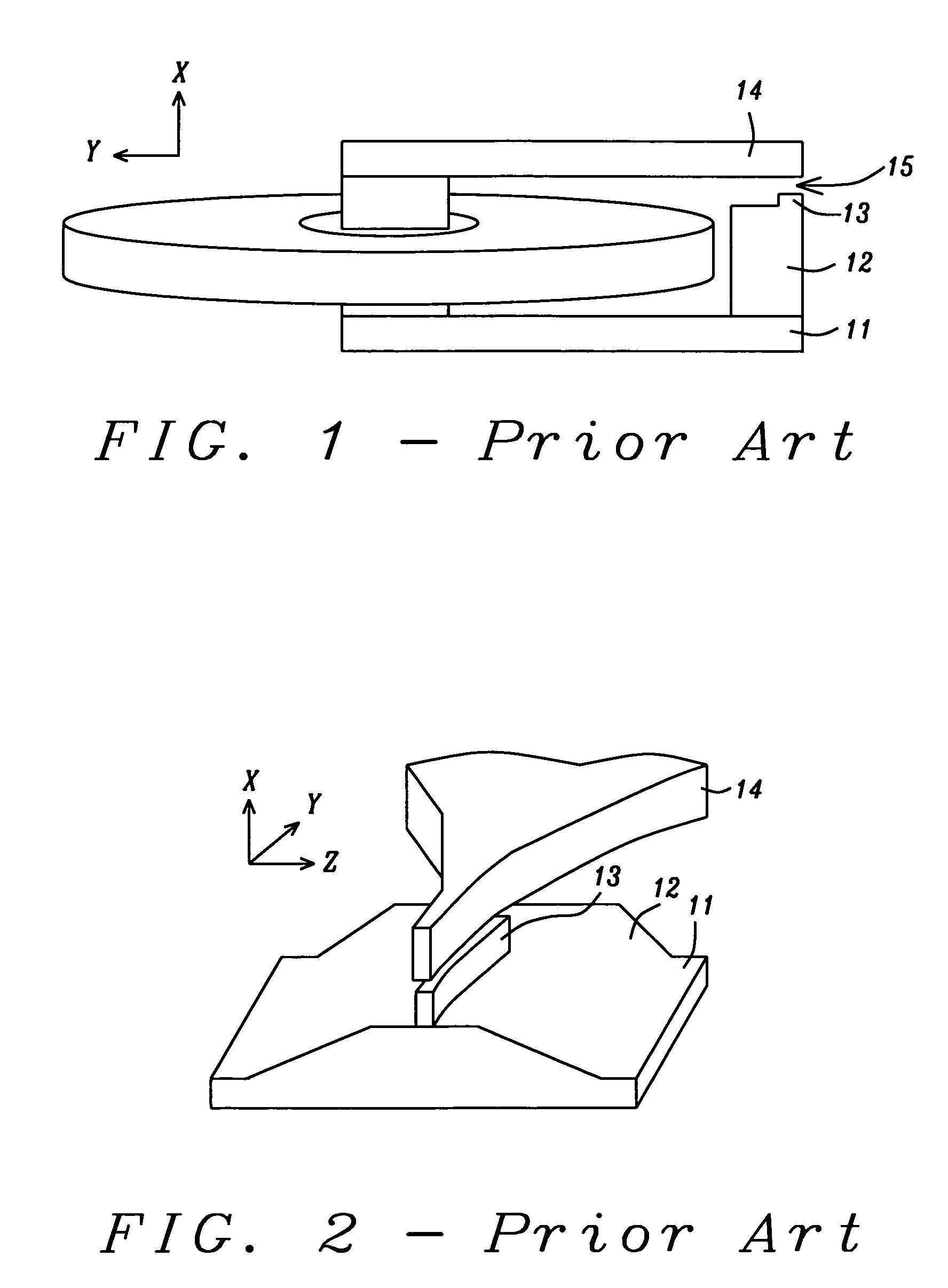

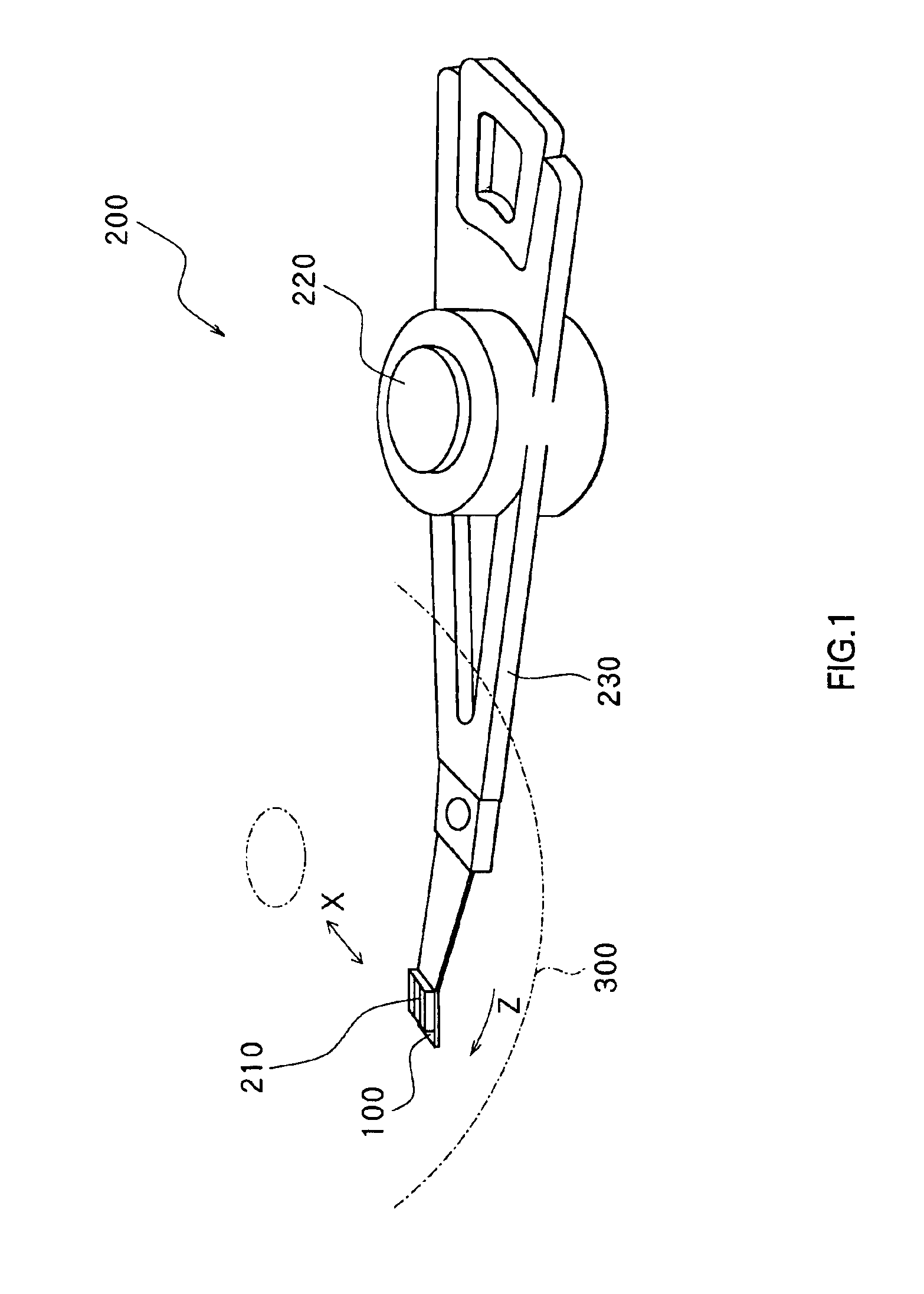

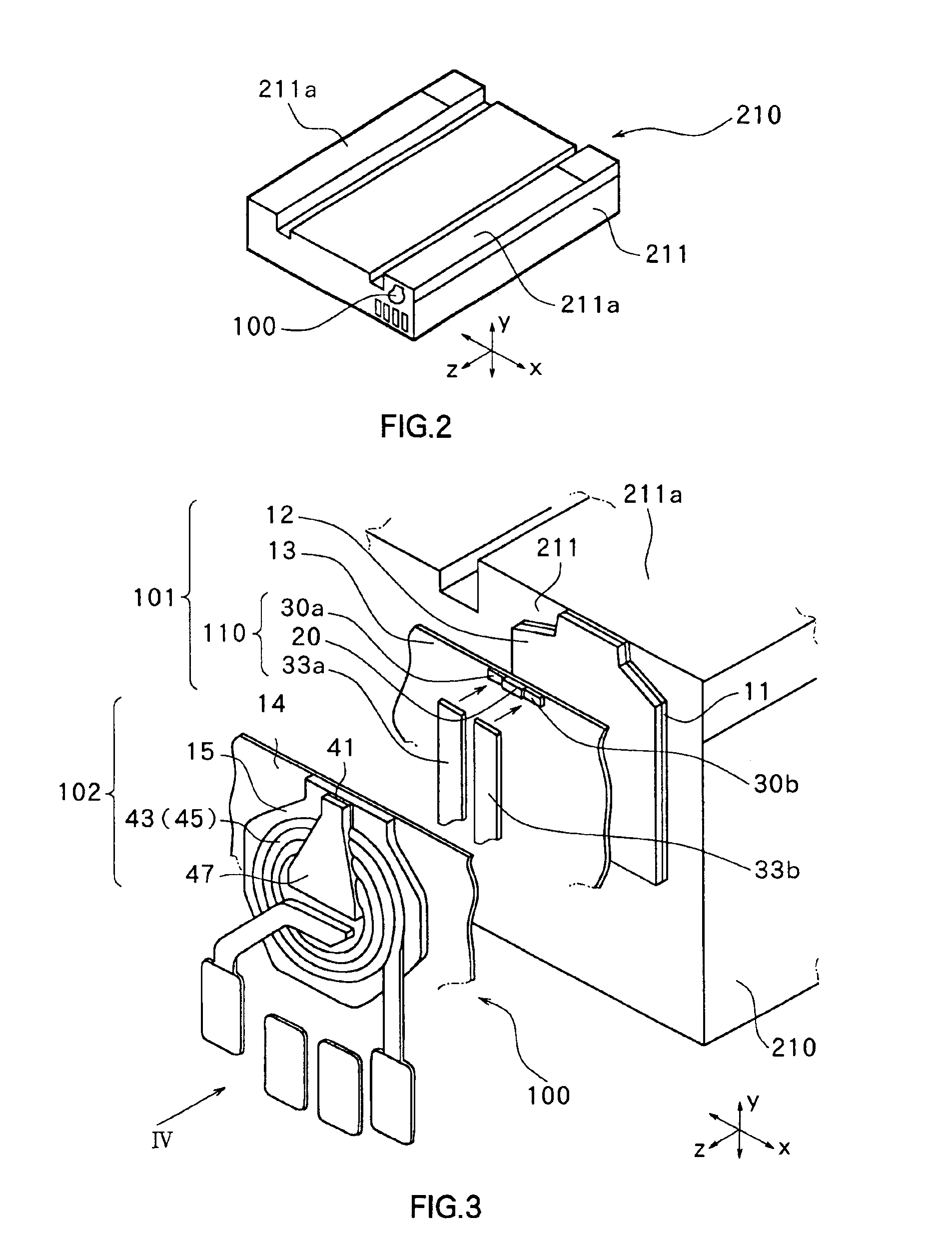

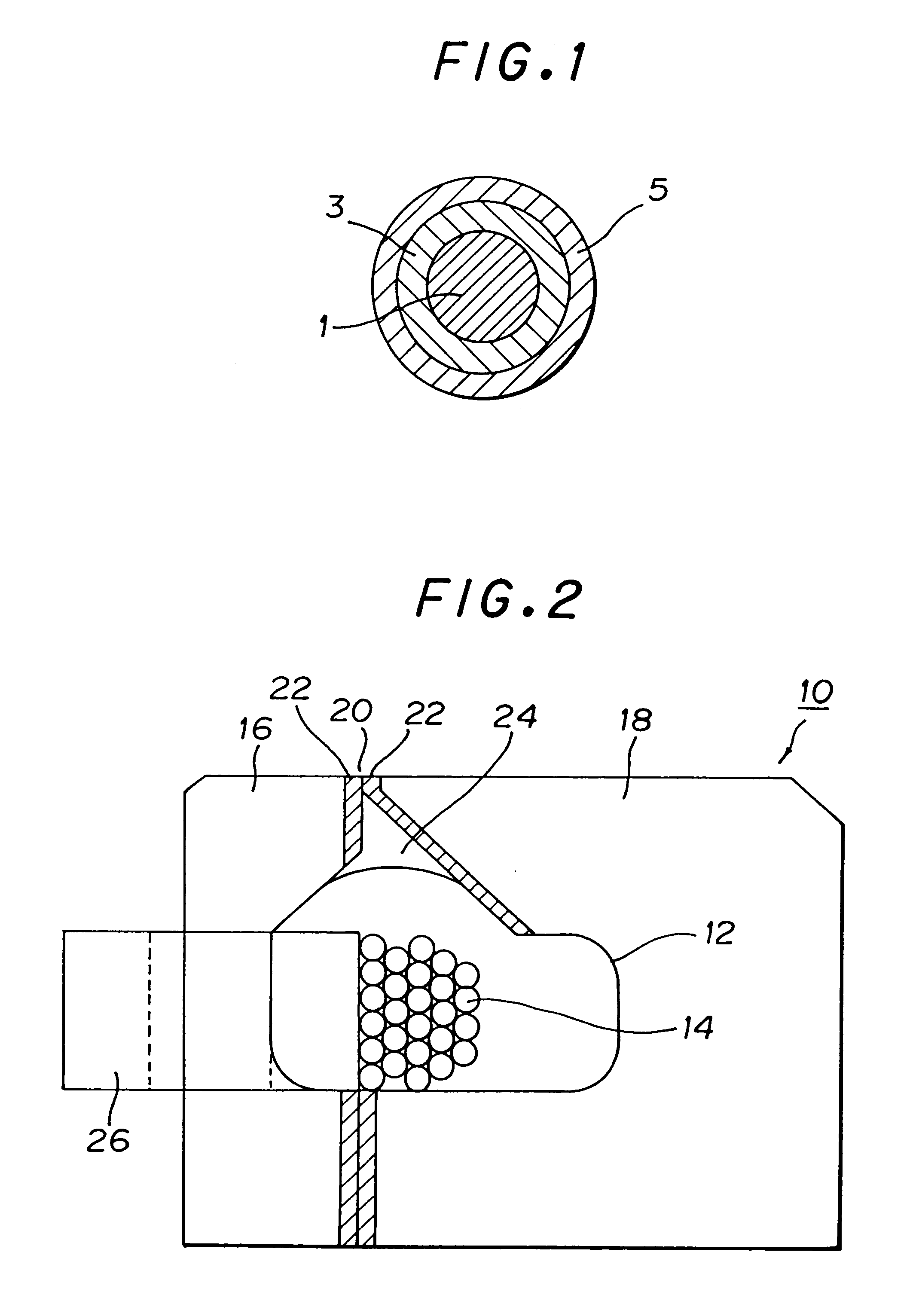

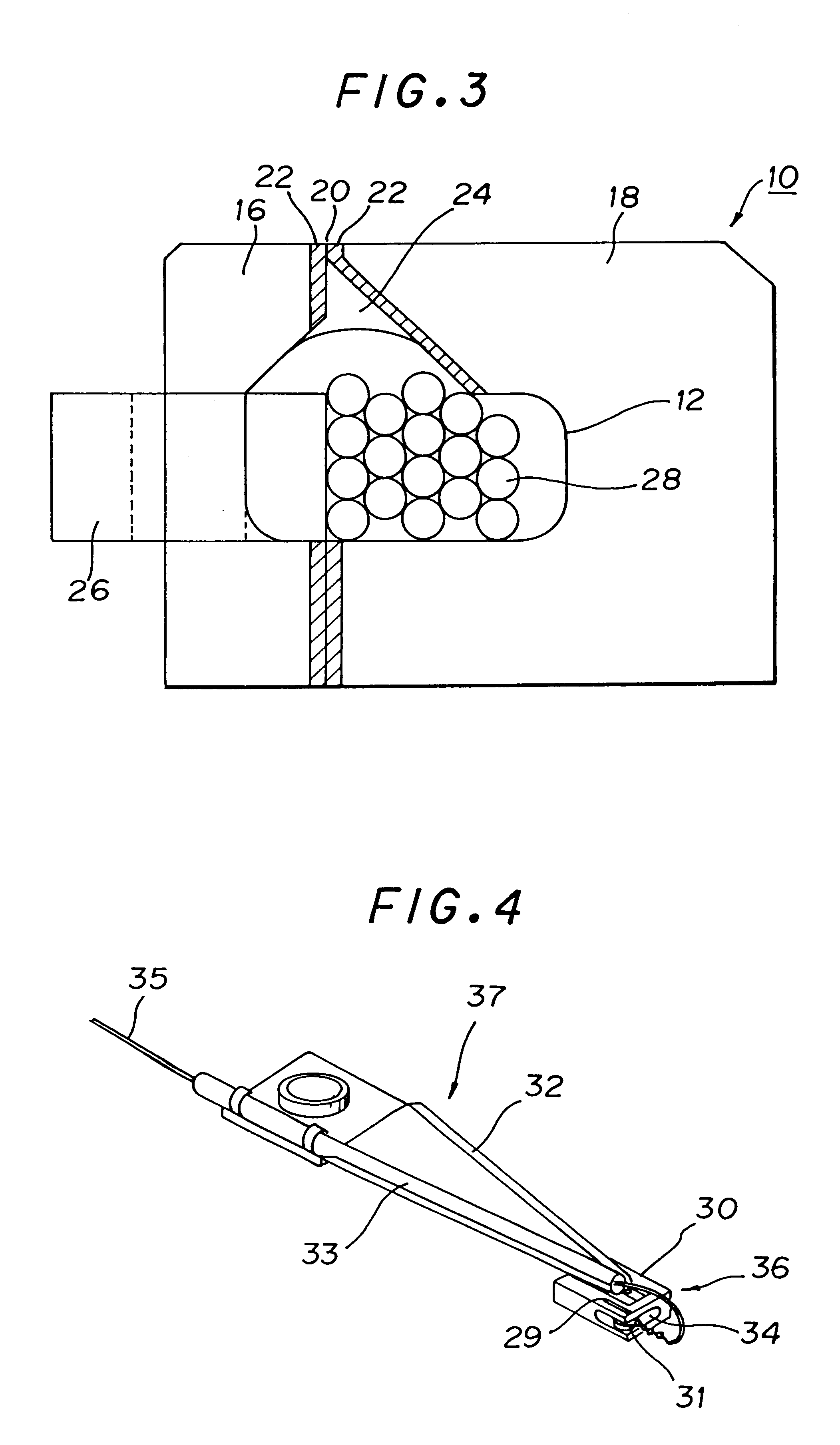

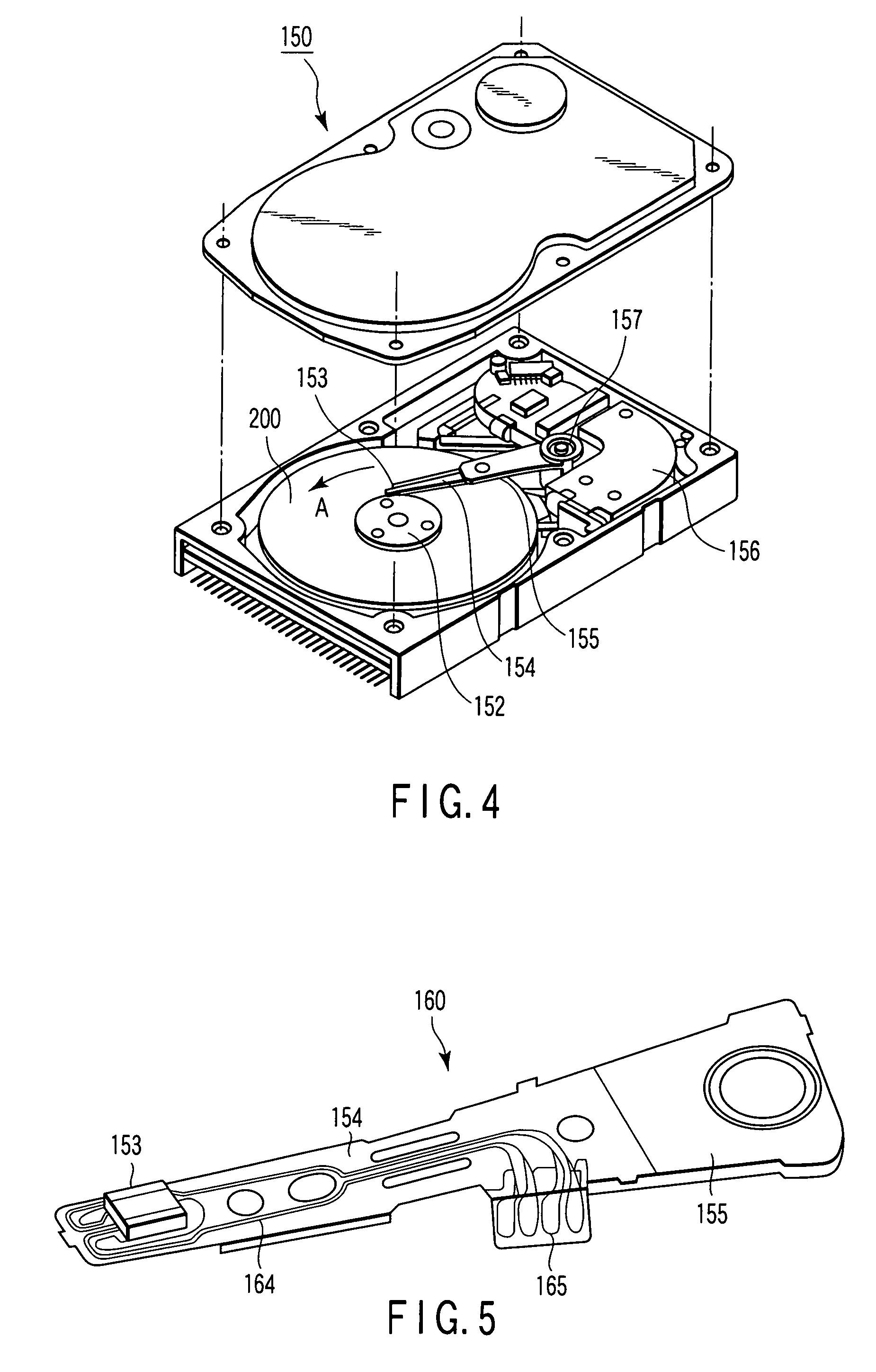

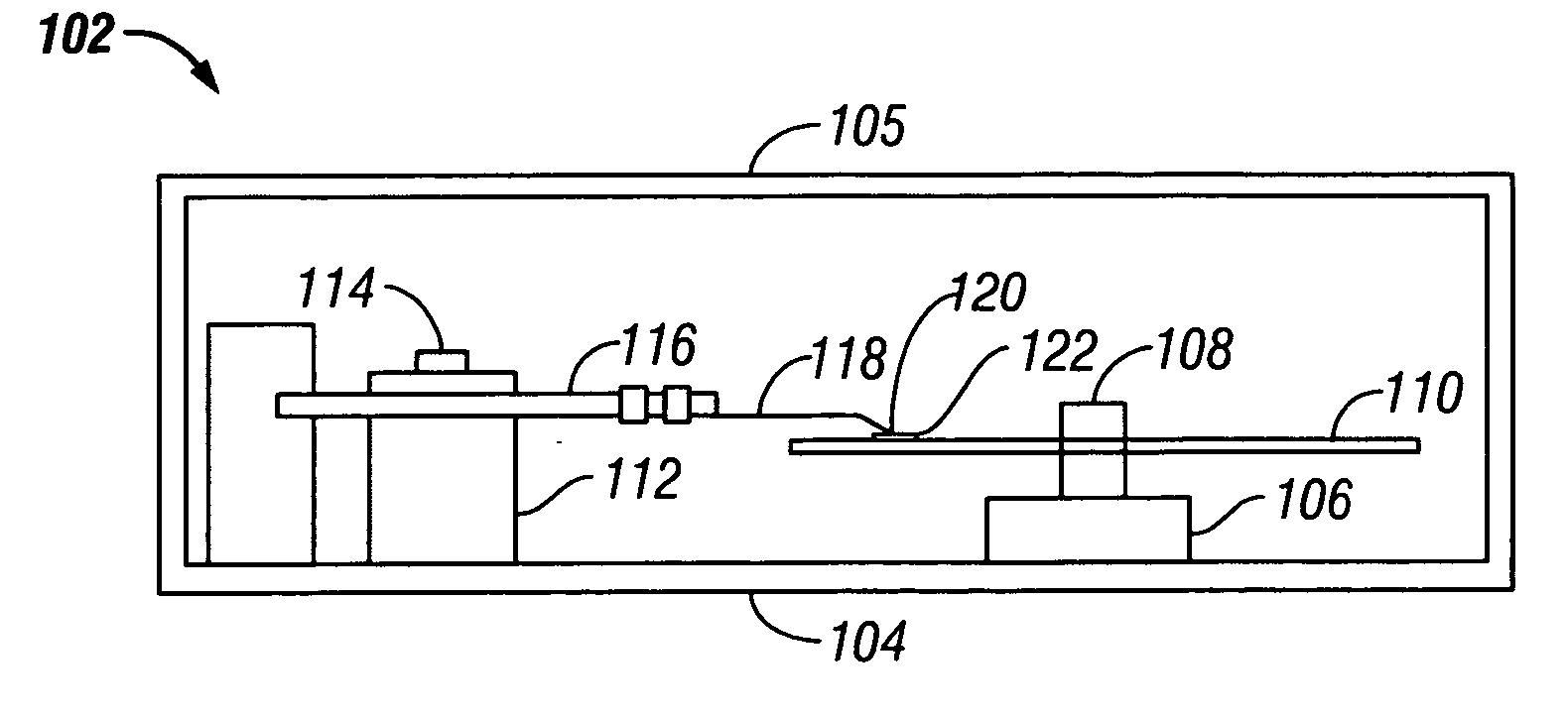

Integrated bidirectional Recording head micropositioner for magnetic storage devices

InactiveUS6859346B1Fast trackReliable trackingConstruction of head windingsFluid-dynamic spacing of headsMagnetic storageAmbient pressure

Transducer elements of recording heads for magnetic storage media are moved independently in either of two directions with respect to the slider of the recording head. The motion is controlled using a micropositioner having magnetic coils integrated into the recording head. The transducer moves in the x direction between data tracks and in the z direction perpendicular to the surface of the magnetic storage medium. The micropositioners are used for small-scale positioning of the transducers over data tracks and to adjust fly heights. Because of the high minimum resonant frequencies and the low mass of the transducers, the micropositioners also improve settling times associated with track following. The micropositioners can be used during fabrication for dimensional control of recording head components. The motion of the transducers in the z direction enables the recording heads to be used reliably in the presence of asperities and changing ambient pressures and temperatures.

Owner:MEYER DALLAS W

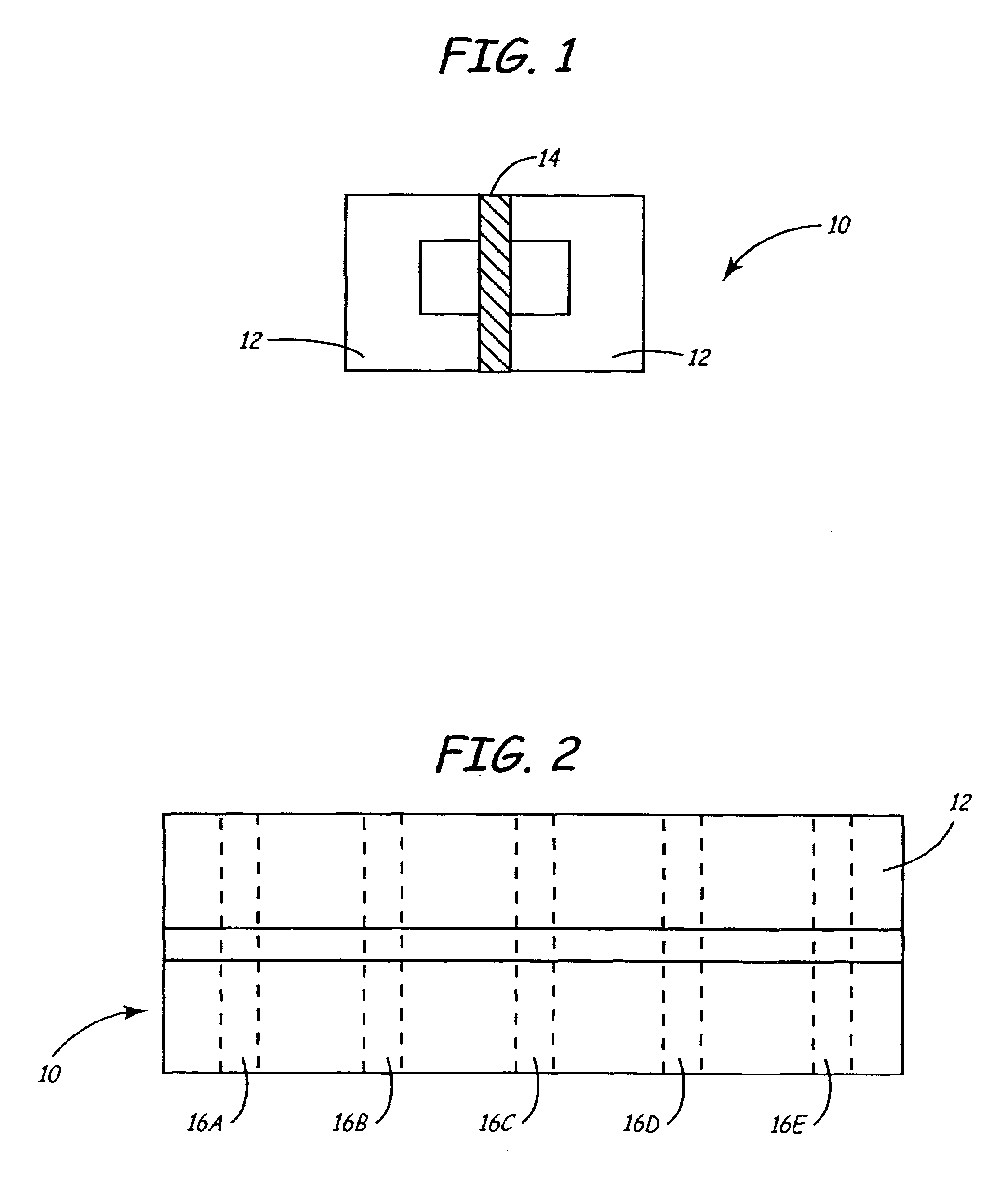

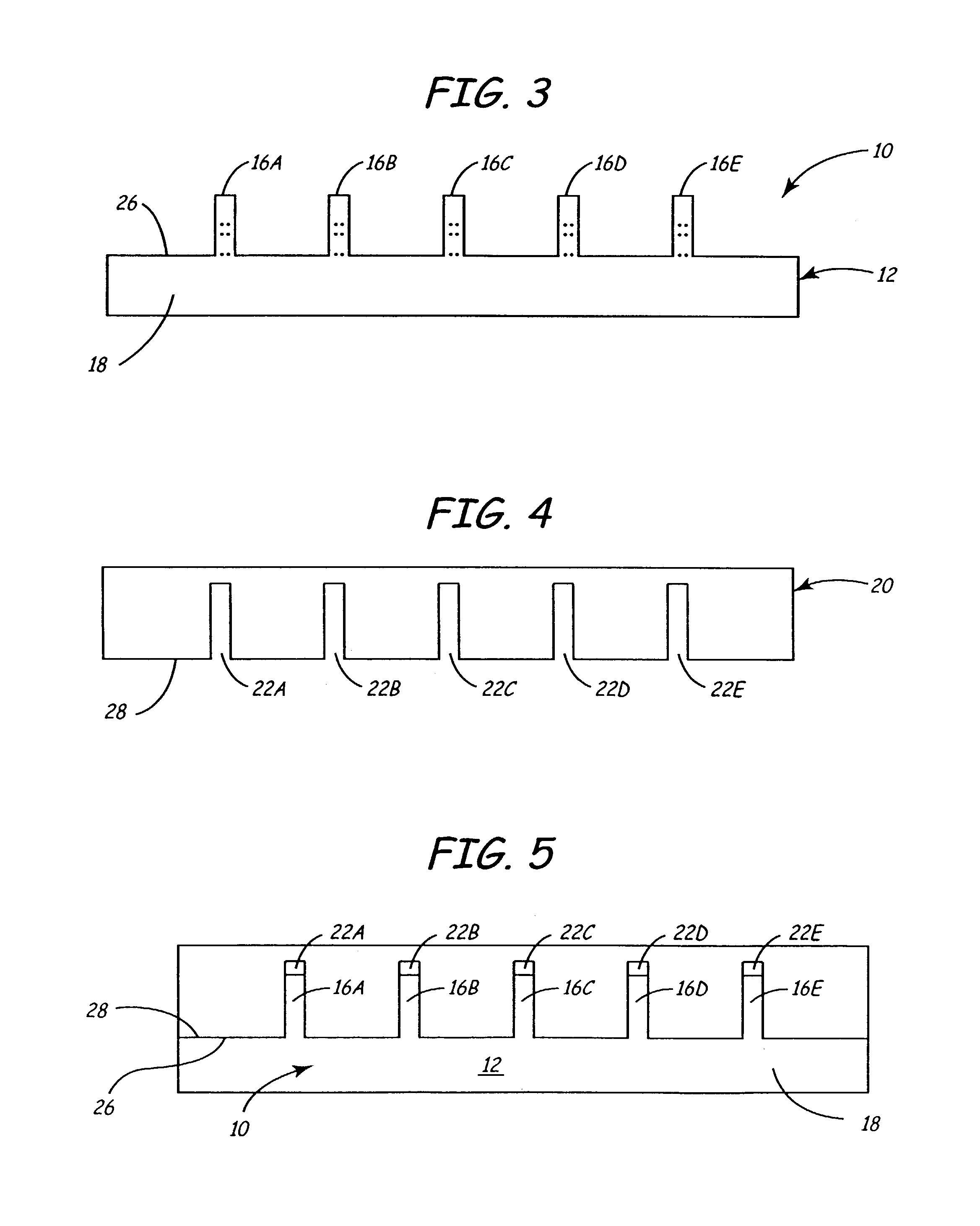

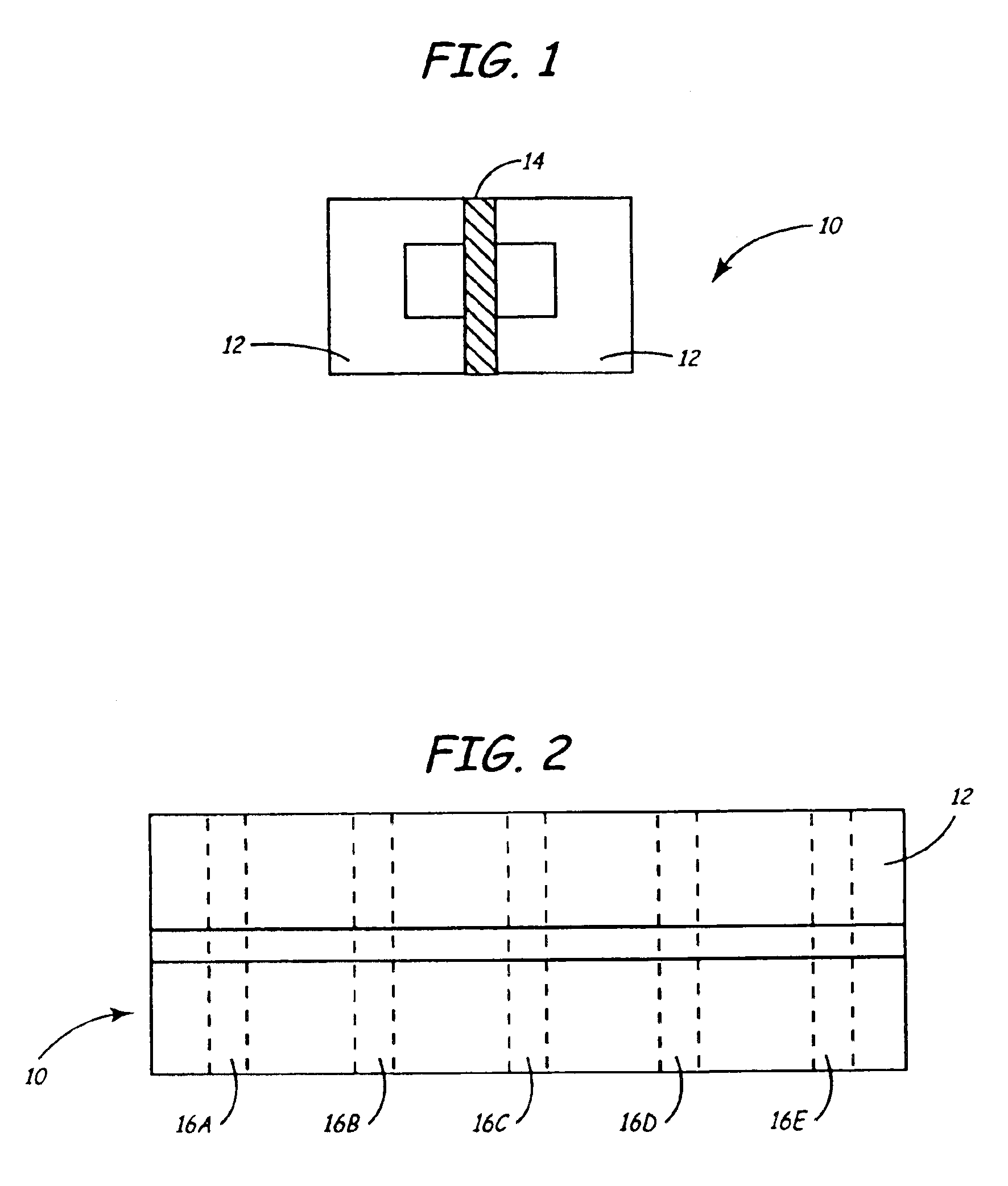

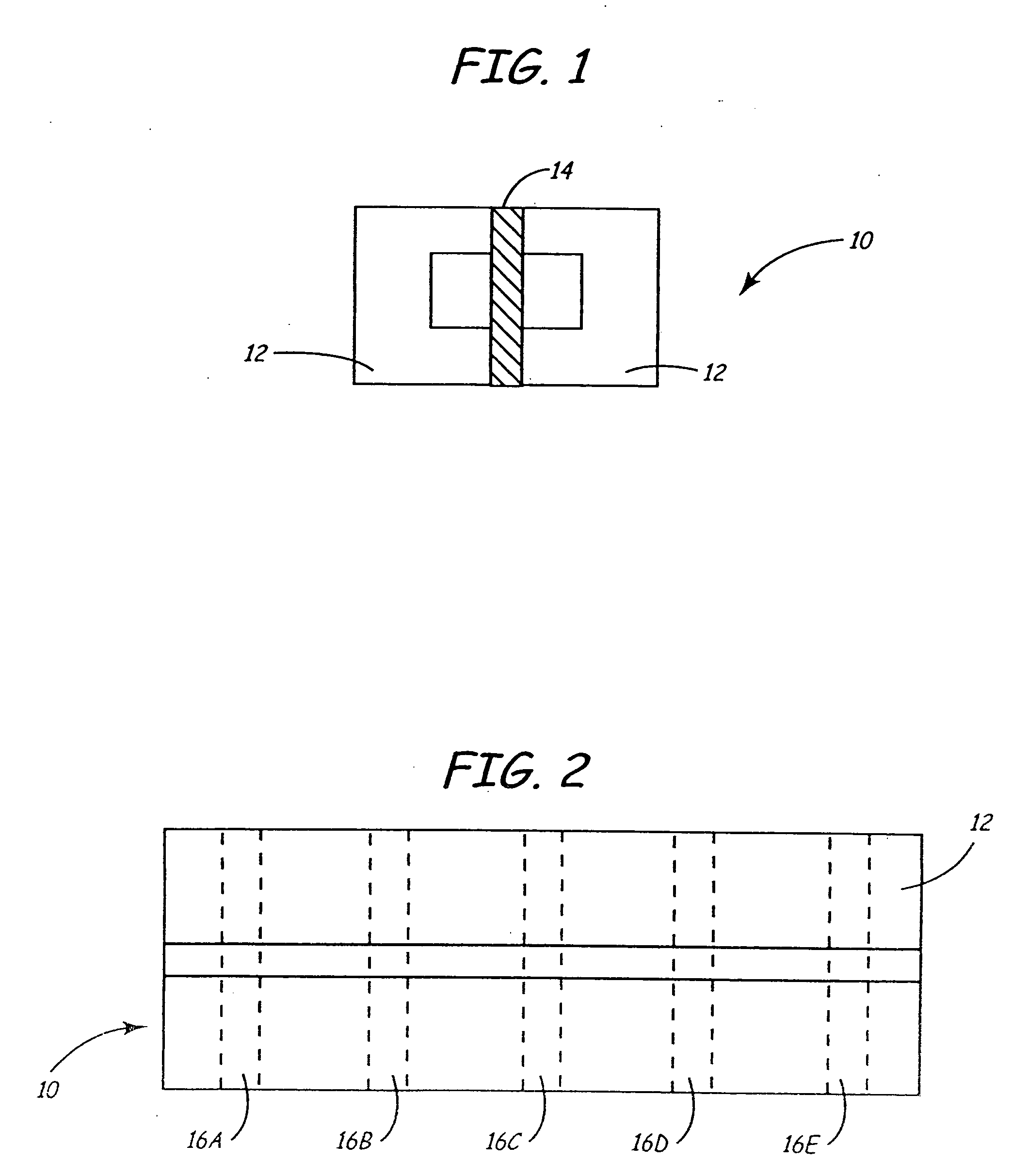

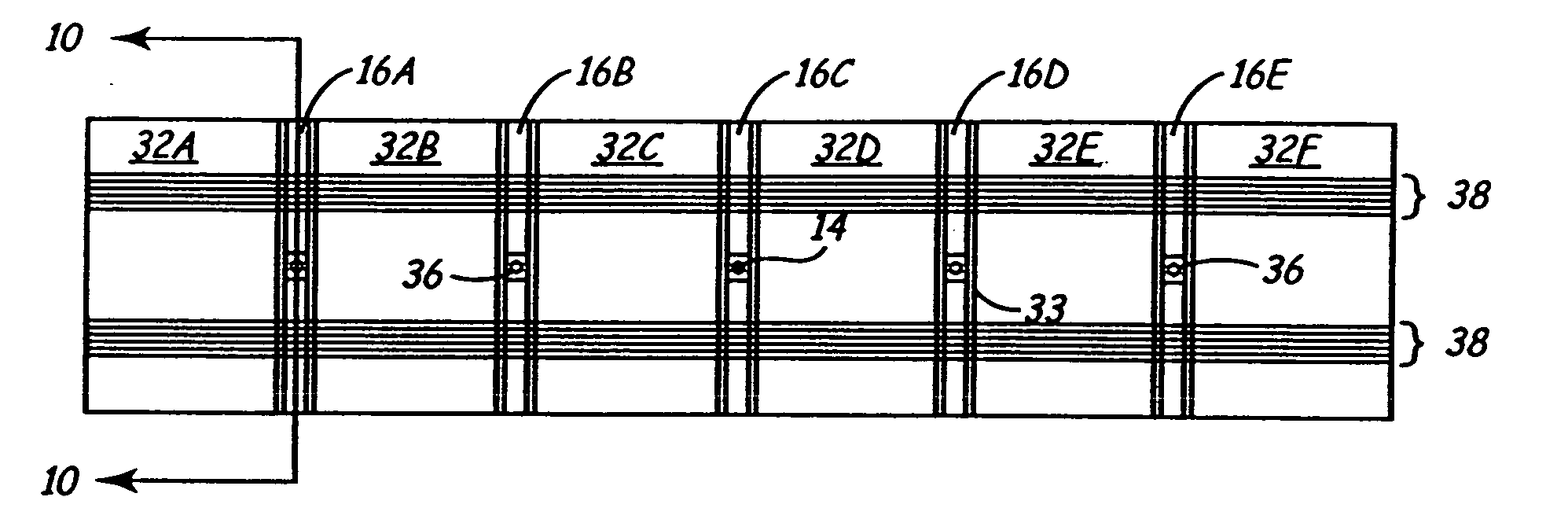

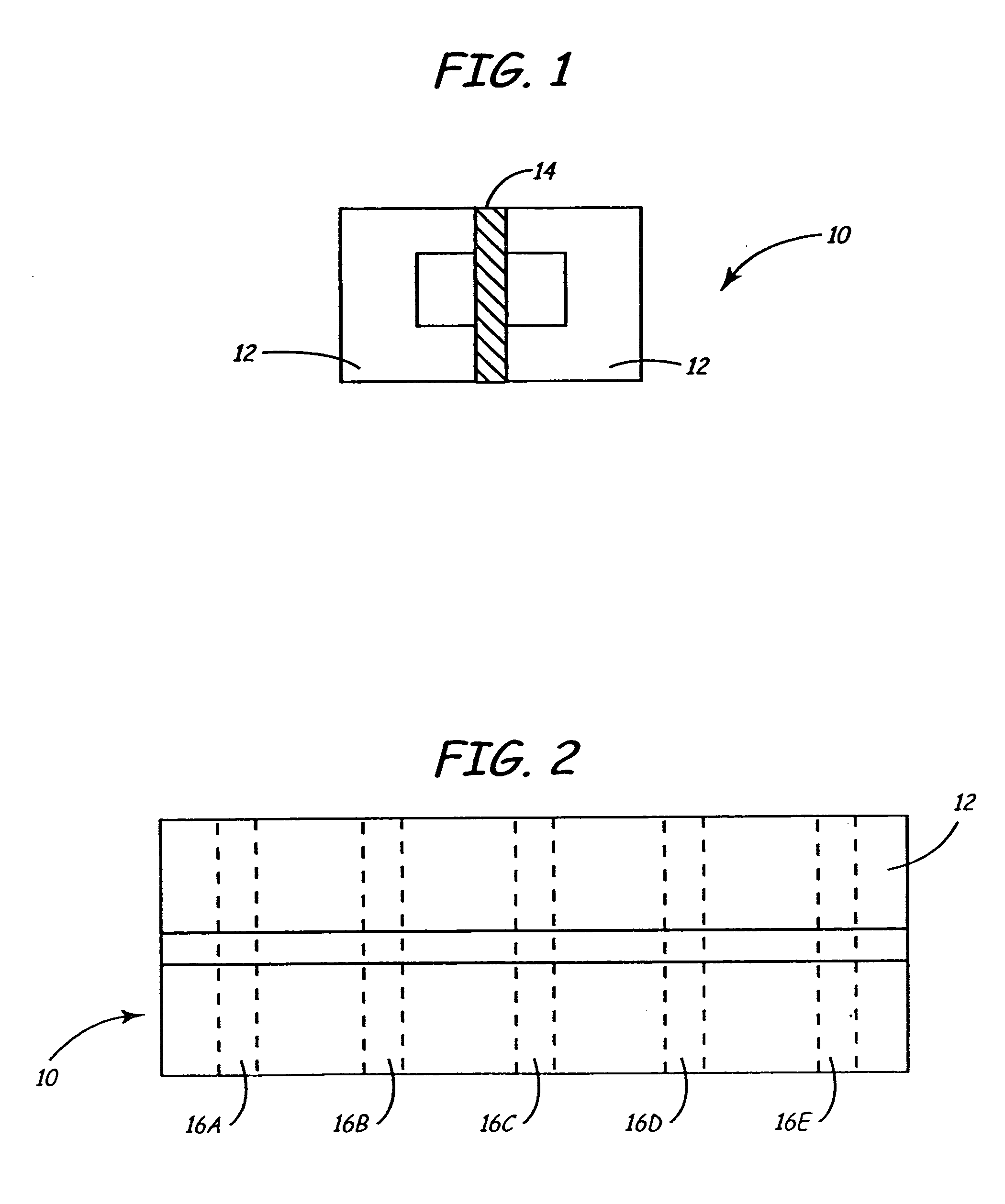

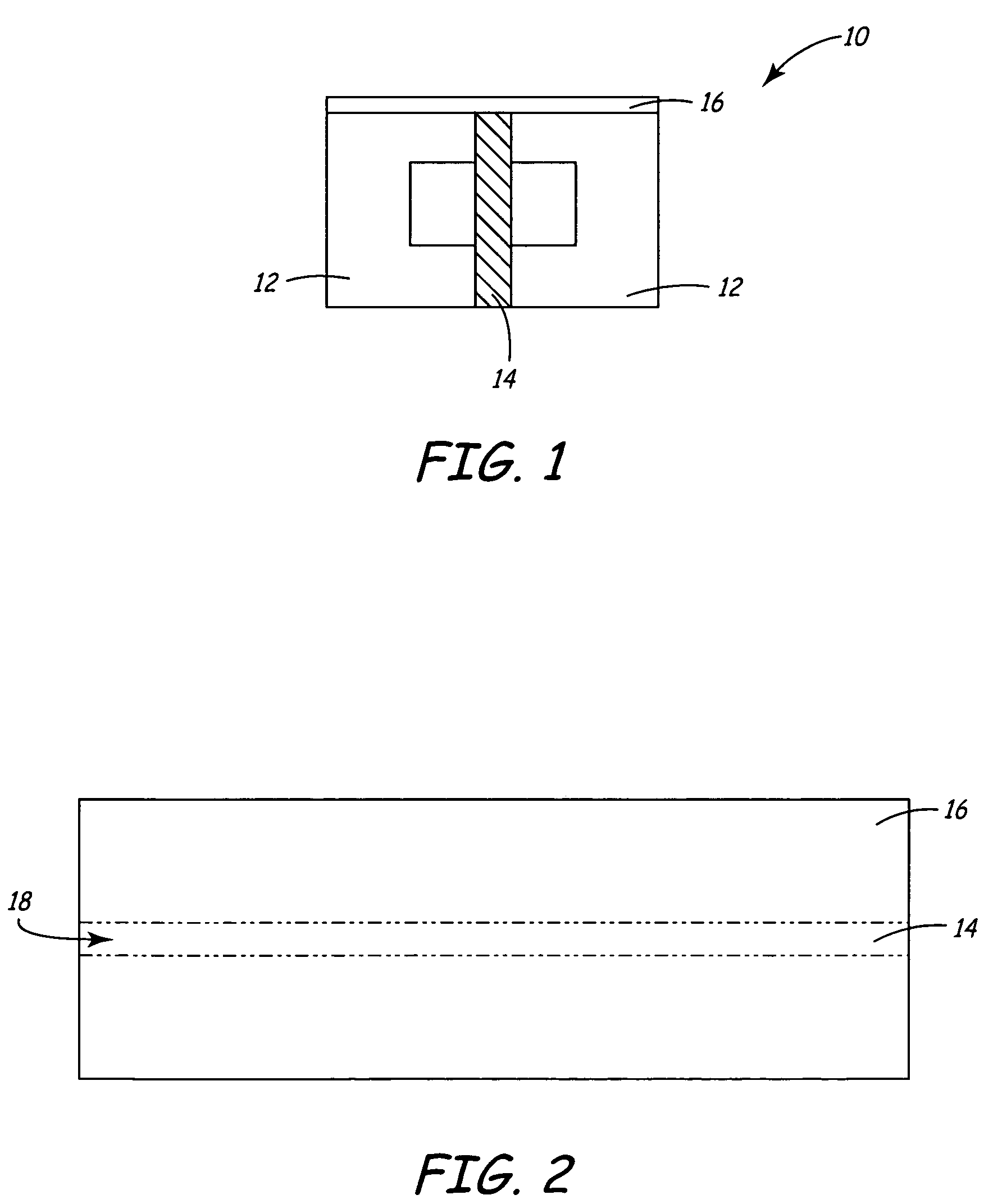

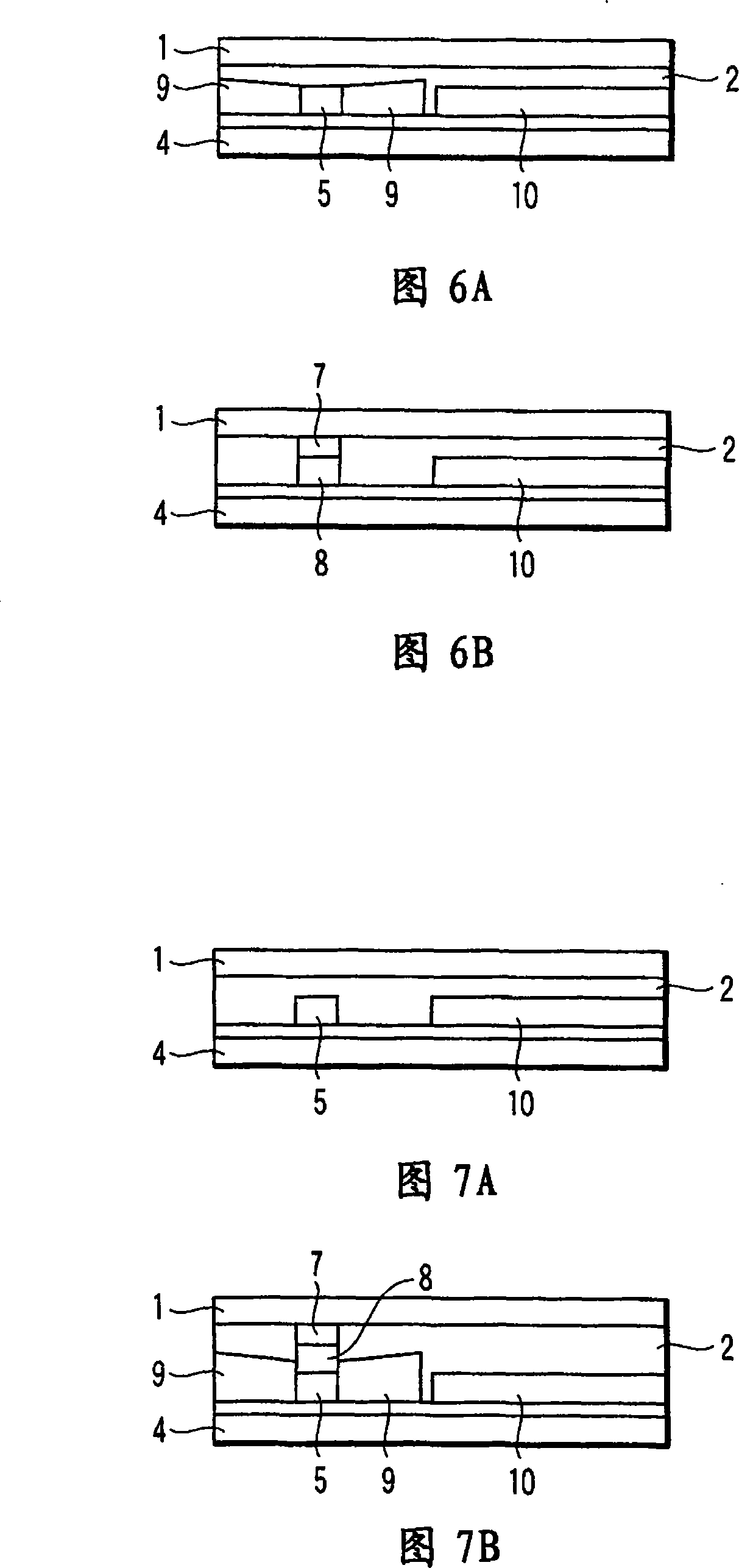

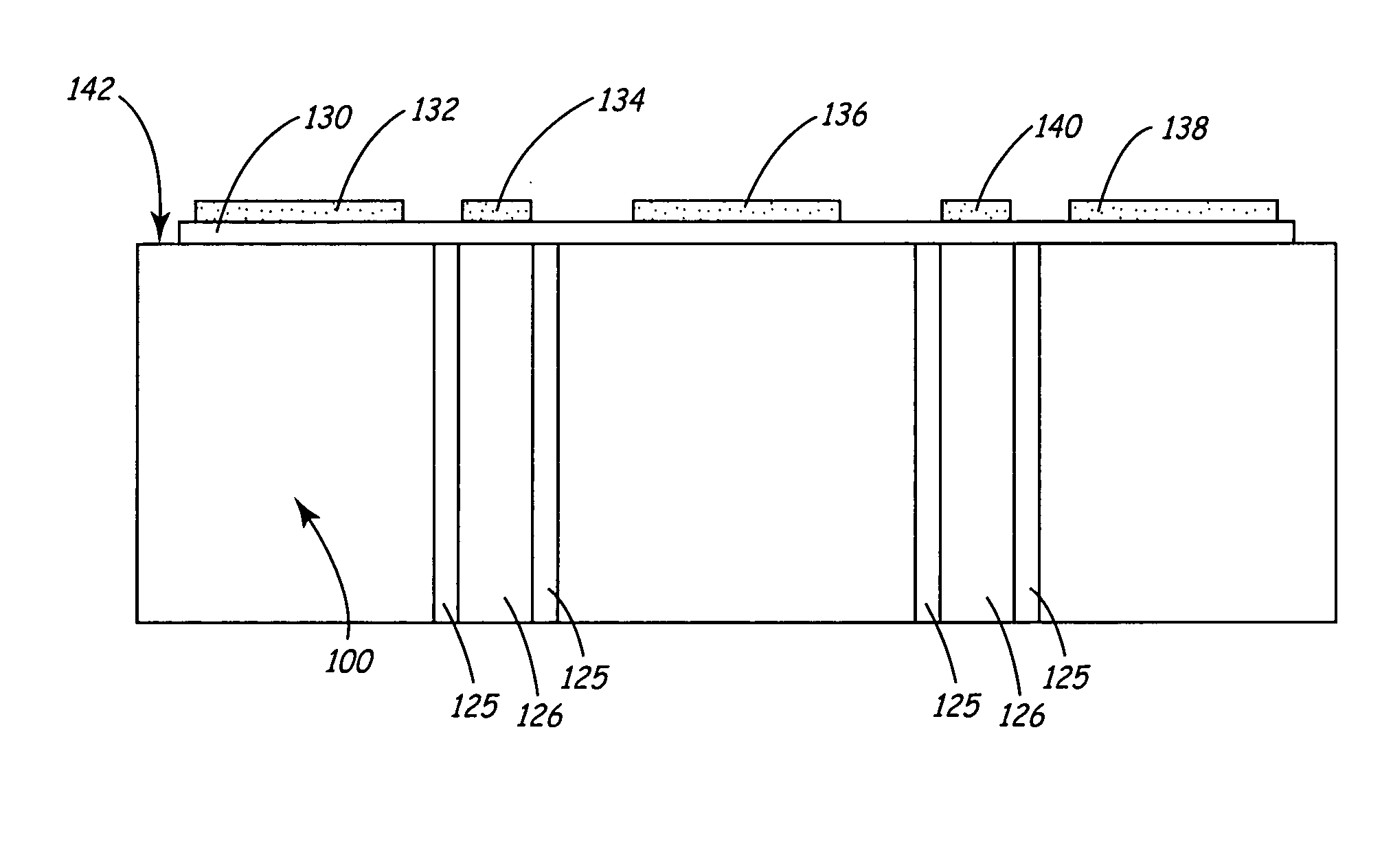

Wear pads for timing-based surface film servo heads

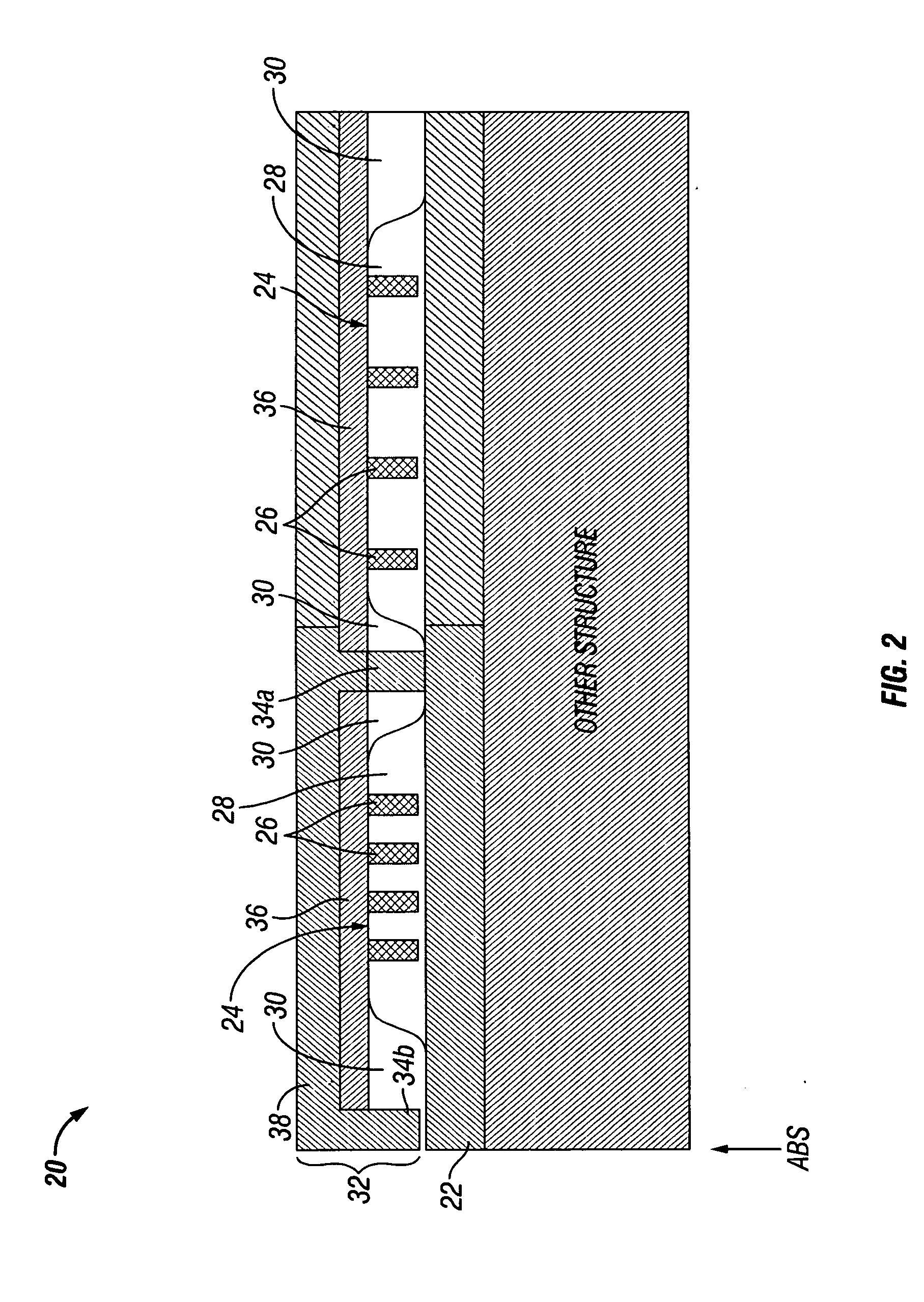

InactiveUS6989960B2Avoid negative effectsQuick wearElectrical transducersManufacture head surfaceEngineeringBearing surface

A thin film magnetic recording head is provided with a tape bearing surface that has magnetically isolated channels while still providing a maximum continuous surface area with which to engage the media. This can be accomplished by providing spaces in the magnetically permeable thin film that are large enough to prevent cross-talk between the channels, but small enough to prevent significant interference with the moving media. Alternatively, magnetically impermeable thin film spacers can be provided to magnetically isolate each of the channels. The spacers are generally even with the magnetically permeable thin film so as to provide a continuous media-bearing surface.

Owner:ADVANCED RES

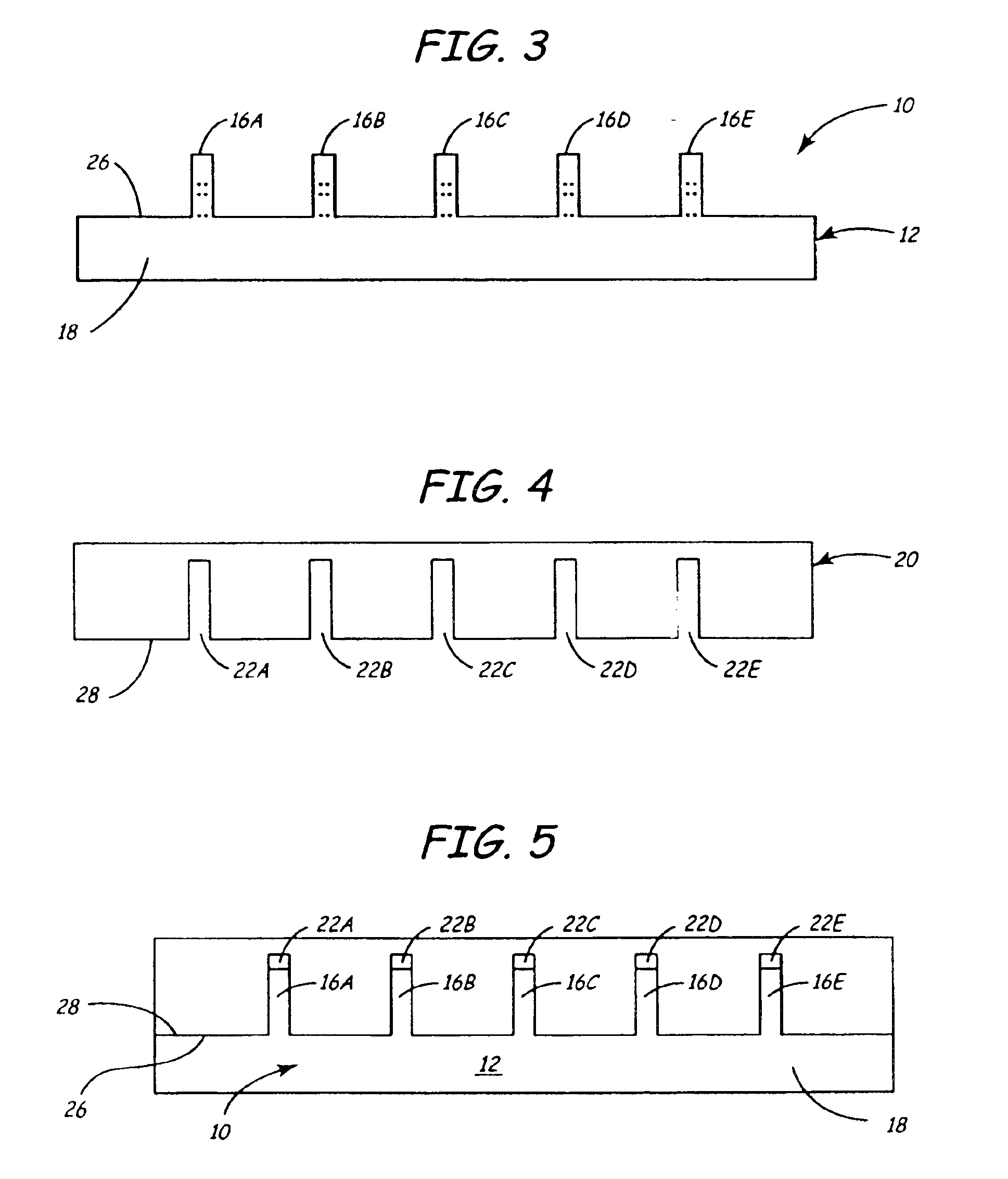

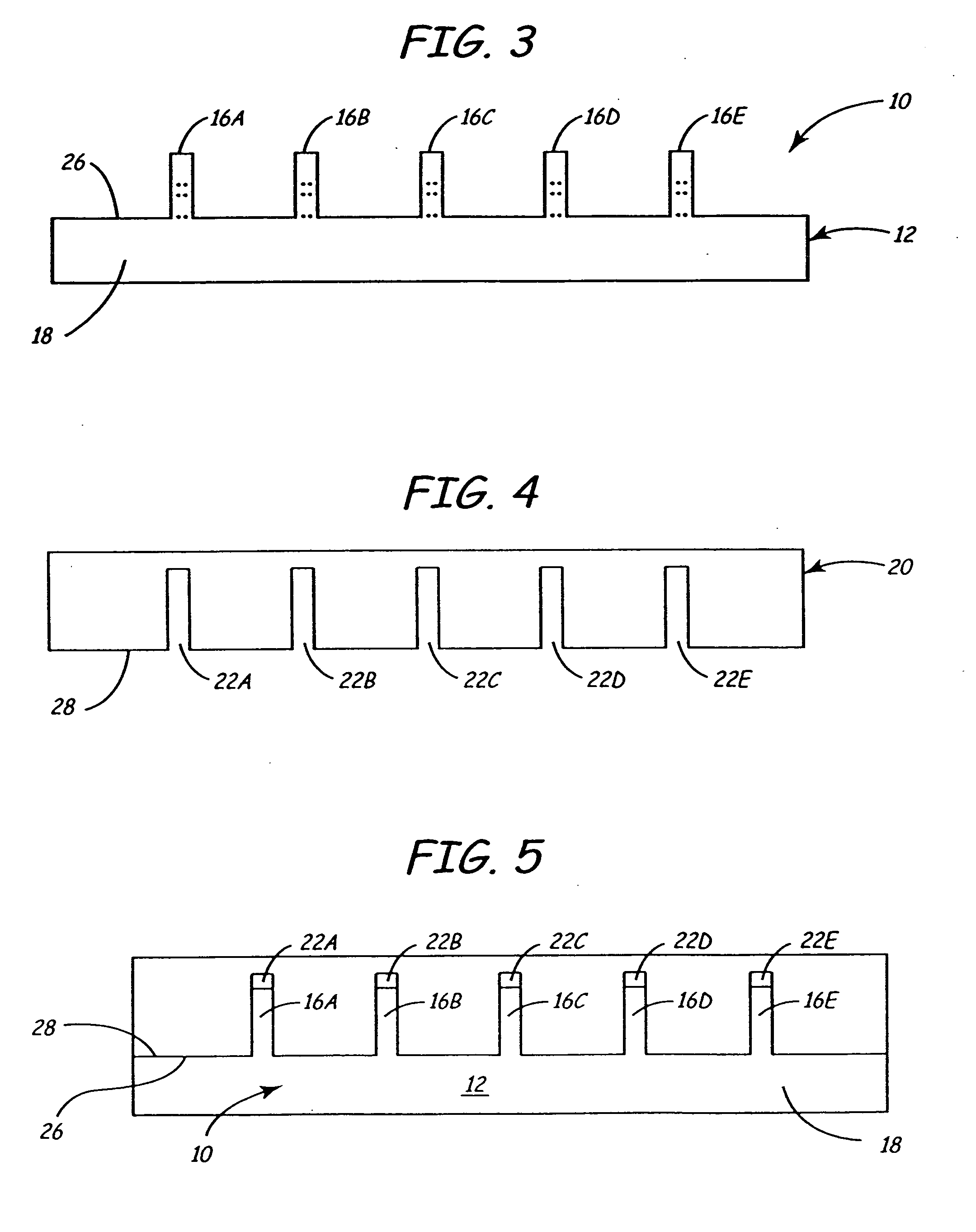

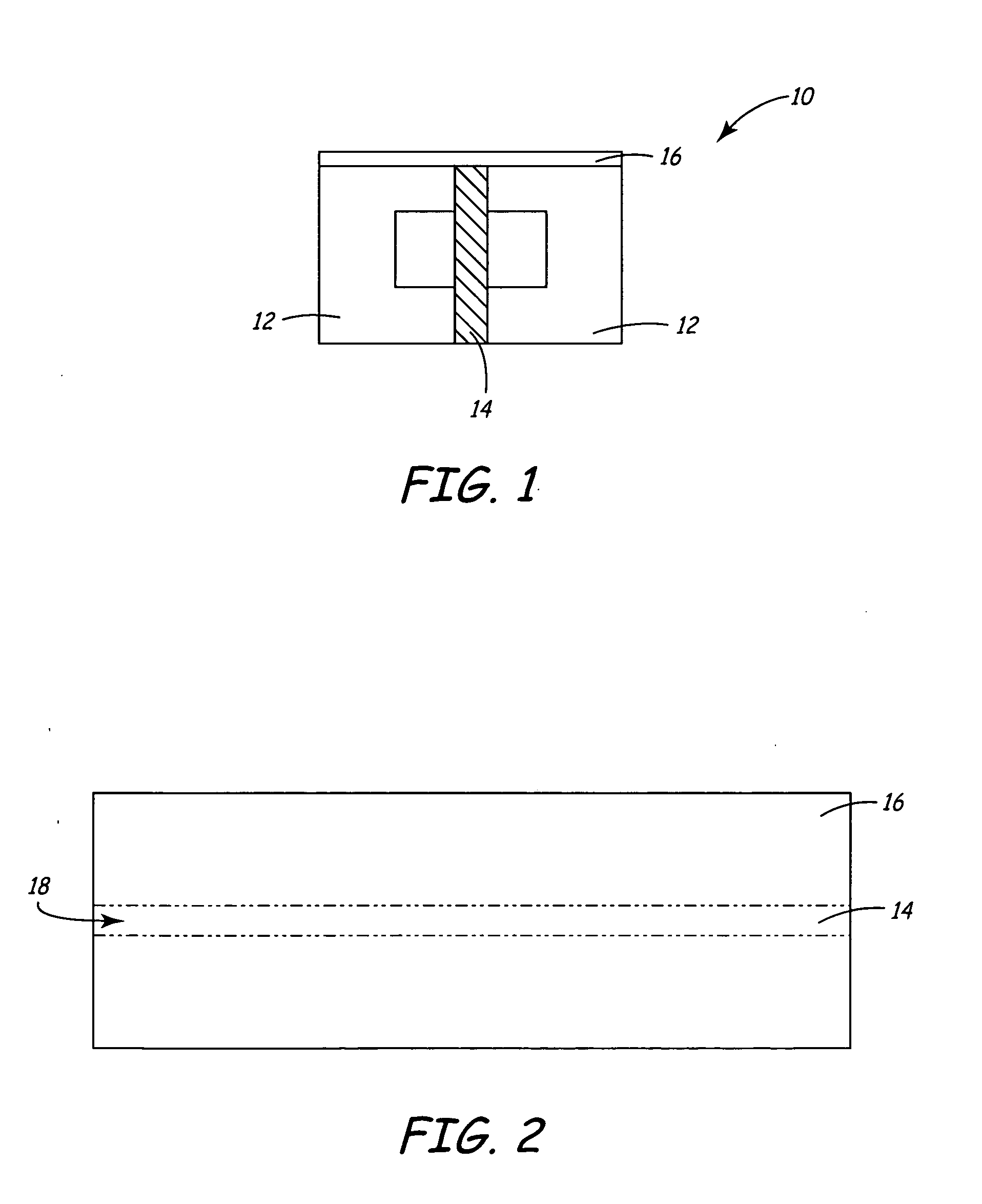

Low inductance, ferrite sub-gap substrate structure for surface film magnetic recording heads

InactiveUS6894869B2Avoid passingReduce reluctanceManufacture head surfaceManufacturing heads with multiple gapsMetallurgyLow inductance

A thin film magnetic recording head is fabricated by forming a substrate from opposing ferrite blocks which have a ceramic member bonded between them. This structure is then diced to form a plurality of columns, wherein each column has a ferrite / ceramic combination. Each column represents a single channel in the completed head. A block of ceramic is then cut to match the columned structure and the two are bonded together. The bonded structure is then cut or ground until a head is formed, having ceramic disposed between each channel. A ferrite back-gap is then added to each channel, minimizing the reluctance of the flux path. The thin film is patterned on the head to optimize various channel configurations.

Owner:ADVANCED RES

Wear pads for timing-based surface film servo heads

InactiveUS20060061906A1Improve linearityEliminate magnetic flux leakageManufacture head surfaceManufacturing heads with multiple gapsEngineeringBearing surface

Owner:ADVANCED RES

Magnetic device to reduce reversal current in current-driven magnetic reversal and magnetic memory using same

A magnetic device includes a first ferromagnetic layer in which magnetic layers and one or more nonmagnetic layers are alternately stacked, a second ferromagnetic layer having magnetization substantially fixed to a second direction, a third ferromagnetic layer provided between the first and second ferromagnetic layers and having a variable direction of magnetization, and a couple of electrodes configured to provide write current between the first and second ferromagnetic layers so that the direction of magnetization of the third ferromagnetic layer is determined depending on a direction of the current. At least one layer of the magnetic layers has magnetization substantially fixed to a first direction. Two or more layers of the magnetic layers are ferromagnetically coupled via the nonmagnetic layers. The ferromagnetic coupling has a strength such that a parallel magnetic alignment of the magnetic layers is maintained when the write current is passed.

Owner:KATANA SILICON TECH LLC

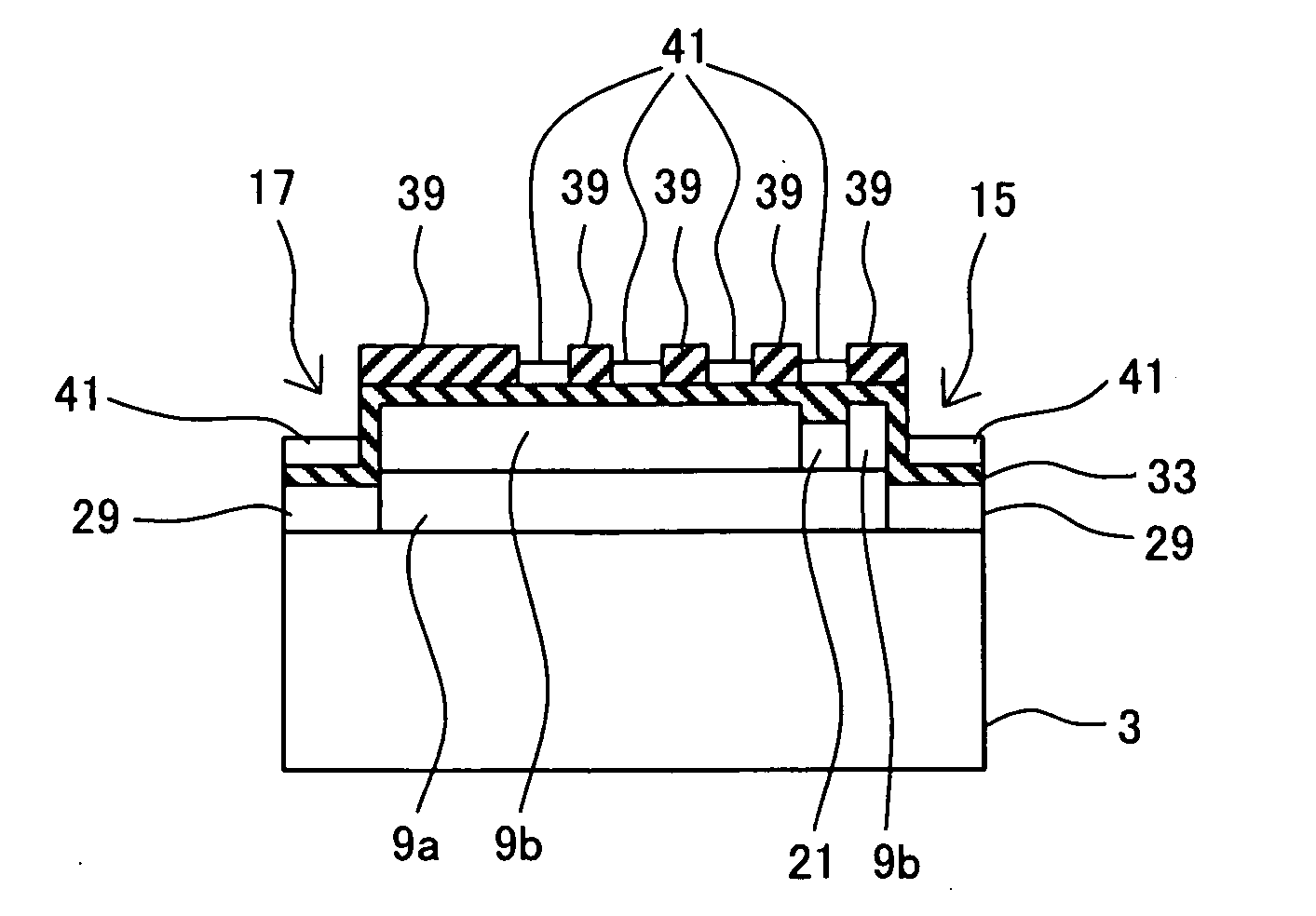

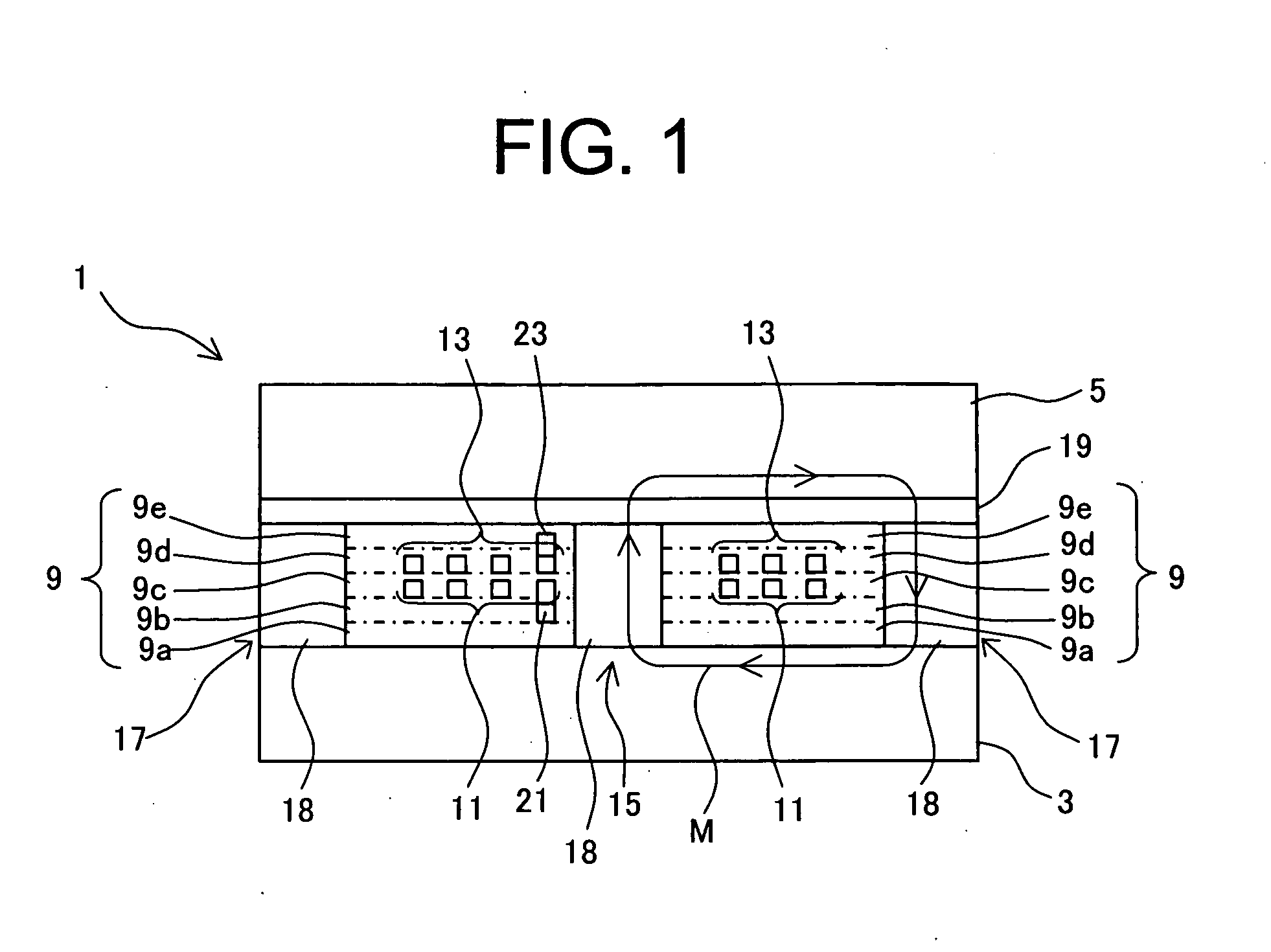

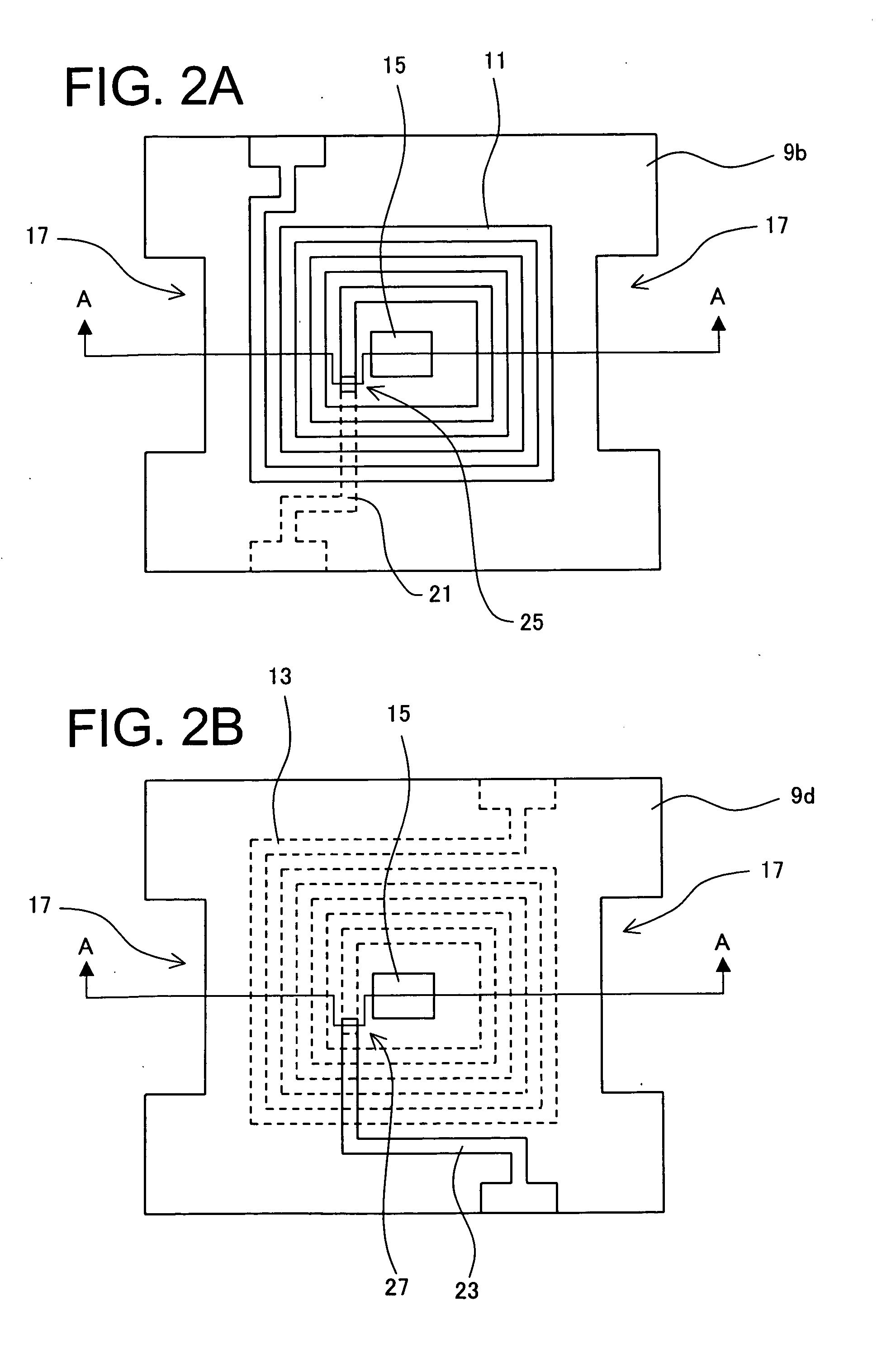

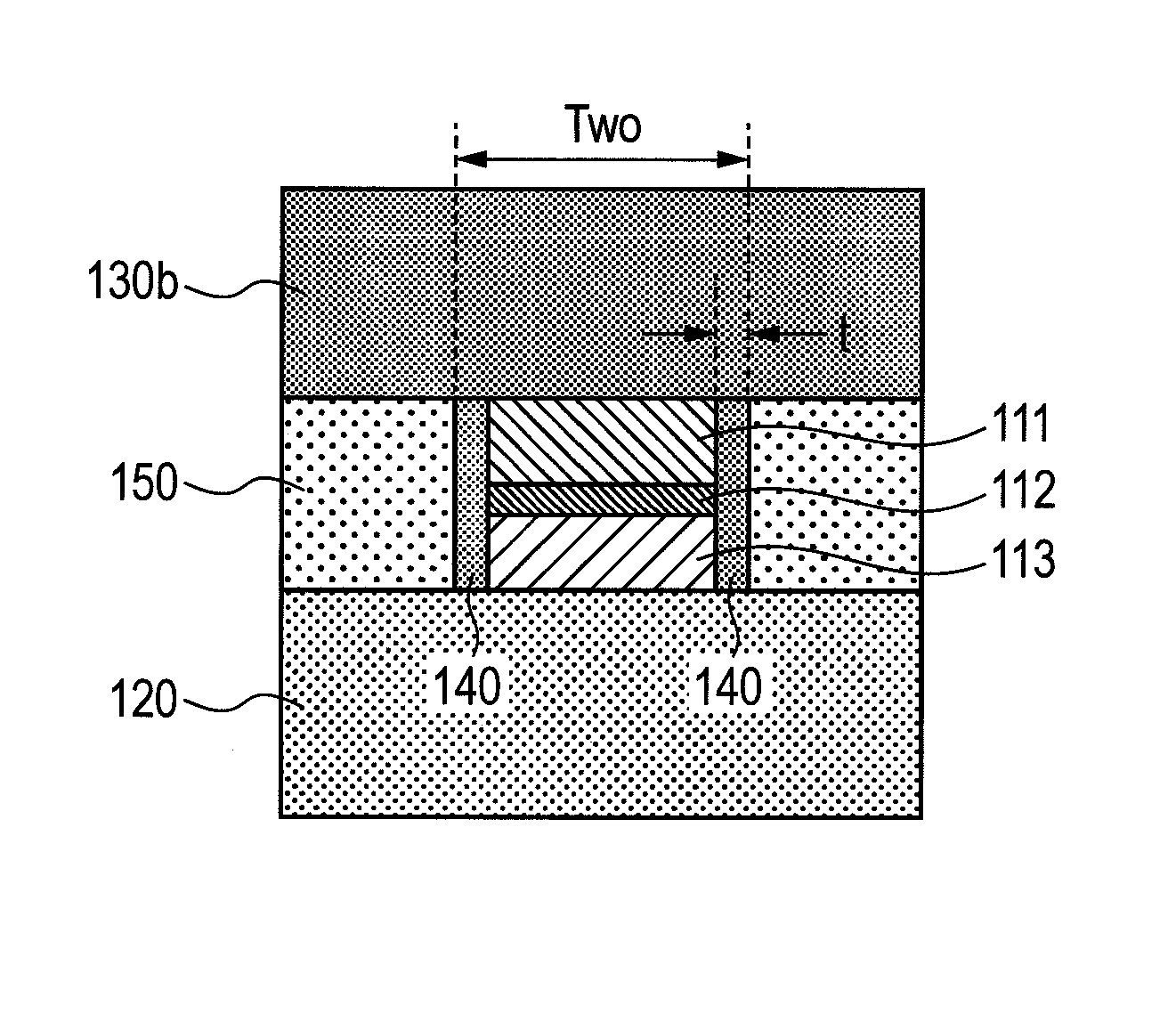

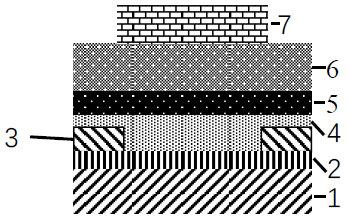

Method of manufacturing coil component

ActiveUS7318269B2Improve impedance characteristicsReduce the overall heightElectrical transducersRecord information storageElectrical conductorTransformer

The invention relates to a method of manufacturing a coil component uses as a major part of a common mode choke coil or a transformer, and there is provided a method of manufacturing a compact and low height coil component in which deterioration of impedance characteristics is low and reliability is high. An insulating film is formed on a magnetic substrate, and open regions are formed in the insulating film. A lead terminal portion is formed on the insulating film, and a planarizing film is formed on the open regions. An insulating film is formed and openings are formed in the insulating film at the open regions. A coil conductor is formed on the insulating film, and a planarizing film is further formed on the planarizing film. After a coil conductor is further formed on the coil conductor through the insulating film, the planarizing films are removed.

Owner:TDK CORPARATION

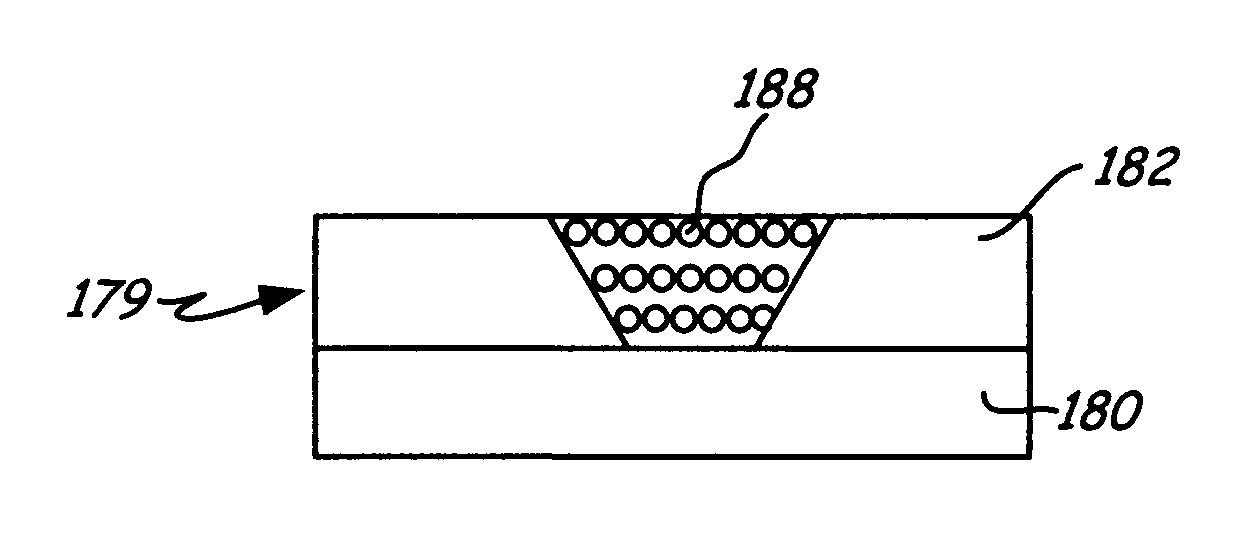

Nanoclustered magnetic materials for high moment write pole applications

The present invention includes magnetic write elements with portions formed a nanophase high magnetic moment material to enable further increases in areal density in magnetic recording. The nanophase deposited high magnetic moment material comprises coated nanoclusters and nanolaminated cluster films that are deposited to form nanophase high magnetic moment material portions of a write pole and SUL layer in perpendicular recording media. The nanophase write poles exhibit high magnetic moments and are generally compatible with conventional writer head fabrication techniques.

Owner:SEAGATE TECH LLC

Low inductance, ferrite sub-gap substrate structure for surface film magnetic recording heads

InactiveUS20050275968A1Avoid passingReduce reluctanceManufacture head surfaceManufacture unitary devices of plural headsMagnetic reluctanceOptoelectronics

Owner:DUGAS MATTHEW P

Transducing head design with low erasure field

InactiveUS20050068670A1Record information storageManufacture of flux-sensitive headsEngineeringElectrical and Electronics engineering

A transducing head has a main pole and at least one magnetic element (such as a return pole or a shield) which provides a potential return path for a magnetic field produced by the main pole. The magnetic element is spaced from the main pole. The magnetic element has a first edge closest to the main pole and a second edge furthest from the main pole. Permeability of the magnetic element increases from the first edge to the second edge.

Owner:SEAGATE TECH LLC

Method of manufacturing coil component

ActiveUS20050050717A1Improve impedance characteristicsReduce the overall heightElectrical transducersRecord information storageElectrical conductorTransformer

The invention relates to a method of manufacturing a coil component uses as a major part of a common mode choke coil or a transformer, and there is provided a method of manufacturing a compact and low height coil component in which deterioration of impedance characteristics is low and reliability is high. An insulating film is formed on a magnetic substrate, and open regions are formed in the insulating film. A lead terminal portion is formed on the insulating film, and a planarizing film is formed on the open regions. An insulating film is formed and openings are formed in the insulating film at the open regions. A coil conductor is formed on the insulating film, and a planarizing film is further formed on the planarizing film. After a coil conductor is further formed on the coil conductor through the insulating film, the planarizing films are removed.

Owner:TDK CORPARATION

Nanoclustered magnetic materials for high moment write pole applications

InactiveUS20050084668A1Increase areal densityNanomagnetismRecord information storageNanometreAtomic physics

The present invention includes magnetic write elements with portions formed a nanophase high magnetic moment material to enable further increases in areal density in magnetic recording. The nanophase deposited high magnetic moment material comprises coated nanoclusters and nanolaminated cluster films that are deposited to form nanophase high magnetic moment material portions of a write pole and SUL layer in perpendicular recording media. The nanophase write poles exhibit high magnetic moments and are generally compatible with conventional writer head fabrication techniques.

Owner:SEAGATE TECH LLC

Transducing head including a magnetic element exhibiting varying permeability

InactiveUS7382575B2Manufacturing heads with multiple gapsHeads using thin filmsEngineeringMagnetic field

A transducing head has a main pole and at least one magnetic element (such as a return pole or a shield) which provides a potential return path for a magnetic field produced by the main pole. The magnetic element is spaced from the main pole. The magnetic element has a first edge closest to the main pole and a second edge furthest from the main pole. Permeability of the magnetic element increases from the first edge to the second edge.

Owner:SEAGATE TECH LLC

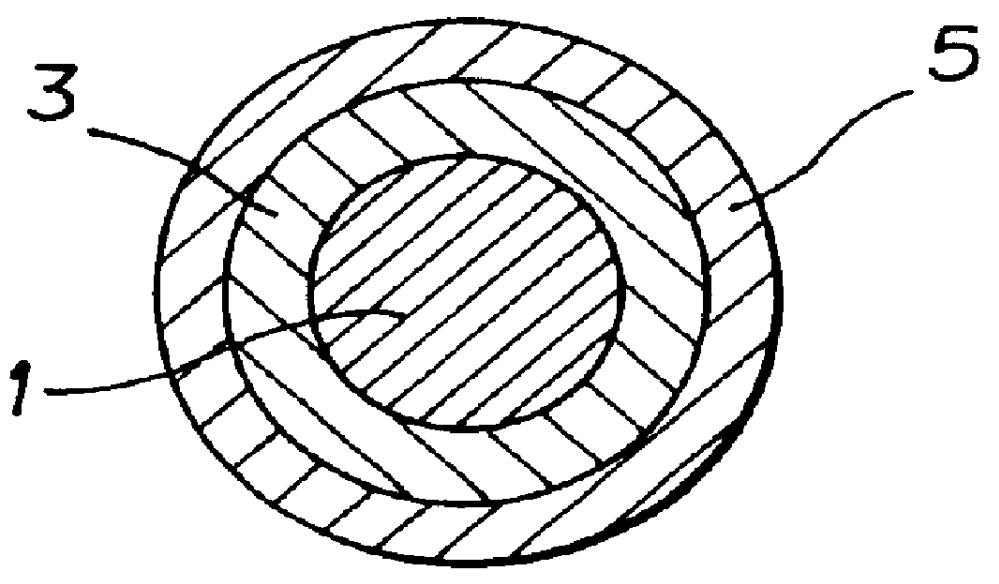

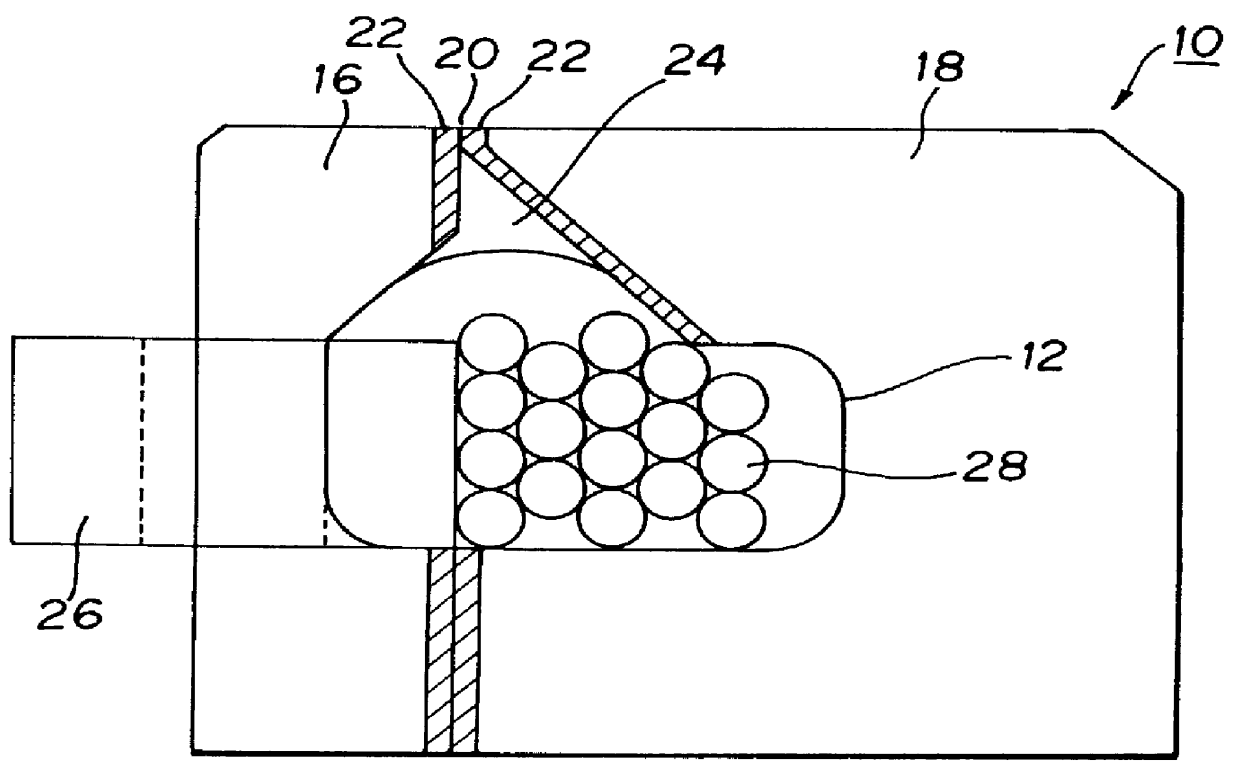

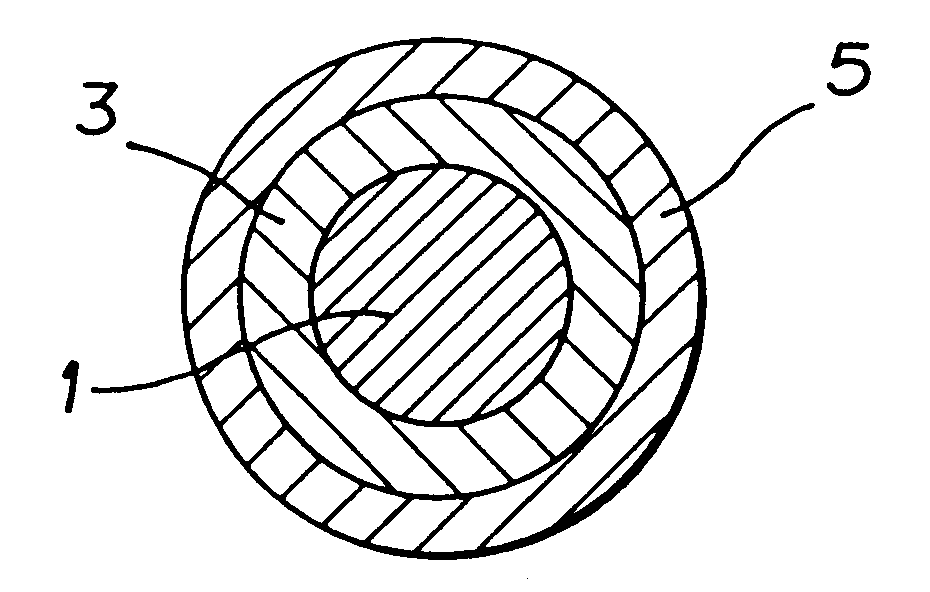

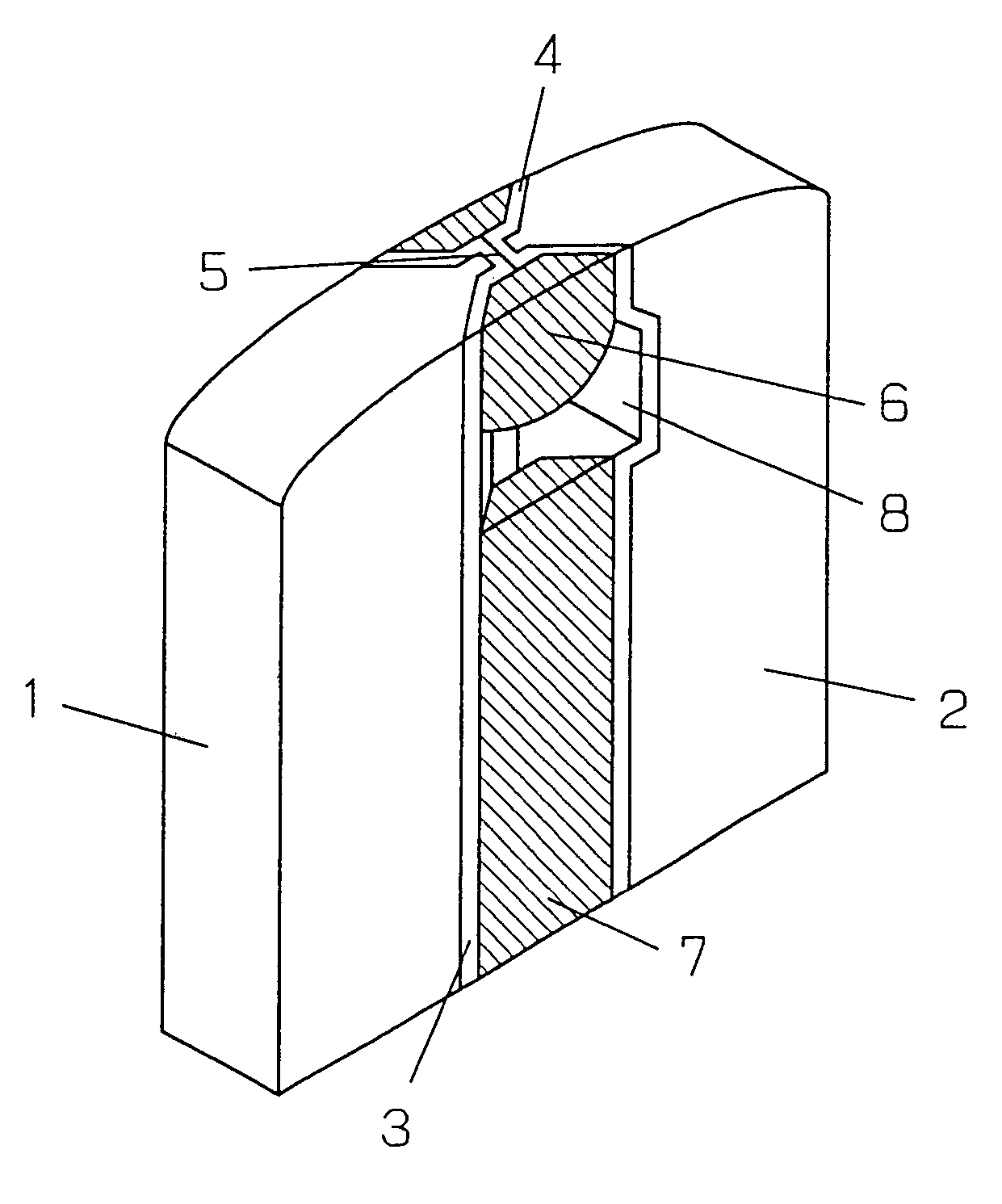

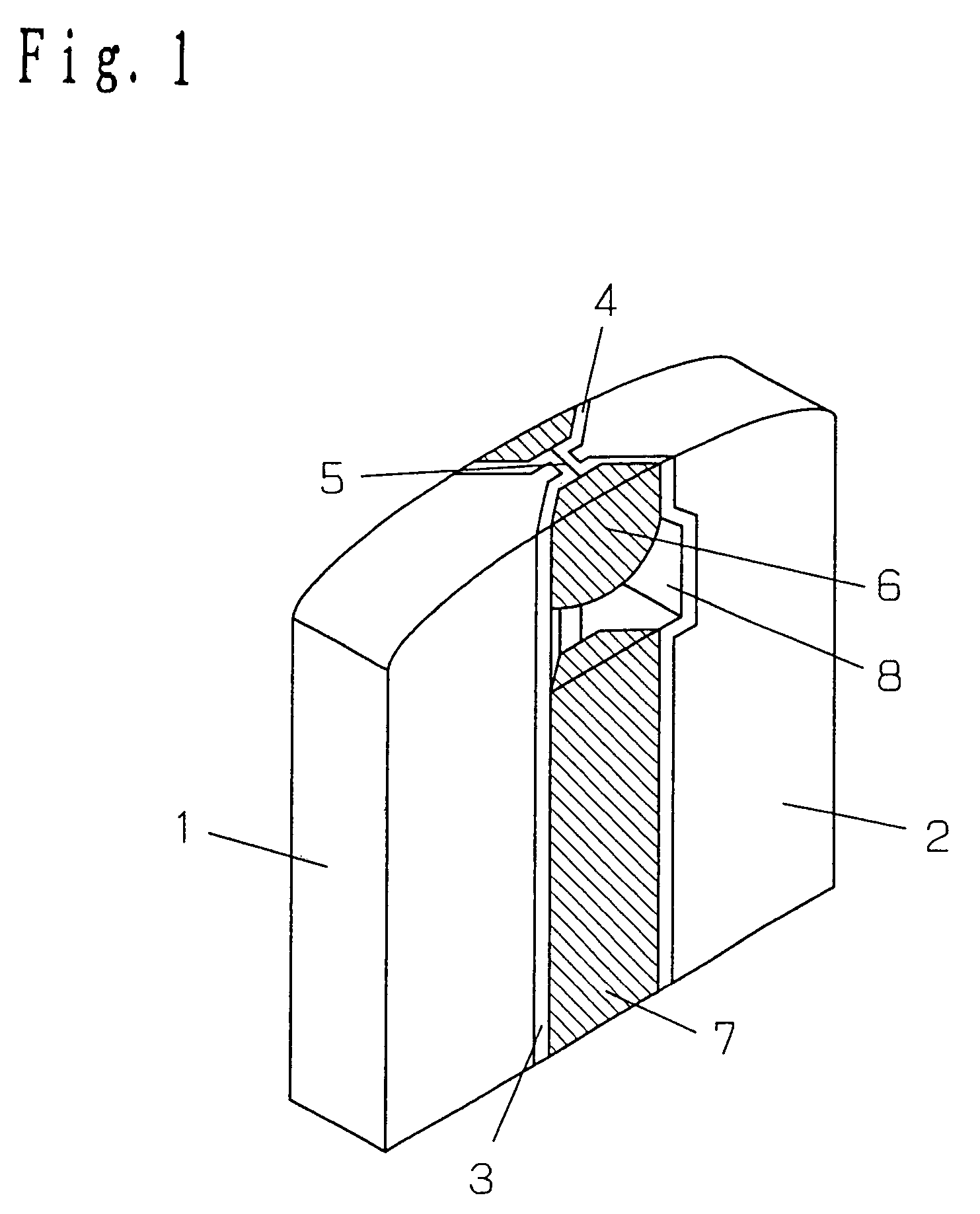

Composite metallic wire and magnetic head using said composite metal wire

InactiveUS6068917ASingle bars/rods/wires/strips conductorsSolid-state devicesElectrical resistance and conductanceMetal

A composite metallic wire includes: an inner layer having a cross-sectional shape of a rough circle; and a metal outer layer having a cross-sectional shape of a rough ring; wherein the composite metallic wire has a diameter of 15 mu m or less and an electric resistance of 300 OMEGA / m or less. A composite type magnetic head using as a coil wire a composite wire comprising: (1) a composite metallic wire comprising: an inner layer having a cross-sectional shape of a rough circle; and a metal outer layer having a cross-sectional shape of a rough ring; wherein the composite metallic wire has a diameter of 15 mu m or less and an electric resistance of 300 OMEGA / m or less, and (2) an insulating coat provided in the outer periphery of the outer layer.

Owner:NGK INSULATORS LTD

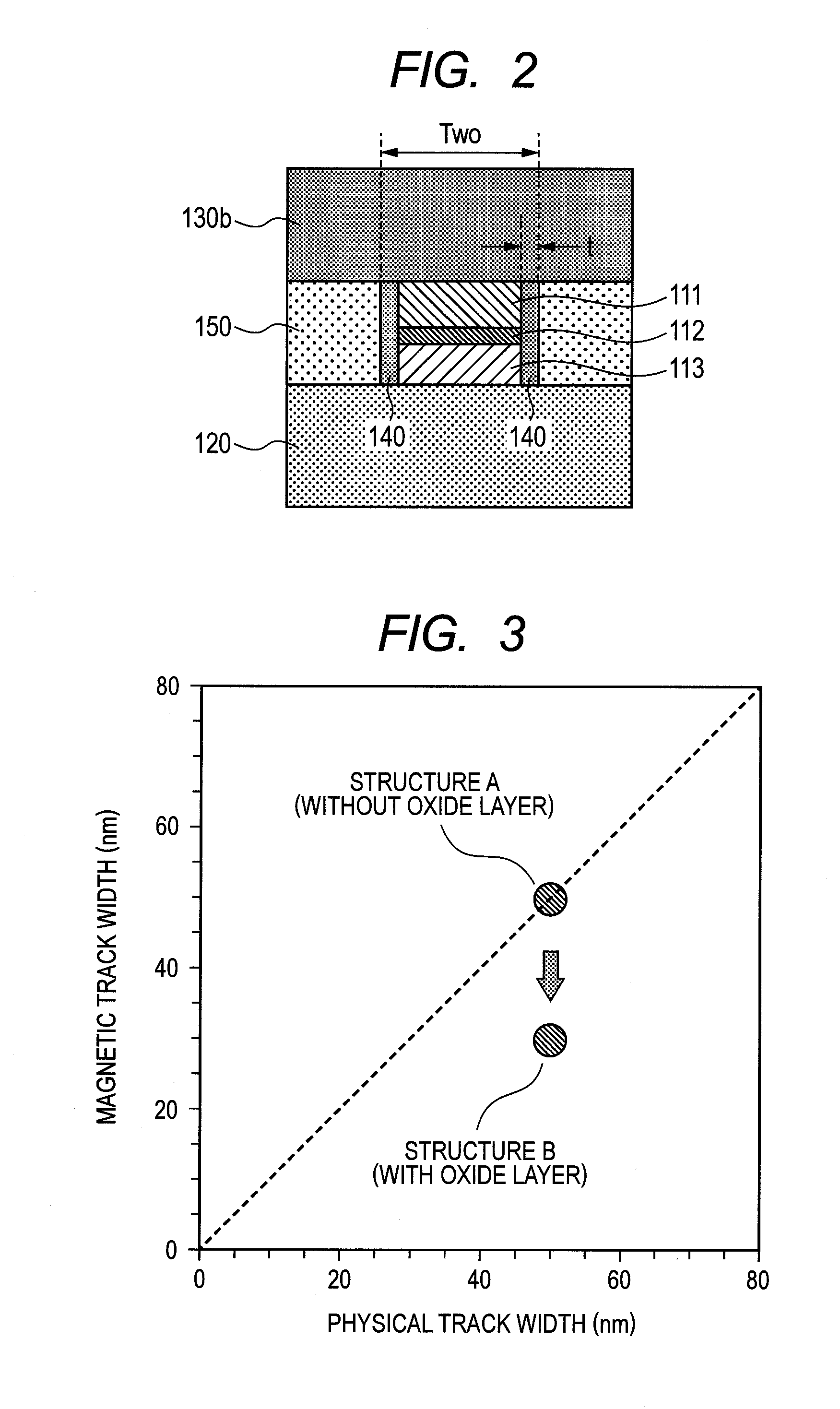

Magnetic head, method for producing the magnetic head, and magnetic recording/reproducing apparatus

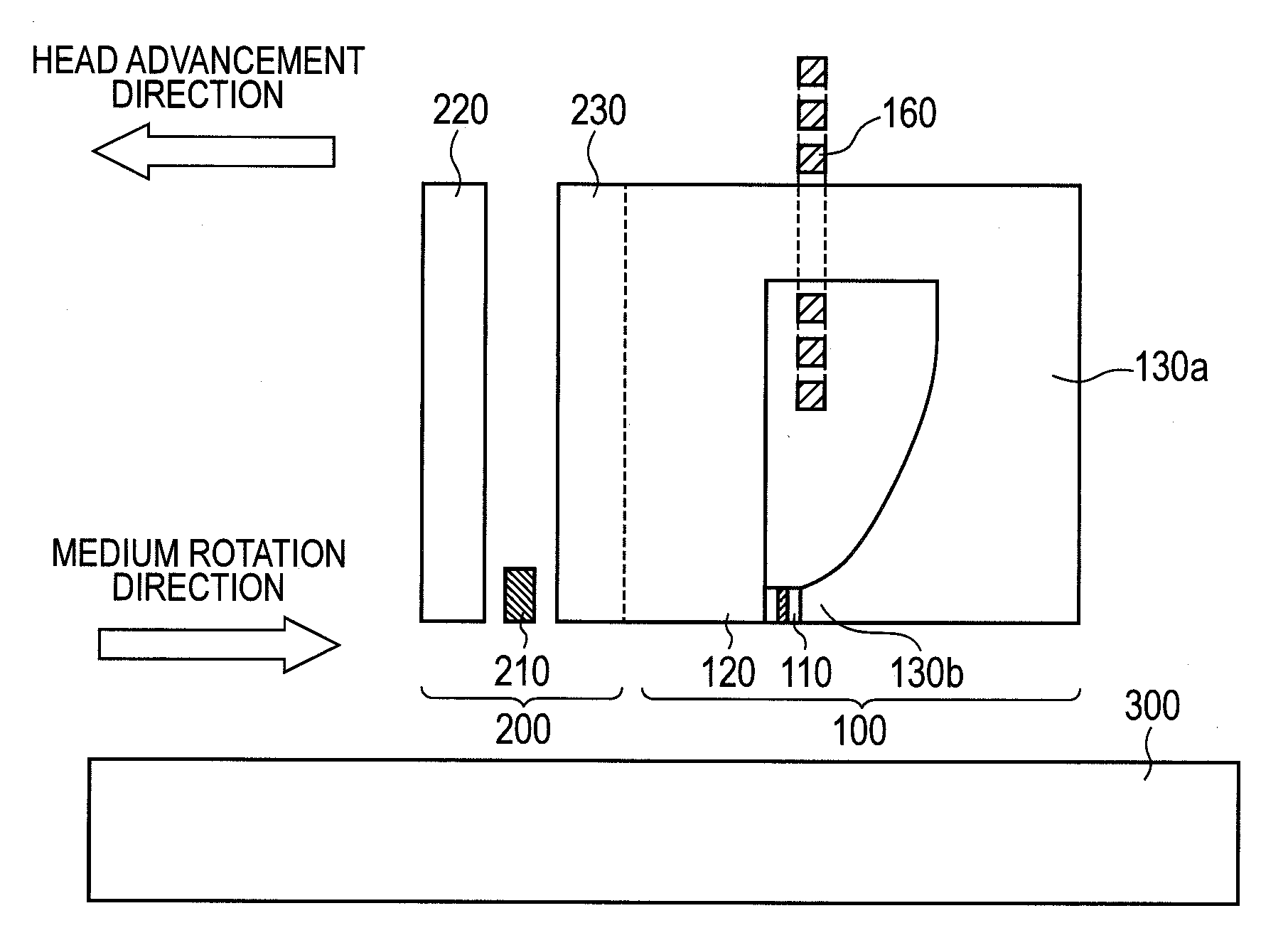

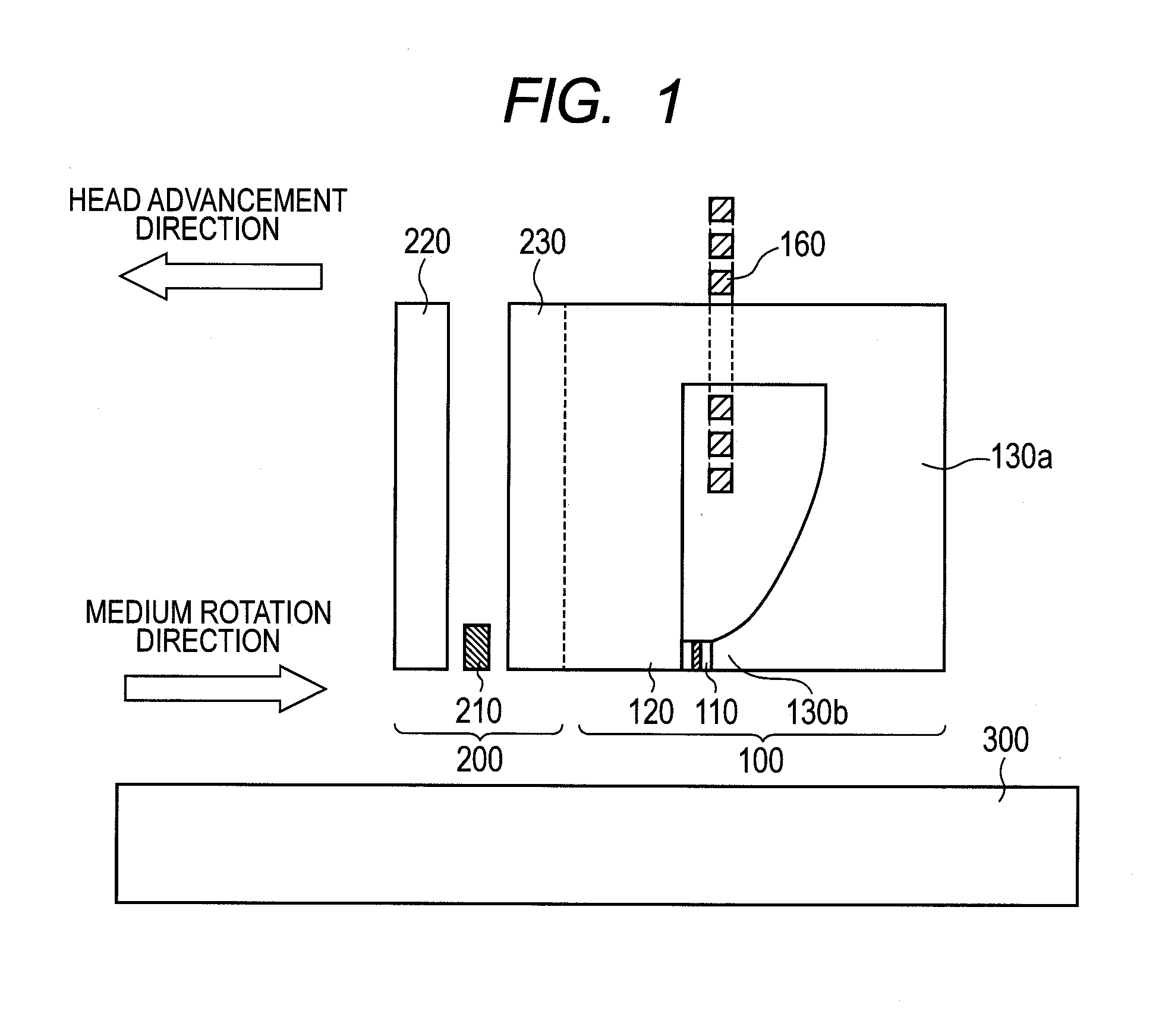

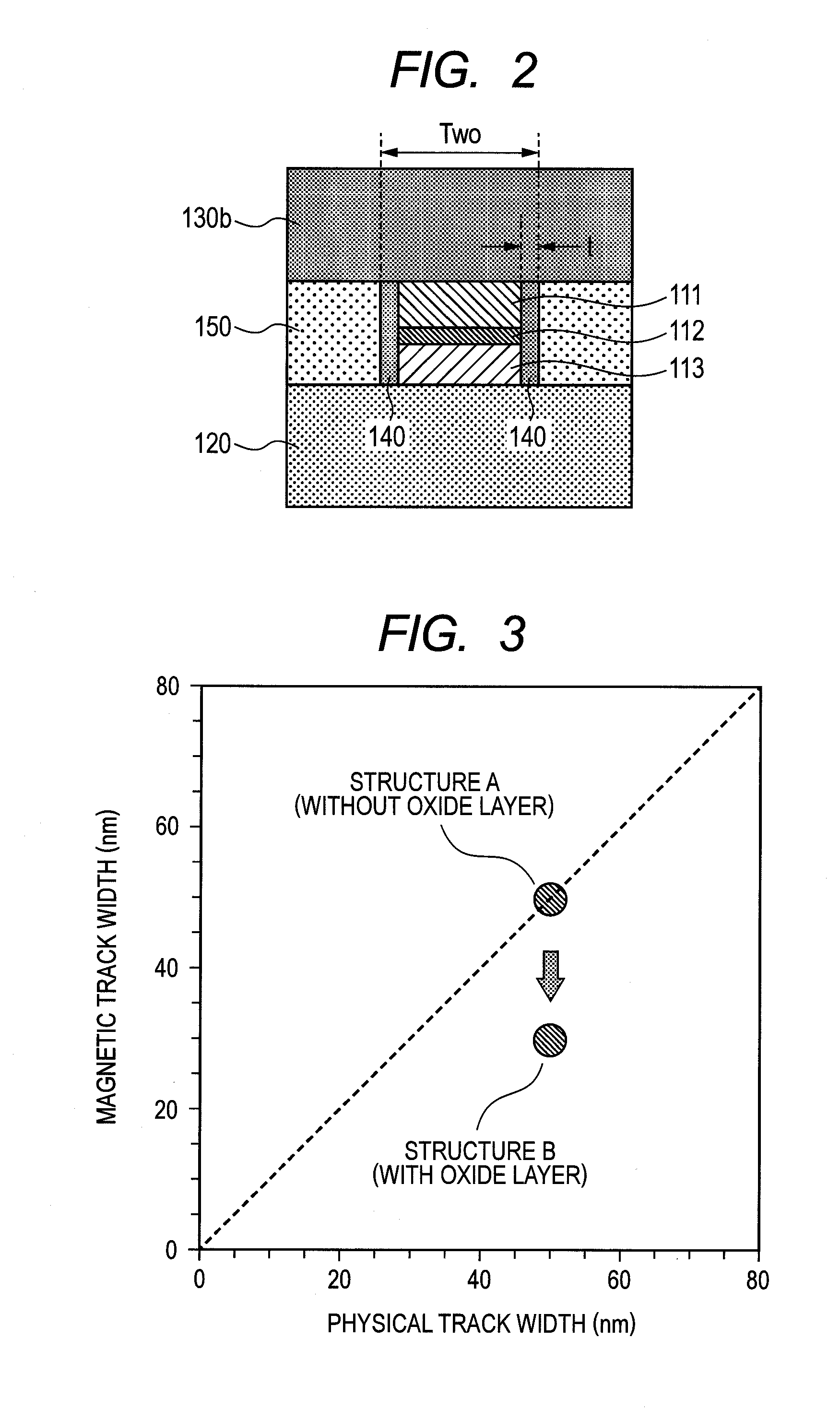

InactiveUS20130222941A1High frequencyHigh-density recordingDriving/moving recording headsVacuum evaporation coatingHigh densityNitride

In a magnetic head of a high-frequency magnetic field assisted recording system, a width of a high-frequency magnetic field from an oscillator is decreased to enhance an oscillation frequency, in order to realize a high-density recording. An oscillator provided near a main pole, which generates a recording magnetic field, for generating a high-frequency magnetic field is patterned by a conventional photolithography, and then, an oxidation, nitridation, or oxynitridation is performed on the side face in a track width direction. With this process, an oxide layer, a nitride layer, or an oxynitride layer, which is made of a material of the oscillator, is formed on the side face of the oscillator in the track width direction, and the shape of the oscillator is formed to be semi-circular.

Owner:HITACHI LTD

Magnetic sensing element including a pair of antiferromagnetic layers separated by spacer section in track width direction and method for fabricating same

InactiveUS7212383B2Easily and properly fabricatedSide reading can be preventedChemical vapor deposition applicationMagnetic-field-controlled resistorsCrystal structureMolecular physics

Owner:TDK CORPARATION

Magnetic head, method for producing the magnetic head, and magnetic recording/reproducing apparatus

InactiveUS8830627B2High-density recordingStably generate high frequencyDriving/moving recording headsVacuum evaporation coatingHigh densityNitride

In a magnetic head of a high-frequency magnetic field assisted recording system, a width of a high-frequency magnetic field from an oscillator is decreased to enhance an oscillation frequency, in order to realize a high-density recording. An oscillator provided near a main pole, which generates a recording magnetic field, for generating a high-frequency magnetic field is patterned by a conventional photolithography, and then, an oxidation, nitridation, or oxynitridation is performed on the side face in a track width direction. With this process, an oxide layer, a nitride layer, or an oxynitride layer, which is made of a material of the oscillator, is formed on the side face of the oscillator in the track width direction, and the shape of the oscillator is formed to be semi-circular.

Owner:HITACHI LTD

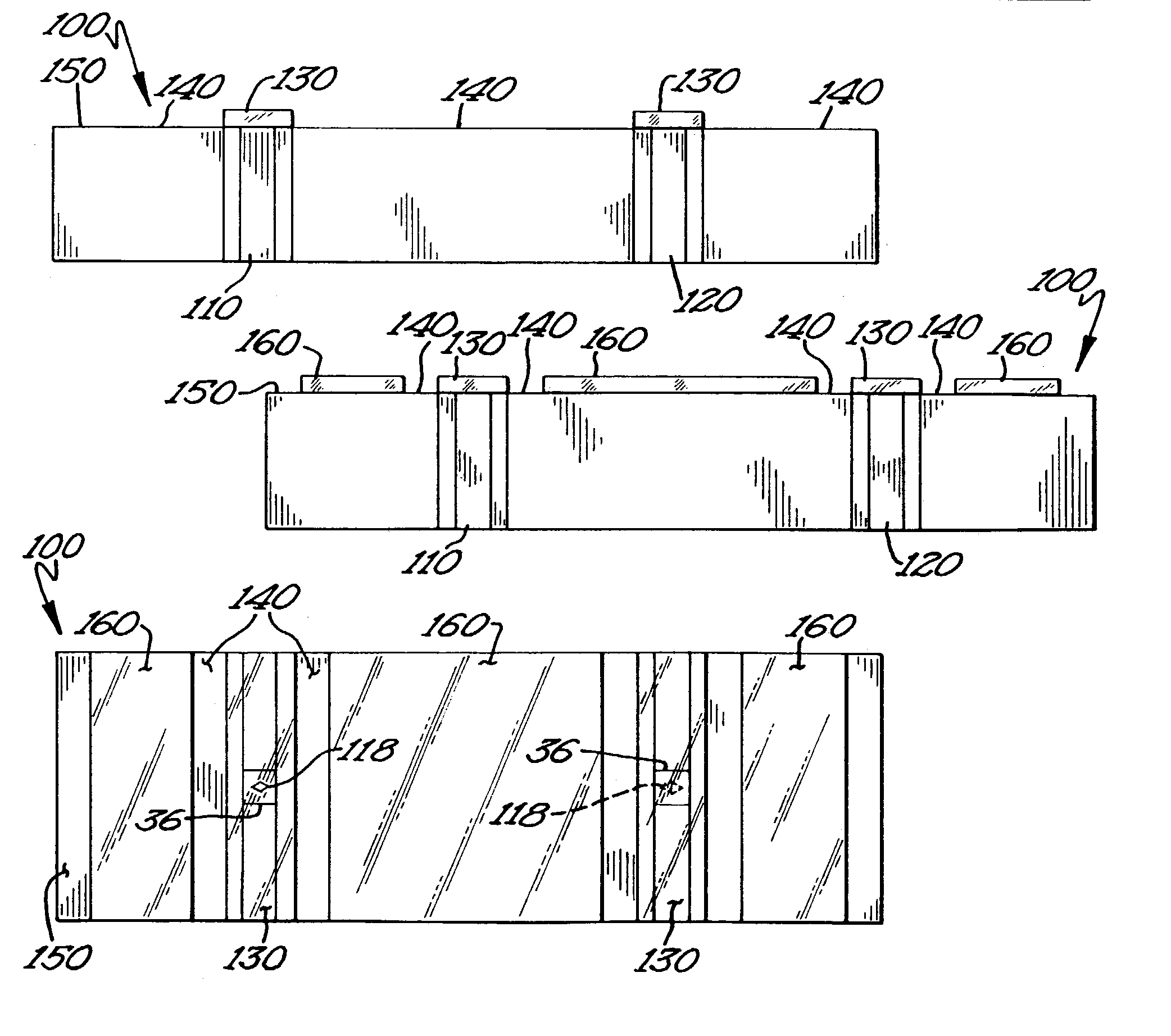

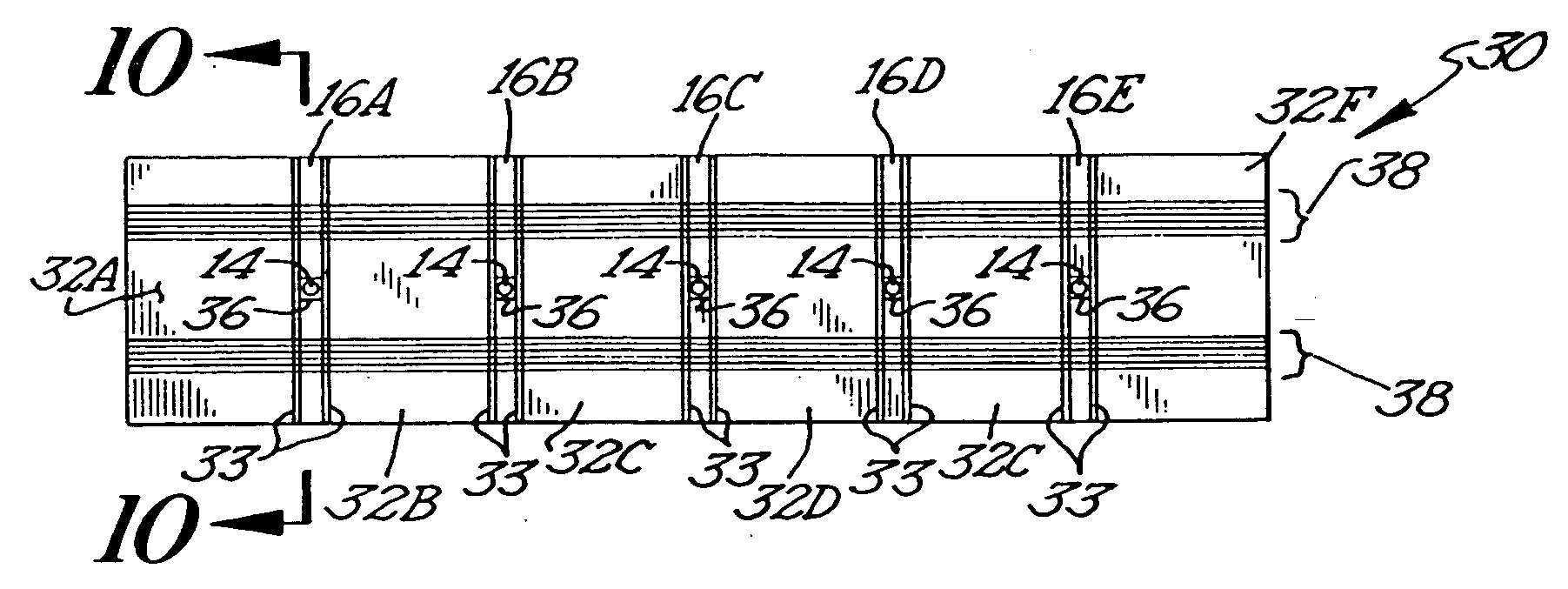

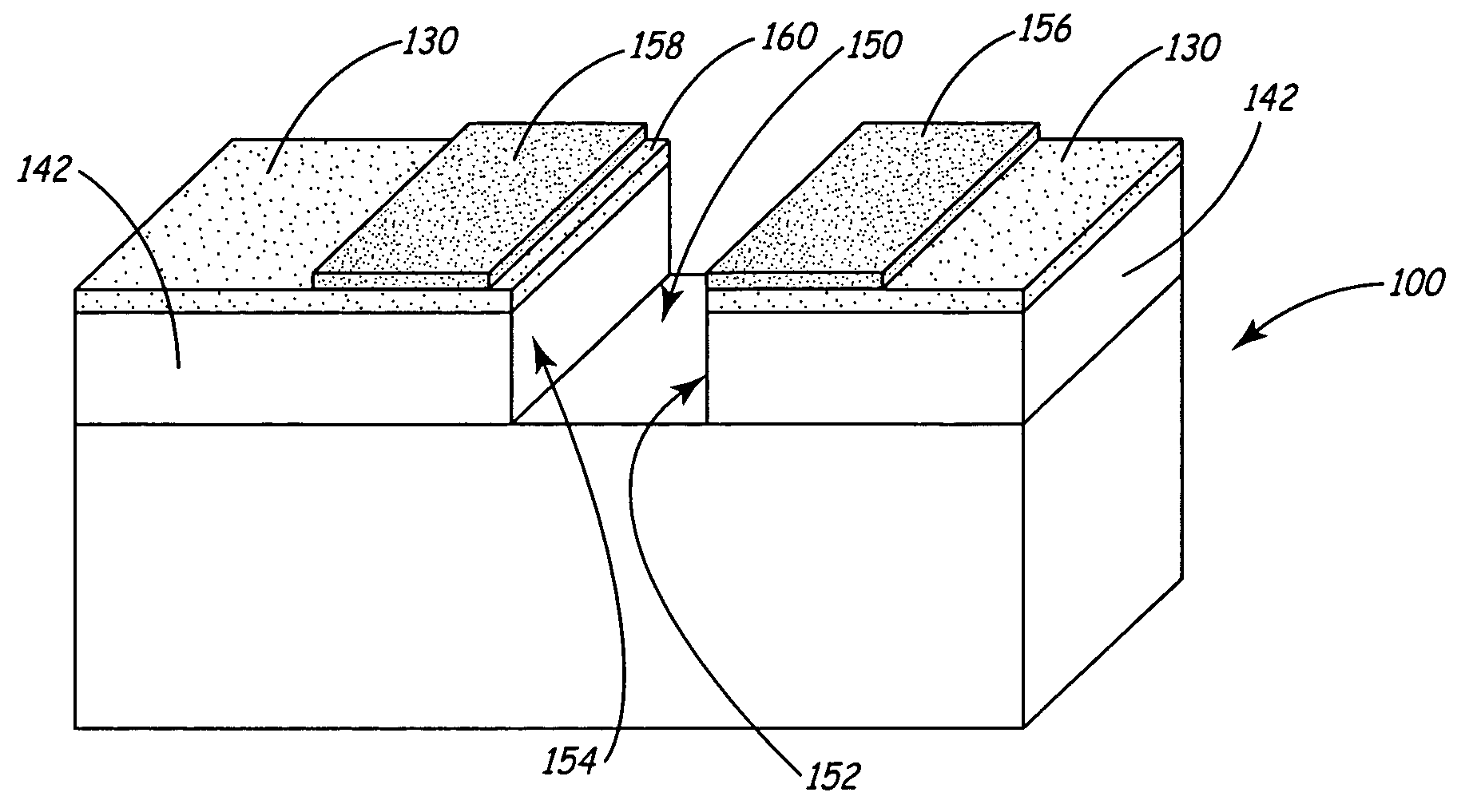

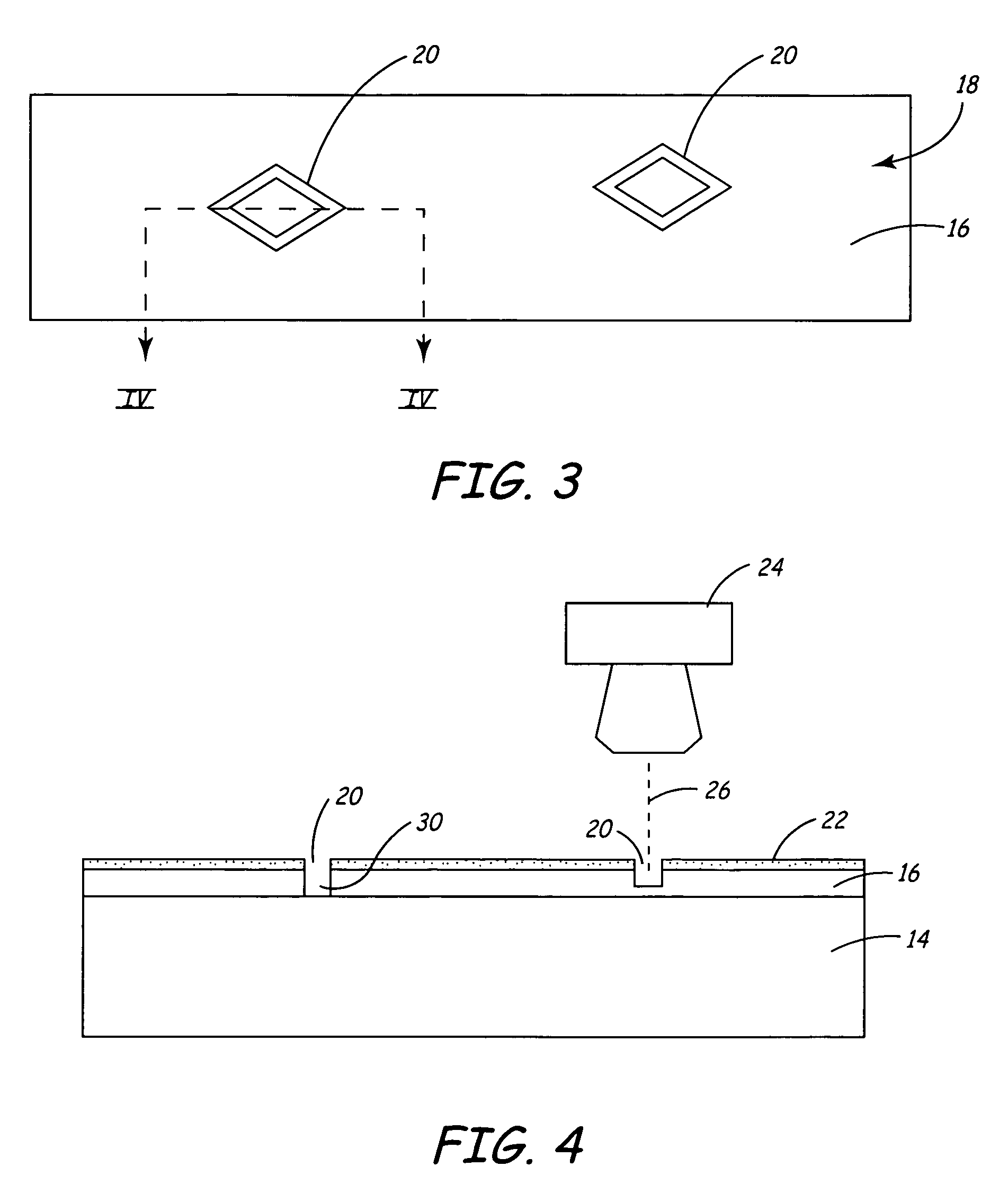

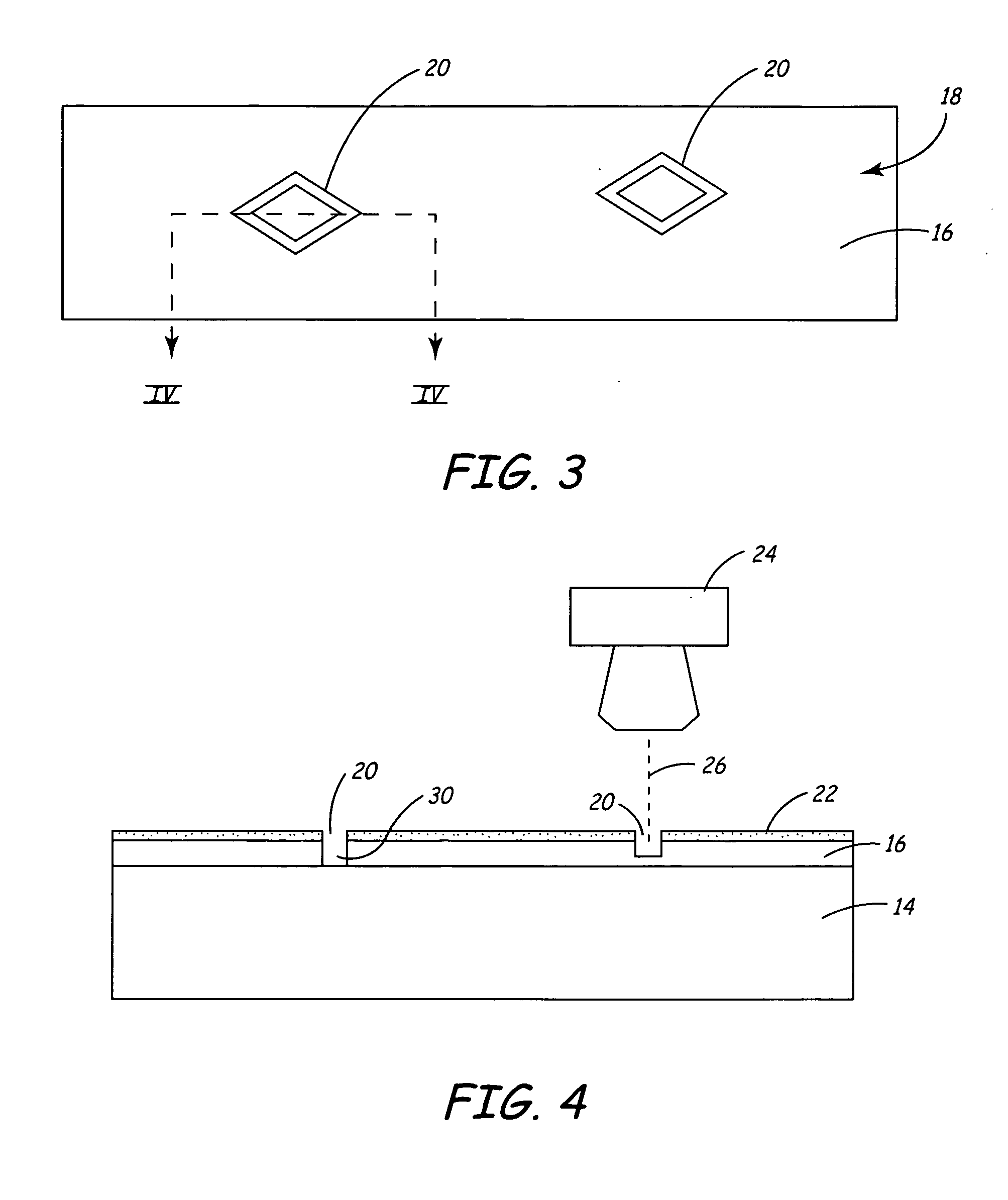

Double layer patterning and technique for milling patterns for a servo recording head

InactiveUS7386934B2Decorative surface effectsAlignment for track following on tapesEngineeringPhotoresist

Double photolithography is used to produce an under-layer of protective and filtering photoresist over a substrate that will have channels milled with a FIB. Secondary layers are applied with precision on top of the first layer in order to define the precise patterns to be milled and to provide targeting and alignment fiducials.

Owner:ADVANCED RES

Magnetization turnover device based on orbit transfer torque and implementation method thereof

ActiveCN113782668ASimple structureReduce power consumptionRecord information storageGalvano-magnetic device detailsHeterojunctionElectrical resistance and conductance

The invention discloses a magnetization turnover device based on track transfer torque and an implementation method thereof. A direct-current write-in current is introduced through a source electrode and a drain electrode to polarize the out-of-plane orbital magnetic moment and then generate an out-of-plane anti-damping moment effect, and magnetization overturning, called orbital transfer moment, of a perpendicular magnetic anisotropy free ferromagnetic layer can be achieved under the out-of-plane anti-damping moment effect without assistance of an additional magnetic field. After the write-in current is removed, the perpendicular magnetic anisotropy free ferromagnetic layer keeps the changed magnetization state, so that the free ferromagnetic layer has non-volatility. A direct-current reading current is introduced through the source and drain electrodes, and the Hall resistance of a heterojunction is obtained through a measuring electrode, so that the magnetization state of the vertical magnetic anisotropy free ferromagnetic layer is reflected. The direction of the write-in current is changed to realize a reverse orbit transfer torque, so that the magnetization of the vertical magnetic anisotropy free ferromagnetic layer is reversely overturned. The critical current required by the track transfer torque for realizing magnetization overturning is smaller, so that the power consumption of the device can be greatly reduced.

Owner:PEKING UNIV

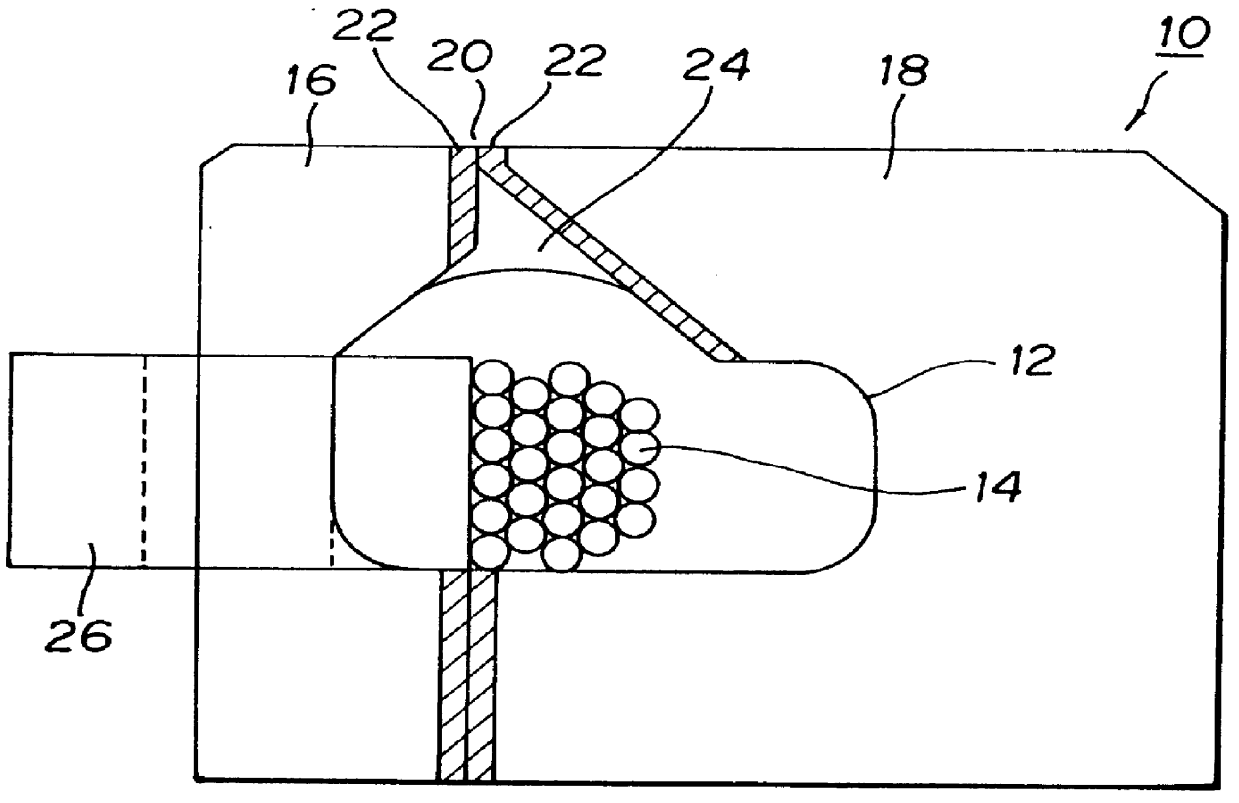

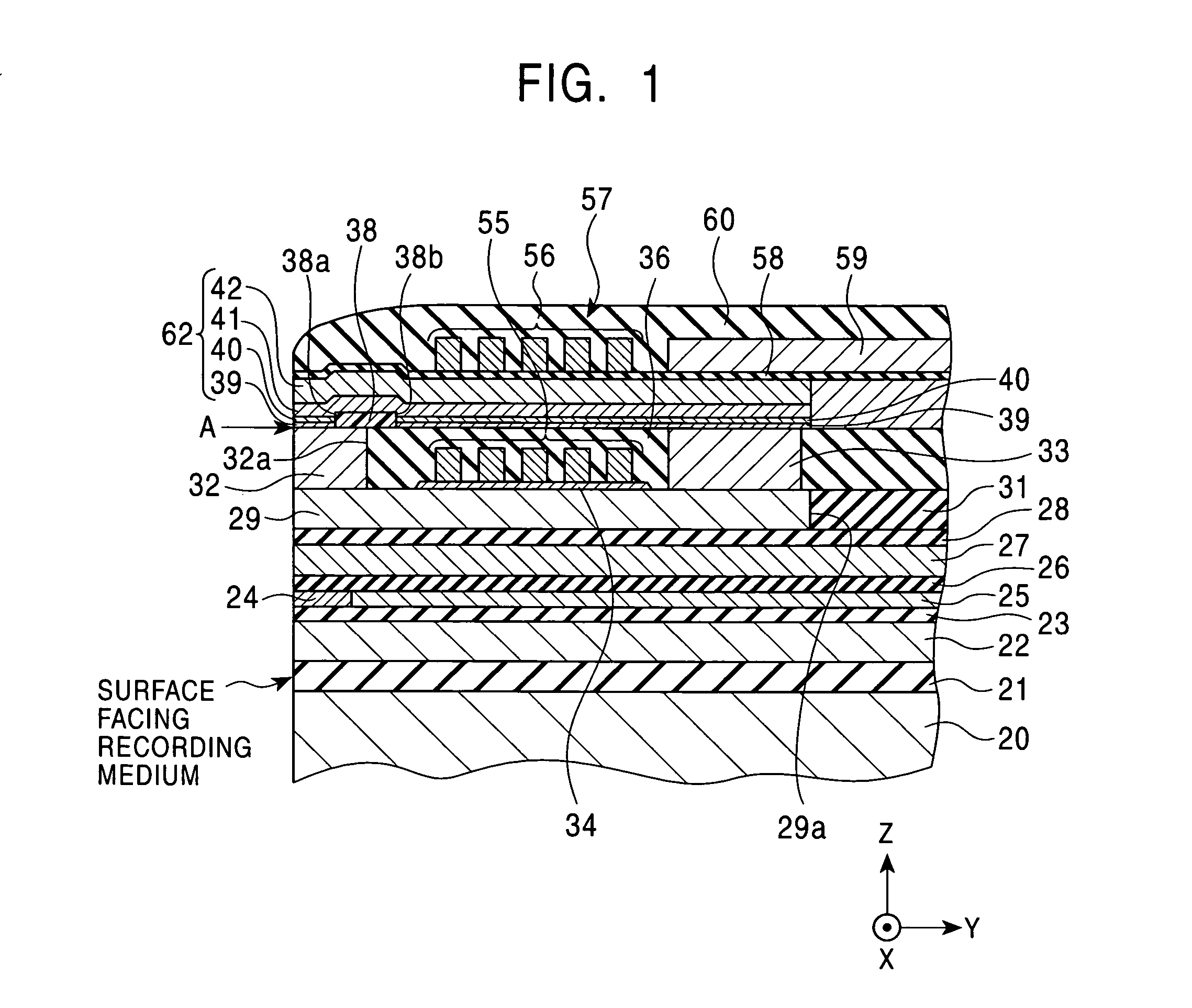

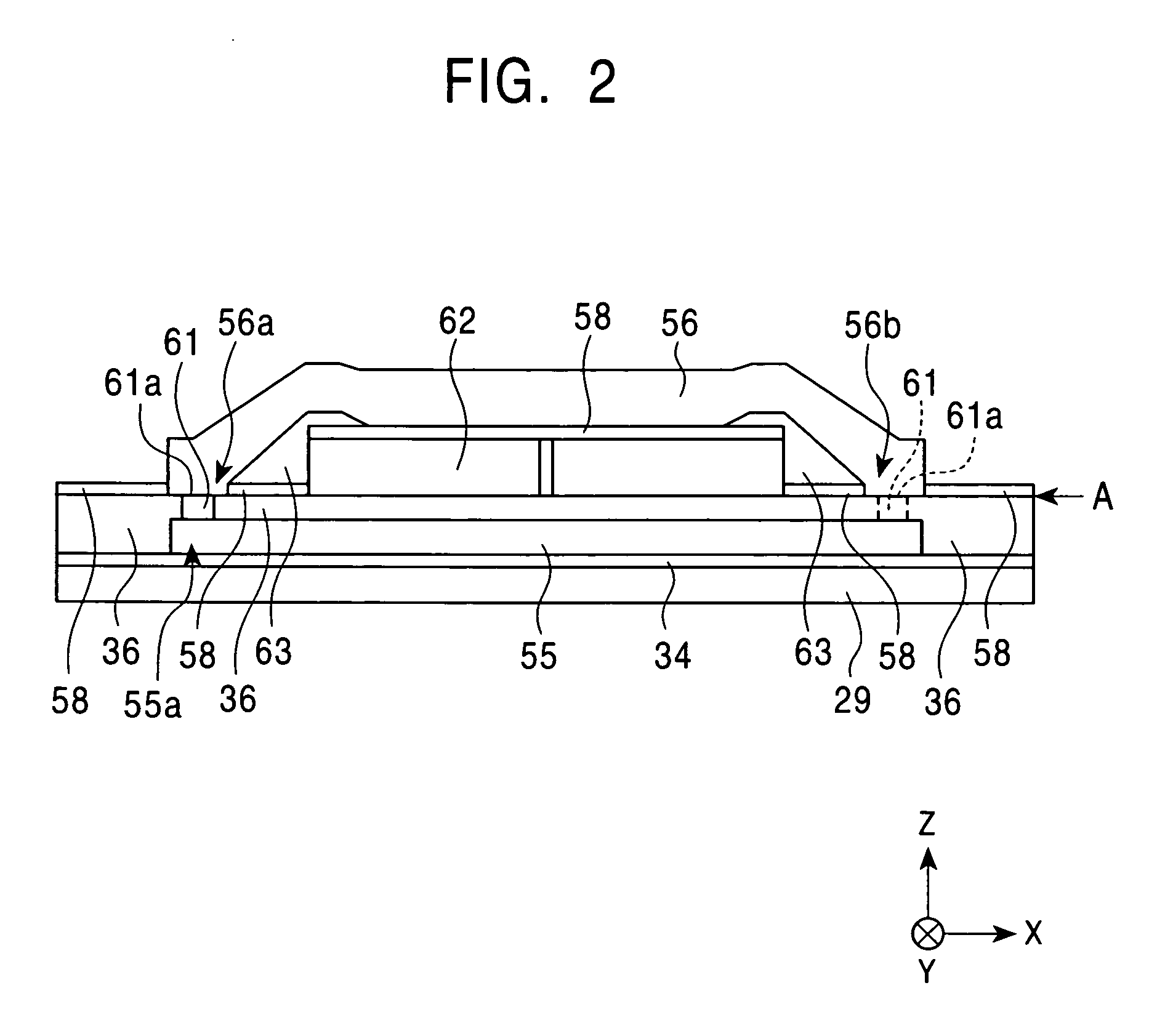

Thin film magnetic head including coil wound in toroidal shape and method for manufacturing the same

ActiveUS6987644B2Known can be problematicConstruction of head windingsHeads using thin filmsInsulation layerMagnetic poles

A thin film magnetic head and a method for manufacturing the same is provided, wherein first coil pieces and second coil pieces provided one above the other with a magnetic pole layer therebetween are electrically connected to each other with reliability and with ease, and the above-described magnetic pole layer can be provided on a flattened surface. A laminate provided on a coil insulation layer can be formed on a flattened surface and, therefore, the above-described magnetic pole layer can be formed into a predetermined shape. As a result, the track width can have a predetermined dimension, and the second coil pieces provided on the above-described laminate can be reliably, easily connected to the top surfaces of connection layers exposed at the top surface of the coil insulating layer.

Owner:TDK CORPARATION

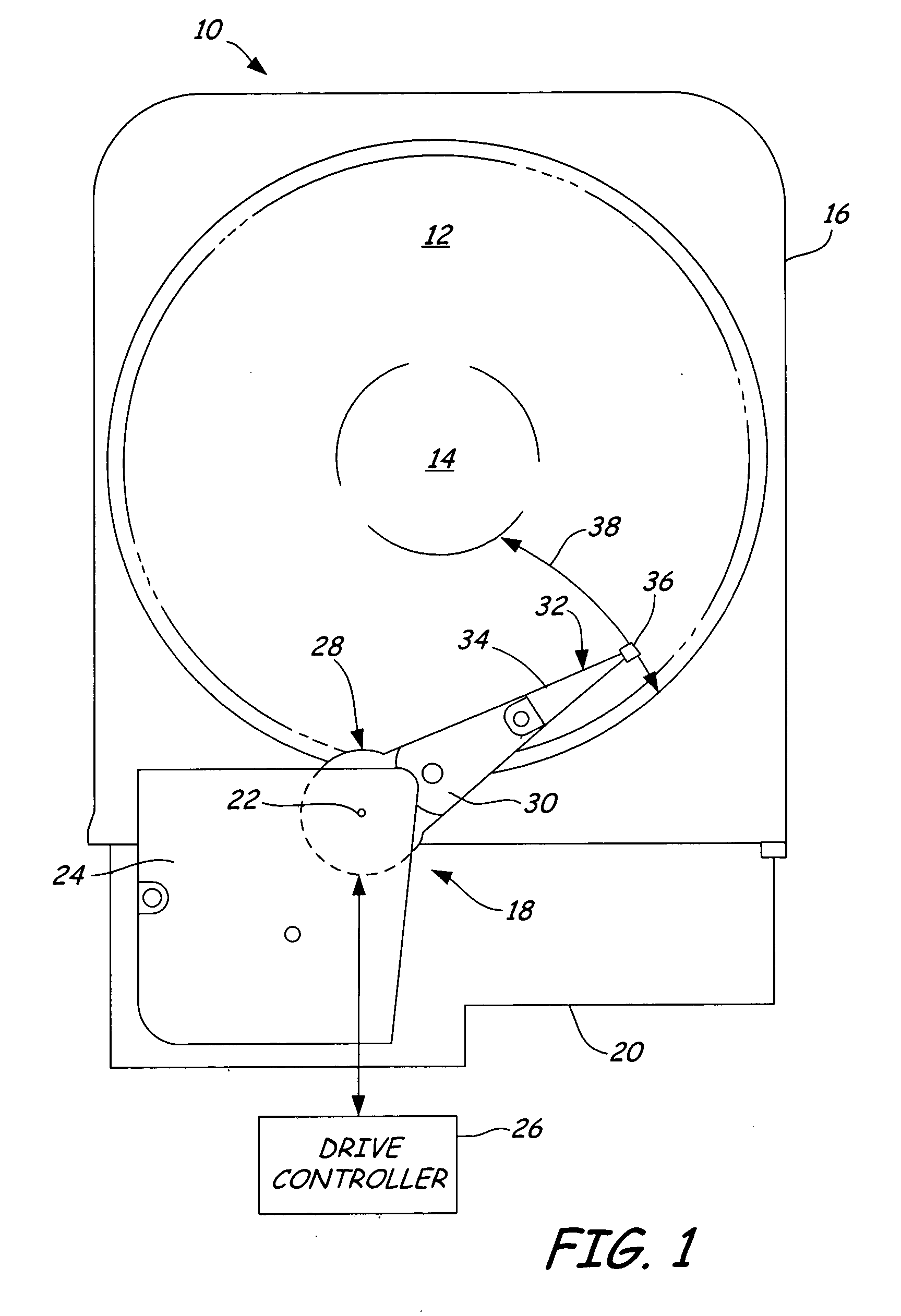

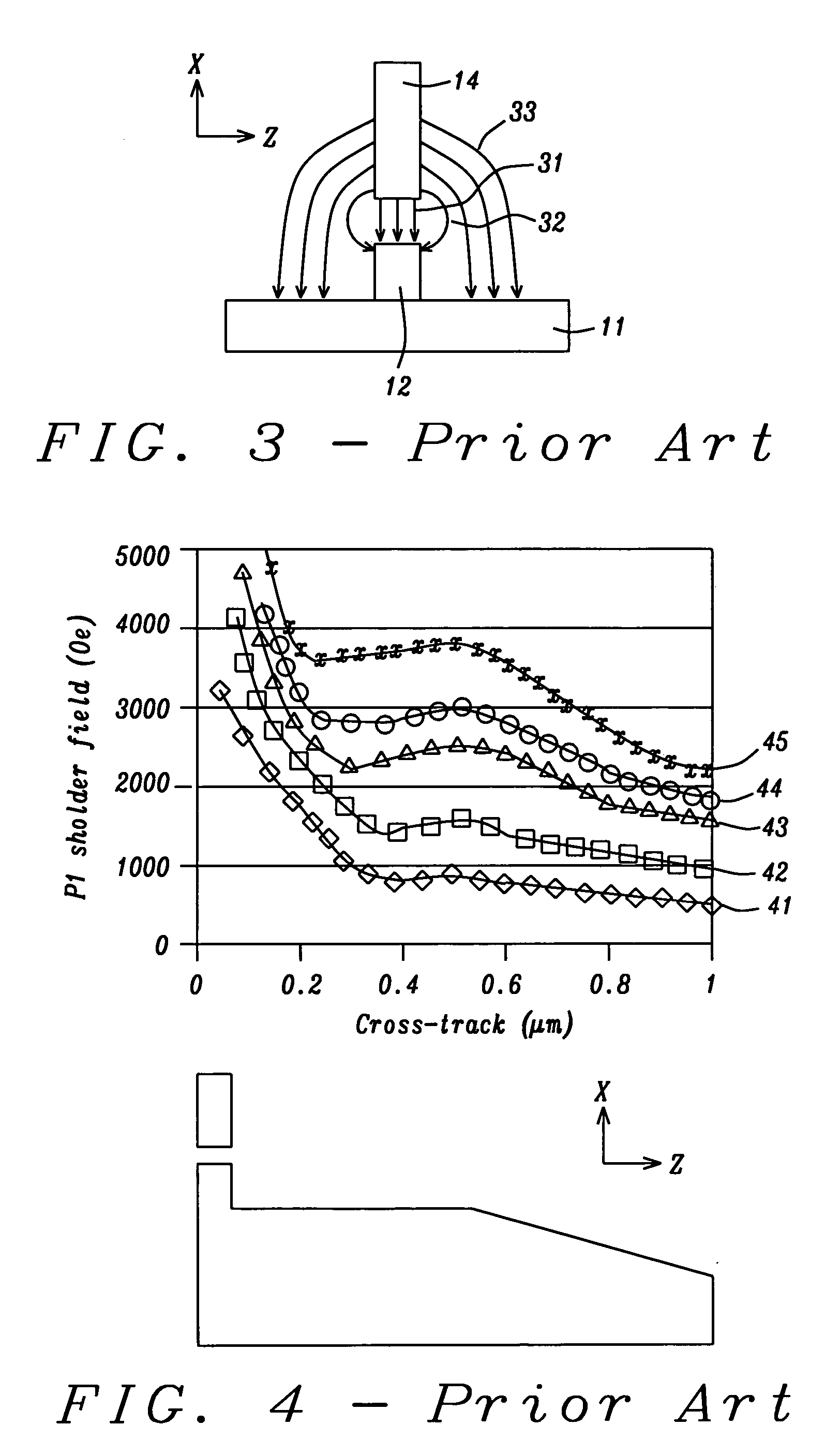

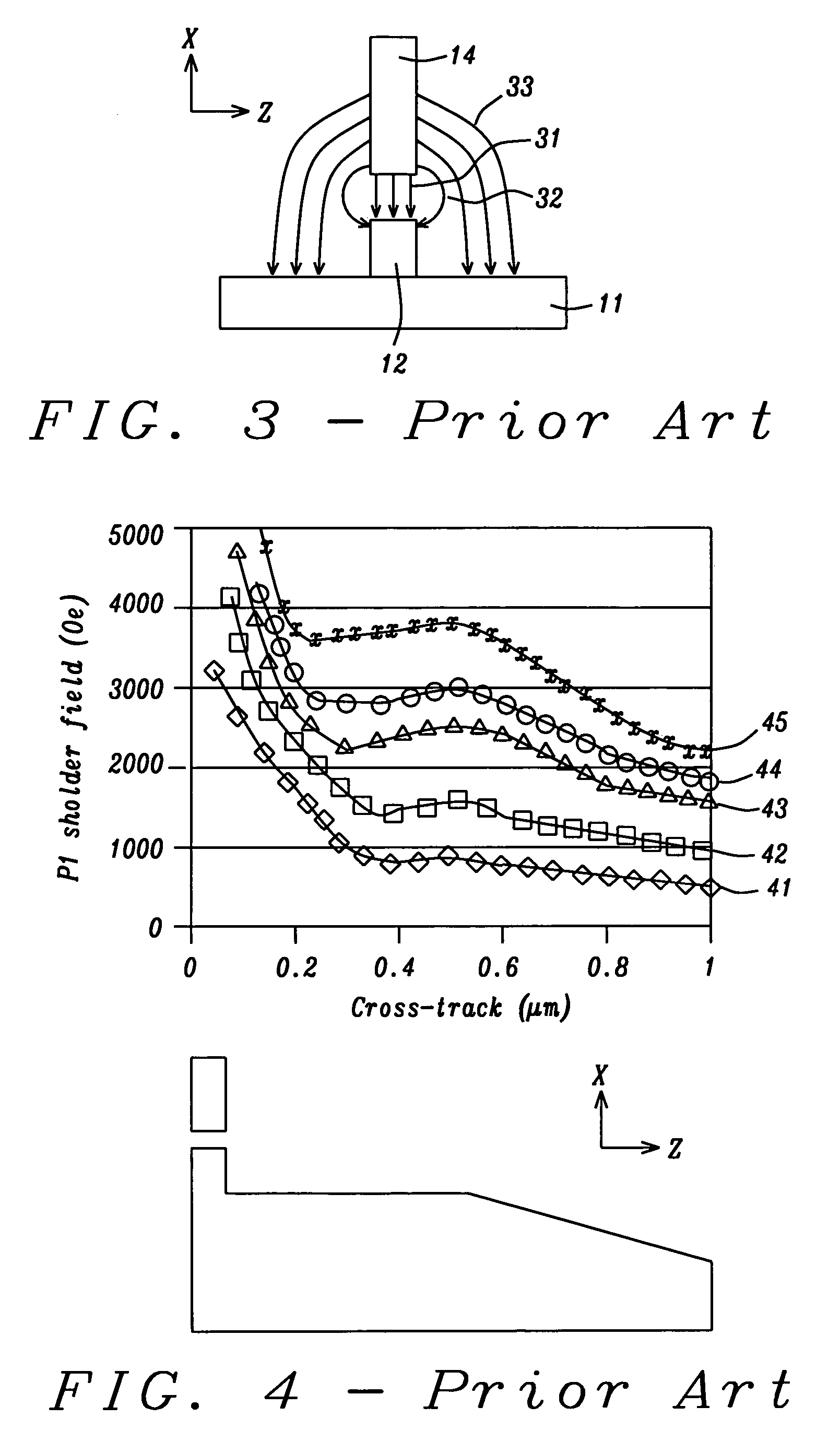

Bottom pole structure with back-side steps

To generate a high data transfer rate from a magnetic write head, a faster flux rise time is needed. This often brings about severe excess saturation of the head and, as a result, adjacent track erasures often occur. This problem has been overcome by dividing the bottom pole into front and rear sections with a step between them. The write gap is part of the front section while the rear section (to which the front section is attached) is closer to the top pole so excess flux generated by higher write currents can be absorbed in a direction normal to the ABS instead of being diverted to the bottom pole shoulder.

Owner:HEADWAY TECH INC

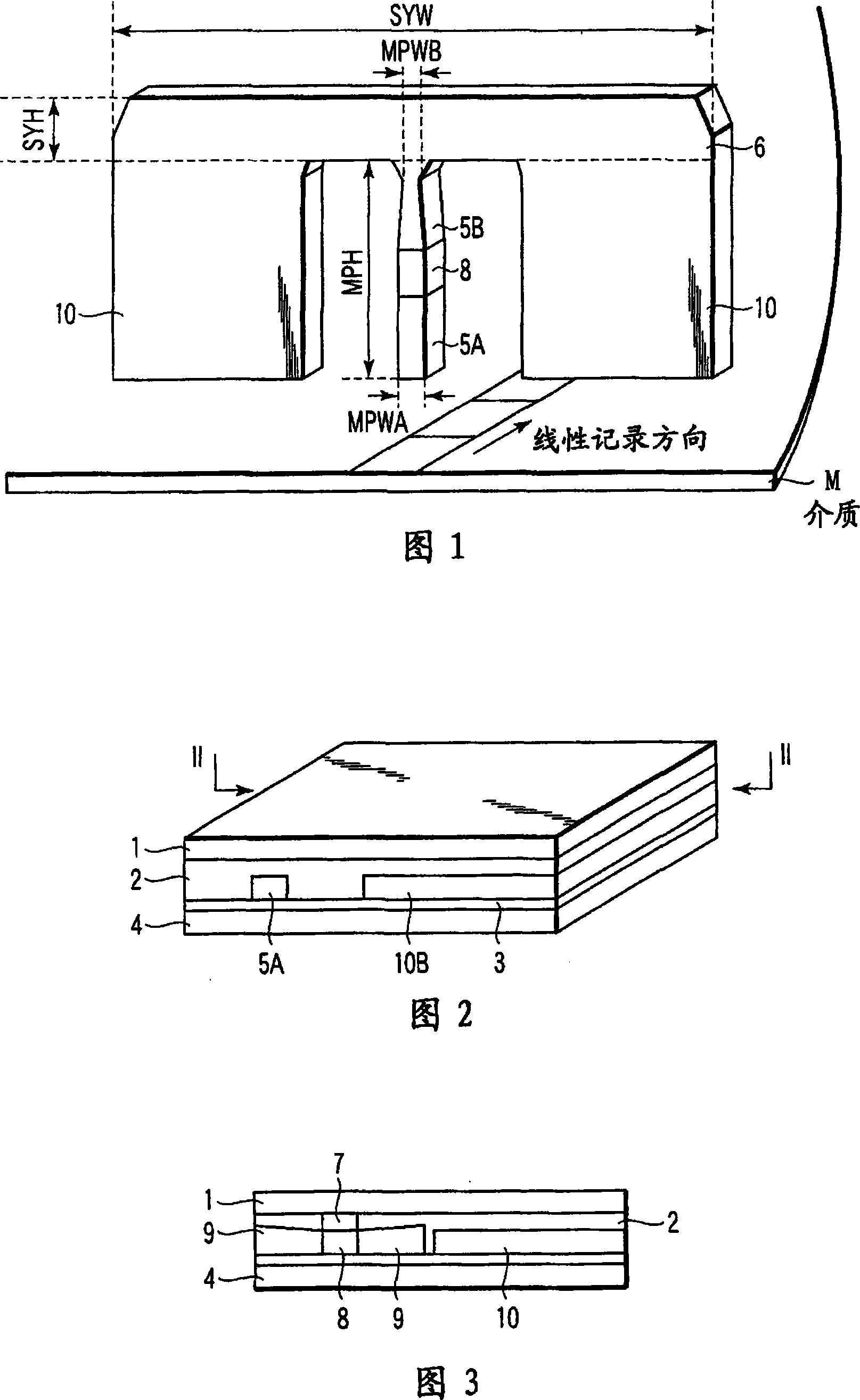

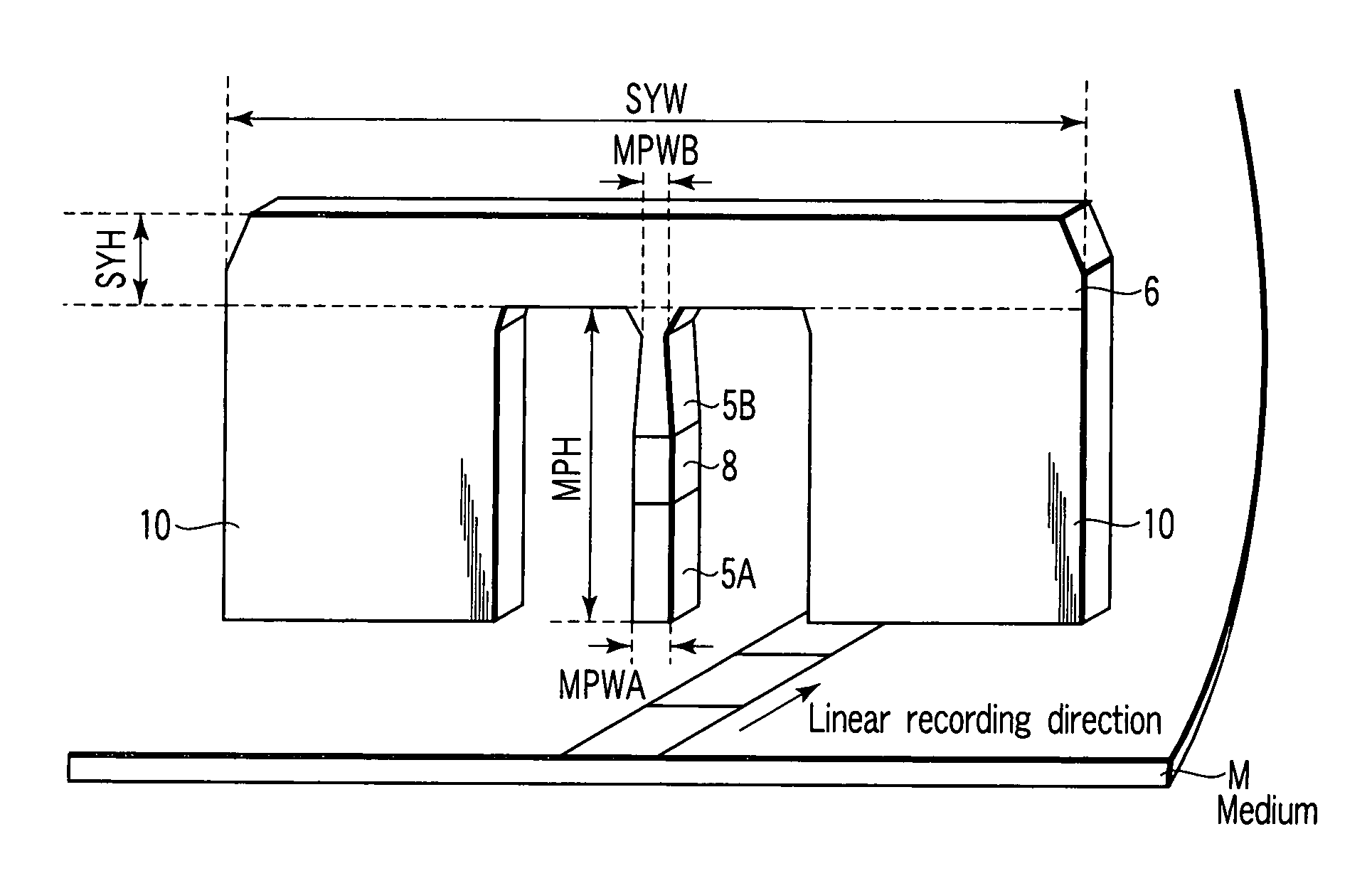

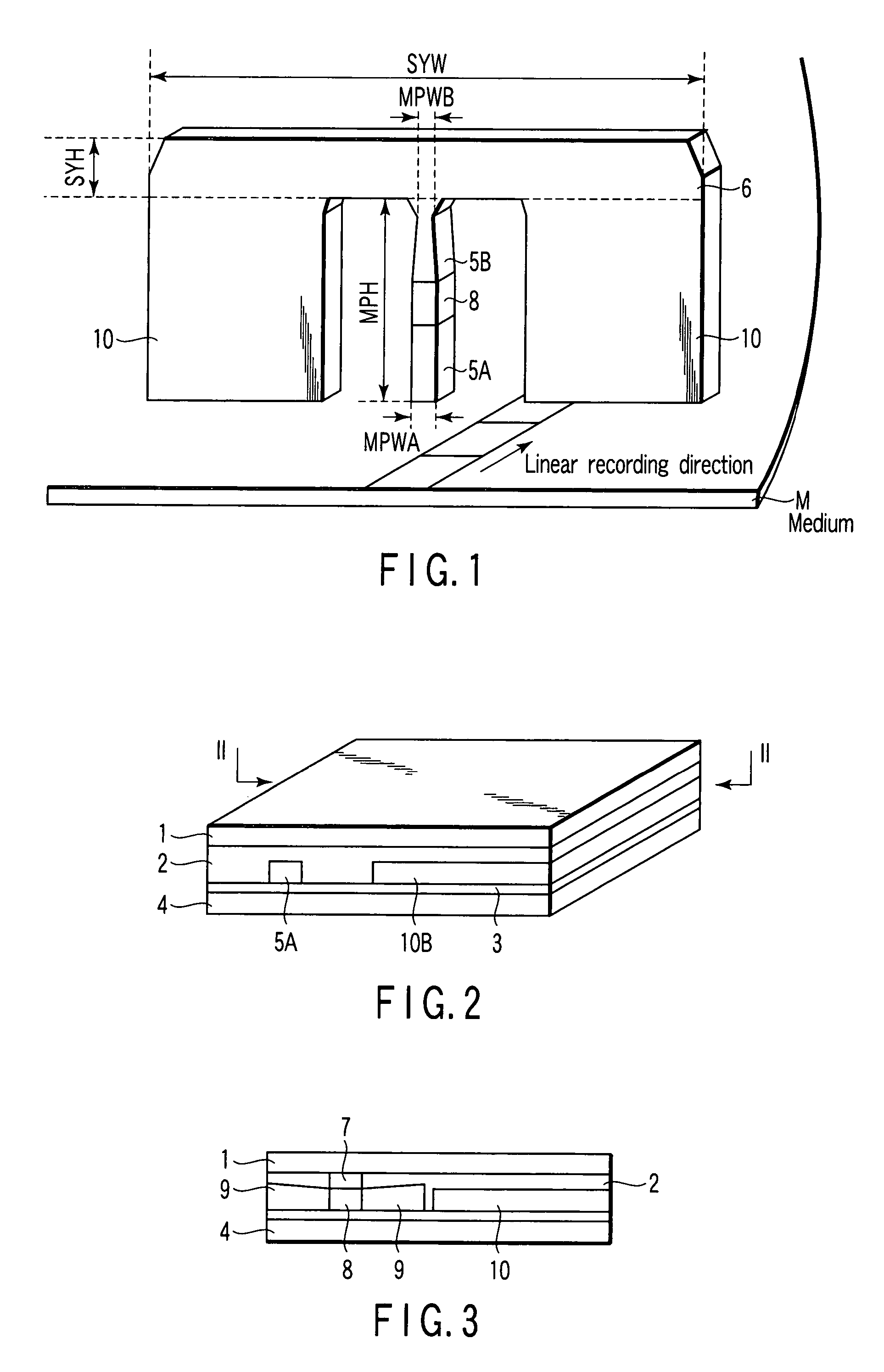

Yoke-type magnetic head and magnetic disk apparatus

According to one embodiment, a yoke-type magnetic head for reading out magnetic information from a medium in which information is magnetically recorded in a track direction, the head includes a magnetic pole which is provided on a plane perpendicular to a linear recording direction and has an opposing surface facing the medium, a saturation magnetic flux density Bs 1 , and a volume V 1 , a sub yoke which is formed on the plane by being connected to the magnetic pole, and has a length SYW in a direction perpendicular to the linear recording direction longer than a length SYH in a direction perpendicular to a surface of the medium, and a saturation magnetic flux density Bs 2 and a volume V 2 , the product Bs 2 V 2 of which is larger than the product Bs 1 V 1 , and a magnetoresistance effect film which is formed between the sub yoke and the opposing surface, and abuts the magnetic pole.

Owner:KK TOSHIBA

Bottom pole structure with back-side steps

To generate a high data transfer rate from a magnetic write head, a faster flux rise time is needed. This often brings about severe excess saturation of the head and, as a result, adjacent track erasures often occur. This problem has been overcome by dividing the bottom pole into front and rear sections with a step between them. The write gap is part of the front section while the rear section (to which the front section is attached) is closer to the top pole so excess flux generated by higher write currents can be absorbed in a direction normal to the ABS instead of being diverted to the bottom pole shoulder.

Owner:HEADWAY TECH INC

Magnetic transducer, thin film magnetic head, method of manufacturing magnetic transducer and method of manufacturing thin film magnetic head

InactiveUS6920022B1Improve thermal stabilityManufacture head surfaceNanomagnetismMagnetic transducersEngineering

Provided are a magnetic transducer having good thermal stability, a thin film magnetic head, a method of manufacturing a magnetic transducer and a method of manufacturing a thin film magnetic head. A stack of an MR element has a stacked structure comprising an underlayer, a first soft magnetic layer, a second soft magnetic layer, a nonmagnetic layer, a ferromagnetic layer, an antiferromagnetic layer and a capping layer, which are stacked in this order on the underlayer. The ferromagnetic layer is divided into a bottom layer and a top layer in the direction of stack. A ferromagnetic interlayer having magnetism and having higher electrical resistance than the electrical resistance of the ferromagnetic layer is formed between the bottom layer and the top layer. The ferromagnetic interlayer magnetically integrates the bottom layer with the top layer and limits a path for electrons moving through the stack, thereby improving the rate of resistance change. Furthermore, the ferromagnetic interlayer contains, as an additive, at least one element in a group consisting of Mn, Cr, Ni, Cu, Rh, Ir and Pt and thus prevents heat deterioration in the stack.

Owner:TDK CORPARATION

Double layer patterning and technique for milling patterns for a servo recording head

Double photolithography is used to produce an under-layer of protective and filtering photoresist over a substrate that will have channels milled with a FIB. Secondary layers are applied with precision on top of the first layer in order to define the precise patterns to be milled and to provide targeting and alignment fiducials.

Owner:ADVANCED RES

Composite type magnetic head using composite metallic wire

InactiveUS6180890B1Single bars/rods/wires/strips conductorsSolid-state devicesElectrical resistance and conductanceMetallurgy

A composite metallic wire includes: an inner layer having a cross-sectional shape of a rough circle; and a metal outer layer having a cross-sectional shape of a rough ring; wherein the composite metallic wire has a diameter of 15 mum or less and an electric resistance of 300 OMEGA / m or less. A composite type magnetic head using as a coil wire a composite wire comprising: (1) a composite metallic wire comprising: an inner layer having a cross-sectional shape of a rough circle; and a metal outer layer having a cross-sectional shape of a rough ring; wherein the composite metallic wire has a diameter of 15 mum or less and an electric resistance of 300 OMEGA / m or less, and (2) an insulating coat provided in the outer periphery of the outer layer.

Owner:NGK INSULATORS LTD

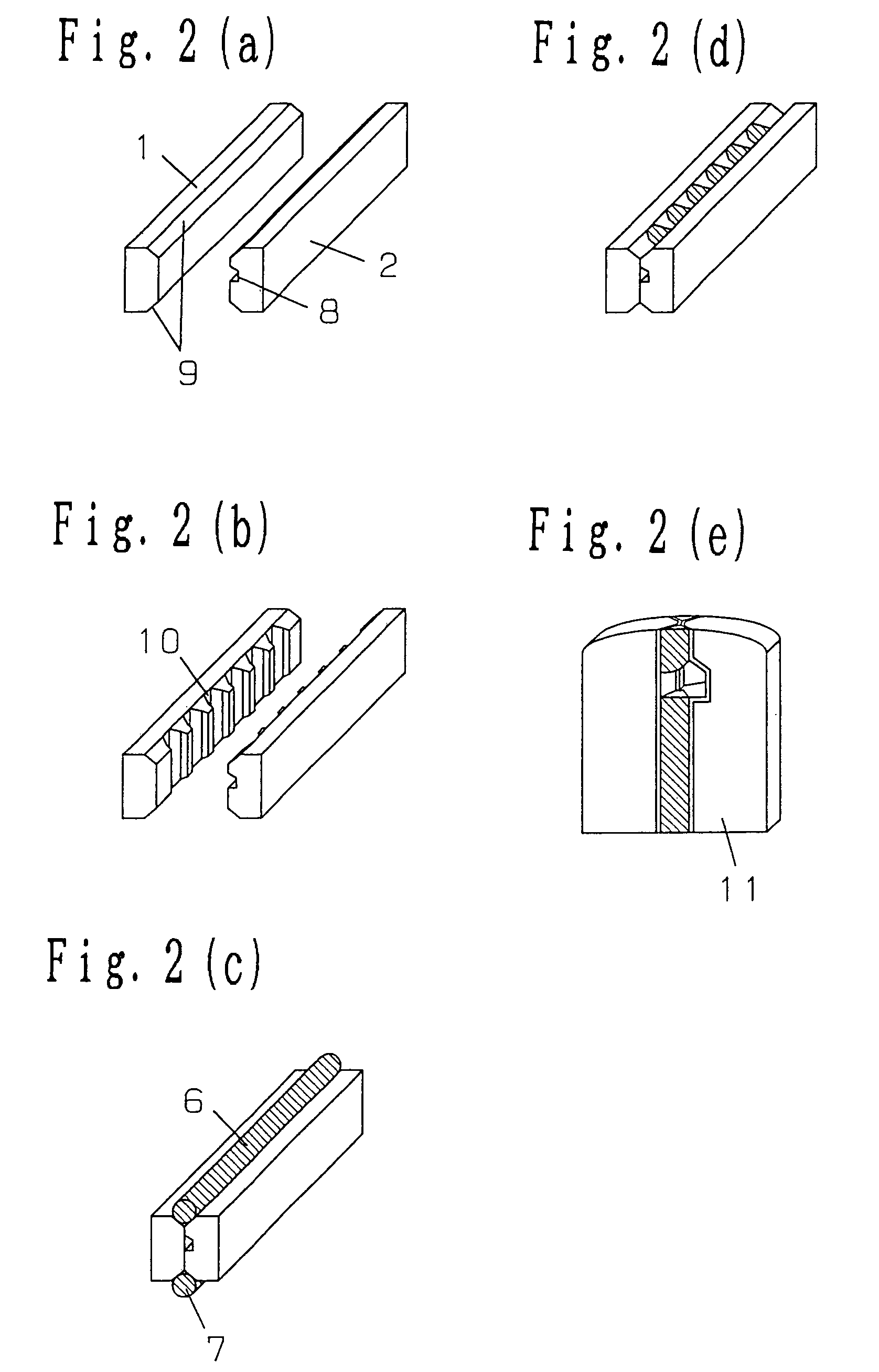

Sealing glass for magnetic head, magnetic head, and magnetic recording/reproducing device

InactiveUS7012783B2Improve performanceIncreased durabilityManufacture head surfaceHeads using thin filmsHigh densityUltimate tensile strength

A magnetic head for a magnetic recording / reproducing device to conform to high-density recording, wherein a metal magnetic film with a high saturation flux density is employed and the mechanical strength of the sealing glass for magnetic heads, is improved thereby achieving a high reliability, high performance magnetic head. Also, this is provided a magnetic recording / reproducing device utilizing the magnetic head.Sealing glass for magnetic heads comprising, by oxide conversion, 17.2 to 25 wt % of SiO2, 1 to 10 wt % of B2O3, 58 to 75 wt % of PbO, 0.2 to 7 wt % of at least one of Al2O3 and ZnO, and 0.2 to 5 wt % of at least one of Na2O and K2O, and a magnetic head and magnetic recording / reproducing device which utilize the sealing glass.

Owner:PANASONIC CORP

Yoke-type magnetic head and magnetic disk apparatus

According to one embodiment, a yoke-type magnetic head for reading out magnetic information from a medium in which information is magnetically recorded in a track direction, the head includes a magnetic pole which is provided on a plane perpendicular to a linear recording direction and has an opposing surface facing the medium, a saturation magnetic flux density Bs1, and a volume V1, a sub yoke which is formed on the plane by being connected to the magnetic pole, and has a length SYW in a direction perpendicular to the linear recording direction longer than a length SYH in a direction perpendicular to a surface of the medium, and a saturation magnetic flux density Bs2 and a volume V2, the product Bs2V2 of which is larger than the product Bs1V1, and a magnetoresistance effect film which is formed between the sub yoke and the opposing surface, and abuts the magnetic pole.

Owner:KK TOSHIBA

Simultaneous planarization of pole piece and coil materials for write head applications

A method for simultaneously planarizing to relatively equal smoothness a thin film magnetic head hardbaked resist structure having relatively low surface energy and one or more additional thin film magnetic head structures containing other materials having comparatively higher surface energy, such as copper, hardbaked resist, alumina and NiFe. The method begins with preparation of a chemical mechanical polishing (CMP) slurry targeted at equaling the removal rate of the materials to be planarized. The CMP slurry includes a liquid vehicle, an abrasive, and a surfactant. The CMP slurry is applied to the surface of the structures to be planarized and the structures are simultaneously planarized using a CMP planarization technique.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com