Laminating orientation extrusion method of rubber short fiber and extrusion device

A technology of short fiber layer and extrusion device, which is applied in the field of laminated orientation extrusion of short rubber fibers and its extrusion device. It can solve the problems of not achieving the desired effect and large-scale application, and achieve convenient installation, low rolling resistance, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

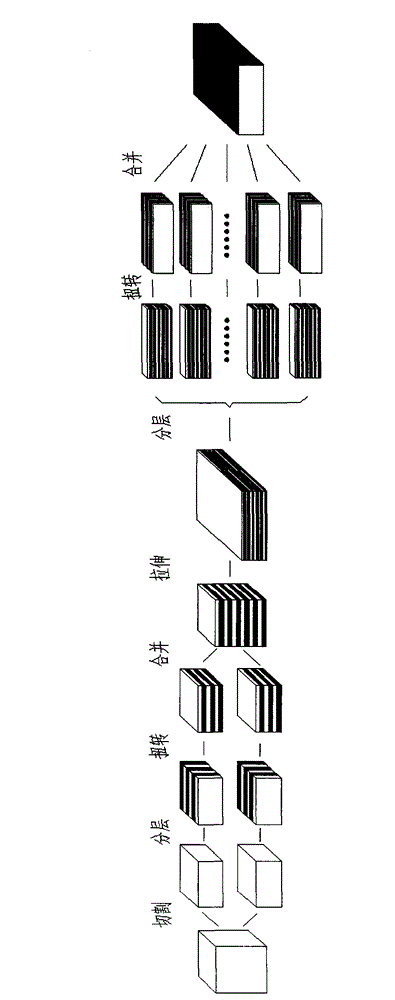

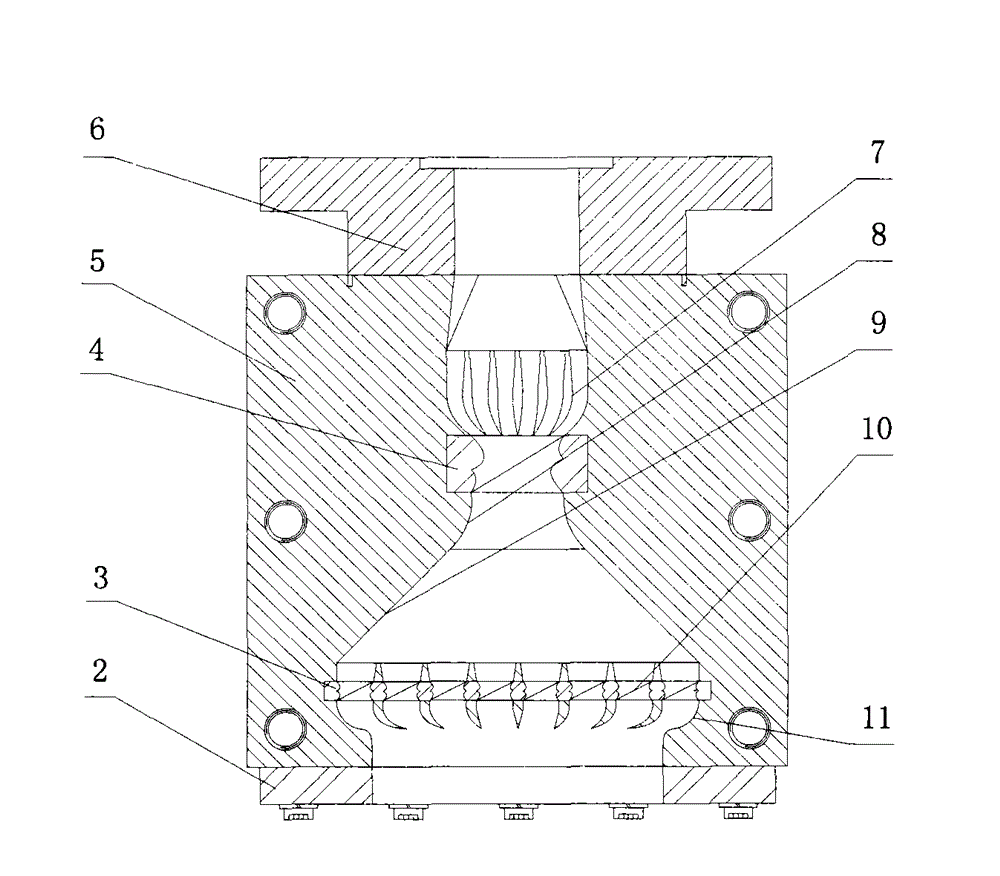

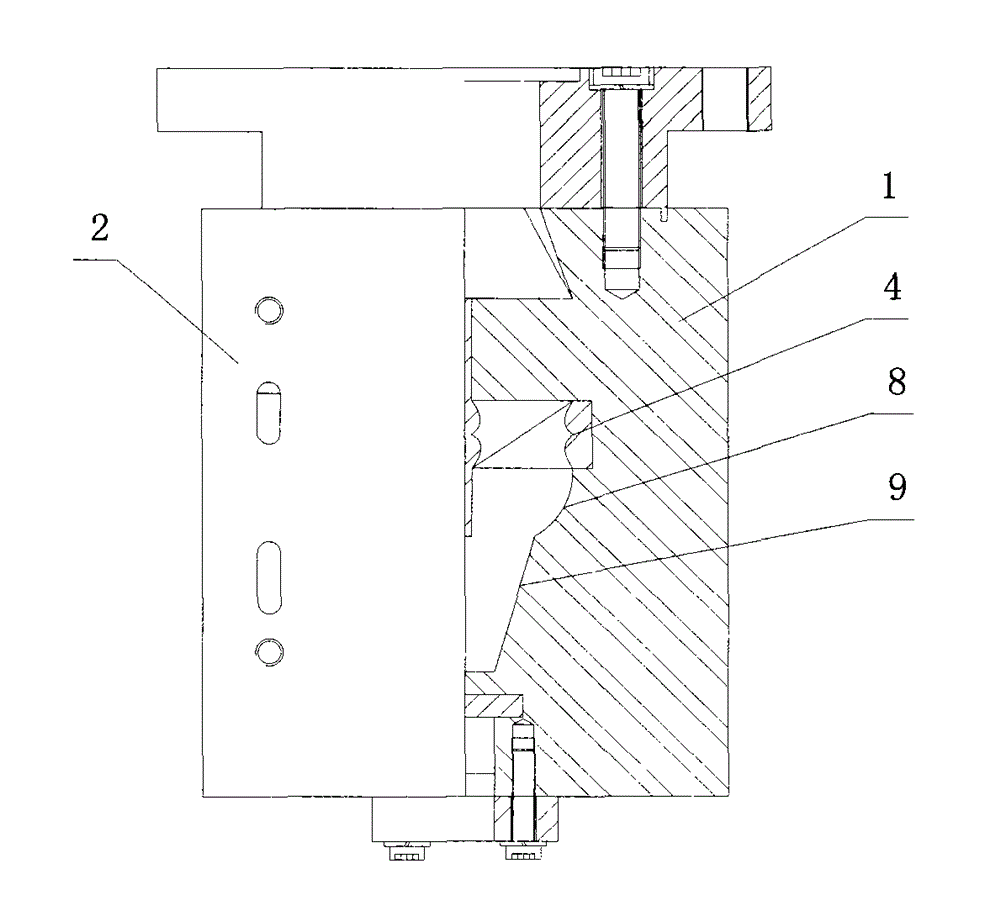

[0042] Example 1, such as Figure 1 to Figure 5 As shown, the rubber short fiber laminated orientation extrusion device includes an upper die 1 and a lower die 5 that are fastened to each other. among them,

[0043] Connected between the upper head 1 and the lower head 5 is a connecting flange 6 that forms the inlet of the flow channel together with the upper head 1 and the lower head 5, and an orifice plate 2 that forms the outlet of the flow channel;

[0044] A first splint 4 with spiral internal torsion ribs, a first cutting rib 7 and a first joining rib 8 are provided in the inner cavities of the upper head 1 and the lower head 5;

[0045] The inner cavity of the upper machine head 1 is provided with a stretching rib 9, a second splint 3, a second cutting rib 10, and a second joining rib 11.

[0046] The first cutting rib 7 has 6 cutting parts arranged vertically, and the second cutting rib 10 has 8 cutting parts arranged vertically.

[0047] The first splint 4 has two spiral inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com