Low inductance, ferrite sub-gap substrate structure for surface film magnetic recording heads

a surface film, low inductance technology, applied in the field of magnetic recording heads, can solve the problems of low inductance, amplitude modulation problems, inability to provide a separate read head, etc., to reduce the overall volume of the ferrite core, reduce the resistance of the back gap, and increase the efficiency of the head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

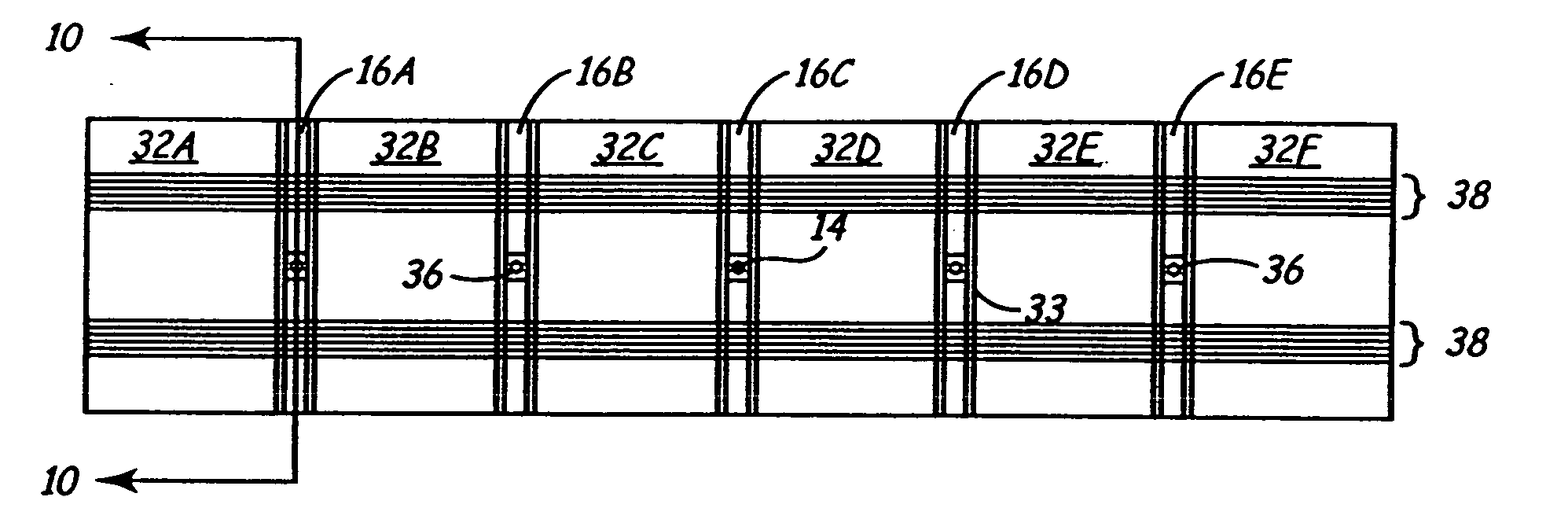

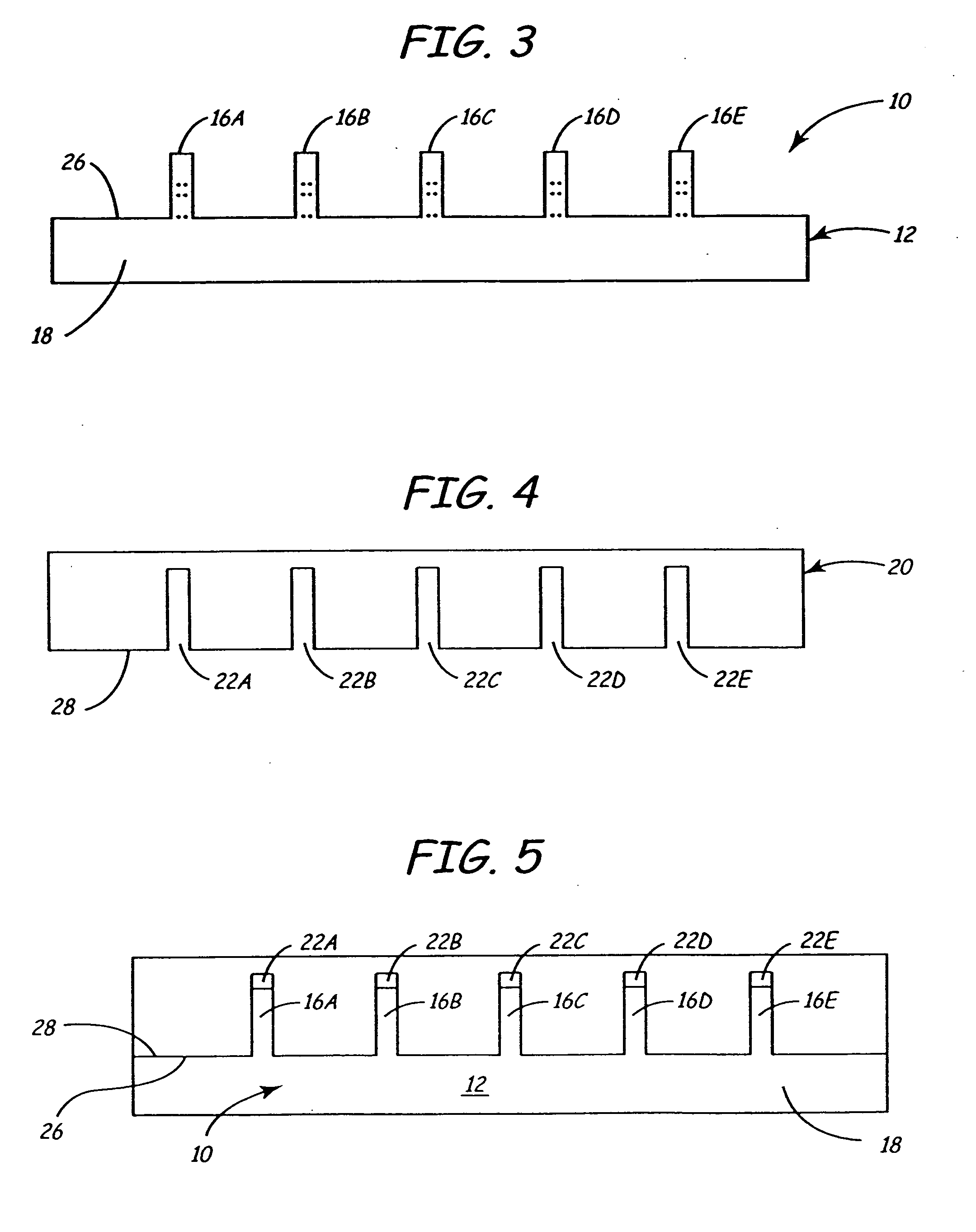

[0048] The present invention is a multi-channel head and method of making the same. Referring to FIG. 1, a substrate 10 is created by glass bonding two C-shaped ferrite blocks 12 to a medially disposed ceramic member 14. The sizes, shapes and relative proportions of the ferrite blocks 12 and ceramic member 14 may vary as dictated by the desired parameters of the completed recording head. Furthermore, the choice of materials may also vary so long as blocks 12 remain magnetically permeable while member 14 remains substantially magnetically impermeable. FIG. 2 is a top view of the substrate 10.

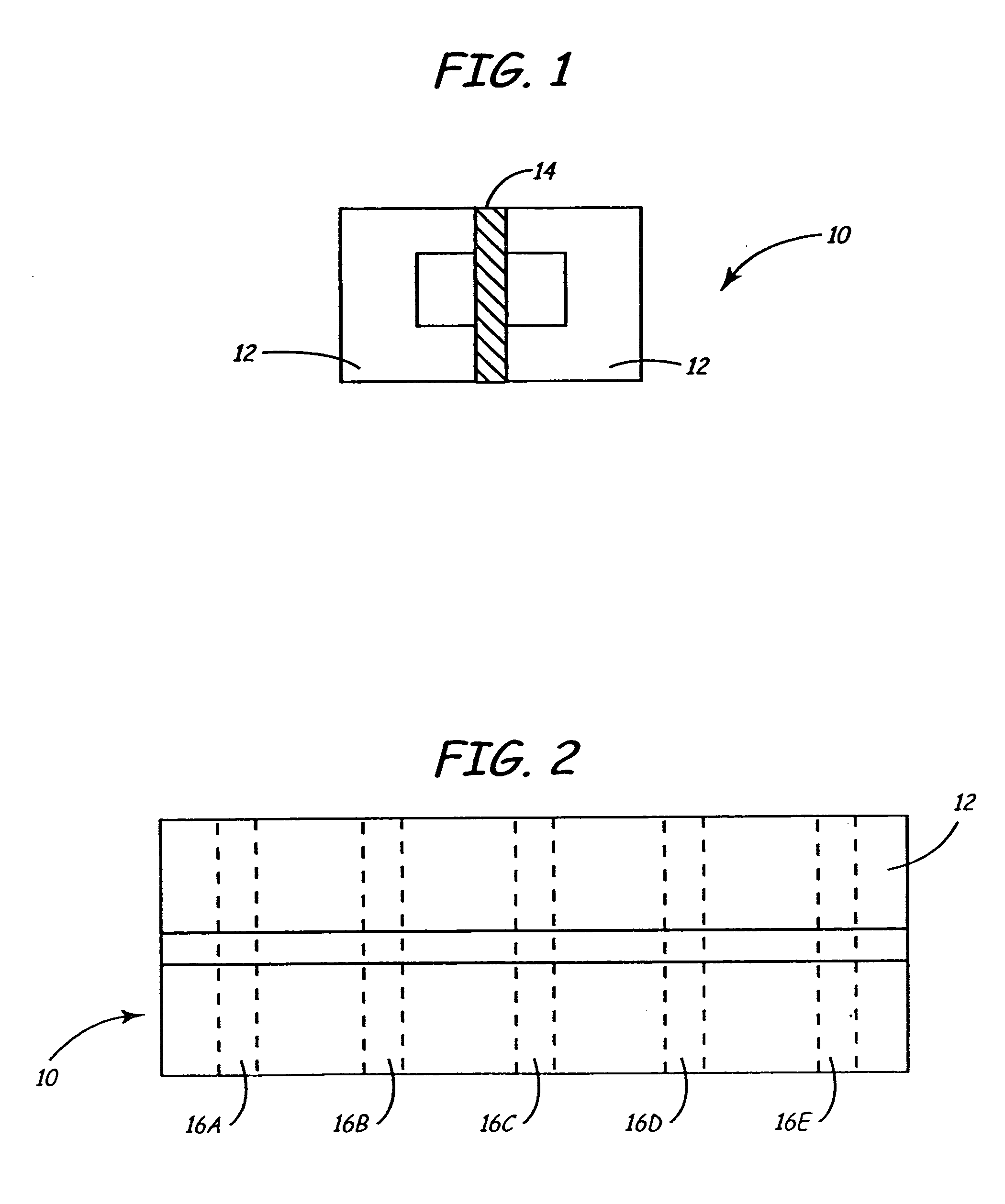

[0049] Referring to FIG. 3, substrate 10 is diced so as to form a plurality of columns 16A-16E which remain adhered to base 18. Columns 16A-16E are also shown by the dashed lines in FIG. 2, which illustrates how each column will have a ceramic portion (sub-gap) bonded between two ferrite poles. The dashed lines are merely illustrative of future columns, as the substrate 10 in FIG. 2 has yet to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductances | aaaaa | aaaaa |

| inductances | aaaaa | aaaaa |

| permeable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com