Magnetization turnover device based on orbit transfer torque and implementation method thereof

A technology of orbital transfer and magnetization reversal, applied in the field of spintronics of condensed matter physics, can solve the problems of poor device durability, non-separation of read and write current paths, and increased device complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

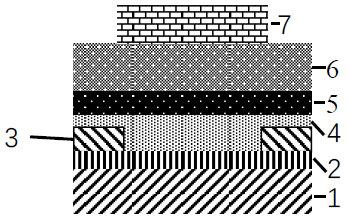

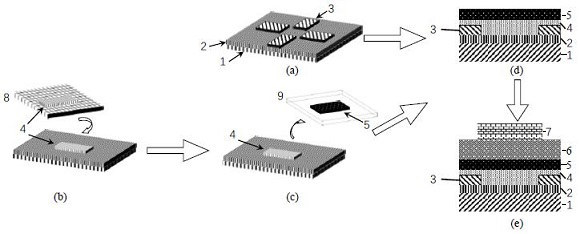

[0045] Such as figure 1 As shown, the magnetization switching device based on track transfer torque in this embodiment includes: a substrate 1, an insulating dielectric layer 2, source and drain electrodes, a measurement electrode, a heterojunction, a top gate and a back gate; wherein, on the front side of the substrate Form an insulating dielectric layer 2; form a back gate on the back of the substrate; form a source-drain electrode and a pair of measuring electrodes on the insulating dielectric layer, the source-drain electrodes are parallel to each other, the measuring electrodes are parallel to each other, and the source-drain electrodes and the measuring electrodes are perpendicular to each other , the source-drain electrodes and a pair of measuring electrodes constitute a cross-shaped bottom electrode 3; a heterojunction is formed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com